How to tightly connect the threaded connections of the aqueduct at home. Material for sealing the pipeline

To make connections sewerage systems It is necessary to use additional adhesives that provide a tightness of attachment. In general, for this purpose, sewer pipes.

Necessity of sealing

Sealing is the provision of complete obstruction to the surface of gases or liquids from pipes. This process is mandatory for the construction of sewer systems. Some of the home masters neglect sealing, but re-holding it is considered a more difficult task than the primary treatment of tubular joints.

Why seal plastic and cast iron sewer pipes:

- To prevent leaks, which arise from the strong pressure of sewage;

- To protect the connections from changes in ambient and water temperatures in the pipes;

- To ensure the protection of pipes from penetration of water from outside. It can be the groundwater, precipitation, etc.

Despite the external strength of joints, they need additional support.

Kinds

There are the following sealants for connecting sewer pipes:

- Special tapes;

- Silicone compounds;

- Technical sulfur;

- Episkid resin;

- Ropes made of jute or hemp;

- Portland cement;

- Different mastics.

Self-adhesive tapes are a novelty of the market, and are used mainly for plastic pipes internal sewerage. They are known for their durability and ease of use. In addition, if you have installed metal-plastic pipes, these tapes can become an additional protection of joints from corrosion processes. They are used not only to protect against leakage at the connection points, but also to strengthen the turns, plugs of the mortise elements, etc.

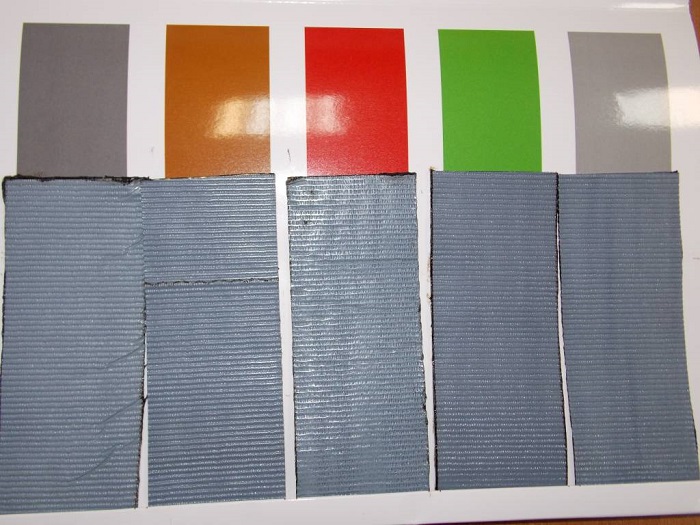

Photo: self-adhesive aluminum tape

Silicone sealants are the most popular among all masters. They can be selected by color to the pipe. They are used to seal fistula in plastic and metal pipes, they also help to strengthen the connection, to give it rigidity. The composition of silicone sealants for sewer pipes are divided into two types:

- Neutral;

- Acidic acid.

Neutrals are known for their composition, which does not destroy pipes that are afraid of "mineral" components. At the same time, acid costs a little less, but are not used on fragile pipes, as well as those that are destroyed under the influence of certain acids.

Silicone sealant for external and internal sewer pipes is characterized by the following positive qualities: it is sanitary composition (prevents mold and rot), protects PVC pipes from leaks, when hardening resembles rubber. In addition, silicone compositions are known as quick-setting, i. E. those that freeze a few hours after use. Most brands for complete fixing are needed from 4 to 6 hours, although there are those that dry up only after 24 hours. Also, silicone can be applied to pipes without disassembling them.

Video on the topic:

Technical sulfur is used mainly for cast-iron pipes. It is a rather aggressive but very durable sealant. At the same time its cost is an order of magnitude lower than self-adhesive tapes and silicone adhesive compounds. Portland cement is also used for the same purposes. It should be noted that the latter is increasingly replaced by serocene or sulfuric concrete. In most cases, these materials are used for sewerage in large industrial facilities or apartment buildings.

Photo: Mixture for sealing from industrial sulfur

Photo: Mixture for sealing from industrial sulfur Epoxy resin - a special type of sealant, which is very widely used not only in the sewer, but also in the construction various designs, requiring additional impregnation. For example, it is used for fiberglass, as a cold hardener, creating hot curing, and even simple household glue.

In water supply and drainage communications it is used for ceramic pipes and cast iron, which need more serious connection than plastic pipes. The advantages of epoxy resin include its durability and resistance to more than 50 aggressive chemical compounds. The resin is unstable only with respect to nitric and sulfuric acid, acetone, methyl ethyl ketone and hydrogen peroxide. Fluid gases also adversely affect it.

![]()

Previously, jute, treated with resins, was used to seal various household pipes. They act as well as self-adhesive tapes, but differ significantly in the principle of fastening. The fact is that jute is an ordinary string made in a special way. But if it is treated with certain resinous substances, it becomes quite strong and durable hermetic means for the funnels of sewers made of cast iron or ceramics.

In the book Pereshivkin in some detail describes the variety of mastics for sewer pipes. For different types of pipelines, the following mastics can be used: bitumen-talc, bitumen-asbestopolymer, bitumen-rubber, bitumen-polymer, and other types.

How to use

Regardless of the type of sealed compound, you need special attention to give the state of the pipes. You must first clean them from dirt and degrease, the surface to be treated must be dry, so if you repair or replace part of the working pipeline, there is a reason to turn off the water supply.

Photo: Sealing of sewer pipes

Photo: Sealing of sewer pipes Consider the principles of hermetic sealing sewage pVC pipesusing tape and silicone sealant. Self-adhesive tapes are glued to the joints at a constant angle and tension. This is necessary in order to prevent air layers from forming on the fistulas or sockets on their surfaces. The overlap overlap should be half the width of the tape.

Now the most popular silicone sealants of Sinicon brand, which are used for processing various types of pipes and sealing compounds, cracks, fistulas. Before starting work, be sure to check the surface for cleanliness and dryness, then use a special gun to distribute the silicone on the crack or joint. Do not need to smear it further, apply the mixture in several layers, and slightly outside the binding. In this case, it is impossible to wet the pipes not only before and during operation, but also after it. Additional instructions for the use of silicone sealants are available on the packaging of the selected product.

When sealing joints at the initial fastening, the sealant is actually poured into the socket socket. Silicone sealant for sewer pipes, like self-expanding cement, can take the form of a slot, so you do not need to use extra precautions in the form of bands or bundles.

The main problem in the operation of pipelines from various materials is the possibility of leaks at the junctions of separate elements of the main line. Particularly acute is the question of how and what should be done sealing the sewer pipes, which usually have a bell-shaped structure.

Separately, it is worth noting the need to join the elements of sewer lines from heterogeneous roads, insert separate branches, in which it is impossible to use standard fittings. These sections of the pipeline are considered to be the most problematic, and the solution to the problem can differ both in value and labor intensity of the process.

First of all, it is necessary to consider the need for high-quality insulation of the connection of elements of external sewer lines.

What sealant for sewer pipes would not be chosen (it is only about high-quality materials), it will solve two main problems:

- Prevention of leakage of sewage into the ground. The main task is not only to observe the norms ecological safety, but also to eliminate the possibility of flooding underground parts of buildings (cellars, basement rooms).

- No less important is the removal of sludge and hitting groundwater or parts of soil in the sewage system. Soil water can seriously damage the movement of sewage through the pipeline, in addition, there is the possibility of silt sewage.

|

|

Eliminating the consequences of any of these problems will require a considerable amount of work. At the same time, the cost of excavation, associated with the opening of the highway, almost do not differ from the cost of laying a new line. Therefore, it is economically feasible to purchase materials for sealing sewage pipes, and not to spend money on the work to eliminate accidents.

Main types of sealants

It should be taken into account that most types polymer pipes does not require additional insulation due to the use of rubber butt seals. In general, the means of sealing the sewer pipes are necessary for the laying of cast iron or ceramic lines. The installation of the elements of such trunks requires the obligatory presence of a so-called compensatory expansion joint, which makes it possible to maintain the integrity of the pipes with certain shifts in the soil.

Whatever the sealant for sewer pipes would not be chosen, it is necessary to comply with the technology of its application, otherwise the use of even expensive materials can bring a zero effect. In practice, various types of materials are used that can ensure a high-quality sealing of joints, with most pipe sealants known and effectively used by masters several centuries ago. Recently, polymeric substances and various resins, including epoxy ones, have been added to the list of sealing compounds.

All existing sealants can be divided into two main classes:

- Means applied in the form of paste (glue).

- Self-adhesive sealing tape.

Both types of materials can reliably seal and secure the connections of fittings and individual sections of the pipeline. They are used not only for the installation of sewerage, but also for the implementation of tie-in in the mainline, the implementation of emergency repair work, the elimination of emergency leaks.

Paste-like materials based on various silicone rubber. They feature high sealing ability, they can provide resistance to possible deformations. In the process of polymerization, silicone sealants are converted into a rubber-like substance, characterized by high resistance to various influences.

Can be used for laying and repair of sewer pipes from metal (steel, cast iron), ceramic and polymer pipes.

There are two main types of silicone:

- Neutral, which is used in most cases, ensures reliable sealing of the elements.

- Acid silicone is necessary for the device of the trunks working with aggressive environments.

Hermetic sealing of sewer pipes with silicone is affordable, while ensuring the quality and durable work of the joint, to date, this material is most popular both among professionals and in solving various household issues.

This type of sealant is a metallized scotch on a bitumen-rubber base. Aluminum or copper layer provides sufficient strength and reliability of sealing.

To achieve the required quality of connection with a similar tape, you need to remember the basic rules for its installation:

- Before use, you must carefully prepare the pipes or fitting, on the dusty or damp surface the tape will simply not be glued.

- The winding must be spiraled, with an overlap of approximately 50%, this will ensure that the two-layer coating can be covered with a tape of the entire surface.

- The winding should be carried out with a significant stretch of the self-adhesive, this will prevent the possibility of its spontaneous adhesion after removing the protective layer and ensure the uniformity of the coating (no wrinkles and other defects).

To date, self-adhesive tapes for sewer pipes are considered to be the most simple to use material, while they provide a high degree of sealing compounds of various types. They make it possible to significantly simplify the elimination of emergency leaks.

The pipe sealant is designed for tight junction joints, when rubber seals can not provide high-quality sealing on water supply pipes. The choice of the means depends entirely on the material of the pipes and the method of their installation.

Advantages and applications

Among the merits of the composition determine the following points:

The pipe sealant does not change its structure over time and does not lose quality under the temperature pressure of the water.

Viscous composition that does not spread during application.

Fills all the existing cracks between the pipes, repeating their bends.

The possibility of disconnecting the pipeline components when dismantling the system.

The use of sealant is advisable:

in the period of plumbing work to connect the thread;

when installing cast-iron lines, in which there are no rubber cuffs;

during repairs, when it is necessary to eliminate water leakage.

Variety

To connect the water pipe, the following types of sealants are used:

silicone;

polymeric;

self-adhesive;

homemade.

Consider each species separately.

Liquid means and polymer tape

These include a polymer material that retains flexible properties even after its application. The sealant of the liquid composition completely covers all the gaps between the pipes, and when solidified it forms an integral protective layer, which is firmly fixed to the joints. He can not squeeze out water.

Polymer tape is a reliable and high-quality material. The application should be made by a specialist, since the tape should be distributed evenly, otherwise under the pressure of the water thread may fail.

Silicone sealing and self-adhesive tape

Silicone is a widely applicable compound for sealing water supply pipes. When applying it, safety precautions are required, since silicone, when in contact with polyethylene, releases acetic acid. This compound firmly seals all types of threaded joints. The pipeline sealant is suitable for a small water pressure. If water comes under high vibration, there is a risk of depressurizing the silicone tape.

Silicone is a widely applicable compound for sealing water supply pipes. When applying it, safety precautions are required, since silicone, when in contact with polyethylene, releases acetic acid. This compound firmly seals all types of threaded joints. The pipeline sealant is suitable for a small water pressure. If water comes under high vibration, there is a risk of depressurizing the silicone tape.

Self-adhesive tape has an anti-corrosion property and dielectricity. The tape is applicable as connecting material For branching tees, rotary plugs and threads. The tape is created on a rubber base with aluminum spraying, the layer of which is torn off during installation. Before application, the tape is leveled and the winding of the butt section is stretched. This pipe sealant is reliable and practical.

Apply tape is recommended for water lines that are hidden from sunlight, as it changes its qualities and can weaken the tightness. To avoid this, a layer of protective material is applied after winding it.

Homemade sealing

This process involves a method in which linseed oil and linen tow are used. Drying before the plumbing work is heated, and the solution is lowered for 48 hours. After the set time, the patch is removed and mixed with a leaden meerkate until a uniform composition is obtained.

Homemade means for sealing pipes can be used on any metals, both hot and cold water. If lead oxide is not available on the premises, it is replaced with PF varnish.

Cast-iron pipes

The sealant for the pig iron pipe is applied by means of a bell. They are built on each other, and the joint is wrapped in a cabbage - a fiber of vegetable origin impregnated with oil.

Using a screwdriver, the fiber is jammed into the junction zone, after which the winding occurs several turns. After winding, the fiber is smeared with a heated technical oil of viscous composition with the addition of glue.

On sale there is a ready-made hermetic. Connect firmly the pipes can be pre-packed on top of each other, after which the finished sealant is applied to the joint, and waiting for complete drying. All work on the sealing of joints should be carried out in a ventilated room.

Sealing rules

To seal the pipe using linen tow and PF varnish, these rules should be taken into account:

Cover with a varnish carving, preliminary having cleaned it and degreasing with a white spirit. Leave for a few minutes to dry the varnish.

Thread threaded impregnated in the lacquer of the stick, which should not contain a thick accumulation of fibers, otherwise the application will have clearances. After each application to the thread, the material is varnished.

When the winding is evenly distributed on the thread, the pipes are connected. The action to fasten the pipeline should take place slowly, so as not to break the not dried up until the end of the patch.

The sealing process should be taken seriously - this will depend on the operational timing and water supply. During the period of plumbing works, it is recommended to conduct verification work. In the case of an insufficient number of wound pakli, parts of the pipes are disassembled, and the action is repeated anew. The consumption of the pakli can not be determined, therefore it is necessary to make a medium winding, since the excess of the winding rings will serve as an obstacle in the tightening, which will cause the thread to break and deform the water pipe.

Plumbing is a complex technical meansrelated to the operation of the water supply and sewerage system. This includes baths and sinks, shower cabins, toilet bowls and bidets, piping. In a broader sense, such equipment as water heaters, washing and drying machines also applies to plumbing. Those. all that a modern person uses in a bathroom and a bathroom. Sealing materials are necessary to sustain the entire system. They connect and unite individual installations, which ultimately provide comfort and normal functioning of the house and apartment. The quality of these materials depends a lot - the speed of installation, safe operation systems, shelter protection from flood and accidents.

Today the market offers professionals and home masters a wide range of different means - from classical to innovative. We will understand, in what pluses and minuses of everyone.

Four Leaders

From today's presented in the shops of sealants for sanitary ware we have made a rating on the basis of data on the demand and the level of sales of a material. It turned out that more often than other professionals buy:

Linen Strand

FSM tape

Polymer thread for sanitary engineering

seals

The popularity of flax and FUM tape is easy to explain - these seals are well known and tested. Many generations of locksmiths have grown on them and more than one million threaded connections have been made. As for the last two materials, they cause research interest, still remaining a novelty of the market. Which, upon repeated purchase, is replaced by satisfaction from the work done.

All four sealants are effective and in their own way cope with the task: to change the mixer, to connect the machine, to lay new ones water pipes. Therefore, the master is best to keep them at hand - in his suitcase. Situations at the site are different and you can not predict where the tow will be needed, and where you can not do without the gel.

Hermetic for sanitary ware: linen

In plumbing - a topic that has become particularly relevant in recent times. The appearance of new sealants pushed the flax, but in the end did not displace. So, he has undeniable advantages.

Price. Linen strand is the cheapest sealant on the market. It costs from 50 rubles. for 100 grams. Any thread. Paklut is wound on a dirty, wet thread, without conducting any preparatory work. In addition, flax is used for threading of any diameter, just cut off the right amount from the skein.

Everything else that can be said about plumbing, if it is not a minus, raises questions.

Flax is not used in dry form. Winding without additional impregnation is impossible, otherwise on the system cold water the strand will quickly rot, and on hot it will dry up. Both will lead to leaks. For impregnation use a special paste, which strengthens the sealing properties of flax and increases its cost. Now, depending on the type and brand of impregnation, the price for 100 grams of flax tends to 150 rubles.

To properly wound flax, you need experience. Folding everywhere fibers, slipping winding, the inability to twist the connection from the first time - these are just a few unpleasant moments that accompany work with this sealant. Add here dirty impregnating hands and sticking literally to all strands. Not the most pleasant option.

Sealing of threaded connections in plumbing on flax requires effort during installation. Do not tighten the connection, it is tightened with a key. What further affects the dismantling or alignment. It is difficult to disassemble such a connection. In addition, flax is used with caution on plastic pipes, shallow and thin-walled threads.

Let's sum up - linen is relatively cheap, and work with it is connected with a lot of additional actions that "eat" time.

Plumbing tape

Once came to replace the flax, but continues to compete with him to this day. Unlike flax, the tape is allowed to use on plastic, metal plastic, fine carving and for the most jewelry plumbing work. Many masters use it only on a thread with a diameter of one inch or less, considering that at a larger diameter, tape consumption is not economical.

FUM tape is afraid of systems with antifreezes, vibrations, pressure drops and temperatures, any mechanical influences. This is a whimsical sealant for threaded joints in plumbing and its main disadvantage is that the ribbon inside the thread can burst, move and begin to flow water. Protection from leaks in this case is very conditional, and connections on the tape FUM require constant monitoring and verification. Those. do and forget it is unlikely to work.

The price for a tape varies from 30 to 160 rubles per coil. And it's not just the size of the tape. The price depends on the quality. A good FUM tape does not tear when stretched, but does not break at work. But here's the question - how to find out about this before buying? It's unlikely that the store will be allowed to open the package and test the product for nothing.

Flax and FUM tape are a good option for temporary connections and those that are always visible. When making connections on these sealants, you must be sure of the quality of impregnation and application.

Sanitary thread

It consists of thousands of microfibers, each of which is impregnated with a special sealing compound. Suitable for dirty and wet thread, regardless of diameter. It is intended for sealing of metal and plastic threaded connections. There are no restrictions for thread sealing in the plumbing for the thread, even if you are building a drinking water system.

The thread is wound in all environmental conditions, whether it is heat or frost. The operating temperature range is from -60 to + 120ºC.

Due to the abundant impregnation and application technology, which covers the entire volume of thread, the thread keeps the connection in vibrations, shocks, water hammers, temperature drops. It is a universal sealant. It does not require any preparatory operations - you just buy a thread, reel according to the instructions and collect the connection manually. If necessary, you can adjust the connection up to 180 degrees.

In comparison with flax, the polymer thread is, of course, more expensive. But the difference in price will be about 100 rubles, if we talk about flax with impregnation and threads of Russian production. And this very small amount at the first use will pay off due to high sealing speed and simple winding technology. The connection to the threads turns out neat, clean and, most importantly, reliable. Warranty from leakage is 20 years.

Anaerobic sealant for sanitary ware

It is a viscous gel that polymerizes inside the compound - where there is no access to oxygen. After installation it is converted into a solid polymer. During the application, it covers completely the entire thread, it spreads evenly around each turn. The gel does not spread, it is very convenient to apply. To do this, anaerobic gels sealants are released in tubes with a special neck - the sealant is applied to the thread directly from the tube or use a miniature brush for this.

Anaerobic gel is suitable for sealing metal and flange threaded joints. It is not recommended to use it on plastics, although there are such successful examples. Nevertheless, this sealant is the most effective on metal.

Among the advantages of anaerobic gels: protection from corrosion, simple installation (takes 2-3 minutes), quick sealing (5 to 15 minutes), resistance to antifreeze, shock, temperature and pressure drops.

The connection is assembled manually, it does not need a key. Dismantling is possible, regardless of the limitation period of assembly - the speed of dismantling is affected only by the type of sealant, its composition. There are gels with light dismantling, and there are those that require heating with a plumbing fixture or a burner. In any case, disassemble the connection even in hard-to-reach place it is possible at the first necessity.

Perfect for building new systems. The easiest way to use this sealant on a clean thread, where there is no contamination. However, the poor state of the thread is not a limitation

The surface is cleaned, degreased and begins to apply sealant.

Hermetics for plumbing: which one to choose?

We offer a checklist for the selection of the seal:

Material and diameter of thread

Scope of application - water supply, water disposal, drinking water, installation of equipment or plumbing fixtures

Access to the connection is free or limited

Repair budget

Timing

Responsibility of the system and the expected service life

Features of the object - a private house, multi-storey house, connection to central communications or self-sufficiency

- the material does not change with time or with temperature fluctuations in volume;

- does not spread;

- retains plasticity even after drying, repeating exactly all the bends of the parts, and thus forming a unique gasket for this joint that can not be displaced by the pressure of water;

- sealant for water supply pipes does not clog the system;

- always allows the dismantling of communications.

In what cases can not do without sealant?

- at any threaded connections during the assembly of the water supply;

- when installing pipes made of cast iron, where there are no sealing rings;

- at repair work and the elimination of leaks at the joints as an additional waterproofing.

Types of sealants for water pipes

Today, there is a large selection of sealing means, with different features and purposes, among which you can most accurately choose exactly what is required in a particular situation. Consider what options exist:

- Self-adhesive tape

The main advantage is its anti-corrosion and dielectric properties. The tape is used for connections different types, pipe bends, plugs, swivel angles and other elements.

The basis of the tape is bitumen-rubber, and outside it is covered with an aluminum layer with a protective film, which is removed during installation. Despite the fact that the tape is very easy to use, it is a very effective and reliable method of pipe insulation. If you decide to use this tape, then remember: from the effects of sunlight, it loses its qualities, so the pipes in open areas are additionally wrapped with protective material.

How to use self-adhesive tape:

- before starting work, the surface should be cleaned and dried

- to avoid wrinkling, the tape must be pulled during winding

- it is important to wrap in such a way that each coil lies half the previous, covering the entire surface in two layers.

- Silicone Thread Sealants

One-component liquid sanitary plasters for pipe joints are used to prevent leaks through connections and fittings on metal or plastic pipes in water supply systems with both cold and hot water.

They have gained popularity because of their reliability. In addition to the rubber that is part of the mixture, the silicone sealant contains various additives and additives that provide an excellent sealing ability. Such material has a high degree of adhesion to almost any surface even without their preliminary treatment.

- Glue-sealant plumbing designed specifically for use in humid places: kitchens, bathrooms, where there is a risk of fungi.

Important feature: Depending on the hardener in the composition, silicone sealants are acidic or neutral. Acid, though cost less, is not suitable for use on surfaces that are afraid of acid. But neutral sealants are universal and harmless for any materials.

Attention: do not confuse silicone sealant with sealant for rewinding

- FUM tape, polymer thread

A good alternative to silicone sealant, easily wound on all types of threaded joints and quite effective, but with vibrations and loosening of pipes, over time can leak.

- Portland cement

This material is part of the composition of cement and asbestos cement mixtures, which are used for the assembly of cast iron sewerage communications in the places of minting of socket joints.

Petroleum bitumen, mastic, epoxy resin

Used in the preparation of an insulating fill for sealing joints of pipelines made of ceramics, including at home.

Which sealant to choose

Choosing a plumbing sealant for pipes, it is important to understand that it can be in direct contact with the water coming from your tap. Therefore, it is worth paying attention to products certified for contact with drinking water.

For the correct selection of the sealant in your case, try to answer the following questions:

- Do we deal with metal parts or with plastic parts?

- If it is plastic or its combination with metal, will it be necessary to evenify the system further, calibrate after installation?

If the answer is yes. We use ready-to-use sealing thread white with impregnation on metal, plastic or mixed surfaces. The maximum thread diameter should be up to 4 inches, with a low effort at disassembly. Provides rapid sealing at full pressure and withstands a temperature range from -50 ° C to +130 ° C. Special equipment for application is not required.

If there is no answer. A silicone gel sealant is used, for example, Loctite 5331, white on plastic, metal and plastic-metal fittings that come in contact with hot and cold water. The maximum thread diameter is 3 inches, the force at disassembly is weak. Quite quickly it is sealed at low pressure, operating temperature from -50 ° C to +150 ° C. Does not require special equipment for application.

If the metal parts, the carving is large or small?

If small, work with a gel for metal, for example, Loctite 542. It is a brown sealant, which is applied using a hand gun. It is intended for fittings with fine thread, 3-4 inches, as well as communications of pneumatic and hydraulic systems. When unscrewing, unscrew it with medium effort. At low pressure, there is no sealing, the operating temperature is -55 ° C - +150 ° C.

If large, then gels, liquid and paste-like sealants will work.

Gel Loctite 511 - a rapidly polymerizing white blend, due to its low strength, is suitable for sealing thread 3 inches in diameter with a small gap.

General purpose gel sealer, eg SantehMaster Gel, suitable for coarse thread and 3-inch diameter pipes. It has an average force at disassembly, and at low pressure it freezes quite quickly. Convenient for rapid application in low temperature. It is used on inactive surfaces.

Liquid sealant red Locite 572 is used on large metal thread in fittings with a diameter of 3 inches. Due to the slow polymerization, allows you to adjust the fittings during installation.

Paste Sealant Selon is a red material for low disassembly forces, operates in the temperature range from -55 ° C to +150 ° C. Does not spread over the surface, as it is specifically designed for metal communications with large threads, where regular disassembly is not required.

If we are talking about the choice of sealant for sewer pipes, then the quality of products should be treated very seriously. If the sewage disposal system is disturbed, it is fraught with sewage into the running water.