Plastic pipes for heating. What are the plastic pipes for heating

In this article we will consider plastic pipes for heating, characteristics of polypropylene and metal-plastic systems. After reading the material, you will have an idea of whether it is possible to use plastic pipes for heating, how to choose and which one to give preference to.

Comparative characteristics

Types of plastic pipes

Let's start with materials that are used for the production of plastic and polypropylene products. These plastic pipes for heating have similar characteristics.

Both types of plastic pipes for heating consist of five layers:

- two layers of plastic;

- reinforcement;

- two layers of glue.

To answer the question about which plastic pipes are better for heating, we will consider the materials for their manufacture.

Metal-plastic pipes are made of three types of plastic: polypropylene, polyethylene or cross-linked polyethylene. Marking, respectively: PP-R, PE-R and PE-X. And for production polypropylene pipes homopolymers, block copolymers and random copolymers are used. Their labeling is PPH, PPB and PPR, respectively. It is important that for systems in which hot water circulates, only reinforced plastic pipes for heating are used. How to choose the type of stabilization?

Structure of reinforced plastic pipes

Metal-plastic is reinforced with a layer of aluminum, and polypropylene besides aluminum can also be stabilized by glass fibers. Reinforcement is necessary to reduce the coefficient of linear expansion - this property of the contour becomes longer. Stabilization layer is continuous or perforated. Due to this, both types can withstand heating up to 95 degrees, while the dimensions of plastic pipes for heating practically do not increase.

Reinforced plastic pipes for heating are able to withstand a nominal pressure of 20 atmospheres. Nominal pressure is the indicator at which the system will last fifty years with the condition that the temperature of the coolant will be 20 degrees. When the temperature rises, the service life, of course, decreases. Pipes can withstand a larger brief increase in pressure. In this case, the tightness of the system largely depends on the type of connectors and the method of their installation.

Based on the results of the first block, it is possible to distinguish the common for both types of pipes:

- equal number of layers;

- the presence of reinforcement;

- the same temperature regime;

- the same limit pressure;

- the declared service life of plastic heating pipes in fifty years.

What fittings are used

In order to understand which plastic pipes are better for heating, let us consider the types of connectors used for the installation of polypropylene and metal-plastic systems. Here you can see significant differences. Let's start with metal-plastic. To connect parts of the contour of metal-plastic, two types of fittings are used:

- clamping.

Clamping (collet) fittings

This is a detachable type of fittings for heating from plastic pipes. The fitting consists of a body with a shank, a clamping ring (collet) and a nut. On the shank there are two rubber rings that serve to seal the joint. The collet is a ring in which there is a gap of several millimeters. Its width is much shorter than the length of the shank and does not exceed the height of the nut. When the nut is tightened, the collet shrinks. This kind of connection is also called "collet";

- thrust.

Sliding (press) fittings

Also called press fittings for plastic heating pipes. They consist of a body with a shank, on which there are seals, as well as rings. Unlike the collet, the press-fitting ring is solid and wide. Its width is approximately equal to the length of the shank. The ring is clamped with a special tool.

Both types of fittings can be either straight or curved at an angle of 90 degrees. There are also tees intended for branches of the coolant flow. For example, when you make heating from plastic pipes yourself and you need to attach additional equipment to the circuit.

The reliability of the connection in both metal-plastic and polypropylene circuits strongly depends on the quality of the fittings used. It is better if it is made by the same manufacturer as the pipes.

Muffs and fittings for polypropylene

Couplings and fittings are used to connect polypropylene pipes to each other and to other contour elements. Couplings are completely plastic products, which can be:

- direct;

- curved at right angles;

- tees;

- adapters from a larger diameter to a smaller one.

Fittings suggest a transition from polypropylene to metal thread, which can be internal or external. If the couplings are intended only for connecting the lengths of the contour with each other, the fittings are needed to install the removable elements. Clutch connection is permanent, and fitting allows you to remove equipment for inspection or repair. For example, when you need to clean .

Mounting Features

Metal-plastic pipes can be bent

As you have already understood, the main differences between plastic heating pipes are the method of connecting the elements of the contour and the fittings used for this. Because of which you choose the pipes, depends also on their further installation. Between polypropylene and metal-plastic there is one significant difference - this is flexibility. Polypropylene can not be bent and to change the flow direction of the coolant, couplings must be used. Metal plastics, in turn, can be bent at different angles, which allows to minimize the number of ruptures in the contour.

This is a significant plus, especially when it comes to installing a heating system with plastic pipes under the screed ("warm floor"). You can even bend metal plastic with your hands, but you need to be careful. The bend should be round, you must not allow a kink. The basic tools that are needed to install both plastic heating systems are:

- scissors - the use of special scissors makes it possible to obtain a smooth and smooth cut;

- shaver - with it, you can calibrate the hole in which the fitting is inserted, as well as remove the chamfers. There are shaverers that clean the aluminum reinforcement layer.

The main moments of installation of metal-plastic.

If the installation is carried out by means of detachable fittings, then, in addition to the basic tools, only a wrench will be required to operate. What you should pay attention to:

- you should remove the chamfers - these are the burrs that form on the cut.

Before you yourself make heating from plastic pipes, you need to remove the chamfers so that the sealing rubber rings on the shank of the fitting do not tear. If they become damaged, then the integrity of the joint will be under big question. Even if the defect does not manifest itself immediately, then it will necessarily remind of itself in the process of exploitation, which will lead to systems;

- control the force.

Crimp fitting (collet - ring in the middle)

This applies to the installation of plastic pipes for heating a private house with compression fittings. If to squeeze, the collet will begin to squeeze out into the gap between the contour and the nut. Since the collet is thin and has sharp edges, it can cut through the shell of the tube, which leads to a leak or a significant weakening of the joint;

- use a quality press.

If you decide to use press fittings, then the reliability of the connection depends largely on the quality of the press, which can be manual or electric. Take care of this in advance, since it is extremely difficult to make heating from plastic pipes without a good tool yourself.

The main moments of installation of polypropylene.

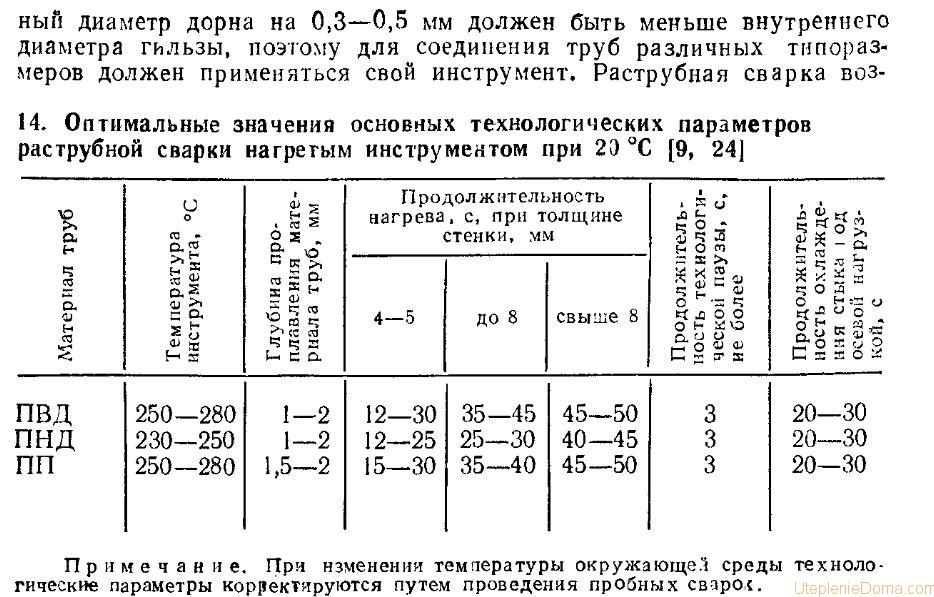

The contour is assembled by soldering. To do this, you need a special welding machine (soldering iron), which you can buy for 1200 rubles. The price and the producer do not matter much. There are models with temperature control and other options that are of little help. The optimum temperature of the soldering iron head is 260 degrees, so the possibility of temperature control is just a marketing move. And such an option, as an audio signal when the polypropylene reaches the optimum temperature, will not replace the experience.

When installing polypropylene it is important to heat the part to the required level. Insufficient heating, as well as overheating, lead to deterioration mechanical characteristics connection.

What you need to pay attention to:

- heating time.

Welding of polypropylene

If this condition is violated, polypropylene loses those necessary characteristics that make it possible to make a reliable and sealed connection;

- the parts must be connected with some force.

If the head of the soldering iron parts are worn easily, then there is a marriage. The same applies to their connection with each other;

- ring in place of jointing.

In the place where the contour enters the coupling or fitting, a thin uniform ring of extruded plastic should form. This indicates that there is no air left in the junction.

Plastic pipes combine excellent quality and high reliability.

Recently, professional builders prefer working with this material, which helps the heating system to meet the following requirements:

- The system should be installed easily, so that self-assembly did not cause undue anxiety.

- The pipeline should be light and strong.

- Heating - effective without unnecessary loss of heat.

- Heat transfer from the material should be minimal, so that all water is delivered to the radiators in primeval high temperature. This is the only way to save fuel for heating water.

- The pipeline should be designed for minor overheating and not cause leakage at the slightest fluctuation.

Polypropylene Is a chemical compound that, as a result of prolonged laboratory tests, has turned out to be easy, with high performance characteristics and excellent elastic properties.

Due to this, polypropylene became very promising in the sanitary engineering field. The price of the material is relatively high, however, taking into account all the universality, the use of pipes made of propylene is more relevant and expedient.

Polypropylene can withstand both cold and hot water supply. It has high strength, so it can be used in the organization of industrial, chemical, medical and domestic pipelines.

Plastic pipes are made of a copolymer of polypropylene, belonging to a reliable group of thermoplastics. When compared with metal options, plastic are harmless to the human body and the environment, over time they do not rust and are not covered with a corrosive coating.

Price

Plastic pipes Rexay

The production is organized in Turkey, Czech Republic, China, Germany and Russia:

- The most high-quality and durable pipes are German. Often, preference is given to such firms: Rexay, Aquatherm, Banninger, Wafatherm. Manufacturing technology is at the highest level. Raw materials are selected only the most qualitative, because of what the pipeline turns out strong and very wear-resistant. They are environmentally safe. A warranty from the manufacturer is 10 years. The price starts from 150 rubles for 1 meter linear.

- Not inferior to the practicality of the pipes of Czech manufacturers. These are well-known companies: FV-Plast and Ekoplastik. They are used in both domestic and industrial construction. The main advantage is the high resistance to a significant drop in temperature. They have a multilayer structure and are reinforced with aluminum. Connect such pipes. Their price starts from 140 rubles.

- Cheaper copies are produced in Turkey. There are such companies: Pilsa, Valtek, Kalde, TEBO, Jakko, In the Russian market, Turkish pipes confidently won their place. This is something between the European leaders and the Chinese budget options. On practicality a little inferior, however, serve long enough and do not cause unnecessary operational issues. Prices start from 120 rubles per running meter.

- Chinese and Russian plastic is the cheapest, but not too high-quality. There are even cases of cracking and deformation of materials. Distinguish the following companies: BLUE OCEAN, Dyzain - China, PBK, Santrade, Politec. The price is from 90 rubles.

When the price is formed, the diameter of the product is also taken into account. Suitable for heating pipes from 20 mm. Thus, the larger the diameter, the higher the cost. Also, the price range is formed based on their reinforcing substance.

Production technology

Apparatus for manufacturing

For the production of plastic pipes, special additive additives are mixed in polypropylene, which make the finished material resistant to high temperatures and pressure.

Therefore, when the water in the pipes freezes, the material walls do not rupture, but just slightly deform.

When boiling water, polypropylene expands, however, does not burst.

Process:

- When manufacturing, into the rotating hopper of the extruder, a granular polypropylene raw material is placed.

- Inside the cylinder there is a heater, which melts the material. The whole plane of the extruder is equipped with temperature sensors, which control its swings in different areas.

- Passing through the cylinder, the raw material is converted into plastic, which under pressure is fed into the extrusion head, where the workpiece is formed.

- The finished form undergoes a special calibration process and placed in a vacuum bath, where the pipe is stretched to a certain length.

- That there was no deformation during the drawing process, the finished product is urgently cooled. This is part of the future pipeline.

- Cutting is carried out using special disk and guillotine saws.

Characteristics

Based on the unique composition, plastic materials are characterized by the following properties:

- Stands for chemical attack: do not react with acidic and alkaline solvents, nor accumulate calcareous deposits. This is a very important factor, as modern water supply is far from ideal. Contains a huge amount of impurities and promotes the formation of a solid calcareous plaque, which affects small-diameter communications made of materials with low corrosion resistance. Thus, over time, it is necessary to conduct special maintenance, or completely change the pipeline.

- Thermal conductivity at low level, which allows you to transport water without significant heat loss. On the surface there is no condensation, however, experienced experts still recommend using the merilone for better efficiency.

- Hygiene and environmental Safety . It is used even in the medical field, since plastic specimens have a neutral bacterial flora.

- Elastic and light, as a result of which, the installation of the pipeline is quite simple and quite achievable. In addition, the pipes do not need much support. When installing in the upper part of the room, it is enough to place the holders in steps of 1 meter. So pipes with water will not sag.

- High mechanical strength. Due to its composition, the pipes easily yield to static loads without deformation.

- Frost resistance of the material makes the heating system simply irreplaceable. The pipeline will withstand a temperature drop of -15 degrees.

- Melting point polypropylene is high enough and is at 160 degrees, so, with a critical increase in the temperature of the coolant, the heating system will withstand and remain operational.

- Softening point is at 140 degrees, which is higher than the boiling point of water.

- High coefficient of thermal deformation, the index of which is 0.15 mm / m * C.

- Low level of hydraulic resistance.When the water moves through the pipes, there is no vibration.

Kinds

All polypropylene pipes are based on reinforced elements, so they can be divided into several types:

- Polypropylene with aluminum sheet. Reinforcement in this case, can be laid as close to the outer layer, and in the middle and inside the pipe.

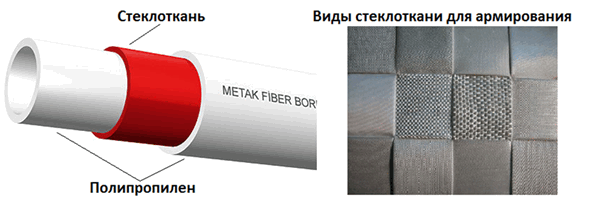

- Polypropylene with fiberglass. As a rule, in this case, the reinforcement is carried out in the middle layer, and the outer ones are made of polypropylene.

- Polypropylene with a composite material. The composite consists of fiberglass and polypropylene, which is located in the middle part.

There are several most popular brands that deserve attention and are widely used in construction:

PN10

Used for cold water and withstand pressure up to 1 MPa.

PN16

Universal pipes for both cold and hot water with a maximum pressure of up to 1.6 MPa.

PN20

For hot water with nominal pressure up to 2 MPa.

PN25

Pipe with reinforcement, which is used in the organization of the heating system. It will withstand a pressure of 2.5 MPa.

Advantages and disadvantages

Polypropylene pipes have several advantages:

- Have a long service life.

- Do not corrode, as a result of which, the internal diameter remains unchanged.

- Hermetic, which guarantees the absence of oxygen penetration inside the product.

- High sound insulation.

- Easy to assemble.

- They are connected together monolithically.

- Resistant to deformation.

- There is no need to paint.

- Do not conduct electricity.

- Withstands the load with a high head of water.

- Do not ignite.

However, in the use of such a pipeline in the heating system, there are also disadvantages:

- From the quality of the selected material the accuracy of the installation and the further performance characteristics depend very much.

- When exposed to temperatures above 120 degrees, the pipe can stretch out and take the shape of an onion. It will not be possible to restore such a pipeline any more.

- It is better to give preference to more expensive manufacturers, as this reduces the likelihood of errors during production and the use of poor-quality raw materials.

Criterias of choice

The main factors that influence the choice are the manufacturer, material of manufacture and diameter. With the manufacturer, we have already figured out, but as for the diameter and material, let's consider in more detail.

Diameter depends on the purpose and scope of use:

- AT heating systems household and industrial values mainly pipes of 20 mm in diameter are used.

- For heating it is better to give preference to options reinforced with fiberglass and aluminum. These materials have a low level of linear expansion.

- The product must be multi-layered, which guarantees greater strength and durability.

- Also, it is worth paying attention to. Its value should exceed 20 atmospheres. Therefore, the models PN20, PN25 will be more relevant for heating systems.

Advice:

- Polypropylene heating system - an excellent option, however, do not use them in regions with excessively cold winters, where the temperature can drop below -30 degrees. In this case, it is better to give preference to galvanized options.

- For heating only reinforced specimens are used. This can be both reinforcement with aluminum and glass fiber. In both cases, during installation, no cleaning is required.

- When buying, it is better to give preference to more expensive analogues, because heating is carried out for many years, so there is no economic savings.

- Do not install a plastic pipe in wall partitions and slabs without a gap designed for thermal expansion.

To the plastic pipes can be attributed pipes made on the basis of polymers. However, their polyethylene pipes and PVC for heating are not suitable, because they have a high coefficient of linear expansion, and such pipes at high temperatures are easily deformed. In connection with this, the most demanded pipes for heating are metal-plastic and polypropylene pipes. You will learn more about their technical characteristics, cost and installation features using our article.

Technical characteristics of pipes from different materials

There are not many significant differences between polypropylene and plastic pipes. In fact, they are made of one material, polypropylene. Metal-plastic pipes are sometimes also called polypropylene reinforced pipes. Let's consider more main differencestechnical characteristics of these types of pipes, using the table below.

There are not many significant differences between polypropylene and plastic pipes. In fact, they are made of one material, polypropylene. Metal-plastic pipes are sometimes also called polypropylene reinforced pipes. Let's consider more main differencestechnical characteristics of these types of pipes, using the table below.

Comparison of the main characteristics of metal, metal-plastic and polypropylene pipes for heating.

| Polypropylene pipes | Metal-Plastic Pipes | Metal pipes |

| ease of installation and transport | transportation and installation require heavy construction equipment, as well as a welding machine | |

| service life 30-50 years | service life 30-50 years | service life 10-15 years |

| the maximum diameter is 3000 mm | maximum diameter of 40 mm | the maximum diameter is 1430 mm |

| pipes are well protected against heat losses | pipes are not protected against heat losses | |

| due to the smooth inner surface, no lime deposit is formed in the pipe | with time, on the inner surface of the pipe, calcareous deposits, rust and other deposits | |

| good sound insulation | good sound insulation | poor sound insulation |

| do not conduct an electric current | conduct an electric current | |

| high linear expansion | rather high linear expansion | low linear expansion |

| in the process of burning, toxic substances are released | pipes are not subject to combustion | |

| not | suitable for embedding in the wall | suitable for embedding in the wall |

| do not exfoliate | exfoliate | do not exfoliate |

| at a temperature difference can deform | at a temperature drop less susceptible to deformation | at a temperature difference are not subject to deformation |

| have a low price | have a low price | have a high price |

| pipes are subject to mechanical deformation | pipes are less susceptible to mechanical deformation | pipes are not subject to mechanical deformation |

Reinforcementis the presence in the pipe of a layer of metal or fiberglass. Advantages of reinforced pipes:

Reinforcementis the presence in the pipe of a layer of metal or fiberglass. Advantages of reinforced pipes:

- This interlayer significantly reduces the coefficient of linear expansion of the pipe (in a typical polypropylene pipe it is 0.15 mm / Mk, while polypropylene glass fiber reinforced pipes , 0.035 mm / Mk), and it can be used in heating.

- It is preferable to use pipes, reinforced with aluminum, because the metal is better adapted to the high temperature, and the heat carrier due to the pressure in the pipe becomes larger than the operating temperature of 95 ° C.

Even more resistant to high temperatures Composite pipes ASG, the inner layer of which consists of heat-resistant polyethylene. Such pipes have an internal self-supporting layer of polyethylene, cross-linked high pressure. Even in case of aluminum damage, the inner layer maintains its operational properties.

Composite heating pipes with aluminum

Advantages and disadvantages of plastic pipes

The main advantage of polypropylene pipes for heating, for reviews users, is their almost perfect tightness. They are mounted by the method of polyfusion welding, which excludes the possibility of depressurization of joints. Welding machine for polypropylene pipes heats the connection point of the pipe with the fitting up to 260 0 C, and the connected parts become a single unit. The heating time depends on the thickness of the pipe: 16 mm - 5 seconds, 25 mm - 7 seconds, 32 mm - 8 seconds, 40 mm - 12 seconds. Squares serve to rotate the pipes at 45 and 90 0.

The main advantage of polypropylene pipes for heating, for reviews users, is their almost perfect tightness. They are mounted by the method of polyfusion welding, which excludes the possibility of depressurization of joints. Welding machine for polypropylene pipes heats the connection point of the pipe with the fitting up to 260 0 C, and the connected parts become a single unit. The heating time depends on the thickness of the pipe: 16 mm - 5 seconds, 25 mm - 7 seconds, 32 mm - 8 seconds, 40 mm - 12 seconds. Squares serve to rotate the pipes at 45 and 90 0.

Tees are needed for branch pipes, and the couplings help to switch to a different pipe diameter. At the working pressure in the pipes up to 16 atmospheres, compression fittings for polyethylene pipes low pressure (HDPE). But the main and main drawback is the coefficient of linear expansion of the pipe.

Some features of plastic pipes:

- When a hot heat carrier is exposed to a pipe, the polypropylene pipe can extend 10-15 times.

- If the temperature of the carrier rises to 140 ° C, the pipes will soften and hang on the fasteners.

- If the heating system is functioning without circular pump, then there is a high probability of narrowing the flow section as a result of the formation of air bags in the pipes.

The non-problem-free polypropylene pipes were replaced by pipes reinforced with shallow aluminum. Their main drawback was the need to use shaverers, stripping devices, which greatly complicated the installation process. In response, there were polypropylene pipes with a deep layer of aluminum. They are mounted using press-fittings for metal-plastic pipes .

But the most popular among polypropylene reinforced pipes are pipes reinforced with fiberglass. Their main advantage is impossibility stratification of plastic and fiberglass, making such pipes reliable in operation.

The main reasons why people do not trust their heating with plastic pipes are:

The main reasons why people do not trust their heating with plastic pipes are:

- high coefficient of thermal expansion

- quite large heat loss.

To avoid both, you need to use a special insulator Merilon. In addition to the above, this material removes excessive vibration, absorbs excess noise, protects against condensate formationon cold pipes, etc. Merilon has a low weight, waterproof, it does not crumble, it is easy to cut it. The material is resistant to chemicals, protects the pipe from minor mechanical damage.

The cost of the material "Merilon" standard length of 2 linear meters.

| Diameter, mm | Thickness, mm | Price, growing. rub. |

| 15 | 6 | 6,64 |

| 18 | 6 | 6,64 |

| 28 | 6 | 6,64 |

| 35 | 6 | 8,3 |

| 42 | 6 | 8,3 |

| 52 | 9 | 16,6 |

| 65 | 9 | 18,26 |

| 76 | 9 | 23,24 |

| 89 | 13 | 33,2 |

| 102 | 13 | 49,8 |

| 114 | 13 | 59,76 |

Of course, you can mount the heating system yourself. Moreover, the average man thinks that there is nothing terrible here. But imagine what can happen if to lay the heat pipe illiteratelyin the "Warm Floor" system! Do not test fate, it is better to immediately turn to the services of specialists.

List and cost of services for installation of plastic pipes for water supply

| Service | List of works | Cost | Organization | How to contact |

| Installation of supply pipelines | Laying of plastic pipes with a diameter of up to 25 mm | 50 rubles / running meter | Inzhin | (495) 410−12−00 (495) 979−00−22 |

| Warming of pipelines | Installation of tubular insulation on pipes | 24 rubles / running meter | Inzhin | (495) 410−12−00 (495) 979−00−22 |

| Installation of a heating device with a gasket | Laying of plastic pipes, installation of a heating appliance | 3000-4000 rubles per point | ICC "StroimTeplo.ru" | (495) 648−41−21 (495) 648−81−84 |

| Floor heating | Stacking insulation, flooring heat insulation tape, laying reinforcing mesh, wiring the pipeline and attaching it to the grid, pasting around the wall sections with a damper tape | 450-650 rub / m2 | ICC "StroimTeplo.ru" | (495) 648−41−21 (495) 648−81−84 |

| Installation of heating pipes | Gasket, placement and fixing of polypropylene pipes with a diameter of 20-50 mm | 150-350 rub / running meter | HeatCom | (495) 966−31−71 |

| Installation of heating pipes | Gasket, placement and fixation metal-plastic pipes with a diameter of 20-50 mm | 250-400 rub / running meter | HeatCom | (495) 966−31−71 |

| Installation of heating pipes | Gasket, placement and fixation polyethylene pipes with a diameter of 16-50 mm | 150-400 rub / running meter | HeatCom | (495) 966−31−71 |

| Installation of a warm floor system | Layout of insulation, fixing grid, heating pipeline in steps up to 150 mm | 1050 rub / m2 | HeatCom | (495) 966−31−71 |

| Installation of a warm floor system | Layout of insulation, fixing grid, heating pipeline in steps up to 300 mm | 850 rubles / m2 | HeatCom | (495) 966−31−71 |

| Installation of a warm floor system | Layout of the heater, fixing the mesh, mat with latches up to 150 mm | 950 rub / m2 | HeatCom | (495) 966−31−71 |

| Installation of a warm floor system | Layout of insulation, fixing the mesh, mat with clamps up to 300 mm | 750 rubles / m2 | HeatCom | (495) 966−31−71 |

Approved by the expert

Heating systems for decades were installed using metal pipes - steel and copper. But conventional steel pipelines have a number of serious shortcomings, and pipes made of stainless steel and copper due to the high cost are not available to everyone. These factors led to the emergence of a new material with high characteristics - plastic pipes of several varieties, differing in functionality and cost, but with an affordable price range for use in everyday life.

Plastic pipes for heating, due to specific operating conditions, occupy an independent niche in the group of polymer pipe materials, and therefore deserve a separate consideration.

Pipes of plastic - a material based on polymers, the functionality of which depends on the characteristics of the substrate. Plastic pipes are used in heating systems, cold and hot water supply, sewerage, ventilation, as sleeves and channels for electrical wiring. Each field of application presents certain requirements for this material, therefore the characteristics of plastic pipes for heating are specific. But at the same time there are common properties inherent in all varieties of polymer pipes.

Varieties of plastic pipes

Polyethylene pipes (PE, Russian abbreviation - PE) are produced for high and low pressure pipelines (HDPE and HDPE pipes), used for internal and external water supply, sewerage and drainage systems, in heating systems, use is only possible as a supply pipeline expansion tank open type heating systems.

Pipes of cross-linked polyethylene - a material of polyethylene, in which one of four methods is performed by molecular "cross-linking", increasing strength by creating additional cross-links between molecules of polymer in the lattice. They are used for the installation of heating systems, as well as for the layout of the circuits for cold and hot water supply.

Polypropylene pipes (PP, Russian designation - PP) - a group of several types of pipe material based on polypropylene, differing in the values of the main characteristics (operating temperature and pressure). Widely used in heating systems, cold and hot water supply, sewerage and ventilation.

Pipes made of polybutene (PB, Russian abbreviation - PB) are a high-quality material that differs from polypropylene with increased flexibility, frost resistance and maximum working pressure.

Pipes made of polyvinyl chloride (PVC) - a material of two varieties (unplasticized and chlorinated), obtained from vinyl chloride by polymerization.

Important! Due to the increased rigidity and the release of chlorine in contact with hot media, PVC pipes for the installation of heating systems, as well as SGS are not used.

Pipes made of fiberglass - the walls of this high-strength pipe material are made of fiberglass with a filler based on epoxy resins, in heating systems, these products have not found wide practical use because of the time-consuming method of connection.

Metal-plastic pipes - products with multi-layered construction of walls, providing material high specifications and a wide distribution in heating systems, especially when installing warm floors.

General characteristics of plastic pipes

- Strength - the ability to withstand the stresses typical for operating conditions of pipelines, including hydraulic hammers.

- Plasticity and elasticity - the preservation of characteristics unchanged after deformations from the effects of temperature and pressure stresses.

- Corrosion resistance - the neutrality of the material for making pipes to contact with moisture and dissolved compounds in it.

- Low coefficient of thermal conductivity - material along with external thermal insulation participates in the process of reducing heat loss and condensation.

- Dielectric properties - the absence of static electricity and wandering currents.

- Low coefficient of friction - reducing the load on the circulation pump when the friction of the liquid over the internal surface of the pipeline wall is overcome.

- Resistance to biological effects - they do not decompose and are inert to the presence of bacteria.

- Absence of calcareous formations on internal walls.

- Durability - is due to the above characteristics.

- High sound insulation properties - the movement of the medium in the pipeline is noiseless.

- Low specific weight - low transportation costs.

- Ease of installation technology.

Plastic pipes for heating should have all of the above properties, and some of them (heat resistance, flexibility) - more than, for example, polyethylene or PVC products, not suitable for heating systems.

Thus, among the listed types of plastic pipes in heating systems, only the following materials are used:

- polypropylene;

- cross-linked polyethylene;

- high-temperature polyethylene;

- polybutene;

- metal plastic.

In order to have an idea of which plastic pipes are better for heating, let us consider the products from this list of materials in more detail.

Polypropylene pipes

Polypropylene - the material is flexible and durable to break, which causes its wide application in the construction of pipelines. On products made of this material, produced with a diameter of 16 to 110 mm, there is a Latin marking PP. The high quality of the polypropylene pipe material was not achieved immediately. The melting point of polypropylene is 175 degrees at a value of 90 operating temperatures. Even short-term operation of the pipeline made of polypropylene at a coolant temperature of 110 degrees is permissible, which implies that the material is perfectly suitable for the installation of heating systems. But polypropylene has a high value of the coefficient of thermal expansion, which means that the usual polypropylene pipes in the place of installation will increase considerably in length when heated from the passage of hot coolant through them. In addition, when heated, it will also increase, which will limit the use - the finishing tiles for the finishing of warm floors can crack or flake off the base when the heaters expand underneath.

The solution of the problem was found, which significantly reduced the temperature expansion of products from the PP-material. Thus, polypropylene pipe products began to be produced in two main types:

- solid (single-layer) - for cold water supply;

- with reinforcement (multi-layer) - for hot water and heating systems.

Reinforcement of pipes made of polypropylene

The fittings for PP pipes are made of aluminum or fiberglass, the location of which in the pipe wall can be different. Aluminum reinforcement is also called stabilization, and PP-reinforced PP pipes are stabilized, so the word Stabi is included in the labeling of such products.

As a result of the reinforcement, the walls of the PP pipes are already multi-layered structures that differ not only in the material of the layers, but also in their layout.

Execution of reinforcement of polypropylene tubular products can be as follows:

- aluminum layer in the thickness of the wall is closer to the outer surface - when welding such products, the aluminum shell must be removed together with the outer layer of polypropylene;

- layer of aluminum foil in the middle of the wall section - the foil is not removed during welding, no thickening is produced on the pipes of this section;

- reinforcement with a layer of fiberglass fabric - pipes with a slightly higher coefficient of thermal expansion than aluminum, but a simplified soldering process.

The layer of aluminum foil has a thickness of 0.1 to 0.5 mm - the thicker the foil, the higher the working pressure of the pipe. Aluminum shell, which not only increases the strength of the PP pipe, but also is an oxygen barrier, can be either continuous or evenly perforated.

Polypropylene has the property of passing oxygen through its mass, including that contained in the air. Consequently, oxygen will flow through the walls of the pipeline into the coolant. This is a negative factor if in the heating system, antifreeze is used as the coolant - some of its species, in interaction with oxygen, form compounds that damage the boiler and circulating pump. For such a heating system, the pipeline should be installed from PP pipes with solid aluminum reinforcement.

If water is used as the heat carrier, then pipes with a perforated cover are better for the heating pipeline. Perforation of aluminum, which is made through or embossed, allows you to fasten adjacent PP layers without using glue. Such polypropylene pipes are minimally susceptible to thermal expansion and do not form thickenings from temperature and pressure drops.

Recently, basalt fiber, known for its high heat resistance and low coefficient of thermal expansion, has been used to stabilize polypropylene tubular products. An example is the polypropylene pipes EKOPLASTIK produced in the Czech Republic, reinforced with basalt fiber, fused in plastic, which reduces the coefficient of thermal expansion by three times.

In terms of the allowable pressure and temperature, PP pipes are divided into the following groups:

- PN 10 - thin-walled material for installation of cold water systems with operation temperature up to + 20 ° C and floors with heating medium heating up to + 45 ° C, operating pressure 1 MPa (10.0 kg / cm²);

- PN 16 - pipe material for circuits of cold and hot water supply with a temperature of up to + 60 ° C, working pressure 1.6 MPa (16.0 kg / cm²);

- PN 20 - products of universal purpose, including for СГВ with temperature up to + 80 ° С, working pressure 2 MPa (20,0 kg / cm²);

- PN 25 - aluminum-reinforced tubular products for the installation of hot water and heating systems with operating temperatures up to + 95 ° C, pressure up to 2.5 MPa (25.0 kg / cm²).

The nominal pressure is included in the product labeling, for example PN10, PN16, PN20, PN25.

For the installation of heating systems the most common are PP pipes of the following sizes:

- 20 mm - for internal wiring of the water main and the heating circuit;

- 25 mm - for the manufacture of risers in low-rise buildings, the connection of heating radiators and floor heating systems;

- 32 mm - for the manufacture of risers and feed pipes in apartment buildings increased number of storeys (6 floors and above).

Connection of polypropylene pipes of heating systems

Connections of PP pipes are of the following types:

- non-removable - by welding;

- threaded connections.

When installing DHW and heating systems, it is usually necessary to use both methods, since the connection of the pipeline fragments is welded to each other, and the connection to the riser and the connection of the radiators are threaded.

Welding is performed using a special tool - a welded soldering iron, which correct use creates a lasting tight connection, based on the penetration of molecules of contact surfaces into each other.

The process of welding PP pipes is simple - the skills are acquired after several trial connections of unnecessary scraps and a pair of elbows-bends.

For threaded connections use fittings that are pre-welded with a soldering iron to the prepared section of the PP pipe.

Disadvantages of polypropylene pipes

What is called a disadvantage is often a feature of this material. So in the case of PP pipes. If we consider their flammability to be a disadvantage, then the furniture also burns, especially from natural wood, but its naturalness does not qualify as a drawback.

Basically, we have to deal not with the shortcomings of the polypropylene pipe products, but with the poor quality of the products from a certain manufacturer, the wrong choice of material for the existing operating conditions and the installation errors that cause claims to the PP material.

Let's list the features of polypropylene pipes:

- when installing horizontal sections on the brackets in order to avoid slack spans, the pitch of the supports should be carried out, depending on the diameter of the pipeline, 0.5-1.0 m;

- preparation of joints of the material before welding should be carried out carefully - cleaning from foil, facing;

- when welding PP pipes, it is necessary to accurately withstand the time of heating of welded joints;

- insufficient flexibility is neutralized by using the necessary fittings (bypasses, half-bends);

- when purchasing material for heating system installation, it is better to purchase pipes and fittings from one manufacturer;

- it is necessary to avoid the use of PP pipes of doubtful quality, for example, even with barely noticeable external defects.

Pipes made of cross-linked polyethylene

To improve the characteristics of polyethylene (conventional, low pressure - HDPE),

there is a special technology for changing its molecular structure called cross-linking, which creates additional bonds between molecules with an increase in the strength and heat-resistance properties of the polymer. PEX pipes have the designation PEX and have a solid wall of solid or multilayered cross-section - one or two shells are made of a basic material, and between them or outside there is a reinforcing layer that also acts as an oxygen barrier.

The material has been successfully applied in many areas, including the distribution of hot water and heating systems, conventional and high-temperature.

The connection of plastic heating pipes from PEX-material is carried out by one of three methods:

- compression (compression) - collapsible joint;

- pressing - conditionally dismountable connection;

- electrowelding - non-assembled installation.

Each of the mounting methods corresponds to a certain tool and fittings.

There are 4 methods of cross-linking polyethylene, after use of which from the received material is manufactured the pipe production, which has in the marking the corresponding designation:

Characteristics of PEX-pipes using the technology of cross-linking

PEX material from PEX-a has a uniform cross-linking and a good percentage. Products from PEX-a have the greatest flexibility of all the sewn pipes and good molecular memory - the ability to restore its shape after deformation. This allows you to easily correct the configuration defects and the creases formed during the installation of the circuit, using a conventional construction hair dryer.

PEX-a is a long-used method of cross-linking, which allows to obtain a material with a wide range of operating temperatures, retaining its strength characteristics even at peak short-term fluctuations from -100 to +100 degrees. The production of peroxidised cross-linked polyethylene is a costly process, but the high cost is justified by the quality of the finished products. PEX-a pipes are successfully used for the installation of heating and hot water supply systems, retaining their characteristics for many years.

With these advantages, PEX pipes have two significant drawbacks. During operation, this material is prone to intensive washing out of chemicals by the coolant, which adversely affects heating equipment and automation. In addition, the cost of this type of sewn pipes, as well as its fittings, is much higher than the materials of PEX-b and PEX-c. As a result, taking into account the cost of work, the total costs for the equipment of a heating system made of cross-linked polyethylene PEX-a can be several times higher than when using products made of polyethylene of another type of cross-linking.

PEX-b cross-linked polyethylene pipes began to be produced after the previous version, but 40 years of presence on the market is also a sufficient time to evaluate the material characteristics. Products from PEX-b are in great demand due to a successful combination of affordability and quality - high tensile strength.

Of the disadvantages of this type of PEX pipes, one should note the rigidity and low degree of molecular memory - it is quite difficult to make the necessary configuration necessary for coils of casing material.

PEX-c (radiation) bonding is performed by irradiating polyethylene with a stream of charged particles, at which part of the existing bonds are destroyed with the formation of new ones. The method is inherent in the inevitable unevenness of the cross-linking, which causes a high degree of risk of cracking, but this technology does not require high costs, and PEX-c pipes are still manufactured for systems with low requirements for the strength and heat-resistance characteristics of the heaters.

PEX-d pipes (nitrogen structure of the material) - production technology is complex and costly, while the high cost of material is not justified by the characteristics of the material, so the demand for products is not high.

Polyethylene of increased thermal resistance

The material marked PE-RT was created as a more perfect alternative to cross-linked polyethylene and is a thermoplastic, in the technological chain of which there is no cross-linking, which significantly increases the productivity of equipment. At the same time, according to the strength characteristics, PERT pipes are superior to PEX-polymer products, as well as for the convenience of connection - their joints can be welded. This is the reason for the popularity of this material, which by definition is suitable for mounting any hot water supply and heating systems.

Polybutene pipes

Pipe products from polybutene (PB, Russian abbreviation PB) - a modern high-quality material, combining the advantages of polypropylene and cross-linked polyethylene. In hot water and heating systems, polybutene pipelines are used relatively recently, but have already proven themselves to be superior to the technical characteristics of identical products.

Advantages of polybutene pipes:

- preservation of strength characteristics at critical temperatures;

- a high degree of flexibility is maintained even at negative temperatures;

- low coefficient of thermal expansion;

- the possibility of mounting with the use of joint welding;

- low thermal conductivity;

- resistance to chemicals.

Polybutene tubular products are produced in bays and rods of both conventional and pre-insulated versions. High technical characteristics stipulate not only wide application of polybutene in heating and hot water supply systems, but also their high cost for today.

Pipes from металлопластика

Metal-plastic tubular products - a material with a high-strength wall consisting of 5 layers: an aluminum pipe with external and internal shells of cross-linked polyethylene, fastened with a high-quality binder.

The design of the outer and inner shells may differ in the way of cross-linking or be made of high-temperature polyethylene.

The technology of production of pipes from metal-plastic is complex, but the cost is justified by the high technical characteristics of the final product, which is produced with an external diameter of 16 to 40 mm and a wall thickness of 2-3.5 mm, the form of realization is the yardage, bays.

The field of application of metal-plastic pipes - industrial and domestic systems of heating and hot water supply.

Advantages of the material:

- anticorrosiveness;

- internal and external resistance to chemicals;

- low thermal conductivity;

- low coefficient of friction of the internal surface;

- small values of the radius of curvature with mounting bending;

- antistatic;

- dielectric properties;

- reliability of butt joints;

- durability.

Disadvantages:

- a significant amount of temperature expansion (the need to install expansion joints);

- lack of resistance to mechanical damage;

- necessity of tightening compression fittings;

- low relative steel pipes heat resistance;

- high cost stop valves and accessories.

The main technical characteristics of metal-plastic pipes are present in the marking of the material applied for convenience on each linear meter.

Performance characteristics of pipes made of metal-plastic:

Important! At a coolant temperature above 140 ° C, the internal polymer shell melts and the remaining structure of the pipe is stratified.

Installation of pipes from metal-plastic is made with the help of fittings and a special tool. With certain production skills installation works It is possible to install a heating system or CSG from this material on its own.

Conclusion

The success of home heating equipment depends on many factors, including the correct choice of material for the heating pipeline. Today's market of pipe materials is so rich that it allows you to pick up plastic pipes for heating to anyone heating unit. It is only necessary to have a clear idea of the operating conditions of the equipment to be installed.