High-pressure electric pumps for water. Video reviews of high-pressure equipment. Classification of pumps for pressure lifting

At the cottage or on a site outside the city, there must always be one or another source of water. Without it, it will be impossible to take care of the garden, and staying outside the city without water will not be comfortable. Far from every village or village there is a possibility of central water supply. And even if it exists, there may be problems associated with pressure, and in fact in the summer of water you need to use much more.

The problem is solved by means of water pumps high pressure, which will provide you with water in the right amount and with a good head. What is a high-pressure water pump, what is its price and much more, you will learn all this from this material.

Advantages of water pumps

Water pumps of high pressure have many advantages. In particular, with their help you can save a lot of time, if you use such pumps for watering the garden or garden, because you can install them easily and without too much help.

Water pumps of high pressure have many advantages. In particular, with their help you can save a lot of time, if you use such pumps for watering the garden or garden, because you can install them easily and without too much help.

In addition, buyers are attracted by such characteristics of water pumps as:

- a huge selection of types and models;

- acceptable price of products;

- ease of use of the unit.

Regardless of which product model you choose, be sure to use it strictly according to the instructions.

Classification of high-pressure water pumps

Different types of high-pressure pumps differ from each other in such characteristics: working conditions, tasks, methods of creating a vacuum.

Different types of high-pressure pumps differ from each other in such characteristics: working conditions, tasks, methods of creating a vacuum.

But the principle of operation of all high-pressure devices is the same. During operation, the pump creates a vacuum inside, then the liquid passes from the reservoir into vacuum chamber, and then pushed out under high pressure.

Description of vortex models

Vacuum in high-pressure pumps of the vortex type is created by rotating a flat disc where vortex blades are radially placed. Such a disk is also called a vortex wheel.

When the disk rotates, the moisture passes into the body cavity of the structure, and then under pressure is forced out by rotating the blades. The main advantages of such models:

- good suction;

- they are not dangerous air bubbles.

However, high-pressure pumps of this type are very sensitive to suspended particles, which creates difficulties when pumping dirty water.

High Pressure Vibration Pumps

The key element of this model is the electromagnet. Its principle of operation is very simple:

- After filing aC voltage The magnet attracts the armature to the winding.

- When the polarity changes, the armature returns to its original position.

- In a short time, the armature and the piston are able to change their position about a hundred times.

- Vibrations provoke vibrations that eject water particles through the valve into the discharge nozzle.

Also, the undoubted advantage of such a pump is absence of rotating particles and the electric motor.

Characteristics of centrifugal models of high-pressure pumps

![]() The water pump of the centrifugal type is divided into the following types: submersible. With a working shaft, located horizontally and with a working shaft, placed in an upright position.

The water pump of the centrifugal type is divided into the following types: submersible. With a working shaft, located horizontally and with a working shaft, placed in an upright position.

Impeller blades are able to act on water, this gives labor, creates a movement of water and pressure under pressure.

Hand pump For wells the most attractive in terms of prices and unpretentious in operation. It can be used even where there is no electricity and do not need water in large quantities. Such a device is triggered by a single human effort. There is practically no idling in it.

Similar models are piston and vane. Piston is more popular, they are able to feed water from a depth of 20 m and are able to pump up to 2000 ml per operating cycle. Wing structures are more compact, but with the same depth they will pump out a little less.

High-pressure water pumps are indispensable when the required water pressure is not available at a given pressure.

Circulating and drain pumps and their characteristics

Not always enough for work only water-lifting pumps. For example, for heating system need a circulating pump, and for the drainage drainage is required.

Not always enough for work only water-lifting pumps. For example, for heating system need a circulating pump, and for the drainage drainage is required.

Circulation models are needed for forced circulation water by means of an autonomous heating system. They differ in quiet work, but at the same time they are energy-intensive.

But drainage models are needed for such needs:

- with a view to evacuating water after precipitation;

- for cleaning sewage sludge;

- for pumping water out of cesspools.

When using the product mainly in clean water, you can take an inexpensive model with plastic elements, but for works in dirty water it is better to purchase models on the basis of materials having anticorrosive properties.

Drainage structures are often equipped with special float to control the desired water level. Pumps of this type have the following properties:

- for its production materials with increased technical and operational characteristics are used, they are resistant not only to corrosion, but also to various chemical substances;

- basically, such models are equipped with shredders, which crush large particles so that there are no problems during the drainage of water.

Average prices for high-pressure water pumps

The cost of such products is different and depends on the following factors:

- water pressure;

- bandwidth;

- manufacturer.

The average price of a high-pressure pump - from 60 to 300 y. e. At the same time, remember that margins in different outlets are different, accordingly, the price of identical models can differ significantly in two stores.

Also the price depends on the availability of the pump special mechanisms for automation his work, if they are, then the product is more expensive. Also more expensive will have to pay for a model with a higher level of electrical protection.

Besides, the price is affected by the material, used to make the case. Stainless steel models are the most expensive, aluminum and cast-iron will be cheaper.

Also, an important role in price formation is played by manufacturer company. Better price has products from well-known brands that guarantee high quality of their products.

Manufacturers of pumps

![]() The most famous company that manufactures them is Grundfos (Denmark). It was founded more than 60 years ago and produces more than 15 million items a year. The company's production facilities are in different countries.

The most famous company that manufactures them is Grundfos (Denmark). It was founded more than 60 years ago and produces more than 15 million items a year. The company's production facilities are in different countries.

The second most popular pump manufacturer in the world is Cat Pumps. Its products are quality and reliable, in addition, it is distinguished for its versatility. And in the market of water pumps this company takes a leading position due to the fact that its products are very long term operation.

The special feature of Cat Pumps products is the use of a three-plunger version, which, at low pulsation, can produce high pressure. In addition, the three pistons operate in synchronous mode, which gives constant and smooth flow, this reduces almost 90 percent of the main pulsations.

Another famous manufacturer of water pumps is Karcher. They are used for such areas as:

- Water supply systems.

- Treatment facilities.

- Washing installations.

- Industrial facilities.

In the domestic market, these models especially popular, they are low-noise, reliable and versatile. Buyers use them in such areas of their life and work as:

- Agriculture.

- Production.

- Industry.

- Care of the car.

- Country economy.

Karcher products have such advantages:

- low weight;

- compactness;

- economy of use;

- suitable power;

- small costs for the operation of the product.

Also good feedback has another German company for the production of pumps Wilo, which has been engaged in this direction for just over a decade, although it has been known in the market for a long time.

Products of this brand are of high quality, they are always the embodiment of new technologies and ideas. The company has capacities all over the world, including South Korea.

Along with the well-known European models, there are always cheaper analogues from China on sale. As a rule, such pumps have dubious quality and short-lived. However, there are also exceptions among Chinese brands. It is worth noting the products of the brand Sprut, which is of high quality.

This company has been making high-pressure pumps for a long time already, and domestic buyers successfully use them for apartments, private houses and offices. Low price of products in this case, only a plus to a quality product, and not a low-grade indicator.

Features of the choice of high-pressure pump

However, when choosing the right product, you need to rely not only on the brand and price, but also on other indicators. For example, you need to know in advance required capacity and pressure of the model, these indicators should be calculated in advance.

However, when choosing the right product, you need to rely not only on the brand and price, but also on other indicators. For example, you need to know in advance required capacity and pressure of the model, these indicators should be calculated in advance.

It is better not to do this on your own, but turn to specialists, who are professionally engaged in this.

You can buy a high-pressure water pump in many places. This is a home appliances stores, and online stores, and construction markets.

But best of all choose branded salons similar products, where there is a great choice, and consultants will be able to help you professionally choose the right pump model. In addition, in such outlets you will be given a guarantee for the selected product.

Water pumps have different purposes. Depending on your needs and financial expectations, you can always choose the most suitable solution for yourself.

The pump for increasing water pressure plays a key role in the arrangement of an autonomous water supply system. Its main task is to stabilize the pressure in the system. What pumps the modern market offers, and how not to be mistaken in choosing - we will consider in detail.

High pressure pump - unit purpose

Regardless of where the water comes from - from the nearest well or reservoir, with automatic feeding it in a private house an ordinary pump can help. However, for the normal operation of modern appliances in a private house requires a head of water within 2.5-6 atmospheres. This can be achieved only if tenants use a water pump to increase the pressure.

Regardless of where the water comes from - from the nearest well or reservoir, with automatic feeding it in a private house an ordinary pump can help. However, for the normal operation of modern appliances in a private house requires a head of water within 2.5-6 atmospheres. This can be achieved only if tenants use a water pump to increase the pressure.

The device of this kind is used in the case of a very low head of water, which interferes with the normal functioning of household appliances. In practice, it is permissible to install such a pump in the apartment, but only in cases where its residents experience an acute shortage of water.

The most relevant is the operation of such a pump for water supply, the head of which does not exceed 1.5 atmospheres. A compact pump can be installed not only for public water supply, but also for the output to a particular household appliance. For example, a mini pump can be installed on a pipe through which water is supplied to a boiler or washing machine. In the case of installing equipment on a common pipeline, you will have to buy a sufficiently powerful boost pump. If you want to connect the device only to the water supply of a certain household appliance, then you can do with a small, cheap unit.

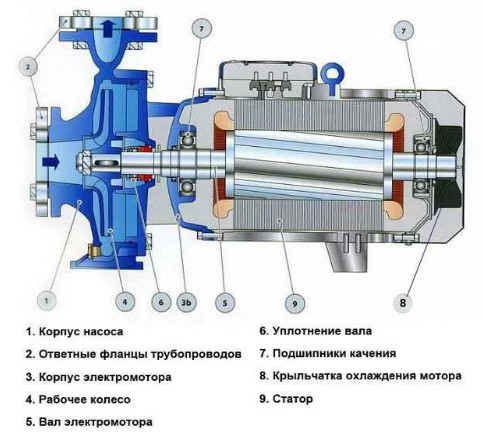

An ordinary pump to increase water pressure has a simple design and consists of several elements.

The principle of operation of the unit can not be called difficult. The injected water enters the impeller through the inlet pipe, which is driven by the motor through the shaft. Getting the required acceleration, the water is pushed through the structure into the outlet pipe, and then - it passes through the water pipe of the house.

To prevent water from seeping through the grooves between the shaft and the walls of the body, they are fitted with special rubber seals. The engine is cooled by means of an impeller mounted above the rolling bearings.

Types of pumps for increasing pressure

Depending on the type of drive, the pumps can be:

- Manual - such equipment works continuously regardless of whether there is a water pressure at a particular time. At the same time, the unit is switched off manually;

- Automatic - these devices turn on automatically when the crane is opened. The sensor is responsible for the adjustment of the automatic pump, which, when the crane is closed, turns off the unit.

By way of cooling the engine, the water boost pumps can be of two types:

- Instruments with a dry rotor - such units have an asymmetric design, which has an advantage in the direction of the power part of the pump. The motor of such a device is equipped with a wing cooler, and does not come into contact with water during operation. The unit of this type is also equipped with a cantilever lock, which allows to fix the device on the wall. Due to the fact that the motor in the design is separated by a gland seal on the axle end, this pump can last much longer than analogues of another type. At the same time, the omentum wears out with time, so it must be changed occasionally;

- Pumps with wet rotor - these units are cooled by pumped water. The rotor of such a device is in the water, and is separated from the stator by a watertight damper. Such units operate quite quietly, they are often used for fogging. The sliding bearings used in the manufacture of the device do not need regular maintenance. However, such pumps do not create such a high head as the units with a dry rotor. In addition, there is no sale vertical pumps with a wet rotor, but only horizontal aggregates.

Depending on the design, high pressure pumps are divided into the following types:

- Piston, or plunger pumps - these units are used primarily in the home to raise water from deep wells and wells, less often in the chemical and medical industries. Depending on the number of pistons and their location relative to the drive, such a pump can be one-, two- or three-plunger. Each plunger pump features high productivity and long service life;

- Membrane, or diaphragm aggregates - they relate to overall equipment. On sale you can find appliances with one or two membranes. Each diaphragm unit is easy to use and maintain. With the help of a membrane device, aggressive chemicals can be successfully pumped;

- Sectional pumps - these devices consist of several successively located impellers. Depending on the number of wheels, the units of this type can be single- or multi-sectional. Each sectional unit of high pressure is considered a professional device that gives high pressure of the liquid at the outlet. These devices are used in the industry for pumping water with a high degree of pollution;

- Vortex pumps - these units are used mainly in drilling systems, as well as for pumping liquids with high density. Such devices are small in size, easy to operate and repair;

- Peristaltic instruments are primarily mud pumps of high pressure, used for the purpose of pumping viscous liquids containing a large amount of solids.

Many of the pumps listed are not suitable for household use, since they have large dimensions. For use in a private home, piston devices are the most suitable - they are simple, reliable, but require regular replacement of the oil necessary for lubrication of the pistons.

How to make a high pressure pump by yourself - we study the order of work

The simple design of the pump to increase the pressure makes it possible to produce such a device for everyone. For work you will need:

- Several sheets of steel;

- Plastic container;

- Drill;

- Screws;

- Bulgarian;

- Rubber seals;

- Sealant;

- 2 flywheel from old mopeds;

- The motor from the old Bulgarian;

- Metal pipe;

- Several silicone hoses.

The algorithm of works is as follows:

- First, you need to weld the case - for this, steel sheets are taken and connected using welding machine. The body must be 2 times the plastic capacity;

- After that, you need to assemble the drive. For this it is necessary to take the engine from the Bulgarian and connect it with steel pipe, which will serve as a shaft. At the other end of the pipe you need to make a thread and install one of the flywheels - it will serve as a working wheel;

- The second flywheel is attached to the other side of the engine, and will serve as a cooling element;

- After that, the motor is placed inside the plastic container, and all grooves are treated with silicone sealant;

(HIGH PRESSURE SUCTION PRESSURE PUMP).

Consider how a high-pressure pump works (HP pump). I think it's right to start with pistons or plungers (call it convenient for you), because they brew all the porridge, namely, moving back and forth, create an alternating pressure on the sign in the compression chambers. When the piston enters the chamber, pressure is created - when it exits, it is discharged. In the movement of the piston are driven by a crank mechanism (I think you know what it is, if not - the Internet to help), which in turn is driven by a motor (electric or internal combustion). So, the piston is drawn in and squeezed out water from the compression chambers (see picture) and water is pumped through the pump. At the output, we get the flow of water to which energy is communicated (see the figure, until you take into account the bypass system, let's consider only the pump).

Now if you attach a hose to the end of which a nozzle with a hole of ø 0.7 mm is attached to the pump, the energy of the water compression will be consumed to overcome the resistance of the nozzle, and a jet of water will be produced under pressure.

So, we looked at the process of the pump without the bypass system. Now consider the operation of the HP pump in general with the bypass system. Water getting into zone A is drawn into the compression chambers and squeezed out into zone B, then into zone C and then to the washing gun with a nozzle, flying out of it with energy, using which the washing process is carried out.

The whole difficulty is that the pump pumped through the entire volume of water per unit of time, to which it is calculated. The nozzle on the actuator (washing gun, or a set of detergent nozzles) is always selected to realize the nominal characteristics of the pump, i.e. the nominal pressure at the nominal flow of water. But pumps are not always used in nominal mode, therefore a bypass is necessary.

Under normal conditions, the pump operates in two modes:

- In pressure mode, bypass operates as a pressure reducing valve (supports constant pressure);

- In the bypass mode.

Let's consider the first case. The water pumped through zone A, compression chamber, zone B, is squeezed out into zone C and to the outlet to the washing nozzle. From zone C to zone B, it has no possibility of a return stroke due to check valve. The bypass valve works as a reduction valve in this case, that is, it maintains a constant water pressure at the outlet, dropping excess water into zone A. With increasing pressure, the water will compress (acting on the bypass piston) spring, thereby opening the valve. The pressure is adjusted by pressing the bypass spring manually, the adjusting cap, the washing operator. The bypass must be adjusted to exclude the operation of the pump with increased pressure.

The second case. When the valve of the cleaning gun is closed, the pressure in the zone C increases to the cutoff pressure, the piston squeezes the spring, thereby completely opening the bypass valve. The water begins to circulate in a circle: zone A - zone B - zone A. The valve remains in this position until the trigger of the detergent gun is pressed because the pressure in the zone C retains the spring in the compressed state. After pressing the trigger of the gun in zone C, the pressure drops to the working level, the spring squeezes the rod and closes the bypass valve, the pressure mode starts.

As you know, without water, and neither there, nor syudy. For residents of holiday villages and not covered by the centralized water supply system of private houses, these are not just words from a song, but a sad reality. And even if there is a water supply in the village, in the summer, life-giving moisture often has to be guarded at night, as there is not enough pressure for everyone in the daytime.

In any case, despair is not necessary. High pressure water pumps installed in the well or installed in the system solve such problems in two counts.

Pumps for individual water supply systems

Regardless of where you get the water - from the well (see), the well or the nearest reservoir - its automatic supply to the site and the house with the optimum pressure can only be provided with a properly selected pump.

Parameters required for selection

You can not go to the store and buy any pump simply because you are satisfied with its appearance or price. It must be selected according to the parameters appropriate to your needs and the source of the water.

These include:

- Performance. It depends on the amount of water you need, which consists of household and household needs. And calculate it based not on the accepted standards, but on the maximum consumption of all points of water consumption per unit time. In other words, you need to add the number of liters that follow in one minute, for example, from a tap in the kitchen, a shower head and a watering cock in the courtyard, add to it the consumption of the washing machine in order to get the maximum flow, provided they are switched on at the same time. The obtained value will serve as a reference point when choosing an aggregate with the required capacity.

Note. The performance of high-pressure water pumps should not exceed the productivity of a well or well. If the source is emptied faster than replenished, it will cause the equipment to run idle and its failure. How to solve this problem, we will tell just below.

- Head. This is the height in meters, on which the device can lift water. But in order to calculate the required head, it is necessary to take into account the distance of its supply horizontally. According to the simplified formula, it is assumed to be equal to 1/10 of the length of the horizontal line.

Example. To feed water from a well 10 meters deep to the second floor of the house, located at a height of 4 meters from the ground and 12 meters from the well, the minimum pump head is calculated as follows: 10 + 4 + 12/10 = 15.2 m.

In fact, it should be higher, because this formula does not take into account the pressure drop when passing water through pipes, nodes and turns, the diameter of the pipeline and many other indicators. But the most important thing is the required outlet pressure.

And it will be low if the pump you select will have insufficient head pressure. That is why for comfortable use of the water supply system it is necessary to choose a high-pressure water pump - the device of this unit allows to extract water from great depths and supply it to consumers under sufficient pressure.

For reference. For stable operation of water-separating devices and household appliances, the pressure is considered to be not less than 1.5 and not more than 3 bar. Higher values lead to rapid wear of pipes and plumbing fixtures, experiencing increased loads.

Types of high-pressure pumps

The choice of the unit should be based not only on its technical parameters, but also on the design, the ability to work under certain conditions.

The most popular types are:

- Vibration (see). The principle of operation is based on the ability of a magnet under the action of alternating current pull to him and release the anchor, connected with the piston. Within one second its position changes several tens times. As a result of such vibration vibrations and pressure changes in the working chamber, water is first sucked into it, and then discharged into the pressure pipeline. The absence of rotating parts makes this type of device reliable and durable.

- Vortex. In the cavity of the body of this unit is a flat disk with radially located blades. Rotating, it displaces the liquid outward. Such pumps have a high suction power and are not afraid of air bubbles in the water. But quickly fail when pumping a dirty liquid with a high content of suspended particles. Therefore, the instruction does not allow their use in wells and sand wells (see).

- Centrifugal (see). Pumped water due to the appearance in the working chamber of the areas of high and rarefied pressure created when the impeller with blades rotates. This is the most common type of pumps that provide high pressure in the network.

All water pumps are classified and by other attributes. For example, there are surface and submersible models (cm. ).

The first work, being installed outside the source of water, on the surface of the earth. The second ones are immersed in the pumped liquid. They have higher values of pressure and pressure.

Also, water-lifting devices differ in the type of actuation on manual, electric, working on liquid fuel. The most popular ones are electric, operating from 220 V. But there are also models capable of operating from a car battery or other device giving a voltage of 12 V.

Pumps for increasing pressure in a centralized system

If your house is supplied with water from a centralized system, but the pressure in the pipes is not enough for normal operation washing machine or a shower cabin, it is possible to correct the situation by cutting a water boosting pump into it.

It is installed on the input and either turned on manually when necessary, or equipped with an automatic adjustment system. It turns on the device when the pressure in the network drops and turns off when it is sufficient.

Note. Such units are also suitable for increasing the pressure in an individual water pipe, if the water-lifting pump does not cope with the provision of a normal head.

There is nothing difficult to install a high-pressure water pump with your own hands. To do this, cut the pipe section and weld to the ends of the adapter with a thread.

But this device will be completely useless if the water is simply turned off for a while during the day or if your source has a low production rate and is not able to provide the maximum flow.

In such cases, pumping station from accumulator tank - Accumulator. In the period of normal supply, the pump will fill it with water and you can expend it, regardless of whether there is water in the system.

Unfortunately, such a station takes up a lot of space, and during operation it produces a noticeable noise, so installing it in small apartments is problematic. But here everyone decides for himself what is more important for him - silence and spaciousness or normal water supply without interruptions.

Conclusion

Perhaps, this is all that an ordinary consumer should know about high-pressure pumps. Their choice according to the parameters is better still to be entrusted to the specialists, providing them with all available data on the source, water quality, availability of electricity, etc. But, if you want to get more information, watch the video in this article.

Water along with air and earth are elements that are probably the most familiar for us, which, we think, does not need to be studied. But this is not so! The powerful magical energy contained in these natural resources is, indeed, amazing. It is necessary to be able to use it for the good of mankind. High pressure plunger pumps - here is a tool for decorating this element. Using them, a person, as if with the help of a magic wand, creates real miracles.

Plunger pumps for water

Interpump Group is a company that works with water and is the world's largest manufacturer of high-pressure plunger pumps. It was founded in 1977, at the initiative of Fulvio Montipo. He made significant technical changes in the design and construction of high-pressure plunger pumps. They introduced radical innovations, thanks to which, produced by the company plunger pumps for water became more compact, quiet and easy to maintain. Another element of these innovations was the completely ceramic piston group, which provided a higher reliability to the plunger pumps for high pressure washers , in comparison with the analogues in steel construction. Thanks to this approach, the company Interpump Group, to date, is recognized as the benchmark in its field, producing plunger pumps for water. World leadership is maintained due to quality standards, which guarantees full control over the production process, starting with raw materials ending with the finished product.

Pump for washing

The main part of any high-pressure apparatus is washing pump. Without which, no washing machine can perform its functions. It is the pump for washing that creates the necessary pressure, by means of which water turns into a powerful jet. In the assortment of our company you can find pumps for sinks of different characteristics and, consequently, for different purposes. We can offer you both ready-made solutions for popular ATS, and design stationary washer High pressure with any characteristics you need.

High pressure washers for washing

All components of the high-pressure pump for washing are made of high-quality materials that are systematically checked and tested at every stage of production. The audit is carried out with the utmost precision, in order to ensure that the final product is resistant to severe wear during operation in industrial conditions, including car washes.

Scope of sump pumps

The company Annovi Reverberi produces high-pressure pumps for car washes with a pressure of 50 bar to 4000 bar, with power consumption up to 750 kW. High-pressure plunger pumps are used to clean most surfaces. Including surfaces of ships and pipelines. And also for cutting and removing concrete, asphalt, paint, cement or metal surfaces. The ultra-high pressure pump is used in the following sectors of heavy industry: construction, ferrous metallurgy, chemical and petrochemical industry, as well as for water purification.

Among other things, high pressure plunger pumps have proven themselves in the chemical industry. They are used for pumping chemicals, fuel and other corrosive liquids.