Where and how to install a check valve in the pumping station. Where and how to install a check valve in the pumping station.

The constant presence of hot water in a house or apartment - for most people it has long become a habitual norm, without which it is difficult to imagine a normal, comfortable life. If the water supply is stretched to the house or an uninterrupted uninterrupted water supply is organized, for example, , then there is nothing to think about - you need to install a water heater of one type or another.

Probably, the electric water boilers are the leading position in the field of water heating devices for household needs. They are extremely simple to operate, their installation does not require any additional coherent procedures or drafts of individual projects. Installation of such a boiler is quite feasible and for self-conduct. That's why information is needed, which will be set forth in this publication - each of the home masters should clearly understand how important a safety check valve is for a water heater.

how would nor warned workers of housing and communal services, emergency and rescue services, supervising bodies of state supervision, which would plots with the consequences of accidents nor shown on television, still with frightening regularity are "clever", which all these technical recommendations and just good advice - not an edict, they themselves "know how easier and better". Alas, but the ignoring is very small in size, inexpensive, easy to install, and at the same time - an extremely important obvjazki electric water heater can turn into a very big trouble, and, it is possible, even a tragedy.

First of all, a very important reservation must be made immediately. Although very often, in order to obtain information, the search query "check valve for the water heater" is hammered in by interested people, much more correctly, it will be more correct to talk about a safety valve that combines several functions. These devices have a certain similarity, but there is also a huge difference, which predetermines the main task - security safety of electric heater operation.

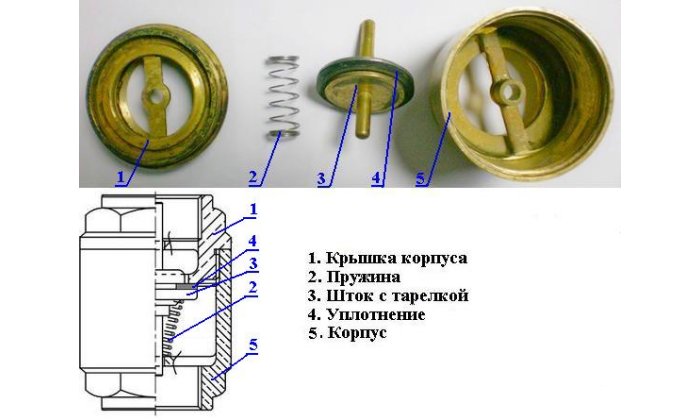

For comparison, consider the device of a conventional check valve:

So the usual non-return valve is arranged. But for his boiler - not enough!

It's a metal cylinder, on both sides of which there are threaded areas for "packing" in a straight pipe section of the corresponding diameter. Inside the disk valve is stopped - a disk with a rubber seal around the circumference, on the central axles - stock (shown in the figure with a green arrow). The disk is constantly in a spring-loaded state, blocking the internal channel for the passage of water.

When water flows in the direction of the arrow (the direction of the permissible fluid flow is always indicated on the valve body - in the figure this mark is indicated by a red arrow), the pressure in the pipe through the "plate" compresses the spring and opens the passage. As soon as the pressure decreases, the valve again automatically switches to a closed state.

Such a precautionary measure is, of course, necessary that the tank is always filled, under any circumstances, in the water heater. However, such a measure is clearly not enough to ensure security - this will be described below.

The safety valve is somewhat more complicated:

In fact, these are two valves in one housing, placed perpendicularly to each other.

In a larger cylinder (item 1), which runs along the water, the same valve is installed, which prevents the reverse flow of water. On the feeding side, the "daddy" threaded section (item 2) for tapping into the water supply system (in particular, it will be convenient to connect a flexible water hose here). FROM the opposite side - threaded coupling "Mama" (item 3), which in some cases is wound directly on the nominal branch pipe cold water in the electric heater.

In the figure, the "plate" of the check valve (item 4) with a sealing ring around the circumference is very clearly visible, and the spring (key 5), which keeps the valve closed.

But now - the main difference. Perpendicular to the cylinder with the check valve there is one more, a bit smaller in size (pos.7). In fact, it has the same poppet valve, but the spring is much more powerful - this is the same safety "stall" valve. Ordinary and even slightly high blood pressure in the water system can not compress the spring and open it - this requires much more serious efforts.

In the cylinder cavity, behind the "safety valve" plate, there must always be a hole with a branch pipe (item 8), where, when the valve is operated, a surplus of liquid will be discharged.

The cylinder with the safety "break" valve can be completely damped, and sometimes it ends with a screw plug (plug), behind which is the adjusting screw (usually - under the "inner" hexagon). But the most common safety valves with an additional lever:

In the figure, the features of such a device are clearly visible. The lever (key 9) is intended for manual opening of the safety valve with discharge of water through the pipe (item 8). Note that the nozzle can have a special relief design, which allows you to put on it thin hoses to drain water into the drainage (sewage). The function of manual valve control is convenient, for example, for draining the contents of the boiler when carrying out repairs or preventive works. Nevertheless, it is not necessary to "get carried away" using such manual control - it can be dangerous in some cases (this will be described below).

On any safety valve there is always an arrow indicating the direction of the cold water flow towards the electric water heater. (in the diagram - a red arrow). Very often the body designates the ultimate pressure of the "break" valve, in this case it is 0.7 MPa or 7 atmospheres (yellow circle in the figure).

How the safety valve works in different situations

To finally verify the importance of the safety valve, it is best to consider the cases in which it works, as well as those situations that may occur if, for some reason, the valve is missing or defective.

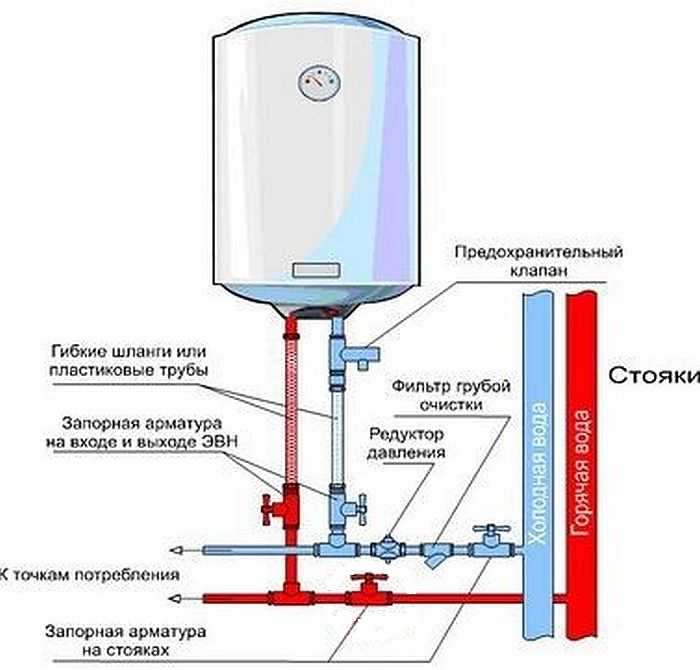

For clarity, once again - the simplest, but also the most understandable scheme of piping a boiler with a safety valve. The blue and red arrows show the direction of the flows, respectively, of cold and hot water. The green arrow points to the position of the safety valve.

1. After the electric water heater is installed, completely "tied up", it should be filled. To do this, just open the cold water supply and the hot tap on one of the mixers. Pressure in water pipe it is enough to open a check valve for unimpeded flow. As the volume of the tank of the water heater is filled, air is displaced. As soon as the flow of water comes from the mixer - the entire container is filled up to the upper intake branch pipe, the supply can be switched off.

The pressure in the boiler at this moment is roughly equal to the pressure in the cold water main - it seems to be "propped up" by it. However, it can be even slightly higher - due to the remaining compressed small volume of air in the upper part of the tank. Plus, when the power is turned on, the heating of the water starts - and this, too, naturally leads to an increase in pressure.

2. Imagine the situation that the check valve is not installed, or is in a faulty condition. That balance, which was reached when filling the boiler capacity, sooner or later is broken, as the pressure becomes higher than the pressure in the pipe. The "hot" faucets on the faucets are closed, which means that the heated water will look for an outlet in a different direction. This can lead to hot water suddenly starts to flow from the "cold" tap, or it is filling it with a drain tank on the toilet. Meanwhile, the boiler's thermostat can not understand the situation and does not give a signal to turn off the heaters. Expensive electric Energy is wasted absolutely.

3. But even this is not the saddest thing. It's no secret that pressure in the water main, especially in multi-storey buildings, often decreases to critical values (from the tap, as they say, barely flows), or even completely disappears. The reasons for this are a great many, for example, an accident on the mainline, preventive maintenance, planned pressure reduction, for example, at night hours, etc. What happens if the check valve is missing or malfunctioning? Yes, nothing good - the boiler just emptied, since all of their water will flow out completely into the feed pipes.

Well, if the boiler provides protection from "dry" heating, and it will work quickly! And if not? Powerful heaters will idly heat the air in a closed volume, and this will end either by their burning out or by the cracking of the enamel - in any case, nothing good to expect in this situation is not necessary.

4. A reasonable question may arise: is it possible confine oneself only installing this same check valve? It would seem, judging by the description, he is able to solve all the problems.

Do not consider it an exaggeration: such an installation is a bomb planted in your house!

No, it's by no means impossible. The installation of a complex valve, combining both the reverse and safety, is a prerequisite safe operation water heater.

If somewhere the reader will encounter such a picture - only a check valve at the entrance, then he must understand that this is comparable to a powerful bomb that is not known when it explodes.

Another example of "suicidal creativity"

We consider the situation in detail. When the boiler is turned on, heating starts, and as the temperature rises, according to the laws of thermodynamics, pressure begins to rise in a closed volume.

Designers of household appliances lay in each water heater a certain operational resource, which allows the device to operate up to certain values of pressure in the tank - usually this value is indicated in the technical documentation. Usually, all boilers are very balanced thermodynamic systems, in which the optimum ratios of permissible temperatures and pressure levels are very accurately calculated. Nevertheless, everything happens. And as soon as the pressure level, for whatever reasons, begins to approach the permissible upper mark, a spring is compressed on the safety valve, and the resulting excess liquid is discharged into the drainage branch. As a result, the system again enters a state of dynamic equilibrium.

The water emerging from the drainage pipe is normal

But now let's try to imagine what can happen in a situation where there is no emergency valve, and everything is limited only by the reverse

Heating water should be limited to a thermostatic regulator, but quite often these electromechanical devices are far from perfect, and can simply fail. In this case, the heating continues uncontrolled.

The pressure inside the tank of the boiler increases, but there is no way out - the mixers are closed, and the check valve reliably cuts the supply line. It would seem that the temperature will reach only 100 degrees, to the boiling point of water? Nothing like this! With increasing pressure in a closed volume, the boiling point of the liquid also increases sharply. For example, the data is shown in the table:

| The pressure in a closed volume, atm (MPa) | Boiling point of water, ° Ċ |

|---|---|

| 1.0 (0.1) | 99.09 |

| 1.033 (0.1) | 100.0 |

| 1.5 (0.15) | 110.79 |

| 2.0 (0.2) | 119.62 |

| 2.5 (0.25) | 126.79 |

| 3.0 (3.0) | 132.88 |

| 4.0 (0.4) | 142.92 |

| 5.0 (0.5) | 151.11 |

| 6.0 (0.6) | 158.08 |

| 7.0 (0.7) | 164.17 |

| 8.0 (0.8) | 169.61 |

| 9.0 (0.9) | 174.53 |

| 10.0 (1.0) | 179.04 |

| 20.0 (2.0) | 211.38 |

| 25.0 (2.5) | 222.90 |

| 50.0 (5.0) | 262.70 |

| 100.0 (10.0) | 309.53 |

When the word "bomb" was mentioned above, this is not at all an exaggeration! In such circumstances, the water heater turns really in an explosive device terrible destructive power.

Even at 4 - 5 atmospheres of pressure, the boiling point reaches almost 150 ° FROM, and continues to rise. The growth of pressure on the walls can lead to their deformation, chipping of the enamel or ceramic coating - but this will be the smallest of possible evils. Another circumstance is a terrible drop in pressure in this closed system, and this can happen when a crack appears on the weld seam, if the rubber seal breaks or even just when the hot water tap is opened on the mixer.

A sharp decrease in pressure leads to a corresponding sharp decline the boiling point of water. As a result, the entire volume of liquid (imagine all 50, 80 or 100 liters!) Instantly boils, which, of course, is accompanied by the release of a huge amount of steam. This will not withstand any, even the most solid body - there is a strong explosion that is capable of demolishing everything in its path, including even brick interior walls. There are many good examples of this on the Internet.

It's hard to believe, but it's the consequences of a conventional electric boiler explosion

So, let's take a brief summary of the need for a safety valve.

- It does not allow back water leakage from the tank into the supply line, in case of a drop in pressure.

The presence of a valve at the inlet creates additional protection for the boiler against possible strong pressure spikes in the water pipe, from hydraulic shocks.

- The safety valve will eliminate the possible failure of other levels of safety - it will maintain the temperature-baric mode in the boiler within the limits of acceptable values.

- A safety valve equipped with a lever allows, in addition, to drain water from the boiler if necessary.

Video: the need to install a safety valve

Recommendations for the selection and installation of a safety valve

The choice of the required valve is simple. Most often, boilers (especially from leading manufacturers) go on sale with a valve of the required denomination. The same value will need to be guided, if for some reason have to change the valve in the future.

The value of the limiting pressure in the tank of the boiler, in addition, should be indicated in the technical documentation of the product. If the water heater is not equipped with a valve, you will have to purchase it yourself, based on the value indicated in the passport. It is important to choose the right value - if you install a "weak" valve - water will leak almost continuously from it. The valve with a too strong spring will not create absolutely safe operating conditions.

"Pack" the valve can directly on the pipe of the boiler for cold water (always has the appropriate blue color marking.) For reliable sealing during installation, it is best to use a linseed paste with modern sealing pastes, usually 3 to 4 full revolutions are sufficient. , then there is enough rubber gasket.

Sometimes a valve is inserted between the valve and the boiler itself - this greatly facilitates periodic preventive maintenance. Such an installation is completely permissible, but only under one condition - the valve should stand on the tee offtake, but in no case do not interrupt the straight channel from the water heater to the valve. Any stop valves on this direct site is strictly prohibited!

Step-by-Step Instructions for Strapping an Electric Water Heater

It makes sense to consider step by step how you can independently connect an electric boiler to the water supply system. Below in the table two examples will be shown as examples. Despite some differences, in both cases it will be clearly demonstrated that the safety valve is an obligatory element of the strapping of such a water heater.

| Illustration | Brief description of the operation |

|---|---|

| To begin with - a few words about installing the water heater on the wall. Of course, the place is thought out in advance, before the purchase of the device, so that the boiler is placed in the space allocated to it and does not interfere with it normal operation premises. To the installation site, a power cable is usually pre-installed, connected to a separate machine. Immediately provided and insertion points in the water supply system. To accurately suspend the boiler on the wall, its height is measured. |

| Knowing the height of the water heater, it is easy to determine the bottom point of the device, which it will take after installation. |

| On the back side of the body of the water heater there are accessories for fixing on the wall. In this case it is a conventional mounting plate (bracket) that will cling to the hooks. There may be other options - in the operating manual of the device, it is usually painted, and often 1: 1 templates are also applied to simplify the process of marking. |

| In this case it is necessary to determine the location of the line on the wall, along which the hooks will be mounted. To do this, we measure the distance from the lower end of the water heater to the mounting plate. |

| The same distance is deposited on the wall vertically from the previously planned point of the planned lower edge of the boiler. |

| With the control of the building level, a horizontal line is drawn along which the hooks are hooked. |

| The next step is to measure the necessary distance between the hooks. In this case, the optimal will be 200 mm - the hooks will be placed closer to the edges of the mounting plate, but there will be the possibility of a slight backlash to the left and to the right for leveling the water heater. |

| This distance is transferred to the planned horizontal line - the centers of holes for hooks are outlined. In the example shown, they happened quite unsuccessfully - exactly on the seams between ceramic tiles. If there is such a possibility, it is better to plan a hole away from the edge of the tile - much less the probability of a crack when drilling holes. |

| For the suspension of the boiler, powerful hooks are chosen: the outer diameter of the polymer plug-plug is 14 mm, the length of the plug is 80 mm, the diameter of the metal hook is 8 mm. Often the assembly of the electric water heater includes the recommended fastening elements. |

| At the planned points, the perforator drills the corresponding holes, into which plug plugs are jammed. Then the hooks themselves are screwed. |

| Hooks are screwed to such a depth to ensure a reliable, stable landing of the water heater, without backlash, but also without jamming. |

| Everything, the boiler is suspended on the wall. From the bottom two pipes are clearly visible, through which the device will be connected to the domestic water supply system. The branch pipes are marked with a color marking: blue - cold water supply, red - hot output. |

| In the water pipe has already been made a corresponding tie-in - here are two polypropylene nozzles, to which it is necessary to draw the piping of the water heater. On the left there is a branch pipe of hot water supply, on the right - a cold water pipe. |

| In this example, the master decided to equip the boiler with an optional element - an additional tap, which will be used when the boiler needs to be emptied. For this purpose, a tee will be installed on the water heater inlet. The recommended preliminary "fitting" is carried out - how many revolutions are needed so that the rooin withdrawal takes the necessary position. In general, such fitting is desirable to be done before assembling any fixed node - less chance of making a mistake. |

| After that, the tee is packed onto the wrappings from the pack, smeared with sealing paste "Unipak". |

| Tee is packed, it is given a conceived position. |

| A compact faucet will be mounted on the side branch pipe of the tee. |

| The wrapping is applied, the sealing paste is applied. |

| The crane is screwed in, tightened with a key, for at least three turns, it is given a planned position for easy access to the handle. |

| And now there has come a turn of installation of an obligatory element - the safety valve. Be sure to pay attention to the arrow showing the direction of the water flow. |

| The safety valve will be installed on the lower branch pipe of the already installed tee. The main rule is met completely - there are no locking devices between the valve and the water heater. The crane installed on the side branch pipe of the tee has no effect on the safety of operation of the device. |

| The valve is packed on a tee - in the illustration this entire assembly is assembled. |

| It is desirable to make the piping of the boiler demountable - this will make it possible to turn off the device to remove it, for example, for prevention or for replacement heating element or anode rod. Therefore, the master decided to install on both entrances shut-off ball valves with a cap nut - "American". A sample of such a crane is shown in the illustration. |

| The tap itself will be tightly packed on the lower branch pipe of the safety valve. And the fitting with the union nut itself will be fitted with a fitting for switching to a polypropylene pipe. That is, disconnect the boiler from the pipes half an hour will be quite easy. |

| The second same faucet is also placed on hot water, but directly on the outlet pipe of the water heater. And it is also assumed that the fitting for the switch to the polypropylene pipe will be packed to the removable nipple with the "American". |

| Here the fitting mounted to the fitting is fitted to the installation site. In this case, the fitting-branch is applied to 90 degrees to immediately leave the pipe closer to the wall. |

| Next, another bend will be welded - and the pipe will go down along the wall. |

| On the fitting of the second tap, on hot water, a usual fitting for switching to polypropylene is mounted. But this is done solely because of the aesthetics of the external appearance of the strapping - that the "step" of the transition to a level closer to the wall on both pipes is located at the same height. Further, conventional welding and installation work is carried out with polypropylene pipes. |

| That's how neat the overall knot of the water heater bundle turned out. |

| And this illustration shows how the pipes of the pipeline are welded into the water pipes that were left earlier. The water heater is now installed. You can open all the valves (except the drain), fill the boiler with water, connect it to the power supply. If there is a necessity and possibility, a transparent PVC pipe is put on the drain connection of the safety valve, which is taken to the sewage system, cistern toilet bowl or any container - a stuck excess water will not fall on the floor. |

| Now consider possible variant piping of the boiler with the installation of flexible liner. The illustration shows that the water heater is already suspended on the wall. The arrow shows one of the "water outlets" - branch pipes hidden in the wall for the finishing of pipes of cold and hot water. |

| On these nozzles will be packaged conventional ball stopcocks. To apply the valves with a union nut in this case there is no special need - the strapping will be collapsible due to the use of flexible liner. |

| On the branch pipe, the linen pancake is rewound. Some masters use FSM tape, but still supporters of reliable sealing with the help of pakli - much more. |

| The winding is smeared on top with a sealing paste of the "Unipak" type. |

| Then the tap is wound up - first it is manufac- tured manually ... |

| ... and then - tightened the key, so that the "lamb" is located in a convenient place for use - from above. |

| A similar operation is completely repeated with the second tap. This is now over for here. |

| We proceed to the operations directly on the boiler itself. Its two nozzles are ready for further installation. |

| A sealing winding is performed on the inlet branch - a safety valve will be installed here. |

| In this case, the master decided to confine himself only to the valve, that is, to do without installing a drain cock on the tee. It is quite normal solution - to drain the water from the boiler it is possible and through the valve - a special lever is provided for this. The drain will be somewhat longer, but the installation is simpler and cheaper, and it is not so often necessary to resort to the emptying of the boiler. |

| The valve is screwed and then tightened with a wrench, so that the lever and drain pipe are in a user-friendly position. In fact, it was the last connecting unit, requiring the rewinding of the pack. |

| The safety valve is installed in its original position. |

| Connect flexible hoses. In this case, the master used high-quality corrugated stainless steel hoses, which are considered to be "eternal" in their characteristics. Flexible threading from a rubber or plastic hose in a metal braid is definitely inferior in reliability, and attracts only by a low price. The principle of installation is completely identical. Hoses along the length are purchased taking into account the distance from the boiler to the "water outlets". The gasket supplied with the gasket is inserted into the union nut of the hose, then the nut on the thread of the pipe (in this case - the outlet). No rewinding is necessary, if the end of the branch pipe is in the normal state along the entire circumference - the gasket will provide the necessary level of sealing of the connection. The union nut is first wound by hand - until it stops ... |

| ... and then tightened even literally by ¼ ÷ ½ turn key. Tighten the connection is not necessary - you can squeeze the gasket and thereby achieve exactly the opposite result. |

| The second end of the flexible hose is connected in the same order to the threaded branch pipe of the valve in the corresponding "water outlet". |

| Similarly, the second hose is also installed, with the only difference being that it connects its upper end to the branch pipe of the safety valve. Now you can open the water and check all connections for leaks. If a "tear" is found, you can still slightly tighten the connection with a key, without applying a lot of effort - the leak should disappear. |

| If there is no leakage, you can proceed to the full operation of the water heater. In the illustration - the "bottom knot" of the piping of the boiler: the flexible piping is connected to the faucets of "water outlets". |

| And this - the same hoses, but connected to the top of the safety valve (for cold water) and to the outlet of hot water. The boiler has been installed. |

Video: typical boiler strapping scheme

Frequently Asked Questions (F.A.Q.)

And, finally, it makes sense to answer some of the questions most frequently asked about the operation of boilers with a safety valve.

- Often asked how to deal with irritating water droplets protruding from the drainage branch pipe?

And it's not necessary to fight them - they just say that the valve functions normally. The easiest way is to put a transparent tube on the tube (so that you can visually control it) and bring it out either sewage pipe, or, for example, in the toilet bowl.

- Can the valve be placed so that it does not remain in sight?

By and large, if he is so annoying, then you can. But you need to observe certain conditions:

- No additional elements are allowed between the valve and the boiler - shut-off valves, tees, etc.

- The length of the section from the valve to the boiler inlet must not exceed one and a half to two meters. The fact is that the vertical column of water in the pipe will exert additional pressure on the safety valve spring, and it will work incorrectly, with a strong undercut.

- Leakage from the valve - too frequent and abundant, even at low temperatures of water heating. What can be done?

The reasons for this phenomenon may be different.

- The valve rating does not match the characteristics of the water heater.

- in the valve, the spring has simply relaxed over time.

In either case, replace the valve with a new one, with the required operating force.

Another reason can be found in the instability of pressure in the water supply system. For example, frequent pressure jumps with a large amplitude lead to valve operation even in the absence of heating. In this case, it is recommended to install a pressure reducer at the inlet of the water pipe to the house (apartment).

- Can I try to adjust the valve myself with the adjusting screws?

Definitely - no! Adjustment of such devices requires " calibrated"Pressure, and to conduct similar procedures on their own - is prohibited. Valve - not so expensive product, so you can not buy a new, the desired denomination.

- I have never seen a drop of water come out of the valve. This is normal?

And here this is a very disturbing sign. How to know, perhaps, the valve simply "calms" by its appearance, but completely inoperative. For example, the camera behind the disk spring was overgrown or clogged with scale, the nipple and the like hammered. If the valve is equipped with a lever, then you can try it manually (only better - for small values of the heating temperature, about 40 degrees, so as not to get burned).

It is possible that the valve rating is excessively overpriced - does not match the model of the water heater. In addition, we can not completely exclude, and factory marriage.

The best way out of this situation remains the same - replacing the safety valve with a new one.

So it will be calmer!

Never save on your own safety!

From the correct piping of the electric water heater storage type (boiler) depends not only the life of the equipment, but also the safety of the tenants. That's the way things are. And its proper tying is a safety valve for a water heater with cold water.

What is it needed for

The installation of a safety valve prevents the pressure inside the device from rising above the norm. Because of what the pressure rises? As is known, when heated, water expands, increasing in volume. Since the boiler is a sealed device, there is no surplus to go - the valves are closed, the return valve usually is on the supply. Therefore, heating the water leads to an increase in pressure. It may well be that it will exceed the ultimate strength of the device. Then the tank breaks. That this does not happen, put a safety valve for the water heater.

Maybe you do not need to put a safety valve, but just remove the return valve? With a sufficiently high and stable pressure in the water supply system, such a system will work for some time. But the decision is fundamentally wrong and that's why: the pressure in the water pipe is rarely stable. Often there are situations when the water is barely running out of the tap. Then hot water from the boiler pressure is forced out into the water supply system. In this case, the heating elements are bare. Some time they will warm the air, and then burn out.

But the burnt TENs are not the worst. It is much more terrible if they are heated, and at this time the pressure in the water supply system rises sharply. The water which has got on the heated heaters evaporates, there is a sharp increase in pressure - a jerk - that leads to the guaranteed rupture of the bulb of the boiler. At the same time, a decent amount of scalding water and steam, under great pressure, bursts into the room. Than it can threaten - it is understandable.

How does it work

A safety valve for a water heater would be more correct to call a valve system, since there are two valves in the device.

They are located in a brass or nickel-plated case, which looks like an inverted "T" (see photo). In the lower part of the body is a non-return valve, which prevents the outflow of water from the water heater when the pressure in the system decreases. In the perpendicular branch there is another valve, which, when the pressure is exceeded, allows the discharge of part of the water through the union.

The mechanism of work is as follows:

- As long as the pressure in the boiler is less than that in the water pipe (with filling or with the tap open), the plate of the check valve is wrung out by the flow of water. As soon as the pressure level, the spring presses the plate against the protrusions of the body, blocking the flow of water.

- When the heating is turned on, the water temperature gradually increases, and with it the pressure also increases. While it does not exceed the limit, nothing happens.

- When the threshold level is reached, the pressure compresses the safety valve spring and opens the outlet to the union. Some of the water from the boiler is discharged through the nozzle. When the pressure drops to a normal spring, the passage closes, the water stops draining.

According to the principle of operation it is clear that the water from the nozzle will constantly undermine. This happens when the water is heated, when the pressure in the water pipe decreases. If you see water from time to time, then everything is working fine. But the confluent liquid must be diverted. To do this, put a suitable diameter pipe on the branch pipe, always fix it with a yoke. The normal working pressure of the boiler is from 6 bar to 10 bar. Without mechanical fastening, the tube will tear off in two counts, so that the collar is selected high-quality, tighten well. Take the tube to the nearest sewer.

One more thing: the tube on the choke needs a transparent and preferably reinforced (so-called "Christmas tree"). Why reinforced is understandable - because of pressure, and transparent - for the ability to control the operability of the device.

Types and varieties

If it is a question of usual safety valves for a water heater, they look almost the same, only the nuances differ. But it is these small parts that are responsible for the ease of operation.

In the photo above two safety valves with drain arms. They are needed for periodic testing of operability. The flag of the lever is lifted upwards. He pulls the spring behind him, freeing him to dump the water. This check should be conducted about once a month. You can also empty the boiler tank - raise the checkbox and wait until everything drains.

The difference in the models presented is that the model in the photo on the left has a lever fixed with a screw. This eliminates the possibility of accidental opening and complete discharge of water.

Two more differences are striking. This is an arrow on the body, indicating the direction of movement of water, and an inscription showing the pressure the device is designed for. It seemed to be minor details. But if the direction of the water movement can be understood (see which way the poppet valve is deployed), then the face value is more difficult. How to distinguish, for example, 6 Bar or 10 Bar? Only checks. And how will the sellers distinguish them? No way. On the boxes. And if you put it in the wrong box? In general, it is better not to take without marking on the case. This is usually the cheapest of Chinese samples, but the difference in price is not so great as to be worth the risk.

Also pay attention to the shape of the nozzle for water discharge. The model on the left has a long, non-linear nipple. It is quite easy to get a hose and length is enough to install a yoke. The shape of the fitting on the right of the model is different - with an extension to the end, but more importantly, the union is short. You can still pull the hose on it, but the yoke is questionable. Is that the wire crimped ...

On the next photo, safety valves without a forced pressure relief flag. The one on the left, at the top, has a threaded cover. This is a serviced model. If necessary, you can unscrew the lid, remove blockage, scale and other impurities.

Safety valves - serviced and not

The model on the right is the worst of the options. No designation, forced reset or maintenance. This is usually the cheapest available, but this is their only advantage.

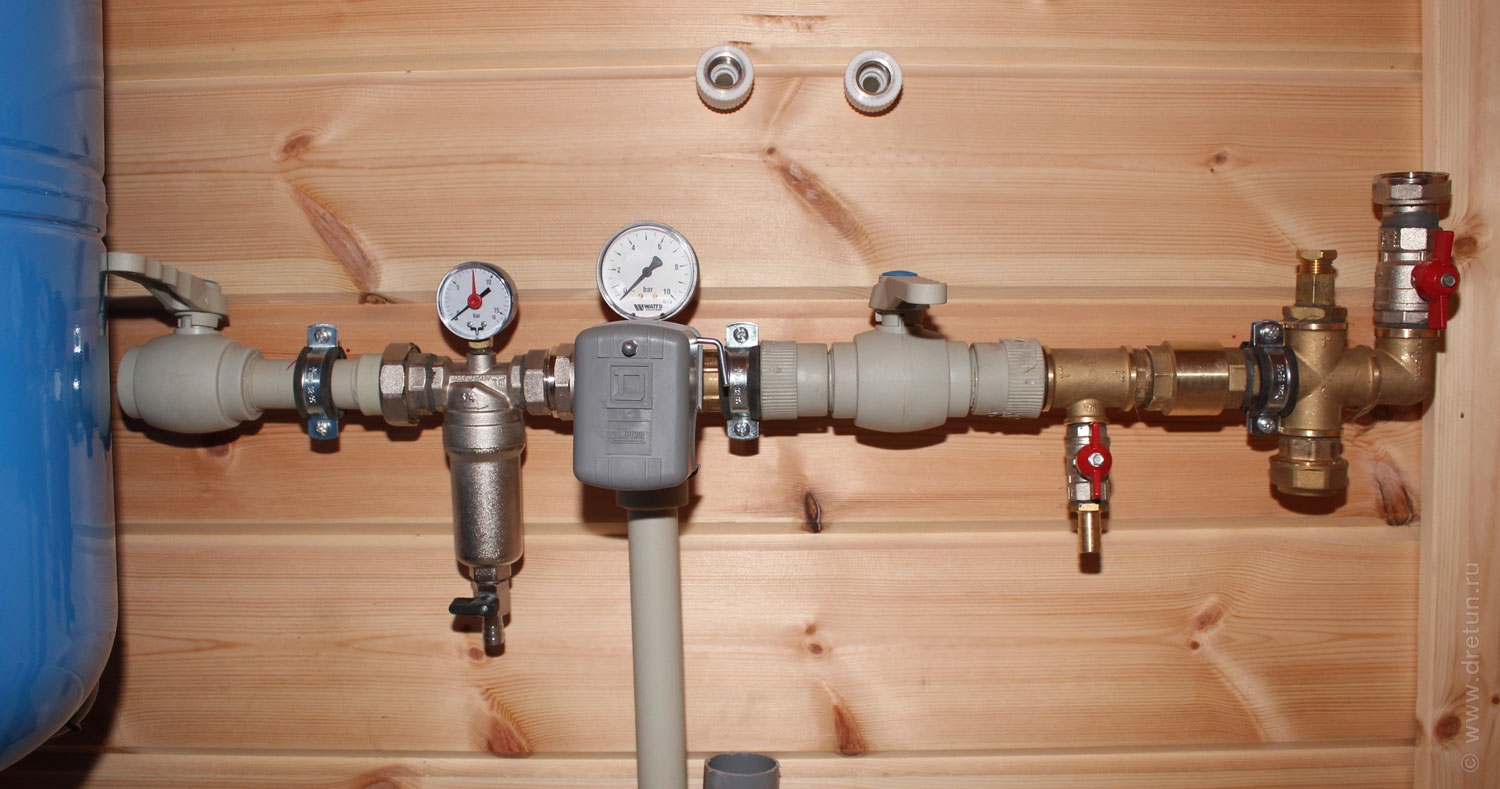

All the above models are suitable for water heaters up to 50-60 liters. For boilers of a larger size, there are other models, many of which are equipped with additional devices. Usually this ball valve and / or a pressure gauge to control the pressure.

The outlet for water discharge here with a regular thread, so there will be no problems with the reliability of the fastening. Such devices already have a fairly high price, but the quality and reliability of their much higher.

Not all in appearance like these devices. For those who attach great importance to aesthetics, very attractive devices are produced. Their price, however, is comparable to the price of a cheap water heater, but beautiful.

Can I put other valves

Sometimes, instead of a special safety valve for the boiler set subversive, which is intended for emergency discharge of water on heating. Although the functions they have and are similar, but the main mode of operation differs in the root. Subversive should only work in emergency situations. It is designed for salvo discharge of a large volume of liquid. For the constant bleeding of small portions of water, it does not fit. Accordingly, it will not work correctly.

Another case is the installation of a non-return valve. It will not drain water when the pressure in the water pipe decreases, but it will not save you from raising the pressure in the boiler. So this option is also not workable.

How to choose and install

Select the safety valve for the water heater according to the pressure to which the unit is designed. This figure is in the passport. The choice of tank capacity also affects the choice. Issue devices with a limit of operation at 6, 7, 8, 10 Bar. In general, all units are designed for this pressure. So everything is simple.

The installation is simple: a flaxen fiber or a tape tape is wound on the thread, after which the valve is wound up and the branch pipe. Until the stop is twisted by hands, then another one or two turns with the keys. It is much more important to choose the right place for its installation. When this valve is installed directly on the inlet pipe of cold water.

Further, there may still be a check valve, which is still called shut-off. But this is already reinsurance - the same device is available in the safety, and even often after the water meter at the entrance. The wiring diagram is shown below. This is one of the normal options.

The diagram has a ball valve. It is necessary for emptying the tank before conservation for the winter (in cottages) or before dismantling for prevention and repair. But more often put it on the tee, which is wound directly on the inlet pipe of the water heater. A safety valve is wound on the tee from below, and a ball valve is placed in the lateral branch.

Actually, these are all normal options.

Breakdowns, causes, elimination

In principle, the safety valve for a water heater has only two faults: water often flows from it or does not flow at all.

First of all, I must say that bleeding water when heated is the norm. This is how the system should work. Water can also be drained when the boiler is turned off, if the pressure in the cold water supply pipes is higher than the limit of the valve operation. For example, the valve is 6 bar, and in the water pipe is 7 bar. As long as the pressure does not drop, the water will be drained. If this situation is repeated often, it is necessary to install a reducer, and preferably on the water in the apartment or house, but there are compact models of reducers that can be installed at the entrance to the boiler.

How to check the serviceability of the valve? If there is an emergency reset lever, this is easy. When the boiler is switched off, it is necessary to raise the lever several times, releasing the excess pressure. After this, the drops stop and do not resume until the heating starts.

If the water continues to drain, the spring might be clogged. If the model is serviced, the device is disassembled, cleaned, and then put in place. If the model is not demountable - you just need to buy a new valve and put it.

This is how the reducer looks - to stabilize the pressure on the boiler

Constantly dripping water - it's unpleasant and "hits" the wallet, but not dangerous. It is much worse if you do not have water in the nozzle when you have heated the water. The reason is that the valve is clogged or the outlet fitting is clogged. Check both options. Did not help - change the valve.

Check valve for downhole pump is a device that allows you to move the flow of water in only one direction. In this case, from downhole pump to the points of draw-off. In order to understand the need to install a check valve inwater well , we will consider what happens in it when the pump is turned on and off.

1. The pump is on. Water, under the influence of the pressure created by the pump, rises from the well and enters the membrane accumulator and further to the points of draw-off. If water is not consumed, it accumulates in the accumulator before reaching the upper pressure threshold in which the pressure switch turns off the pump. There is no reverse flow of water into the borehole, since the pressure created by the pump interferes with this.

2. The pump is switched off. The pressure that created the pump disappears and now, in principle, nothing prevents water from flowing back into the well under the influence of gravity. So that this does not happen and there is a check valve. Without it, when the downhole pump was switched off, there would be no pressure in the system. And every time you turn on the pump, you have to fill it again and again with water. Even if a check valve is installed at the entrance to the diaphragm accumulator (from the pump side), all the pipes that are before it should be filled with water every time, spending electricity on it.

Where to install a check valve for a downhole pump

Here we are smoothly and approached the question of the location of this node. Clearly, it must stand between the pump and the membrane accumulator, otherwise the installation of the latter loses all meaning. But where is more precise? Most preferable is the location of the valve in the area of the downhole pump on the HDPE pipe. In this case:

1. When the pump is turned off, the minimum amount of water is drained back into the well, that is, a minimum amount of electricity is required to replenish this loss when the inclusion of a downhole pump.

2. Through the downhole pump, the minimum amount of water will flow in the opposite direction, spinning its impeller in the opposite direction (extremely undesirable operation of the pump).

3. The more empty space that is not filled with water between the diaphragm accumulator and the pump, the more the water will accelerate when the latter is turned on and, consequently, the more the hydro shock will be.

In practice, a check valve for a downhole pump is installed directly at the outlet of the pump itself. If the pump is shallowly loaded into the borehole and the borehole near the house, then one valve can be limited. If the pump is lowered deeply and artesian well is at a respectful distance from the automation, you should put at least one more valve. Usually it is placed next to the accumulator and automation.

Types of check valves for a pump in a well

Structurally, all check valves for a downhole pump are identical - a stainless steel or brass housing, inside which there is a spring-loaded plate made of plastic or metal with a rubber seal.

In conclusion, it should be noted that many models of downhole pumps have a check valve in their design - Grundfos, Pedrollo, Lowara, etc. But, for example, pumps do not have a built-in check valve.A non-return valve refers to a protective armature. In this case, the system is protected from unwanted water mixing. The valve starts up water in one direction and does not let it in the other. Those. prevents the reverse flow of water through the pipe.

Pumps and pump stations.

Most often, the check valve in the water supply system is put on pumps and pumping stations,

At pumps and pumping stations, the check valve prevents the return of water back to the well or well. Due to its presence, you can get water right after the pump is turned on. It is not necessary to wait until water displaces air from the pipeline if it has already been filled once.

In the video, I skaz generalized about pumps and pumping stations, taking both systems as one.

To be more precise, the pumps are immersed directly into the well or well, and a check valve is placed immediately after the pump, between the pump and the pipe.

Pumping stations are put on the surface. (at home or in a special room), and from the station to the well or well, a pipe descends, at the end of which there is a mesh and a check valve:

After the counters.

The check valve installed after the counters prevents the counter from rotating in the opposite direction, but this is not the most important. Where a more significant service makes the valve with such an installation, when it prevents the effect of squashing in a city apartment.

What is it, see the next video or publication.

At the input of water heaters

If you are connected to a common water system with hot and cold water, then when installing the boiler, install a check valve also on the hot water standpipe.

Otherwise, all or part of the heated water by your water heater will run into the riser in the neighbors down. Neighbors I think not upset hot water, well, you have to pay electricity to the meter.

Inside the eccentrics of some mixers.

Are present only in expensive single-use mixers.

Design

In the non-operating position, the valve is always closed. The shutter is supported by a spring.

Valves come with metal and plastic closures.

With a metal gate are used in heating systems. To open them requires more pressure than for opening the valve with a plastic closure. This should be remembered when building a new system.

It will be useful to know that if you take two ½-inch valves where one with a metal bolt and the other with a plastic one, then the first one will be one centimeter longer. If you change one to another in a finished system, then it's worth keeping in mind.

The valve body is assembled in two parts with a sealant.

Inside the case there is a shutter with a rubber gasket and a spring.

If water is drawn from a well or well, there should be a grid at the beginning of the pipeline. Otherwise, a fallen stone inside the check valve will make the system inoperable.

There are also very small check valves that are inserted into the half-current of the counters. This can be useful if there is no room to install a separate valve.

There are very small check valves that are put into the meter body at the output. Because of its design, this valve has too much resistance.

If you install it, the pressure in the system can drop significantly, and if it is so weak, then water can stop completely.

Look at these photos below and avoid installing such devices.

Cast-iron check valves installed in water meters.

I do not understand their meaning, because they almost do not work right after installation.

The old pipeline:

And an old cast iron check valve:

Of course, he can not fulfill his function:

For the normal operation of the water supply and heating system always install a non-return valve on water. This is one of the elements of the pipeline fittings protection, which allows the water and heat supply systems to function in the house without failures and frequent repairs. In some cases, the water return check valve is a good protection against the occurrence of unscheduled malfunctions and expensive repair with leakage. A non-return valve to the water ensures the passage of water flows only in a given direction, excluding returning the liquid back. On the body you can always see a bright arrow pointing in which direction the stream should be directed.

Operating principle

Water check valve - mandatory element water supply system. Specialists identify a number of points in which the use of the device becomes necessary:

- In the apartment of a multi-storey building, the supply of hot and cold water passes separately from each other. Each water stream has its own riser. As a rule, the water pressure in them does not coincide. When a person opens the tap, hot and cold water starts to flow. Due to the difference in the level of pressure in the pipes, there is an uneven distribution of the water supply to the tap. Those streams that come with high pressure go first. They lead to an increase in pressure in the main. Streams of water with lower pressure may have a reverse outflow into the pipe and riser. For many, the situation is familiar when cold water goes hot. To correct such an incident, use a check valve for water.

- When installing a storage heater (boiler), the installation of a non-return valve to the cold water inlet is mandatory. The peculiarity of the operation of boilers is that they are filled only with a head of cold water. During the heating process, the pressure inside the vessel increases, and hot water tends to enter the cold water main. The installation of a non-return valve eliminates this situation.

- In private modern houses The heating system consists of several circuits. In each of them a different temperature of the coolant. For example, in the building there is one circuit for the operation of the boiler, and the second one is intended for the heating system, the third circuit is for the warm floors. In each circuit there is a resistance, so they are equipped with different in their characteristics pumps. In order to prevent a situation where the pump provokes a reverse movement of the coolant with a smaller pump in the circuit, a reverse valve is used.

- Pumps for water wells must necessarily be equipped with a non-return valve. Taking into account that the pump can be located at a depth of tens of meters, in the event of a shutdown of the unit, water will necessarily rush back from the water pipe. Allow such a situation is impossible, the hose for the pump in this case will not save.

- By connecting heater to the main highways supplying the house, experts recommend installing a check valve on the heating main before entering the system. This ensures the correct direction of the coolant.

Variety of species

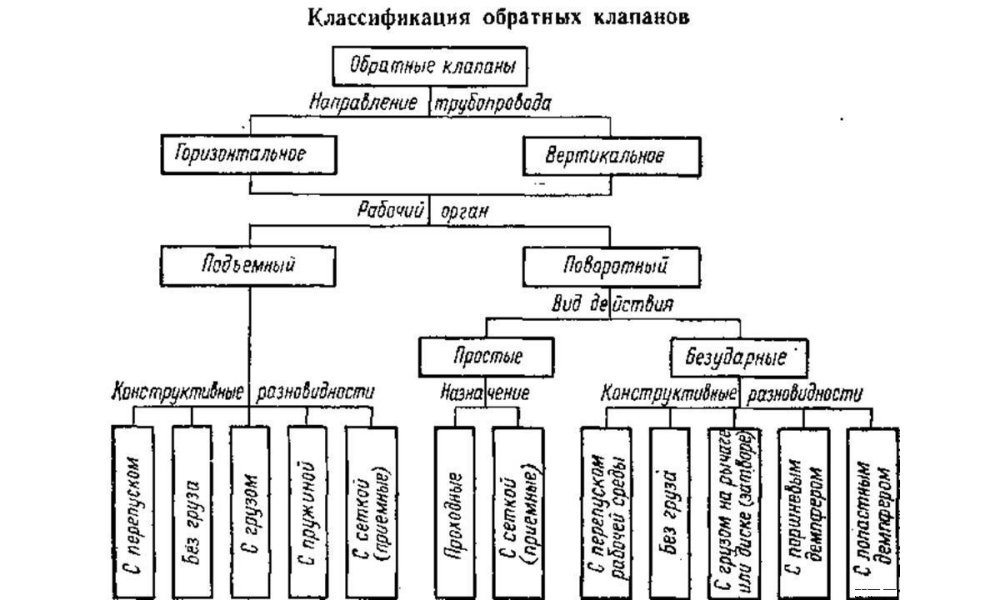

Check valves are divided into several types:

- Spring is the smallest. This element includes a special shutter - a disk or plate, which is pressed by a spring. In operation, the disk, falling under the pressure of water, is squeezed out, thereby providing an easy passage for water flows. If the pressure decreases, the spring presses the plate, blocking the outflow of water. The dimensions of the non-return valve of this type range from 0.15 cm to 0.20 cm.

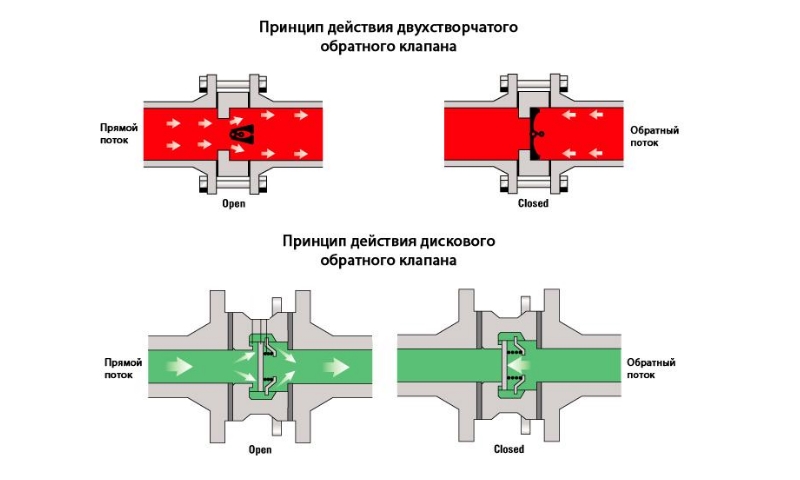

- Bivalve, as a rule, is used in overall and complex systems. For example, if a pump stops in the hydraulic system of the house, a large force water flow will occur, which will cause significant damage to the entire system. The principle of operation of the non-return valve is based on the fact that under the influence of a strong water flow the locking element folds in half. Strong water flows return the original position of the element, pressing it.

- In the petal device, the locking element is a spool. With a strong water pressure, the valve spins over, opening the way for liquid. It is worth the pressure to decrease, the spool falls and closes the access of the passageway.

- The principle of operation of the ball check valve is slightly different. The locking element is a ball with a spring. When low pressure he presses, closing access to the outflow of water. This type of check valves is used in sanitary elements, where pipes have a smaller diameter than in the common pipeline.

- The device of the non-return valve of lifting type includes a special element - a lifting slide valve. High pressure water will lift it, thereby opening the way for the coolant. As soon as the pressure has decreased, the spool will fall and prevent reverse flow. It should be noted that this type of valve is mounted only on horizontal pipes.

Purpose of the non-return valve for sewage

A non-return valve for sewerage is used to prevent the return of human waste. A crowded toilet is threatened with serious trouble if there is no reverse sewer valve. It is he who prevents a return to the drainage system when the general sewage system is blocked. Despite the importance of the question, this device has a fairly simple design. The non-return valve for sewage includes a special spring-loaded lever that is attached to the body and a special round plate with a rubber gasket. It is designed to close tightly. The pressure raises the constipation, and the water begins to flow. As soon as the pressure decreases, the lever is lowered and prevents the return of liquid to the system.

A non-return valve for sewage can be made of different materials. Traditionally, bronze, cast iron or stainless steel is used. In some cases, this device can be found made of polypropylene and polyvinyl chloride.

Installation of a non-return valve to the sewage system requires certain rules:

- Installation of the device is carried out only in the place from which it is easy to carry out inspection and maintenance.

- Choosing a model for sewage, it is important to take into account all of its technical characteristics.

- When mounting the selected valve, it is important to follow the direction indicated by arrows on the body of the device.

- Be sure to check the purchased device for tightness.

In order to install the check valve on the sewer easily and quickly, it is necessary to plan in advance the location of the device and prepare all necessary tools. A piece of surface is cut into the pipeline, into which a non-return valve easily fits.

If the pipe is cast-iron, it is necessary to provide a special adapter from plastic to metal.

Installation of a non-return valve is an important matter, which allows you to protect your house from penetration of unpleasant odors, noise and sewage. The installation works do not require special knowledge or training, the main thing is to do everything carefully and thought out.