Smoke and ventilation ducts. Ventcannals in brick walls. Ways of organization of ventilation system. Factors on which the traction depends

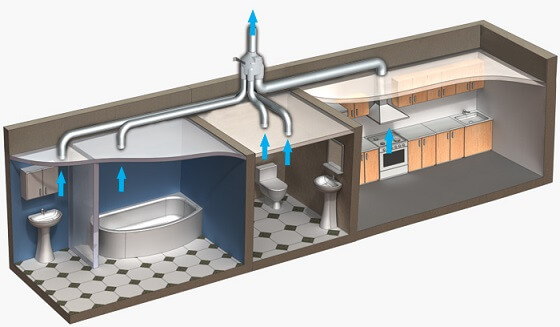

Ventilation channels are necessary for the organization of constant air exchange in the premises. Smoke and ventilation ducts are mandatory installed in a private house for the withdrawal of combustion products from heating, gas appliances, ovens, water heaters.

Features of ventilation systems

Ventilation in a private or apartment house may be:

- Natural;

- Forced.

With a forced system, the air speed is higher. The higher the flow speed, the smaller the dimensions of the hatches. With natural ventilation, the dimensions of the hatch should always be larger. In a private home, a more compulsory system is in demand.

However, natural ventilation. Schiedel ventilation ducts are very popular for natural ventilation. They are usually applied in kitchens and toilets in a multi-apartment or private house. With them, with the additional installation of fans, organization is also possible forced ventilation.

Materials, sizes and shapes

Ventilation channels can be made from different materials. Let's consider for the beginning plastic. Plastic products has many advantages:

- These are smooth walls, which provides low resistance to air flow and no need to regularly clean the structure, since dust does not stay in it. The treatment with an antistatic agent will completely eliminate the attraction of dust;

- Plastic channels are easy to install;

- They are aesthetic;

- Plastic structures, due to their characteristics, are often used in industrial sectors;

- Plastic channels are resistant to corrosion, easy to handle, have low cost, do not throw harmful substances into the air when burning;

- Plastic ventilation ducts can be installed in rooms with excessively polluted air or unpleasant odors. It is important to establish not only plastic structures, but also special fans for them.

However, they also have shortcomings:

- Plastic vent pipes do not withstand high temperatures;

- Plastic products can be installed only in rooms with a temperature of not more than +50 degrees. This factor rather restricts their use.

There are also galvanized ones. Ventilation pipes made of galvanized steel have limitations in use. They can be operated only in rooms with a temperature not exceeding 80 degrees and humidity not exceeding 60%. They are distinguished by reliability, long service life, lightness, easy installation.

In a private and an apartment house rectangular channels are usually installed. Their relevance is explained by technical and operational characteristics:

- Good fit to the surface;

- Aesthetics and simplicity of disguise;

- Quick installation, convenient fastening;

- Rectangular products have a high throughput;

- Saving space and fasteners due to the fact that rectangular structures have a sufficient area at low altitude;

- Rectangular ventilating pipes are convenient in case of presence of false ceilings in the private house.

On sale there are rectangular plastic pipes, and channels from other materials. For the organization of ventilation, not only rectangular but also round tubes can be used. Which ones to choose? Round ventilation ducts are usually used in industries, rectangular in residential buildings.

Installation Rules

Passages are organized when laying walls made of bricks. If the wall thickness is 38 cm, they are fixed in one row, if the thickness is 64 cm - then in two rows. For the organization of channels, a certain amount of full-bodied ceramic bricks will be required. Vertical masonry is carried out. The distance between it and the joints of the walls must be at least 380 mm. The channels should also be insulated by means of heat-resistant materials.

When installing ventilation ducts from brick, the following points should be considered:

- Channels must be square or rectangular;

- Ventilation passages are put end-to-end;

- To strengthen the cross-brick with respect to the passage is required;

- The withdrawal, if it is needed, is performed at a distance of not more than 1 meter, the angle is not less than 60 degrees with respect to the horizon. To do this, you will need to lay a brick, which is cut at the right angle;

- The masonry is bandaged with the help of halves of bricks;

- Buoys, regularly rearranged, will prevent the violation of the shape of the passage and clogging;

- During the laying of the brick, in order that the ventilation shafts are not clogged, newspapers are put in them.

Channels can be made without brick laying. This will require pipes. In addition, there must also be an air duct in each room. One of them should be placed 2 meters above the foundation inside the outer wall. The second duct should be on the roof at a height of 1 meter above it.

For the organization of a natural system, structures with a diameter of 125 x 150 mm will be required. For forced ventilation, the optimal dimensions are 100 x 125 mm. Suitable pipes are made of concrete, PVC, galvanized and so on. The structures placed between the walls must be cemented. To make the system leak tight, rubber or silicone is used. To connect the structure to the ventilation outlet, a corrugated pipe is required.

The installation can be done independently. For this, it is important to check in advance with all the recommendations and instructions.

It is also important to purchase quality materials that are suitable for specific conditions. When correct installation The system will last you a very long time, performing all the functions assigned to it. In addition, with the right selection of materials, you reduce the number of necessary cleaning systems and reduce the cost of operation.

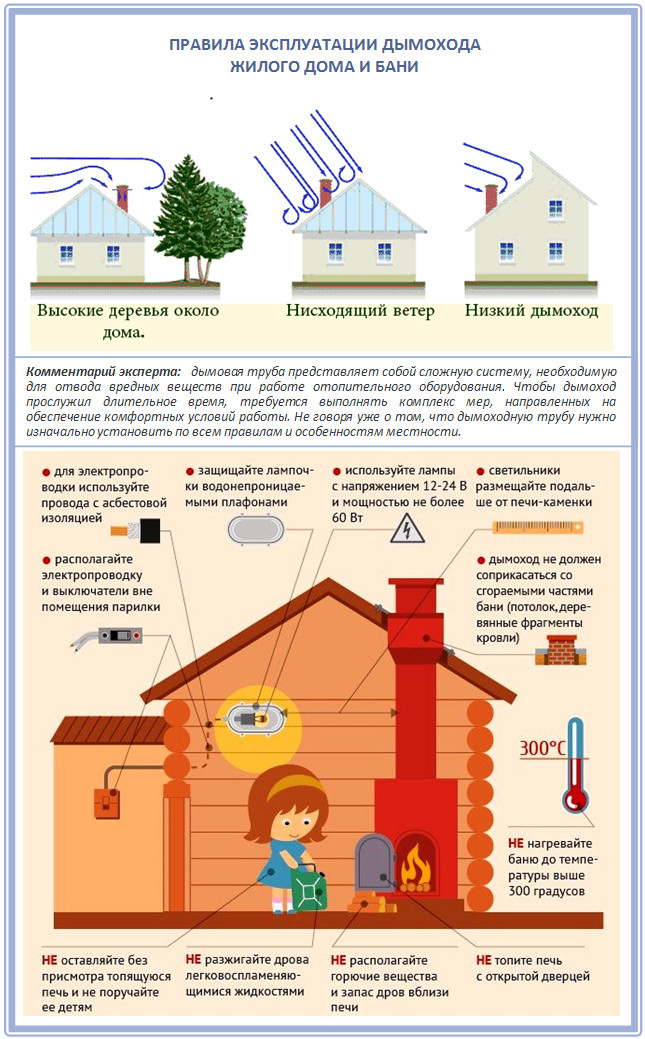

Unfortunately, the fire in most cases does not occur since the first test heating, as well as the lack of oxygen in the house and the presence of carbon monoxide is not felt on the first day - on the contrary, in the first months everything can be fine. But after a year of active operation of the problem chimney or defective ventilation ducts, an inflammation can occur, a disease may develop or engineering Communication just suddenly come to full disrepair. And therefore it is important not only to know the rules for the operation of chimneys and ventilation ducts of a residential building, but also to conduct timely audit and prevention, which this article will be about.

The official rules for the operation of chimneys and ventilation ducts can be downloaded in the .pdf format:

This small document is about how to check the chimneys and ventilation ducts in an apartment building, and what bodies are involved in this control. But specifically in this article we will pay more attention to the safety of the operation of chimneys and ventilation ducts of a residential private house or a bath, which is not often talked about, although there are many important points. Read the article carefully - you will be surprised!

Any chimney is always the most dangerous source of fire in the house. And all because the temperature of the flue gases is prohibitively high. Therefore, even the slightest violations of the installation of a chimney inside an apartment house can lead to dangerous consequences. But the chimney is important not only to correctly establish - it is important to use it correctly and take care of it.

What is included in the concept of fire safety?

To begin with, we offer a more detailed understanding of the concept of fire safety of chimney operation.

Fire safety is the state of the object (and we speak on the chimney), which is characterized by the ability to quickly prevent the occurrence and development of a fire. Fire safety of operation of an apartment house can be divided into the following: the safety of the floor, ceiling and walls that are next to you, as well as the safety of the chimney itself. This means that the insulation of the room should be not only effective, but environmentally friendly, so that when heated it does not emit any harmful substances.

In other words, not to be the source of those very chemical elements that cause cancer (carcinogens). Use only natural safe materials based on stone fibers, glass fiber and stainless steel.

The second point: the chimney must be properly installed and operated:

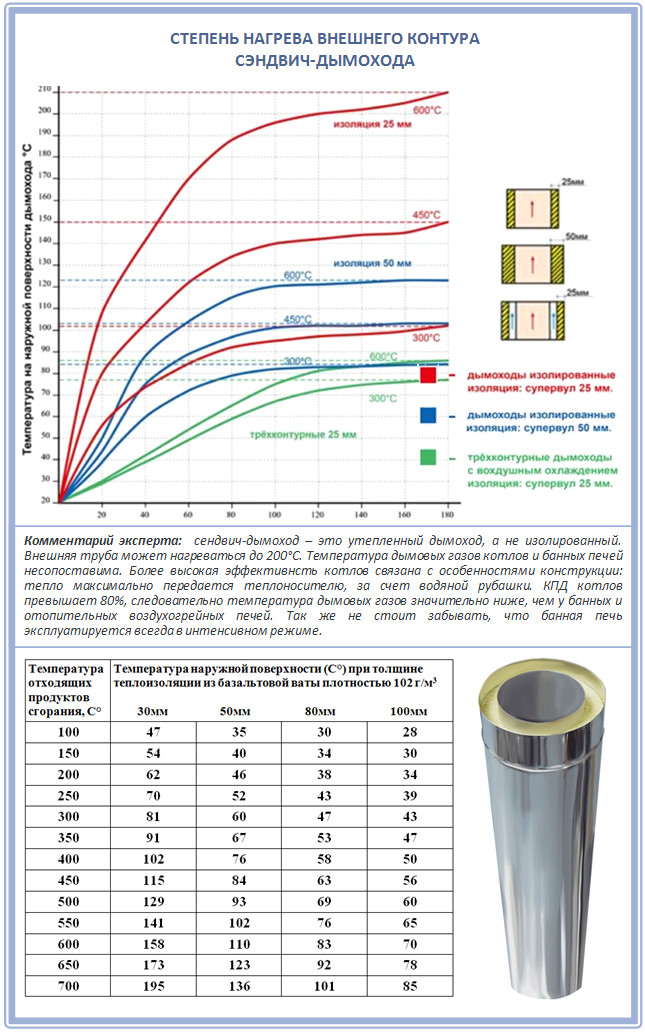

Monitoring of the heating temperature of single- and double-circuit chimneys

Fires, which lead to problems with the chimney, are often due to ignition of soot, and it lights up from high temperatures. What leads to this? For example, the highest temperature is produced by paper and burning plastic, followed by wood from certain types of wood.

Many believe that it is good, if the soot burns, you do not need to clean the chimney in the summer, but quite often it just destroys the inside of the chimney pipe, which is not prepared for such high temperatures. That is why the chimneys, which are initially designed by the manufacturer for low temperature conditions, and the burning temperature of their firewood is high. Let's compare different types of wood according to the ability to burn hot in the oven:

- Pine - 624 ° c;

- Grab - 1022 ° c;

- Poplar - 468 ° c;

- Oak - 840-900 ° c;

- Aspen - 612 ° with;

- Larch - 865 ° c;

- Ash, beech - 1044 ° c;

- Birch - 816 ° with;

- Alder - 552 ° c;

- Acacia - 708 ° with.

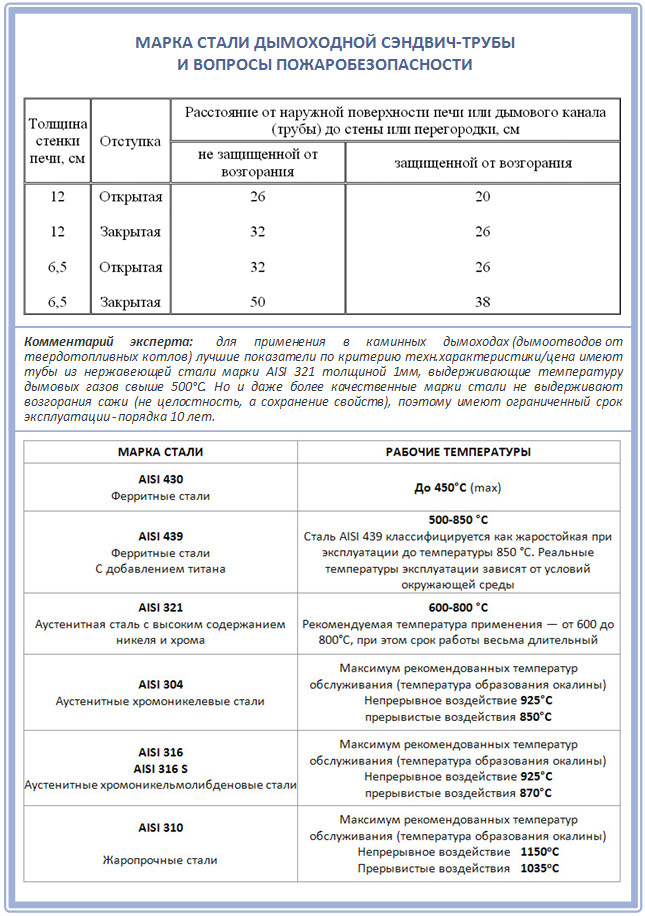

Impressive? That is why, in addition to compliance general rules, you should always take care that the outer contour of the chimney can not heat up more than the metal from which it was made is calculated:

For example, the most common cause of fires in private houses and baths is a stainless steel chimney 0.5 mm, which is put on wood stoves, although it is intended initially only for gas. Unfortunately, it is difficult to distinguish a gas chimney from a wood-burning stove at first glance. You just need to read the label on the pipe and consult the seller.

But this is only one of two factors. The degree of heating of the external circuit depends also on what kind of internal insulation was used and what is its thickness:

Correct arrangement and functioning of the chimney of an apartment house

One of the most important rules for ensuring the fire safety of the chimney of a private house is the chimney's thermal insulation and the correct design of its construction.

Pay attention also that from the outer surface of such pipes to the roofing and rafters of the roof there must remain a distance that corresponds to what is prescribed in modern SNIPs 2.04.05-91:

- For concrete and brick pipes it is 130 mm;

- For ordinary ceramic (without additional thermal insulation) it is 250 meters;

- For pipes in which insulation is present, this is also 130 mm;

- For pipes assembled with a stainless steel sandwich module, this distance is 150-160 from the inner walls of the pipe (according to European standards)

We go further. Where the roof and the overlap are in contact with the chimney, the units must be made of non-combustible materials. These are mineral wool, metal plates, special treatment for wood with flame retardant mastic and other materials, which are full of modern shops of building shops.

It is especially important to take care of the fire safety of the pre-furnace platform, if there is one, it is also made of non-combustible materials if it is being performed. Then you need to purchase ceramic tile, metal sheets or stone slabs. Well, if you still build a partition from the half-brick at the wall, where a stove or a fireplace is placed.

So, the safe operation of a chimney in a private house implies:

- The chimney must be installed by a professional or, at least, inspected by him at the end of the installation.

- Most of the chimney modules should be made of 400 series stainless steel, a thickness of not less than 0.8 mm, and the remaining parts are allowed from 300 stainless steel, but with a thickness that is no less than 1 mm.

- A stove, a fireplace or a boiler are burned with the sort of firewood they are designed for.

And this is only the beginning! Chimney must be monitored, cleaned and protected throughout the period of its operation.

Self-inspection of the chimney of an apartment house

So, when self-inspection first check the chimney for the presence of cracks. Initially, the modules of the metal chimney must not only be connected to each other, but also smeared in the joints with a silicone sealant.

If we are talking about a brick chimney, the smoke from it, too, should not leak anywhere at all. If it does leak, this is evidence that oxygen is sucked into the chimney itself and reacts with the gases. In such a chimney, only if there is only one spark, it is easy to form a fire. But even a sandwich module from the fire burns inside and causes a fire.

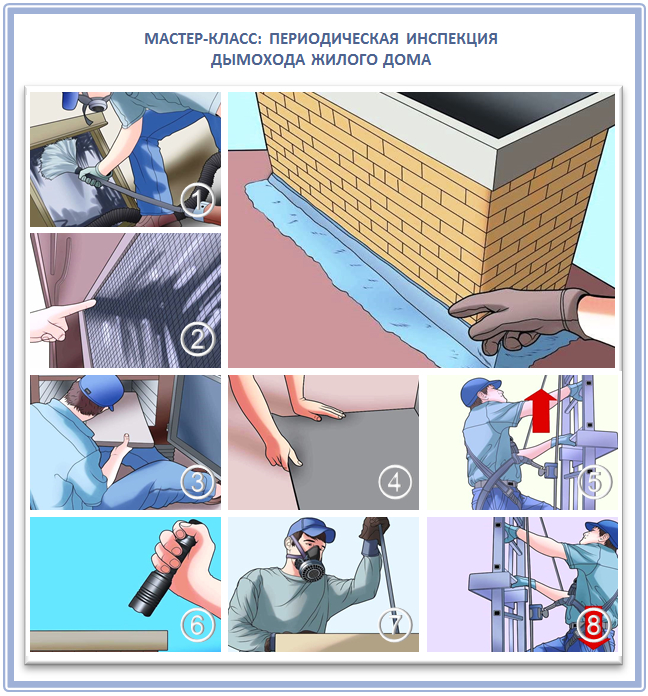

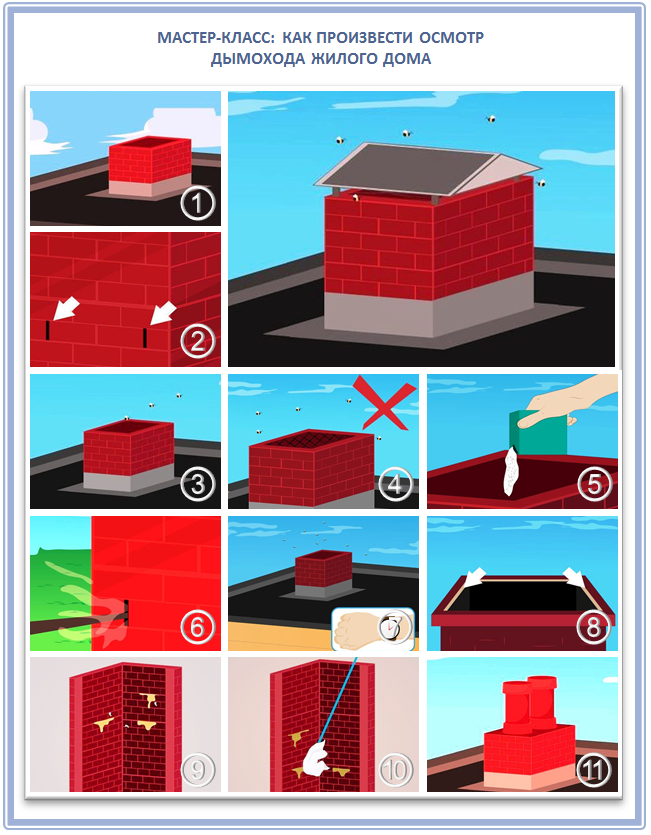

Therefore, every year, step by step, you need to check your chimney for problems that may be initially invisible to the eye:

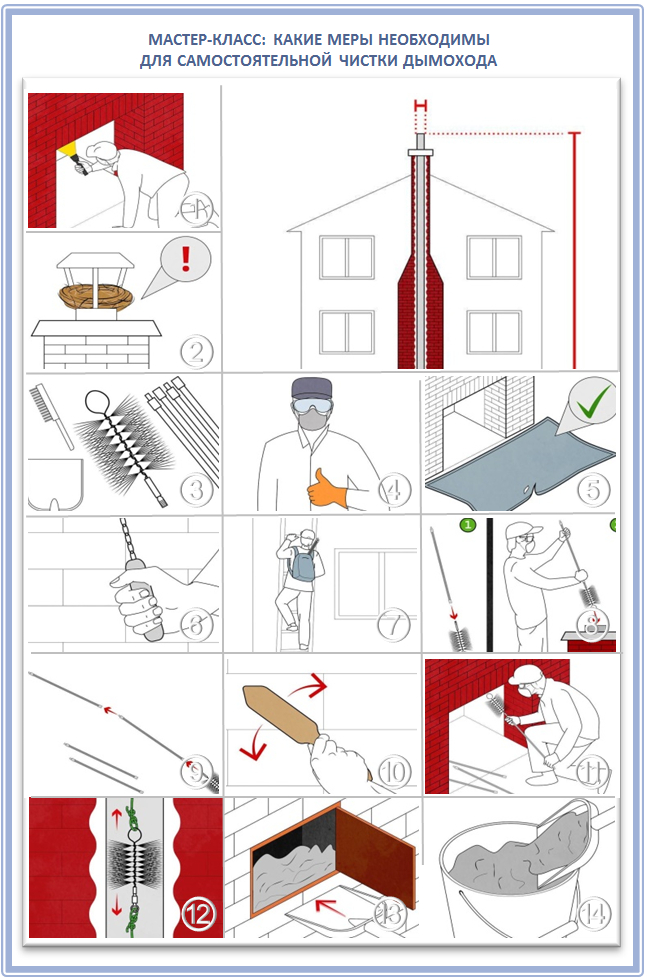

Pay special attention to the moment: is there a white coating on the walls? A fireplace stove or a stove with raw firewood is fraught with the fact that due to moisture on the walls of the chimney a white crust of moist soot forms, and the usual brush does not help - a special scraper is needed. And this is a more complex cleaning technology, because in this case it is easy to damage the surface of the chimney from the inside and give a place for corrosion. Therefore, if you have to resort to such a procedure, get a good brush from modern manufacturers, which are developed specifically for chimneys.

As you may have guessed, the most difficult situation is with a brick chimney. If a metal pipe was not specially inserted into it to protect its walls from corrosive soot, then it will have to be fought with a lot. Examine carefully this chimney: if you see a wort from the fragments of bricks, then the flue itself is already destroyed from the inside and urgent repairs are needed. Namely, the insertion of the pipe is the use. If this is not done on time, brick laying can be destroyed at any time.

For the use of dismantling part of the chimney and inserts the pipe, then make a new masonry brick. Naturally, all this can be organized only in the warm season, when the furnace does not work. But, in principle, the design itself, when a brick chimney holds in itself additional pipe stainless steel, one of the most reliable.

But still, every six months, you need to inspect, clean and prevent such a chimney. If you suspect that the chimney can be problematic or firewood is not of the best quality, then what kind of prevention should be done every two months or even more often. And keep in mind that firewood from spruce and pine have a lot of pitches and are especially harmful to pipes - it's better to refuse them altogether.

Regular cleaning of the chimney from soot and internal blockage

And now a little entertaining physics. When burning wood from wood, white, translucent smoke is formed (there are water vapor in the wood), and black smoke becomes if fine carbon black is raised into the chimney.

At the end of the burning, only coal and ash remain, which do not burn with an open flame, but only smolder and react with atmospheric oxygen and also release carbon dioxide and water vapor. This is just the creosote that is allocated at this moment and represents the greatest danger for the chimney, because the water vapor that comes from the wood at this moment glues such particles and they settle not only on the walls of the chimney, but also on the details of the heater. And form thus resinous adjournment!

Let's talk about soot in the chimney (believe me, everything is more serious than you think). It appears when the fuel does not burn completely. And it depends on its type, quality, incoming air and combustion temperature.

The soot itself is pulverized, glossy and even porous.

- For a fire pulverized only one spark is enough. This soot creates a porous substance on the walls of the chimney, consisting of ash and a small amount of coal. Even with a sharp increase in traction or ignition of paper, dusty soot is capable of catching fire, and a flame - to reach the top of the chimney. Such ignition usually leads to overheating and cracking in the pipe, but sparks that fly out of the chimney (especially when the weather is windy and hot) are still dangerous.

- But the fire glossy soot leads to critical temperatures on the walls of the chimney. This soot creates a dense, flammable layer and can even reach 1000 degrees Celsius during combustion. This is an overload on the chimney, and if that old one or cracked, it risks simply not surviving. In this case, the ignition of such soot can be either fast or slow. With a fast upper temperature, in principle, does not have time to reach the maximum value, but slow burning can last up to several hours or heat the pipe walls so that cracks will appear. Slow burning glossy - the most dangerous, because it is accompanied by a strong gas generation, and smoke clouds create whole tubes in the tube.

- Porous soot is not as dangerous as glossy, although it is similar in structure to it. On the walls of the chimney such a layer is formed when too hot flue gases enter the pipe. But everything is also subject to sudden fire.

All this greatly reduces the efficiency of the chimney, accelerates its wear and even provokes corrosion, and in particularly neglected cases, a real fire occurs. That's why, along with firewood, it is useful from time to time to put a chemical soot cleaner. It is made in different formats and different contents, but usually from a mixture of special crystals that act as catalysts in the combustion process, destroying the structure of tarry deposits. After that on the walls of the chimney there is only a fragile husk from soot, and it, in turn, is easily split, burned and poured.

That is why it is so important to choose the reliable chimney pipe from the very beginning, because the manufacturers specifically indicate the resistance to ignition of soot in the passport. Therefore, if you have the opportunity now to purchase another chimney (if there are doubts in the old), which will withstand the necessary loads and even more. After all, there is a huge difference in whether you heat a fireplace or bake more for a decorative effect or a rare cooking (for example, a stove is in a barbecue-pergola, or this stove will heat your entire house). If you ignore at least one of the requirements of the manufacturer, then nothing good will end, believe me.

All the necessary measures to prevent and clean the chimney, we presented in the form of a step-by-step illustration:

Solving problems with condensate and soot on the chimney

If you are wondering where the condensate can come from in the chimney, let us explain in more detail. The moisture itself is in the air always, in any room - just in different quantities. It is not visible to the eye; is in a state of fine-dispersed droplets. In the house they are more than we say, in the workshop or in the attic.

And it is moisture that gets into the furnace with the air and the chimney, and in the cold part it condenses, settling on the pipes in the form of drops. And this condensate is bad not only for the chimney, as it corrodes it from the inside, but also on the plane that allows the soot to simply stick to the walls. As a result, thanks to the condensate, the thrust is broken, because the air passage is getting smaller. And, finally, moisture reacts with soot, forming a particularly aggressive acid, which gradually destroys the metal. The fewest problems with all this is just a modern sandwich-chimney, although it should be protected from raw firewood.

Ventcannals: air supply

In addition, unfortunately, modern building materials and furniture in most cases do not have high ecological indicators. And all these harmful substances are released into the air. Of course, if there is only one such source of carcinogenic substances in a residential building, then it alone is not dangerous (its effect is insignificant and the human body more or less removes all the toxins obtained during the day) and the producer is absolutely clean before the law.

But there is such a thing as a cumulative correlation, which takes into account that a person will breathe harmful elements not only today, but also tomorrow. And if he has certain problems with health and metabolism, then a toxic plastic shelf or wallpaper will still be harmful. And this is not taking into account the fact that such an everyday person and things are not surrounded by an average person in many ways.

From the current situation, there is a simple and affordable solution - high-quality ventilation. The constant influx of fresh air and the removal of the old can easily lead out all the inhabitants of the periodic table penetrating into the air and thus reducing the above negative influence almost to zero.

For quite a long time in Russia there was a practice of organizing the influx of fresh air into the room due to the leakage in the building structures themselves. Simply put, the old wooden windows have remarkably ventilated the room, but modern double-glazed windows, unfortunately, fully encapsulate it. Well, if you can put the window panes in the micro-ventilation mode or open completely, but sometimes they forget about it in the winter or just save on heating.

In this case, it is extremely necessary to establish compulsory system The ventilation system, which will supply fresh air in the room, is cleaner and warmer. And you can also resort to such an artisanal method as a through hole under the window frame (preferably above the heating convector). For this, a small hole breaks, and the air from it comes straight from the street. If necessary, use an adjustable flap. Thus, the air is also heated.

In addition to providing a healthy indoor climate, ventilation is necessary for the normal operation of any fireplace or stove. For this purpose, it is planned to organize the flow of air, counting it at 200-300 square meters per hour, if the firebox closed type, and 800-1000 square meters per hour, if it is an open type.

And, at last, look at a small news story about how important it is to monitor the normal functioning of chimneys and ventilation ducts, and how to notice the first signs of malfunctions:

Be attentive and take care of your own health and life!

Proper installation of the chimney - a necessary condition for the normal functioning of the fireplace, stove or boiler. This article describes the basic installation rules and calculation principles used in the design and installation of chimneys.

The desire to build a house by own strength arises, as a rule, because of the need to save material resources, because the services of specialized enterprises are not cheap. But, chimney construction requires a special approach: without the use of special knowledge in this matter is indispensable. Therefore, let us recall the basic rules for creating effective smoke extraction systems and the importance of their compliance.

Chimney installation rules: what should be the right chimney

On how well the chimney functions, the fuel consumption, the amount of heat loss, fire safety and air quality in the heated room depend. Therefore, its design and installation should be carried out in accordance with SNiP "Heating, ventilation and air-conditioning" , DBN В.2.5-20-2001 Appendix Ж "Drawing of combustion products" and other normative documents. Let's talk about what should be a properly designed and installed chimney - these are the basic rules for its creation.

A great influence on the characteristics of the channel for the removal of combustion products is provided by the material from which it is made. In new buildings, as a rule, pipes made of stainless acid resistant steel containing molybdenum are installed. But for furnaces and fireplaces, working on wood and coal, ceramic bricks are also quite suitable.

Preferably, the chimney cross-section is a regular circle: this shape creates the least resistance to the emerging smoke. The height and cross-section of the chimney are calculated in accordance with the building codes, further on this will be discussed in more detail.

The correct approach to horizontal sections of the channel is important: they should not be longer than 1 m, otherwise the soot will be deposited and the traction will be weakened.

Connectivity of the heating unit to the chimney pipe is often necessary to carry out when the diameters in the connection zone do not match. To solve the problem, use a reduction adapter. All joints are carefully sealed.

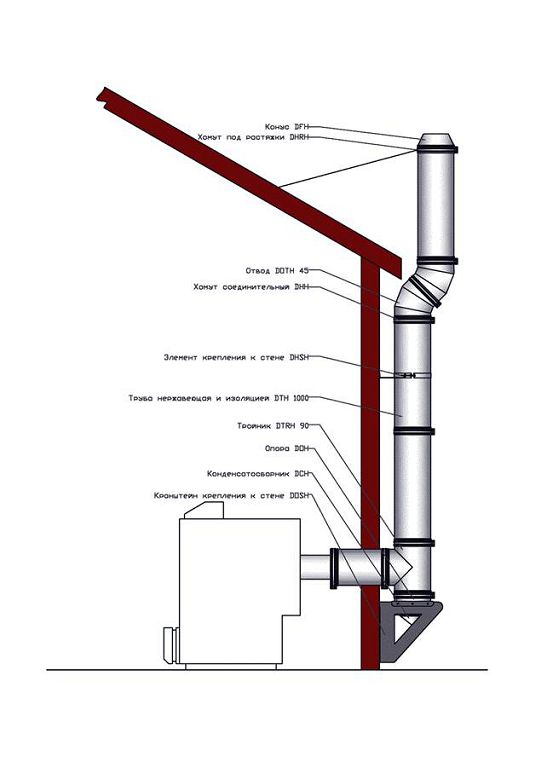

Piping of pipes is carried out in such a way that their extensions are directed upwards. Due to this, condensate and tar can not flow out the outer wall of the pipe.

A brick chimney is erected according to the project: the order of masonry should be prescribed for each layer. At the same time, one should strive to obtain an inner surface with a minimum of roughness and achieve complete tightness.

The old brick chimney can be used with a new gas boiler only after the sleeve has been completed: a steel acid-resistant pipe is inserted into the middle of the channel, leaving a small gap.

Most smoke extraction systems should be provided with revisions for cleaning.

Thermal insulation of external pipes is carried out necessarily: this will not only save the condensate, but will contribute to the fastest heating of the pipe.

When the channel passes through the floors, measures must be taken to isolate the heated parts from combustible materials.

The outer part of the pipe is securely fixed and protected from the wind. The upper part is covered from the atmospheric precipitation by wind vanes or deflectors. The exception is the gas equipment: in this case the installation of the protective cap is a violation.

What is the wrong chimney

To correct mistakes made during the construction of a chimney is very difficult and expensive, and sometimes even impossible without dismantling the old system. Here are some examples of common mistakes and their consequences:

- The use of materials not intended for the construction of chimneys. So, for gas boilers it is unacceptable to use bricks: the acid contained in the products of combustion will destroy it for several years. You can not also use asbestos-cement pipes: they are destroyed when heated. Plastic also does not withstand high temperatures.

- Errors in choosing the diameter of the pipe and calculating the height of the chimney threaten the lack of normal traction and low system efficiency.

- Excessive loads on the chimney base can lead to its destruction.

- Weak insulation - the cause of condensation and ignition of closely located materials.

Chimney height: dependence on the angle of the roof and the distance to the ridge

In place of ceramic bricks, previously used for the construction of chimneys, more and more systems come from other materials. Most often used steel pipes: non-insulated and insulated. In this case, the option without insulation can be used only for indoor installation - in a specially constructed mine. Outdoor installation pipe requires mandatory isolation, otherwise inevitably the formation of condensation on the internal surfaces.

In order to determine the height of the chimney for an industrial boiler, you should use the formula: h (m) = (Δp ⋅ Tp ⋅ Tn) / (3459 ⋅ (Tp - 1,1 ⋅ Tn)), where Δp (Pa) - static thrust, Tr - average temperature in the middle of the pipe (according to Kelvin), Tn Is the average outside air temperature. Temperature in the pipe (Tp) can be determined on the basis of measurements at the outlet from the boiler and indicated by the manufacturer in the technical data sheet of the heating equipment. This takes into account the natural cooling for every meter of the chimney: in brick - 1 degree, in steel - 2 degrees, in steel without insulation - 5 degrees. Outside temperature (Tn) must be summer: at this time the draft will always be weaker than in winter.

However, the results of calculating the height of the chimney in some cases need to be adjusted, but only in a larger direction. The fact is that the house itself is sometimes higher than the value obtained for the height of the chimney. In this case, there is a rule that reads:

- a chimney located at a distance of up to 1.5 m from the ridge should be at least 0.5 m above it;

- if it is located within 1,5-3,0 m from the ridge, then its top should not be lower than the ridge;

- at large distances from the exit of the chimney to the ridge, the height of the pipe is chosen such that it is not below the line drawn from the top of the house down at an angle of 10 degrees.

Chimney height above the roof

For solid fuel and gas boilers, the height of the chimney must be at least 5 m: usually, manufacturers specify this parameter in the accompanying documentation. It should be remembered that the high pipe should be attached additionally - with the help of stretch marks.

But that's not all: if there is another tall building next to the house, then the chimney must be taken out above the roof of the neighboring building.

Cross-sectional area

The value of this parameter can be calculated by knowing the height of the chimney h (m) and the heat load of the burner according to the formula: S = (K ⋅ Q) / (4.19 ⋅ √h), where TO - the empirical coefficient, numerically equal to 0.02-0.03, and Q (kJ / h) - the productivity of the device, indicated in the passport, h (m) - chimney height.

If the procedure is simpler, without formulas, then the following values should be taken as a basis for the section of the smoke channel, made of bricks (the cross-section of circular ducts should be exactly the same area):

- for the unit with a power of up to 3.5 kW - 140 × 140 mm;

- for power from 3.5 to 5.2 kW - 140 × 200 mm;

- for power from 5.2 to 7.2 kW - 140 × 270 mm.

A significant excess of the calculated value leads to a deterioration of the thrust and, consequently, to an unstable operation of the heating equipment. A smaller diameter threatens with poor removal of carbon monoxide and other combustion products and even a complete cessation of this process.

Additional requirements for chimneys for stoves, fireplaces, solid fuel, gas boilers and gas columns

Some rules not mentioned above, which should be observed:

- the use of a solid fuel furnace requires compulsory compensation of exhaust ventilation with a supply air;

- flue ducts can be located in the outer walls, if they are built of non-combustible materials, but you should provide insulation from the outside to prevent the formation of condensation;

- for each furnace (if they are located on different floors) a separate pipe is provided, but it is allowed to use one tube for two furnaces located on one floor: in the junction of pipes, cuts of 1 m or more and 12 cm in thickness are installed;

- smoke channels made of bricks should be built with cleaning pockets, which are closed with a brick laid on the edge and covered with clay mortar (doors can be installed);

- if necessary, pipe deflections from the vertical to an angle of up to 30 ° and the length of the section not more than 1 m, with the cross section of the channel must be the same;

- if the roof is made of combustible materials, a mesh spark detector is installed in the upper part of the chimney;

- between chimneys made of brick or heat-resistant concrete and roof parts constructed of combustible materials, should be equal to or more than 130 mm, for ceramic non-insulated pipes - 250 mm, for them with insulation - 130 mm;

- the top of the chimney for the fireplace is protected by a weather vane or a fungus;

- two appliances working on gas can be connected to a common channel for the discharge of combustion products if these devices are located no further than 750 mm apart;

- the sectional area of the chimney to be connected to the gas appliance should not be smaller than the area of the gas outlet pipe of the device itself, in this case top part pipe does not cover with a visor.

Information from regulatory documents that establish the rules for the design and installation of chimneys

For the laying of chimneys frost-resistant clay brick is suitable. It is strictly forbidden to build channels from cinder and similar materials.

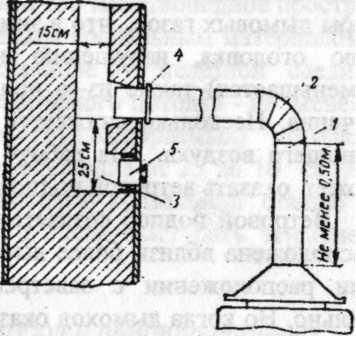

For connection of gas appliances to chimneys, connecting pipes made of galvanized or roofing steel with a thickness of 1 mm or more are suitable. You can also use flexible corrugated metal pipes that complete the equipment. It is important that the connecting pipe has a vertical section, the length of which from the lower level of the branch pipe to the axis of the horizontal section of the channel should not be less than 0.5 m. If the ceiling height is less than 2.7 m, this distance can be reduced by half for equipment equipped with stabilizers of traction and up to 0.15 m - for devices without stabilizers. The total length of horizontal sections in houses of new construction should not be more than 3 m, for old buildings it is allowed 6 m. It is necessary to observe a small slope of the pipe towards the heating device.

Smoke ducts must not have more than three turns, with the radius of curvature being equal to the diameter of the pipe. It is forbidden to lay a chimney through living quarters.

How to care for a chimney

If the thickness of the deposits on the inner surface of the pipe exceeds 2 mm - it's time to start cleaning. From dense contamination can be eliminated with a scraper and a hard brush with a long folding handle: as you move deeper into the channel (work starts from the top), the length of the handle is increased.

The top hole must be closed from below: this will prevent soot from entering the room. In addition, it is desirable to close the furniture with furniture, lock the doors and windows. During operation, you can use chemical detergents, for example, "miracle-logs", which, during combustion, produce a special non-poisonous gas from which the deposit lags behind the surface of the pipe.

There are also effective folk remedies. For example, it is recommended that the stove is sometimes heated with asparagus wood: a high flame is produced, which burns off deposits on the walls of the pipe. But it should be done carefully: a large amount of soot can cause a fire. You can also burn the potato peel: the steam that forms during this process is effective against soot deposits.

Conclusion

The requirements stated in the article are binding for execution. Otherwise, the chimney will be ineffective and even dangerous. This information will serve as a useful reminder for those who already have some experience with chimneys. Those who do not own it, the article's material should convince the need for serious attitude to the details of the process of creating a chimney. Do not overestimate your abilities: to avoid annoying mistakes, you should seek the help of professionals.

Dmitry Portyanoy, rmnt.ru

Safe use of stove and gas equipment it is possible only with the timely removal of combustion products and continuous air exchange inside the premises. This and some other functions are performed by chimneys of all kinds: from elegant decorations of country villas to giant monsters - indispensable attributes of industrial zones.

The principle of natural draft

The outflow of products of combustion of gas from boilers, columns and furnaces is produced through natural draft. Draft is provided at a difference of temperatures in the street and in the house. The higher the ventilation pipe or chimney and the greater the temperature difference, the more intensive the chimney pulls. Therefore, natural ventilation works best on the first floors of multi-storey buildings and in the cold season.

The temperature of the combustion products above the operating plate is about 200 degrees. Air temperature in ventilation and chimneysah no more than 25 degrees and therefore traction is very weak. In summer, when the temperature in the street is higher than in the rooms, the draft can "tip over", that is, air is sucked into the apartments from the ventilation.

To a large extent, the effective operation of the system depends on the frequency of inspections of smoke and ventilation ducts.

Reasons for reducing traction:

- contamination of internal walls of channels;

- roughness, narrowing of the walls;

- increase in the diameter of the channel;

- sucking air.

A significant part of the energy of the air moving through the channel is expended on frictional resistance against the walls, when turning and reducing the diameter of the channel. The indicator of head loss depends on the masonry of the smoke or ventilation duct, its length and condition. In the presence of protrusions, outgrowths of dust and roughness, the resistance rises. Therefore, timely inspection and cleaning of ventilation and smoke channels enhances traction.

In channels of large diameter, even with the ideal observance of the rules safe operation smoke and ventilation pipes, the thrust is reduced, since the combustion products are cooled more quickly.

When the air sucks in the channel, too, the thrust falls, as the air temperature in the channel decreases, and its volume increases. Therefore, all hatchways for pipe maintenance must be kept closed.

The draft in the chimneys during the operation of the boiler or furnace is about 14 Pa. In ventilation ducts, it is much lower. Affects the thrust of opening the windows in the apartments, the direction and strength of the wind, and even the location of neighboring houses. Ventilation and chimneys should not be located in the area of the wind pressure. This space is below the line leading from the highest point of the nearest building to the horizon at an angle of 45 degrees.

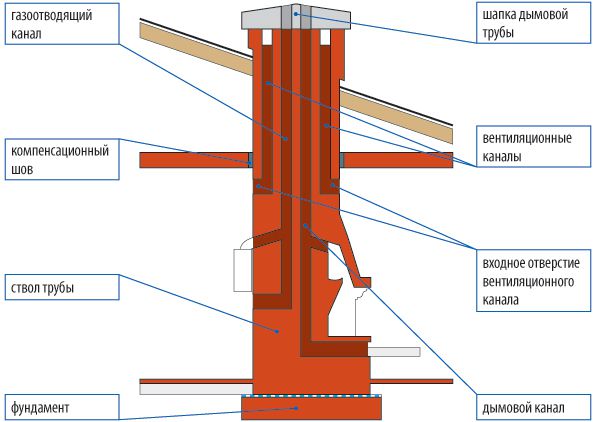

Construction of ventilation pipes and chimneys

According to the rules for the operation of smoke and ventilation pipes, they are installed inside the house to maintain the temperature of the exhaust air. You can arrange ventilation and smoke ducts and outside, then they need to be insulated.

The masonry of ventilation and smoke ducts consists of clay brick or heat-resistant concrete (asbestos cement). The thickness of the brickwork from 12 cm, of the concrete wall of the ventilation or smoke channel is more than 6 cm. The SNiP states that ventilation and smoke channels are arranged only vertically, without transitions and horizontal sections.

Device for pocket (holes) for cleaning the chimney

At the bottom of the chimney, there are holes for cleaning and a pocket depth of 25 cm. The holes are covered with doors and are faced with a brick installed on the edge. Masonry is carried out on a solution of clay. In the asbestos-cement pipes leave a sheet for cleaning.

The pocket is necessary so that when the masonry breaks down, the brick fragments do not block the inlet opening, falling just below. In the pocket all the garbage that gets into the chimney accumulates. If you do not provide a pocket, the garbage will gradually reduce the section of the chimney and worsen the traction.

Unsuitable materials for smoke and ventilation ducts:

- slag concrete;

- silicate, hole, slit brick;

- coarse-grained materials.

Although silicate brick and well resists high temperatures, it is destroyed by carbon dioxide and wet fumes. If there are no other materials, SNiP requires a device in the ventilation and smoke channel of the inner lining of red brick with a thickness of 13 cm.

Chimneys can be:

- nasal (from asbestos-cement pipes inserted into each other);

- whole (of bricks).

Pipes are distinguished by smooth internal walls, they are supported by fireplaces or furnaces with powerful walls (not thinner than 1/2 of a brick). If the pipe is heavy, a reinforced concrete slab is installed on the ceiling of the furnace and a pipe is already attached to it.

Asbestos-cement tube pipes are much lighter than brick pipes, they do not need to be disassembled during overhaul, they are quickly installed.

Brick chimney requires a special foundation, which is laid at a depth exceeding the depth of freezing of the soil.

When erecting low-rise buildings, prefabricated chimneys are used that are built into a wall or form a riser. The walls of chimneys are made of heat-resistant concrete.

In the places of passage through the chimney of the roof it is necessary to leave a hole with a width of 13 cm. The connection of the chimney with the roof is covered with an apron made of stainless steel.

The chimney can have a slope of up to 30 degrees with an offset of not more than 100 cm. Such segments must be of the same cross section, equal to the cross section of vertical segments with smooth walls.

The heads of chimneys made of bricks are covered with 20 cm plaster to protect them from precipitation. Chimneys do not have deflectors and umbrellas.

Chimneys of gasified buildings

The ventilation and smoke channels of the gasified rooms should rise above the flat roof by 50 cm or more. On a pitched roof 50 cm or more above the rib or the height of the rib with a distance from the edge to the chimney is 1.5 - 3 meters.

The height of the chimneys of the gasified rooms should be equal to the height of the exhaust ducts.

To the system of ventilation and smoke channels in the gasified room, the heating equipment is connected through metal adapters. The length of the vertical adapter should be from 50 cm. If the height of the room is less than 2 m 70 cm and stabilization of the traction is used, the vertical adapter can be shortened to 25 cm. The total length of the horizontal adapters can be up to 3 m in new or up to 6 m in the buildings already functioning.

The slope towards the boiler is allowed from 0.01. Pipes must be fixed rigidly without the possibility of sagging. The knee tubes are inserted into each other along the smoke path and overlap by 1/2 of the diameter of the chimney.

The metal adapter is tightly attached to the chimney, not protruding from the channel walls.

If the pipe is made of metal sheet, it is necessary to treat it with heat-resistant varnish.

The pipe is attached to the chimney, leaving a pocket of 25 cm and a hatch for monitoring, as well as the construction of a chimney oven. If the device is not equipped with a traction stabilizer, a damper with a perforation of 15 mm, through which the furnace is ventilated during idle time, is required.

When retrofitting old chimneys from furnaces for gas equipment, there is often a bad draft. The furnaces are heated for a longer time and the temperature of the combustion products is much higher than in operation gas boiler, so the discharge of air from the combustion of gas is not enough.

Requirements for chimneys

Operation of chimneys

The rules for the safe operation of smoke and ventilation pipes require periodic cleaning and inspection. Without cleaning, a long-life chimney becomes a potential source of fire or poisoning of residents. The need to clean the ventilation and smoke ducts determine routine checks.

The chimney, built of brick or made up of asbestos-cement pipes after a while loses its appearance and works worse. On the inner walls, soot and soot accumulate, the flue clearance decreases and the draft decreases. But there is another danger: combustion products can ignite. Substances released by soot destroy the pipe material and the seams of the masonry. The chimney tightness is reduced, the fuel does not burn completely, the traction is deteriorating.

Only periodic checks of smoke and ventilation can help avoid dangerous situations.

If heating equipment is used every day, the frequency of checking and cleaning the ventilation and smoke channels is 8 weeks. If the stove melts from case to case, it is necessary to control the state of the chimney twice a year: in the autumn before the start heating season and in the spring.

Checking chimneys

Examination of smoke and ventilation ducts is carried out in the following cases:

- when transferring furnaces to gas fuel;

- when connecting gas chimneys to the chimneys;

- if necessary to diagnose the state of the chimney and poor draft.

The purpose of checking ventilation and smoke channels:

- conformity of masonry materials of the smoke or ventilation duct and the device to the requirements of SNiP;

- presence of clogs;

- presence of traction;

- density of the chimney walls;

- condition and the presence of partitions separating the adjacent structures of the building;

- state of the head and its location relative to the roof, buildings and trees.

Checking the ventilation and smoke channels:

- To determine the congestion in the chimney, a cargo in the form of a sphere weighing 3 kg and up to 10 cm in size is lowered from above on it. If the load passes unhindered, the channel is clean;

- To determine the isolation and density of channels, the smoke method is used. In the window for cleaning put a burning patch, moistened in gasoline or a bundle of straw, when burning abundantly emits smoke. The outlet of the chimney is covered tightly overhead. If the smell of smoke appears in nearby rooms or canals, then the channel walls are not dense;

- The cleanliness of the canal walls is inspected by lowering the electric bulb into the chimney to 500 watts of power. At the same time, the density of the walls is determined. If there is light in the adjacent channels, then there are gaps.

Cleaning is performed on the basis of the results of checking the ventilation and smoke channels. She may be:

- mechanical;

- chemical.

Mechanical cleaning is carried out with brushes and brushes made of metal wire. Under the weight of the cargo they descend on the cables into the chimney and scrape off all the deposits from the walls. Some pipes (for example, ceramic) are difficult to clean - they can crack.

Dry cleaning is safer. In the furnace burned "log chimney sweep", which burns the soot on the walls of the chimney. The material is impregnated with chemical composition, decomposing soot and soot. But dry cleaning does not cope with thick deposits, so it is used as an auxiliary or preventive.

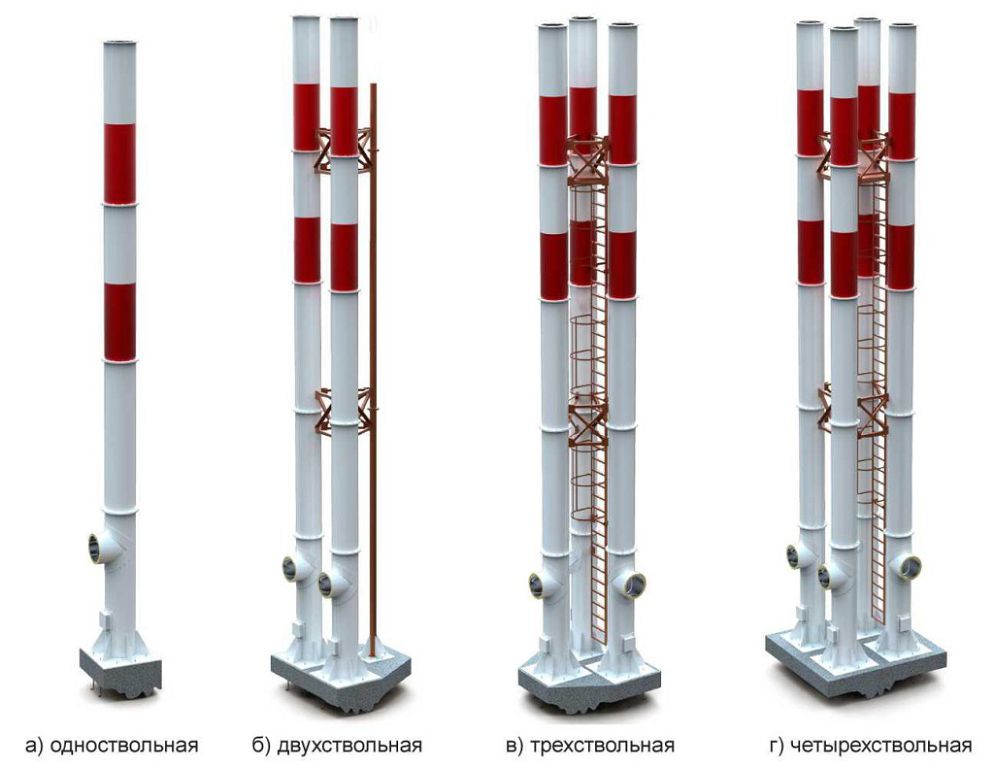

Industrial chimneys

The purpose of industrial smoke and ventilation pipes is not only in the removal of combustion products, but also in the maintenance of combustion in the boiler plant units. In the recent past, most industrial smoke and ventilation pipes were made of brickwork. Today, it is increasingly being installed on its metal pipes with thermal insulation. The height of the structure can reach 60 meters.

According to the rules for the safe operation of smoke and ventilation pipes, they need periodic cleaning. Prevention is carried out at the end of the heating season. And to prevent accidents, scheduled checks of ventilation and smoke channels are assigned.

Design smoke and ventilation pipes for the industry, taking into account each specific enterprise, since the task of the structure is always unique.

In order to always have a comfortable temperature and humidity regime in the house, it must be equipped with well-designed ventilation. If this is not done, you can face many problems (condensation, dry air, etc.). This article will consider ventilation ducts in brick walls.

The need to create this element can not be overemphasized. Modern building materials, for example, are "not breathing", which creates an unfavorable climate in the house. Dry air and high content carbon dioxide often leads to a deterioration in human health.

Tip: Many experts are convinced that plastic windows are one of the main reasons for the lack of air.

In order to get rid of this problem, it is necessary to ensure good air circulation in all rooms. It is best to take care of this at the design stage. We will talk about all the nuances of this procedure below.

A bit of theory

At the beginning of our narration we will consider the most important theoretical aspects that need to be known. Without knowledge, the procedure for creating ventilation system will not succeed.

Ways of organization of ventilation system

Today, two methods of air circulation in the premises are actively used: natural and mechanical.

Natural

It assumes the implementation of air exchange due to the difference in pressure inside the building and beyond. Using this technique, fresh air will flow into the room through means of organized openings in the floors.

In this case, the brickwork of the ventilation ducts must be carried out during the construction phase of the house. In order to increase the efficiency of such a system, it is recommended to install a deflector into the channels.

This is a special aerodynamic device, which creates a region of low pressure. As the amplitude of this indicator increases, the thrust increases.

Mechanical

Such a project is much more difficult to implement with their own hands, but it gives a higher efficiency of the system. It consists in the use of various fans or ejectors. They are installed directly into the ventilation shafts.

It is worth noting the merits of this method:

- The increase in thrust by several times, compared with natural system.

- Allows the installation of special filters that will purify the air of dust.

- There is the possibility of creating climate control in the house due to the installation of split-systems.

- It does not depend on weather conditions, therefore, it can create favorable conditions even in regions with a harsh climate.

Primary requirements

The first step is to get acquainted with the list of basic requirements in order to know what to strive for. These guidelines are contained in SNiP 2.04.05-86, which affects the aspect of ventilation and air conditioning.

- The ventilation shaft made of bricks should be built only if there is a design scheme of the building and with observance of all rules and norms.

- To remove air from heated rooms, it is necessary to create a ventilation system with a natural motivation. Combustion products from furnaces should be removed by means of a smoke channel.

- To place ventilation ducts made of bricks is necessary taking into account fire safety rules. In particular, their location in the vicinity of the stoves or fireplaces is not allowed. If this rule is not taken into account, in the event of a fire, they become catalysts for ignition.

- Lattices on ventkalah should be such that their cells are always open. It is desirable that they do not have vertical protrusions.

- The dimensions of the ventilation ducts from the brick for the chimney must be such that the required cross-section is provided.

Choose it based on the heat output of the furnace:

- 14х14 cm - at a power of not more than 3.5 kW.

- 14x20 cm - at a power of 3.5-5.2 kW.

- 14x27 cm - at a power of more than 5.2 kW.

Factors on which the traction depends

In the cold season, the temperature difference between the street and the room will be considerable. In such a situation, the amount of air withdrawn is greatly increased. Simply put, the warmer on the street, the lower the thrust value is required.

Thrust is the speed of air flow. The amount of air withdrawn from the room depends directly on it. Also, this parameter is influenced by the cross-sectional area of the ventilation duct. The bigger it is, the stronger the pull.

As a result, it can be noted that for the cold regions of our country, more effective system ventilation.

Tip: the lower the temperature, the faster the condensation forms. Therefore, ventilation ducts in cold regions need to be covered with antiseptics.

If you read the above information, you decided to independently organize an air exchange system, then you certainly want to receive useful instructions.

We understand this and present to your attention a few important recommendations.

- Masonry ventilation ducts made of bricks should be made of solid samples. Do not forget about the rules of dressing. It is best to design this element in advance.

- As a rule, the dimensions of the ventilation ducts are 14х14 cm in brickwork, in turn the chimneys should be slightly larger - 27х14 cm. In this case, the thickness of the walls between must be at least half of the brick.

- If you want to achieve the correct form and prevent clogging of mines, insert special inventory buoys into them. In fact, it is a hollow box made of plywood.

Tip: you need to make a box so that it fits into the canal without leaving any voids. Its height should be 9-10 rows of masonry.

- To create channels you can use a conventional solution of cement and sand. Before applying, it is recommended to moisten the brick with water to improve its adhesion.

- It is recommended to make the channels smooth, that is, without any roughness. Also, the presence of protrusions or depressions is not desirable, since they interfere with normal air circulation.

- If there is a need to create a branch, then its length should be no more than 100 cm, and the angle of inclination is not less than 60 degrees, relative to the horizon.

In this case, the cross section in both parts of the channel must be equal, otherwise the thrust efficiency will be reduced. For the laying of inclined areas, it is necessary to use the bricks at the right angle.

- In the immediate vicinity of wooden structures, it is necessary to create a cutting of non-combustible materials. For this, asbestos is perfect.

It is also required to increase the thickness of the canal walls: up to 40 cm, if the structure is not protected, and up to 25 cm, otherwise.

- For masonry, it is best to use double silicate brick m 150, as it has the required coefficient of frost resistance and thermal conductivity. However, the use of other samples is allowed.

Typical errors and solutions

Often people at the construction stage allow a lot of mistakes that lead to various problems. This is especially true for ordinary citizens who do not have a sufficient level of skills.

Therefore, we present to your attention a list of the most typical of them, as well as methods for their solution.

- In a room without windows there is no ventilation duct - this leads to an increase in air humidity, which leads to the formation of fungus and mold. Decide this problem it's easy: just make a separate channel with a capacity of 15m3 / h. To do this, you need to install exhaust ventilation by means of special pipes.

- In the outer wall formed a hole, which promises to hit the room with cold air from the street. To solve this problem, install a fan in the resulting hole (preferably with a humidity sensor).

In this case, the building brick near the fan should be covered with a hydrophobic compound, since moisture will constantly form in the hole.

- In the internal doors there are no ventilation openings, which prevents efficient air circulation. It is easy to get out of such a situation with a winner - you need to insert decorative bushings or grilles in the door that will release polluted air. The total area of such apertures should be in the range of 80-150 cm2.

- Too airtight windows. It is a plastic double-glazed window that prevents natural circulation air. This leads to a risk of the formation of carcinogenic substances, as well as the deterioration of the work of fireplaces and stoves.

Modern manufacturers of window frames are well aware of this lack of plastic, so they began to produce so-called "ventilators". These elements can be installed directly into the window or wall.

Tip: windows in which the infiltration ratio is in the range from 0.4 to 1 M, do not require the installation of additional ventilation. Therefore, before buying, ask the seller about this indicator.

Checking the ventilation ducts

In order to guarantee efficient air circulation in all rooms, ventilation channels must be checked regularly. It needs to be done in time and in full. Otherwise, there is a high probability of clogging of these elements.

As the instruction says, the ventilation system should be checked:

- Before the start of the heating season (the beginning or end of autumn, depending on climatic conditions).

- Every three months, if there are brick chimneys.

- Once a year in the presence of chimneys from asbestos cement.

During the inspection of the ventilation duct, it is required to check the following aspects:

- The conformity of the device and the materials used, in relation to the requirements of GOST.

- Correspondence of sizes.

- Absence of any contamination (soot, fungus, etc.).

Over time, the mine may have various natural formations that should be removed immediately