Sewer shutter with electric drive for the pipe. Sewer shutter: use of non-return valves, ladders

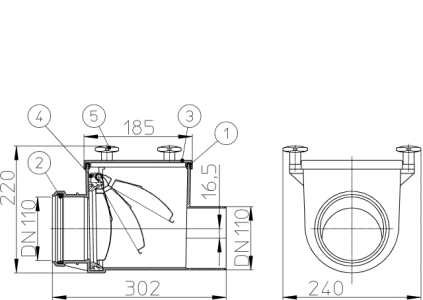

The Russian sewer shutters of Tatpolimer-TP-85.100, TP-85.100.0 and TP-86.50 are reverse shut-off valves that are used in sewerage internal and external systems. Their main purpose is to prevent the reverse flow of liquid, backstopping of the drains, preventing the penetration of small rodents and various insects.

The Russian shutters of the TP series are single-chamber with a mechanically locked shutter. If necessary, the flap can be fixed manually. The gates have a mounting hatch, for cleaning and visual inspection of internal elements. The damper can be made of strong plastic or stainless steel.

For shutters TP-85.100 and TP-85.100.0, the adjacent size is DN 110, the output diameter is B 110. Shutter TP-86.50 is designed for dimensions of 50 mm. The outlet nozzles of the closures are smooth and connect to the funeral pipes from PP or PVC. Input - socket type.

Reverse sewerage valves (closures)

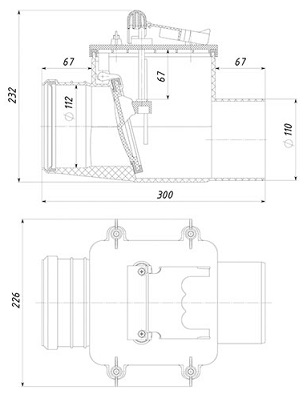

Sewer shutter TP-85.100

|

Appearance |

Description |

||

|

|

Sewer shut-off valve (non-return valve) with horizontal inlet / outlet diameter 110/110. With the possibility of fixing manually the closed position of the flap. The diameter of the outlet is 110 mm. The non-return valve locking system is a single-chamber mechanical shutter with a closing flap. The working pressure of the reverse current is 0-3 meters of water. Weight - 1.4 kg. |

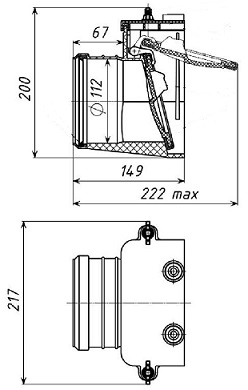

Sewer shutter TP-85.100.0

|

Appearance |

Description |

||

| TP-85.100.0 |

|

Sewer mechanical shut-off valve (non-return valve) for fecal waste water. With inspection cover. The damper can be plastic or reinforced (stainless steel). With a horizontal inlet DN110 and a horizontal outlet with a diameter D 110. The diameter of the outlet is 110 mm. Max. The temperature of the effluents is not more than 60 ° С (for a short time, 2-4 hours, not more than 80 ° С). The working pressure of the reverse current is 0-3 meters of water column. Weight - 1,2 kg. |

1 290 rub. |

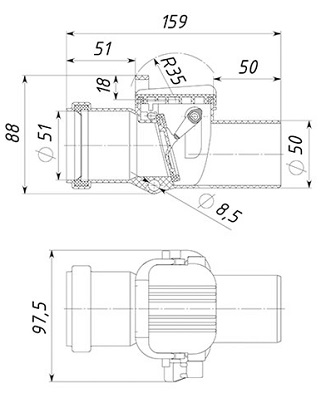

Shutter TP-86.50

|

Appearance |

Description |

||

|

|

Sewer shut-off valve (non-return valve) with horizontal inlet / outlet diameter 50/50. With the possibility of fixing manually the closed position of the flap. The diameter of the outlet is 50 mm. Max. The temperature of the effluents is not more than 60 ° С (for a short time, 2-4 hours, not more than 80 ° С). The working pressure of the reverse current is 0-3 meters of water. post. Weight - 1 kg .. Service life - not less than 50 years. |

Add to bookmarks

Sewer system shutters

In open sewer systems, there is always the danger of flooding various types of premises. The reason for this can be not only the clogging of internal sewerage, but also the overflow of an external highway, which is almost always removed from the building under the ground.

There is a general or local protection against flooding. The general protection is the installed sewer shutter to the sewer outlet. Local protection is to protect specific plumbing fixtures, the release of which is below the level of the well.

Sewer Mechanical Valve

Mechanical valves are:

- single-chamber;

- single-chamber with manual fixing of the shutter;

- two-chamber with manual fixing of the shutter of one of the chambers;

- shutters for overflow wells;

- shutters of vertical installation (single-chamber).

Mechanical dampers are used for conditionally clean sewage that does not contain fecal matter. In addition to two-chamber mechanical closures, which can be used for faecal-containing waste water.

Mechanical sewer shutter is placed in the basement of the building (before the exit of the internal main to the external sewage system) or in the outer pit of the building. In this way, the mechanical sewer separates internal sewerage from the external sewerage system.

This valve consists of a body that is made of ABS material and has a bell mouth and a smooth exit with a height difference in the center. On the bell mouth of the valve there is an arrow that indicates the direction of the fecal runoff. Inside the case, in a special mounting groove, there is a mechanical shutter, which is made of stainless profiled steel. It is installed close to the front of the sewer shutter (concave side to the entrance). The flap has a polypropylene subframe, in the upper part of which is fixed the axis of rotation, as well as a rubber cuff on the through-hole. The damper is permanently in the closed position. Sewage drains, passing through the drain through the sewer shutter, open the flap along the vertical axis. After the discharge ends, under the influence of its gravity, the flap closes.

For mounting the subframe with the flap, inwards mechanical valve, an installation hatch is provided. Also, this hatch is used to service the mechanical shutter during its operation. Indispensable for this hatch and for cleaning in case of clogging of the horizontal section from sewerage valve to the well of the external sewerage network.

Mechanical sewer shutter, for normal operation, must be serviced throughout the life. Proceeding from the fact that the sewerage network of non-pressure and sewage drains has a very low speed (up to 0.2 m / s), often mud flaps form under the flap, which prevent the damper from closing tightly. Relying on the load of the sewage network, the valve must be periodically washed with a large volume of water (for example, pour a couple of buckets of water into the toilet). It is most important to do this in the spring, before the beginning of intensive melting of snow, and in the autumn, before the beginning of heavy precipitation. The mechanical sewer should be rinsed before the sewerage system is terminated for a long time (if you leave your home, for example, on leave).

Sewer can also protect your house when the sewage system dries. Neither mice, nor rats, nor other animals can enter the house through a flap that is made of stainless steel.

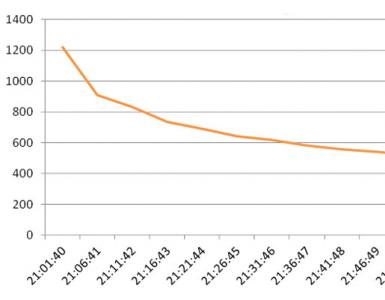

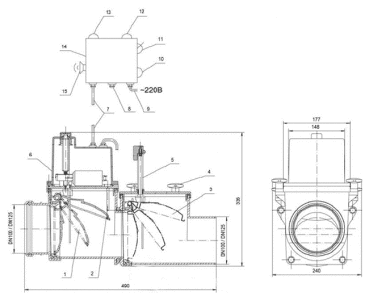

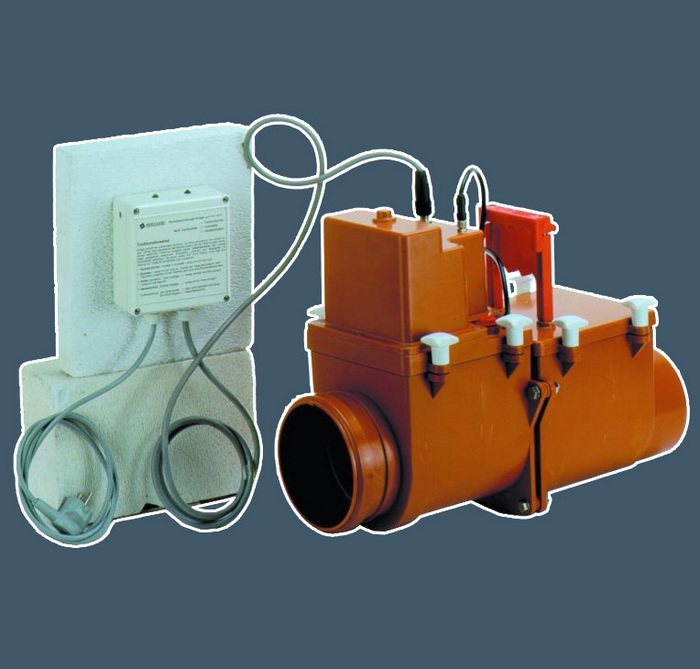

Electrified valve

The circuit of the device of a sewer shutter with the electric drive: (1-Electric valve, 2-electric probe, 3-mechanical (auxiliary) valve, 4- Mounting screws of assembly hatches, 5-Manual lock of the mechanical valve with a safety lock from spontaneous closing, 6-Electric drive of electric valve , 7- Connection cable, length 5 meters, 8- The place of input of a loop from the switchboard to "dry" valve contacts HL 710.2EPC, 9- Electrical cable connection with a plug (220V 50Hz), cable length with plug 1.5 meters, 10 yellow LED, 11 button, 12 green LED, 13 red LED, 14 electronic control unit with built-in battery, 15 audio buzzer. )

Sewer the shutter with the electric drive works in an automatic mode. A valve with an electric drive does not create an additional obstacle to sewage. As a result, the likelihood of the appearance of a mud flap and a loose closure of the flap is reduced in the event of a reverse current. The actuator stem presses the flap with a force of about 600 N.

Complete sewer valve with electric drive:

- valve with two chambers: one valve has an electric drive, the second - a mechanical one, which has the ability to lock the closed position in manual mode;

- electronic indicating, signaling and control unit;

- a built-in fill level sensor;

- connection cable (5 meters).

Each camera is equipped with its hatch, which is also used to service the electric drive or flaps, and for cleaning in the event of a clogging of the sewage system from the gate to the well.

The sewage shutter is installed directly on the sewage main, and the electronic unit is fixed to the wall near the shutter. To connect an electronic unit with a power of not more than 50 W, an outlet with ground and a network of 220 V is required. The electronic unit is equipped with a switch with which it is possible to forcefully close the shutter. If there is a reverse sewage current (filling the pipe by 70%), the sensor will give the electronic unit a signal, which in turn will turn on the sound and light signaling that flooding is possible and will close the valve automatically.

If for some reason the 220 V power is lost, the electronic unit will switch to work from an unattended battery that is built into it and is capable of maintaining the shutter for 168 hours. When the power is restored in the network, the automation will go to work from the network and turn on the battery charging.

The electronic unit has "dry contacts", which are designed to remove the signal about the state of the shutter (closed or open) and transfer it to the dispatching console.

Sewer shutter with electric drive is delivered in full configuration and does not need additional adjustment and adjustment.

Some of the nuances of designing and mounting gates

In the event of clogging in the external sewerage system, sewage within the building may rise to the level of the nearest sewage well (ground level). In this case, if plumbing fixtures are installed in the basement and basement rooms, these rooms will be flooded with their help.

To protect the basement (semi-basement) rooms from flooding, it is necessary to connect the sewerage of all sanitary appliances to a separate system, which is isolated from the general sewerage system of the upper rooms. This sewer line must have a separate outlet with an electrified gate mounted on it. It should be installed on the pipeline in a sewer room, and the alarm should be sent to the control room or duty room.

For an electrified gate, below the flow of sewage, it is permitted to connect the sewerage network of the higher floors, but it is not allowed to place audits in the basement on the riser.

It is forbidden to install electrified gates in wells and sewers and on the street, it is not allowed to pass through them stormwater from the roof.

Proceeding from the fact that for the shutters of the sewage system with electric drive are necessary commissioning works (maintenance of the guarantee), installation of sewerage is carried out only by specialists. Maintenance, such as a leakproofness test, is conducted at least once every six months, and a performance test is performed monthly.

When designing sewage pipelines, it should be remembered that when the external sewage network overflows, the damper closes and the section from the shutter to the well becomes pressure. Therefore it is necessary to consider which pipes should be used in order to prevent flooding of the basement or semi-basement room through the elements of the pipeline connection. It can be pressure head or, which is able to withstand up to 5 meters of water column.

In public and residential buildings, the installation of a shutter with mechanical control, at the outlet of the sewage system, is allowed only with the constant (around the clock) availability of maintenance personnel.

Sewerage is a complex system of communications, the purpose of which is the collection and removal of domestic sewage. In order for the system to work without interruptions and meet the needs of users, it is equipped with special devices. One of them is a water trap for sewerage. Despite its small size and simple construction, it fully justifies its purpose - it provides comfortable living for the tenants.

In any place in the sewage network the hydraulic shutter was not placed, its function remains the same:

- block water hammering to reduce the load on the sewerage systems and pipes;

- prevent the penetration of unpleasant odors in the living quarters.

If the water seal (or siphon) is correctly selected, the house has a favorable atmosphere, and the sewerage network for a long time does without repair.

The structures of the hydraulic locks of different types differ, but all of them in one way or another are pipes with bends of a certain shape, sometimes equipped with additional deadlock or dynamic devices.

One of the most important conditions for the functioning of the water seal is the constant presence of water in its cavity, which plays the role of a barrier against the penetration of gases and unpleasant odors

The screen from the water is kept in the siphon all the time. If you do not use the appliance for a long time (kitchen sink or toilet bowl), the water will evaporate, and eventually the smell will appear. The same will happen when after a long absence you will first flush. But with constant use, the volume of water in the water seal is constantly updated, which prevents stagnation, respectively, and the appearance of an unpleasant "aroma".

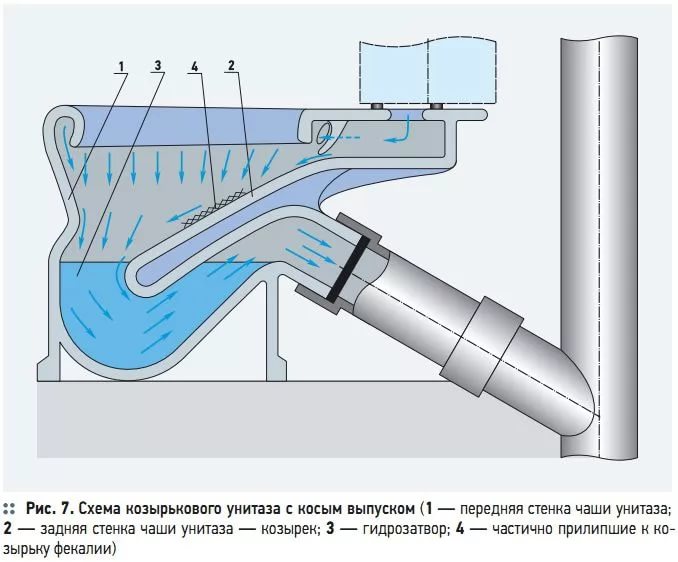

The design features of hydraulic seals are directly related to their purpose. For example, the following structure is typical for toilet bowls: drainage straight, and the outlet leading to the sewer pipe - at an incline

All sewerage systems are interconnected. For example, the correct organization of the fan riser prevents the shutter from breaking - a phenomenon when water does not stay in the water seal, but immediately leaves the pipe. In this case, the plumbing device is deprived of a protective barrier, and unpleasant smells come out - right into the apartment.

Types of hydraulic shutters for sewerage

Classification of devices is made taking into account several factors, but the main are the design features. Based on technical nuances, we can distinguish six main types of hydraulic locks, we will discuss each of them in more detail.

Features of the knee modification

The knee seal can be identified in appearance - it resembles the letter U. The advantage of this type is the strength, which allows it to withstand the maximum pressure in the pipes. The capacity of the device depends on the cross-section of the pipe, which should not be less than the output of plumbing equipment.

The main places of the sewage system, in which the installation of knee locks is appropriate - the plum bath and toilet bowl. Sometimes instead of one they connect two siphons.

For the manufacture of knee devices, cast iron and even bronze were used before, but now it is more expedient and cheaper to use modern material - polypropylene, which is easy, reliable and easy to install

There are different types of knee siphons. Some of them are a single plastic device that can not be adjusted. In case of breakage, it must be dismantled entirely. Other devices consist of several parts, so if necessary, you can increase the length of the pipes and change their position in order to adjust the volume of water. The position of the pipes is fixed with plastic clamps and nuts.

The knee has two bends - at the inlet and outlet. The point of the second inflection should be just below the point of the first (by 5-6 cm). Sometimes for a more reliable lock use S-shaped design, the principle of its operation is the same.

Cleaning of knee structures is done in two ways:

- by completely dismantling the device;

- with a special flexible cable.

Some polypropylene modifications are equipped with an inlet for the drain hose of a washing machine or dishwasher.

Advantages of the bottle device

This type of hydraulic seal is popular in kitchens to equip the drain system under the sink-sinks for dishes. In the process of washing dishes and pans, part of the food waste enters the system, which is fraught with the appearance of clogging.

The design of the bottle model delays the remnants of food, thus contributing to maintaining the operational quality of the sewage system. In addition, the bottle unit also retains its main purpose - preventing the appearance of unpleasant odors in the home.

In addition to the pipes that form the basis of any water seal, this type is equipped with an additional element - a "bottle". This is a kind of container for collecting food debris. The sump is below the level of the drain pipe, so it is not difficult to get to it if necessary.

The connection of the two parts of the bottle model is carried out in the following way: first vertical pipe enters the settler below, then the horizontal branch goes laterally towards the sewer pipe

Bottle device is made of polypropylene, but strength is considered weaker than knee analog. The fact is that unreliable connections can not withstand a strong water pressure, so this type is used exclusively in the kitchen and absolutely not suitable for equipping the toilet or bathroom.

The blockage in the hydraulic seal occurs when a dense mass of food residues completely clog the sedimentation tank and block the way to water. Thanks to the bottle configuration, it is very easy to remove the blockage. It is enough to unscrew the attachment nut, which joins the sump, and shake out the accumulated garbage. Then it is necessary to put the "bottle" in place and tighten the nut more tightly, otherwise water leakage is possible.

Bottle structures are also useful from the point of view of preserving items accidentally caught in the sink. Careless mistresses often took out of their clarifiers their rings, slipping from their fingers while washing dishes with soap.

How is the double-bore hydraulic seal

The design of the bipartite hydraulic seal is reminiscent of the knee device, but differs in a more complex configuration. The drain pipe is connected to the outlet of the sanitary device, and at the junction is equipped with a grill-filter for the retention of waste, hair and other debris. Then it smoothly passes into the knee, which ends with a connection to another pipe. The last element is directed to the drain and is under a slight slope.

Some two-rotary models are equipped with a revision hole for cleaning pipes, tightly closed stopper. The hole function is sometimes performed by a removable knee fragment. The hole is usually located at the lowest point, and the detachable part is at the top

Household double-rotor structures were previously made of cast iron, now - from polypropylene. Cast iron analogs can only be used on industrial enterprises with increased effluent volumes and high pressure in the pipes. More presentable look chrome parts, which are technical specifications are close to polypropylene.

If you compare this model with a bottle alternative, the second option is easier to maintain. However, a two-rotator device is more reliable in terms of protection against leaks and, thanks to a simple adjustable design, can be installed even in tight spaces.

Corrugated model - pros and cons

Among the propylene modifications there are also corrugated models - strong, flexible, sometimes just necessary for equipping the sewage system in small rooms. Due to the plasticity of the pipe, the corrugation is placed in places where it is difficult to place other types of structures. It can be turned at the right angle and directed to either side, while the firmly fixed plastic has only a few positions.

The corrugated water trap is often placed under the bathroom, since less flexible models in the narrow space between the bottom of the container and the floor do not fit. One end is connected to the drain hole, the other to the outlet in sewage pipe

However, when choosing a corrugated version it is worthwhile to know about its only, but weighty drawback. The ribbed walls of the pipe seem to have been created for garbage collection: food remains, hair, pieces of soap, sand and other dirt get stuck in them. With this in mind, when mounting the corrugated drain, it is necessary to provide a filter in the form of a fine-meshed lattice.

If you do not clean the corrugated hydraulic seal for a long time, under the influence of dirt and excess weight, it loses its strength and elasticity. Over time, the folds wear out, begin to crack and let in water. Having installed a flexible siphon, be sure to monitor its condition and clean it in a timely manner. On the contamination of the pipe can be guessed by the sagging, which are formed in places of accumulation of fat and debris.

Principle of overflow operation

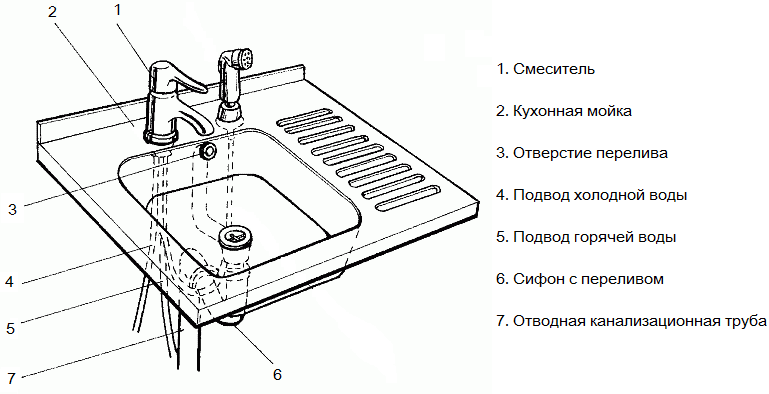

Another type of siphon - with overflow - can also be identified in a separate category, since it is necessarily equipped additional pipe. The main purpose of the overflow equipment is to protect the apartment from flooding, if for some reason, with an open faucet, the water will cease to flow into the drain.

The sinks on which this device is installed have an additional opening - in the upper part of the bowl, under the mixer. When the level of water accumulated in the sink reaches a critical level, the liquid begins to flow into this hole and then into the water seal

The overflow system is necessarily equipped with a bath. This method prevents flooding, but, unfortunately, does not contribute to savings. If you want to get a bath and forget to turn off the tap in time, the water, having reached the overflow level, will safely leave the tank and go to the sewer - along with your money for paying for utilities.

On the market are presented as economical options from plastic, still more robust, but less elastic metal models. Minuses of brass-bronze equipment - in the complexity of installation and high cost. When choosing a device, do not forget to inquire about its throughput. If the overflow does not cope with the volume of excess fluid, it is useless and even dangerous.

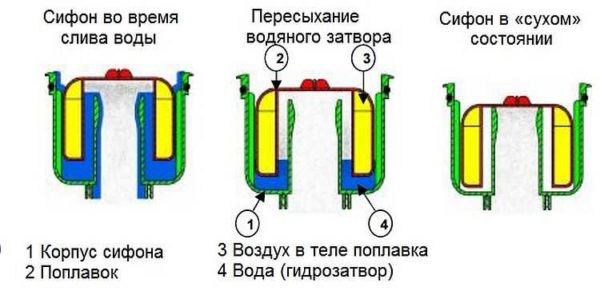

Dry Gate Construction

The design of the so-called "dry" shutter is radically different from hydraulic analogs. It operates on the principle of the "nipple" and is a threaded pipe, inside which a check valve is installed. As a result, the water entering the device can not flow back, just like the smell does not have a chance to leave the pipe.

Installation of such devices is justified on the lower floors of multi-storey houses, as well as in places where water is less used (in baths).

Dry shutters are not installed in principle in kitchen sinks, the use of which maximizes the creation of blockages. But the devices work effectively and serve a long time in the shower cabins, built by themselves.

The "dry" type of shutter does not need constant water inside the shell. Even if it functions in conjunction with the knee device, it does not need to be controlled or regulated

There are several types of dry devices:

- membrane, overlapping after draining the water by an elastic membrane;

- pendulum, gravitating to instant closure, if no liquid enters;

- float, closing the hole, when the water leaves the drain (acting like the valves of the drain tank).

The latter are often manufactured independently, equipping the sewer wiring in the baths.

The simplest is the principle of the float valve. Light weight keeps the float on the surface of the water. As soon as it drains, the float drops down and overflows the drain

If suddenly there is a drying out sewerage systems in view of the rare use, thanks to a dry shutter an unpleasant smell will not bother you.

How to choose the water seal

If you install or change plumbing equipment (bath, sink or toilet), you will definitely need a siphon. To select a device that is fully compatible with plumbing, it is necessary to take into account a number of factors, among which:

- dimensions of the device in the assembly;

- type of siphon;

- material from which pipes and fasteners are made;

- number of drains or additional connections;

- protection against blockage;

- diameter of the inlet and outlet;

- presence or absence of overflow.

Suppose, for a sink in the kitchen, the most suitable option is a bottle model that delays the food particles. A knee can also be used, but then all waste will enter the sewer pipe, and over time, there is a risk of blockage.

If in the project installation of a sink or a washbasin with two sinks, the device with two points of a drain is useful. The principle of its work is the same, the difference is only in the design.

Before buying, be sure to measure the amount of space where the installation will be made. It happens that the siphon simply does not fit in the allotted space (especially in the close space between the bathroom and the floor). If you correctly select a water trap, there will be much less problems with its installation and repair.

Installation instructions for the automatic siphon

To install a bottle hydraulic shutter under the sink of a kitchen sink is quite simple, under the bathroom - a little more difficult because of the awkward location of the drainage system. We present the installation instructions for an automatic bath siphon - an advanced device that can be installed manually.

A complete set can be purchased at the nearest sanitary ware shop. It consists of three significant parts: 1 - the plastic construction of the water trap + corrugated pipe; 2 - details for registration of overflow; 3 - fastening elements for drainage

First, we equip the overflow hole. To do this, take the elastic gasket that comes with the kit, and insert it into the hole on the wall of the bath. For a more intimate connection, you can use a silicone sealant.

We fix the overflow construction in the hole, winding the chrome element from the outside. It is equipped with a rod, which will hold a lamb

Then take the next detail - the lamb - and try to carefully fix it on the rod with a bolt. This requires a small flat screwdriver, which can penetrate a small hole in the side of the lamb.

We put the lamb on the rod, insert the end of the screwdriver into the side hole and with a little effort, but very gently tighten the fixing bolt

We pass the plastic part under the tub and insert the end with a rubber gasket into the hole. From above in the formed hole we put the standard chrome part with a mesh

Among the fasteners we find a long fixing screw, which is responsible for fixing the siphon, and screw it from the upper side, holding the bottom from the structure.

First screw the screw with your hands, then tighten the key, but very carefully, so as not to break the thread. After the end, we check the strength of the installation

It remains to screw the waterproof element. First, on the plastic outlet of the drain thread a rubber gasket, then insert the knee bolt. Tighten the outer plastic nut - the design is ready.

Appearance of the installed automatic siphon. From the drain hole, two pipes go: one (corrugated) - to the overflow hole, the second (curved) - the proper knee hydroshock

Lastly, we connect the polypropylene pipe (straight or corrugated) leading to the sewage pipe to the hydraulic seal.

We test the system - pour a full bath of water and check the work of the overflow and drain hole. We look, whether there are leaks. If we detect a leak, we tighten the nuts more tightly, and we seal the joints with the sealant, but on condition that they do not have to be opened in the future to clean the blockage.

Video instructions for the installation of hydraulic locks

For the installation process to proceed smoothly and without errors, pursuing home amateur plumbers, we offer you to view useful videos.

How to assemble and install a siphon under the sink in the bathroom:

The best option for equipping the kitchen sink:

Installation of the siphon when installing the bath:

The installation of a sewer siphon is a process that can overcome even the ignorant in plumbing matters a novice. If you correctly define the type of the water seal and carefully study the instructions, it remains only to screw a few details. Work for half an hour - and the comfortable environment in the house and the absence of an unpleasant smell - for years.

With the development of technology, mankind has come to the conclusion that it is necessary to create devices that protect against the clogging of the sewage system. In addition, the main main pipe may be overflowed, and because of the pressure difference, the water has the ability to rise up to the ground level, which leads to the flooding of cellars and cellars, brings big troubles and costs of money for cleaning and cleaning the territory. The result of this need was a sewer with an electric drive

A bit of history

Throughout the history of mankind people try to make their existence as comfortable as possible, finding different ways and creating sometimes brilliant works. But, as they say, all ingenious is simple. That's the same with the sewerage. The first mention of artificially created sewerage comes from Babylon about 5000 years BC, repeated in the ancient lists of Egypt about 2000 years BC. But the sewerage, as we perceive it now, came to us from Rome in the 5th or 6th century BC. And the Romans have made a network of plums so well that at present - after almost 2,5 thousand years the city municipality still uses a complex system of underground communications laid by our ancestors.

Types and applications of sewage shutters

![]()

There are two types of protection from sewage system flooding:

- Local. The protection of a certain device is provided, the outlet of which is located below the level of the outlet of the outlet well (sink, shower) and for protection, a check valve is sufficient. After all, the main task of any valve is to control the one-way flow of the liquid and protection from an unpleasant odor.

- The total. With general protection, the mechanical sewer is installed directly on the outlet sewer.

A good example of general protection is a mechanical sewer. The main task of installing such a shutter is to divide the internal domestic sewerage and external sewerage line. Therefore, it is installed directly on the connection of the home output and the external highway input. Mechanical sewer shutters can be divided into types:

- Single-chamber valve;

- Single-chamber valve with manual fixing of the damper;

- Double chamber valve with manual control of one camera;

- Mechanical sewer shutter for wells;

- Single-chamber shutter for vertical installation.

Single-chamber mechanical sewer shutter, as a rule, are used for practically pure drains. Two-chamber designed for drains that contain fecal matter.

Sewer check valve (gate) is an effective solution against many problems:

- An attempt to wash insoluble substances or oversized objects into the sewage system;

- Reducing the internal diameter of the pipes due to their clogging and prolonged use;

- A certain level of slope of pipes. If the pipes are inclined steeply - the flow will not be able to take with it all the garbage. If the pipes are hollow, the water pressure will be too weak to flush heavy particles.

The main part of the mechanical sewer valve is a housing consisting of solid types of plastics or impact-resistant technical thermoplastic resin. This kind of materials is particularly resistant to moisture, acid, alkaline materials and detergents. With the entrance in the form of a bell and the located drop of heights in the center, smooth exit. The housing contains a groove for the stainless steel flap, which is installed in the front of the device with a concave side to the inlet. The entrance of the fecal masses is indicated by arrows. The damper has a polypropylene subframe with an axis of rotation in its upper part, as well as a rubber sealing collar, the diameter of which coincides with the diameter of the access opening.

The principle of operation of a mechanical sewer shutter

The normal position of the flap is closed. When discharging sewage drains, the valve flap deviates to the side, passing the pressure of the sewage. After a pass, it returns to its original position, thanks to the gravitational action of the Earth. The mounting hatch is required for installing a subframe with a flap inside the mechanical valve, also made of polymer material. In addition, this hatch is used to care for the valve during its operation, as well as in case of clogging of the sewerage valve to the well of the main sewerage network.

Important! Considering the fact that there is no constant head in the sewer system, and the current has a rather low speed (less than one meter per second), it is possible to form collars in the pipes. Therefore, it is necessary to service the manual valve during the entire service life.

Sewage pipes should be washed with water. And as much as possible. The mechanical shutter, as a rule, is washed in the autumn, in the spring and before leaving your home for a long time (for example, leave). Among other things, the use of such a barrier helps to protect the territory from rodents and other small animals that consider sewage pipes and the location of various valves as a favorite habitat.

Electrified valve DN 100, 110 and others

The main advantage of such a shutter is autonomy and automatic mode, by means of which the damper in the normal position is open. Due to this, the drains do not encounter obstacles on their way, accumulations of clogs are not formed and the damper is tightly closed. In general, the principle of action is almost the same. Electrified gates include:

- one mechanical chamber;

- one electric chamber, which controls the passage of drains;

- the filling sensor (operates when the filling is 70%) - sends a signal to the flap, which opens with the help of a built-in electric drive;

- electronic unit - performs shutter control; An indication is also displayed on it, and in extreme cases it provides an alarm signal via the built-in alarm;

- battery - provides autonomous operation without connection to an electrified network up to 7 days;

- contacts - are intended to notify the central indicator about the shutter state;

- switch - serves for emergency and forced shutting of the shutter.

Such devices, as a rule, are installed on a common sewer pipe in an apartment or a private house. Mechanical and electric shutters are also divided according to nominal diameters - DN 100, 110, 125, 150, 200, etc. DN - nominal diameter does not have a unit of measurement and is approximately equal to the internal diameter of the pipeline to be connected in millimeters. For example, 110 nominal diameter and 109 diameter of the pipeline. One of the most common nominal diameters is DN 110, 125, 200.

Dry shutters

Sewer dry gates are:

- The pendulum. Because of the gravitational forces, the position locking the drainage system;

- Remembering. It consists of flexible, elastic pipes, which, restoring their shape, serve as a valve and do not let smell into the living room;

- Membrane. The passing stream pulls aside the membrane, the spring of which returns it to its original position;

- Floating. It consists of a fixed float, which can be lowered only after the drains have left.

When planning the sewage system for your living quarters, try to approach responsibly to all the nuances. From the choice of nominal size (DN 110 or 200) to determine the type of valve installed on the sewer network. And though nobody is insured from clogging up the pipes, you will know that you have done everything in your power!

Sewer shutters series HL710 - HL 710.1, HL 710.2 and others are single-chamber or two-chamber mechanical closures with the possibility of manual fixing of the flap in the closed position. They are made of impact-resistant plastic, the flap is made of profiled stainless steel. They have connecting inputs DN 110, 125, 160 and 200, for pipes made of PP and PVC.

Sewer shutter HL with electric drive - HL 710.2 EPC, HL 712.2 EPC and HL 715.2 EPC are 2-chamber valves, with input for computer connection, level sensor, electronic control unit and alarm. They have connecting outputs DN 110 and 160, for pipes PP and PVC. These gates are designed to work in automatic mode.

Mechanical sewer shutters HL, made of impact-resistant plastic (ABS).

DN - 110, 125, 160, 200.

|

Description |

|||

|

HL710.0 - for wells, with a profiled locking flap made of stainless steel. Has a mounting hatch. It is recommended for connection with a plastic socket pipe (PP, PVC). The issue is horizontal. DN 110. Mounted on the end of the pipe entering the well. |

|||

|

HL 712.0 |

As HL 710.0, but with the output of DN 125. |

||

|

HL 715.0 |

Like HL 710.0, but with the output of DN 160. |

11247 rub. |

|

|

|

As HL 710.0, but with the output of DN 200. |

||

|

Mechanical single-chamber sewage shutter HL710 with a profiled locking flap made of stainless steel. Has a mounting hatch. It is recommended for connection with a plastic socket pipe (PP, PVC). For drains without faeces (conditionally clean water). The issue is horizontal. DN 110. |

|||

|

Like the HL 710, but with a DN 125 output. |

|||

|

Like the HL 710, but with a DN 160 output. |

|||

|

|

Like the HL 710, but with a DN 200 output. |

||

|

HL 720.1V |

|

Only for vertical mounting. Equipped with an odor-closing flap made of profiled stainless steel with a built-in float, with the possibility of manual fixing of the flap. Has a mounting hatch. It is recommended for connection with a plastic socket pipe (PP, PVC). The issue is vertical. DN 110. |

|

|

Mechanical sewer shutter HL710.1 with a flap of profiled stainless steel, with the possibility of manual fixing of the flap in the closed position. Has a mounting hatch. It is recommended for connection with a plastic socket pipe (PP, PVC). For drains without faeces (conditionally clean water). The issue is horizontal. DN 110. |

|||

|

HL 712.1 |

As HL 710.1, but with the output of DN 125. |

||

|

HL 715.1 |

As HL 710.1, but with the output of DN 160. |

||

|

HL 720.1 |

|

As HL 710.1, but with the output of DN 200. |

|

|

Mechanical 2-chamber sewer shutter HL710.2 with locking flap made of profiled stainless steel. With the possibility of manually fixing one flap in the closed position. It has two mounting hatches. It is recommended for connection with a plastic socket pipe (PP, PVC). For fecal effluent. The issue is horizontal. DN 110. |

|||

|

HL 712.2 |

As HL 710.2, but with the output of DN 125. |

||

|

As HL 710.2, but with the output of DN 160. |

|||

|

HL 720.2 |

|

As HL 710.2, but with the output of DN 200. |

In houses that do not have plumbing fixtures in the basement, but which have at least one unventilated sewer pipe or riser equipped venting valve, it is necessary to install a mechanical sewage shutter HL on the outlet. The fact is that when flooding the outside network, on a section of the internal sewerage network of the building, a significant excess pressure can be generated, which will squeeze the sewage gases through the hydraulic locks of the plumbing appliances into the living quarters where people can be.

Sewer shutters HL with electric drive.

DN - 110, 125, 160.

|

Description |

|||

|

HL 710.2epc - 2-chamber main sewer shutter with electric drive. With the input to connect the computer. With locking flaps of profiled stainless steel. With the possibility of removing the signal open / closed. ("dry contacts"), with a built-in level sensor, electronic control unit and alarm. It is recommended for connection with a plastic socket pipe (PP, PVC). The issue is horizontal. DN 110. Power supply: 230 V, 50 Hz. The connecting cable is 6 m long, 5x0.75 mm2. The closing force is 500 Newton (50 kg). |

|||

|

HL 712.2 EPC |

As HL 710.2 EPC, but with the output of DN 125. |

||

|

HL 715.2 EPC |

Like HL 710.2 EPC, but with output DN 160. |

The kit includes the shutter itself, one valve with an electric drive, the second - a mechanical (with the ability to manually lock in the closed position), an electronic control unit, indication and alarm with associated connecting wires, a level sensor integrated in the valve body. Each of the chambers of the sewer shutter has its own independent hatch, through which it is possible to control the state of the flap or to carry out a cleaning operation. The bolt is mounted on the outlet from the building. The control unit is placed side by side (cable length - 6 m) and is connected (with grounding) to 220V network. Electric power electric drive - no more than 300 W at the moment of operation.