Water heating from the stove. Features of low pressure systems. Installation on the base of a wood stove

In remote villages, many, weighing all the pros and cons, prefer stove heating. Autonomy has a lot of advantages, but it is difficult to heat a house of more than 50 m 2 using a furnace only qualitatively and evenly. Is that if you install a heat exchanger in it, to which you connect the battery. If water will circulate as a coolant in such a system, then it will be called water heating, if steam is steam.

Sometimes these two types of heating are confused. However, they have their differences, advantages and disadvantages. In addition, steam heating has long been banned in residential buildings due to unsafe operation. But it is much cheaper than water and, in addition, there are measures of protection. True, it is impossible to say about the ease of installation, on the contrary, to arrange steam heating in a private house, and even from brick kiln, you need to make a lot of time and effort. But first things first.

Differences between steam and water heating

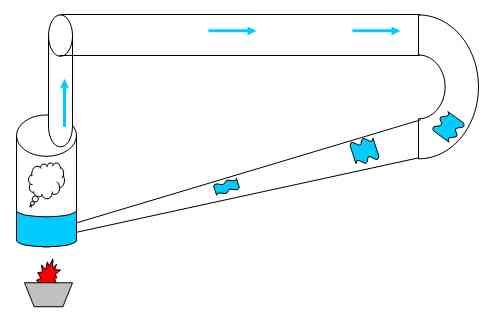

Steam heating works according to the principle:

- first, water is heated in a tank until boiling and converted into steam;

- steam goes through pipes to radiators, giving off heat;

- in batteries, steam condenses, turning back into water;

- water flows down the branches expansion tank and returns to the heat exchanger.

Unlike water heating, steam gives a large heat transfer, heats the room three times faster, has ergonomics. It requires small-sized equipment, which actually reduces the cost of the system as a whole. Another plus: the pipes in the abandoned house do not freeze during the cold season. Therefore, it is easy to start steam heating, arriving in the winter to the country, and when leaving, make sure that the fuel is completely burned out.

By the way, as a generator for steam heating, you can use not only furnaces, but also boilers operating on waste oil. But usually such a system is installed in garages and utility rooms for reasons of environmental friendliness.

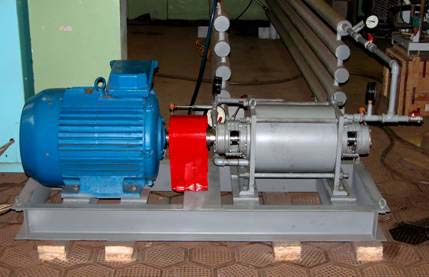

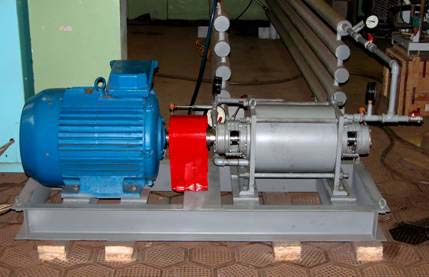

The device of the boiler operating on waste oil

Disadvantages of steam heating and how to eliminate them

System imperfections:

- radiators from steam heat up above 100 ° C, which is why they are dangerous, especially for children and animals;

- the steam heating system is noisy;

- control temperature conditions difficult;

- impossibility of the device of water heat-insulated floors.

The first drawback can be eliminated by protecting radiators and lead pipes with screens. There is a huge selection of these decorative elements of the interior of wood and plastic.

The wooden screen will protect against accidental contact with hot radiators

The noise effect in the system can be significantly reduced by using anti-noise brackets for radiators during their installation, and the steam generator itself can be set up in a separate room.

The third point is difficult to eliminate. But for the fourth solution there is - water heated floors, if desired, can be replaced with film infrared.

Attention! It is undesirable to plan a brick oven with a steam generator at the same time for heating and cooking, since in summer it will be impossible to use it anyway. Or, it is necessary to think up an alternative option for the warm period. For example, make a summer stove on in the open air.

Also can not be used in the system plastic pipes, they will not withstand the temperature regime.

Installation scheme of steam heating from the furnace

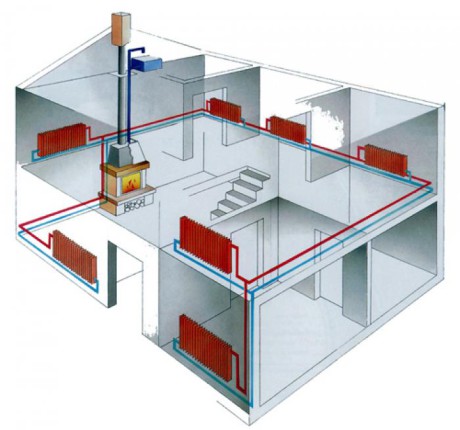

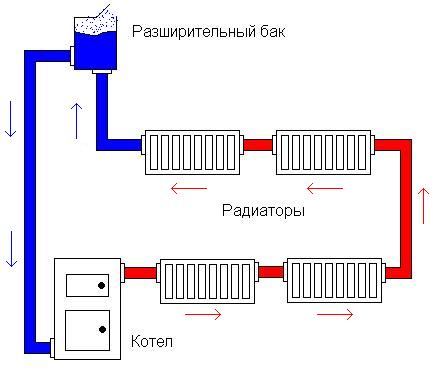

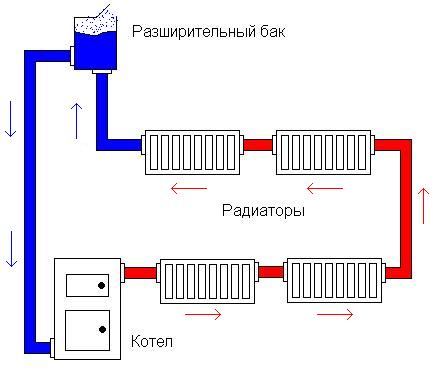

- Natural and forced circulation system

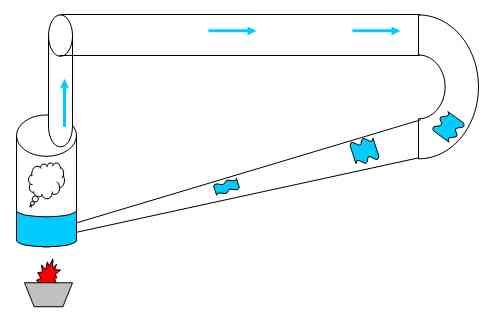

The system operates on the principle natural circulation, requires the location of the heat exchanger below the level of radiators and all pipes at an angle. For forced system A pump is required to ensure uninterrupted heat exchanger circulation.

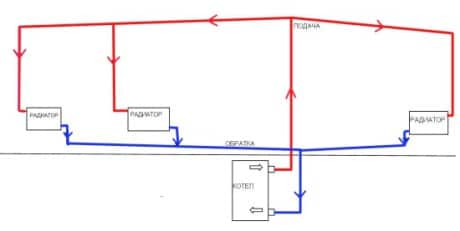

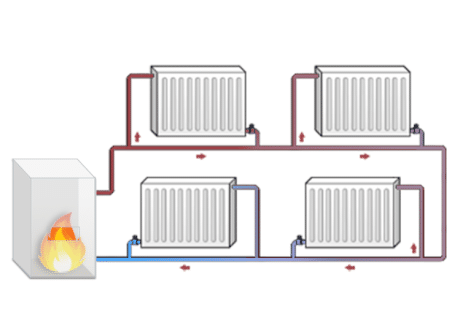

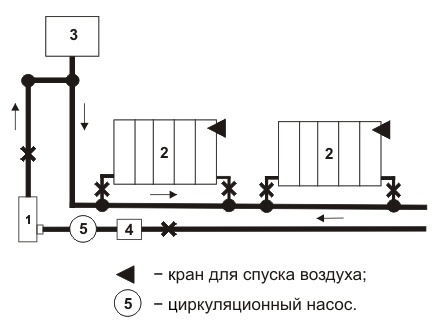

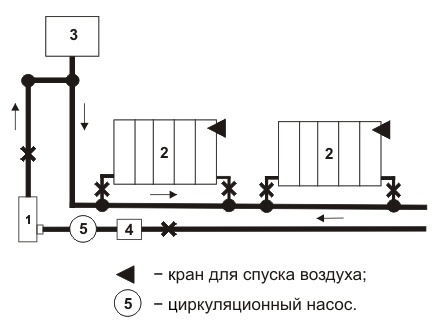

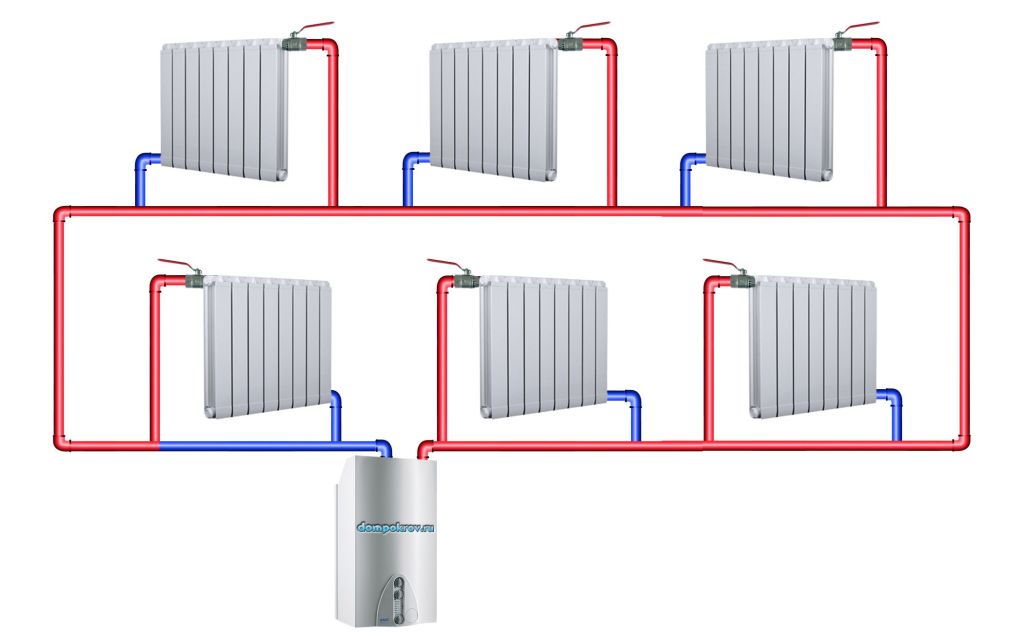

Schemes also happen one-and two-pipe.

- One pipe design private house steam heating

This scheme works on the principle of serial connection of radiators. The coolant moves through the pipe, moving from one battery to another. As a result, the first radiator is the hottest, and the last - almost cooled. Therefore, it is recommended to use such a scheme for rooms with a small area - from 40 to 80 m 2.

Single pipe heating circuit

This system is more suitable for houses with large areas, two-story cottages. It differs in that the radiators in it are connected in parallel, with the help of two pipes: the inlet and outlet (condensing). In this scheme, the coolant is supplied to all radiators with the same temperature, as it does not have time to cool down.

Two-pipe heating scheme

How to arrange steam heating from the furnace with their own hands

Equipment and materials

For the device of steam heating will need:

- radiators (under each window);

- the heat exchanger is essentially a water-tube boiler or steam generator;

- pipes for steam lines and condensate drainage - it is better to give preference to materials resistant to high temperatures: galvanized steel or copper;

- elbows, connectors, pipe clamps, radiator brackets, stop valves: valves, valves for air release;

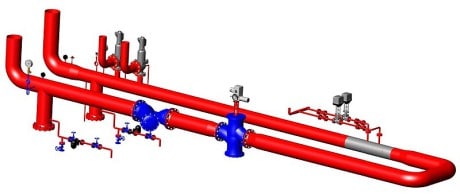

- hydraulic shutterused for the purpose of steam line drying;

- pressure reducing valve to reduce system pressure;

- reduction and cooling unit;

- welding machine;

- condensate collection tank;

- pump.

Pressure reducing valve to reduce system pressure

Expensive equipment is better to rent.

The heat exchanger for the brick furnace will have to be made independently or ordered. To do this, you need pipes made of metal, wall thickness of 2.5 mm and a welding machine. You can connect them as in the figure or make in the form of a coil. The main thing is to monitor the quality of welds. The calculation is done approximately like this: 1 m 2 of the coil surface gives up to 9 kW.

After the construction is made, it is necessary to check it. To do this, pour water into it and make sure that there is no leakage. However, this method is not very informative, because welds may have slag inclusions, which in the absence of excessive pressure will not be detected.

It is best to check the quality of the seams using the “kerosene on chalk” method. To do this, chalk all the welds and pour kerosene inside. In the case of the smallest pore, the chalk will darken as kerosene will leak into it.

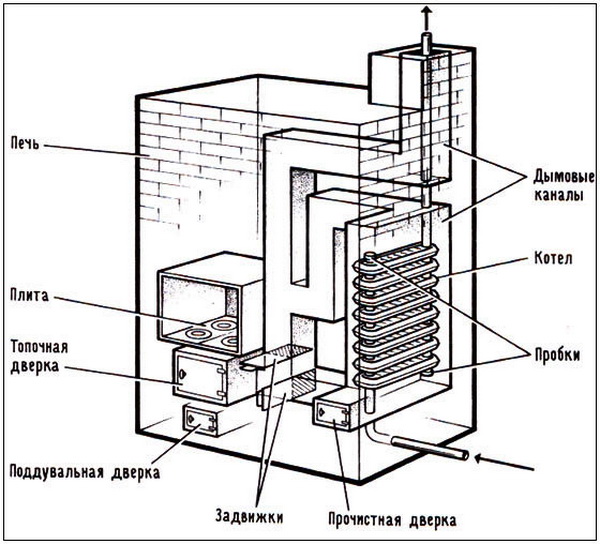

Contour for brick kiln

Another version of the heat exchanger for the furnace

Sequence of work

The heat exchanger is built into the furnace at the stage of its laying directly into the furnace

It should be borne in mind that if you plan to do the oven for cooking, then the pipes in the upper part should not be, otherwise they will interfere. Then it is better to make a heat exchanger on this principle.

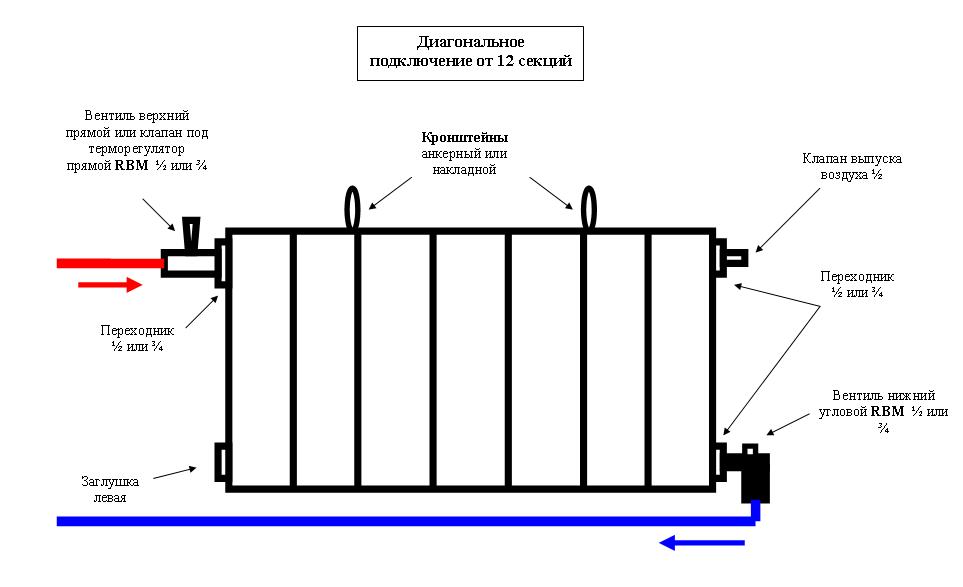

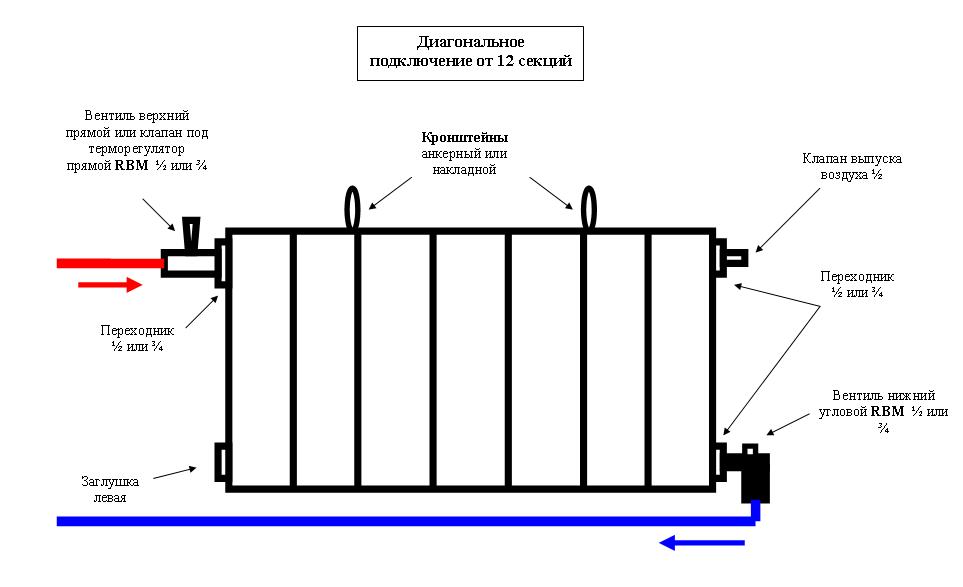

Further, according to the scheme, radiators are mounted under the windows. Connect the inlet and outlet pipes to them. For natural circulation - with a slight slope of 3 mm per meter. Each convector should be fitted with an air vent.

For safety reasons, it is advisable to install shut-off valves in front of each radiator and one in front of the entire system. At its beginning, you should also install a pressure reducing valve and a cooling unit.

At the end of the system, a condensate collection tank is installed, from which water also flows back to the heat exchanger on a sloping basis. It is not desirable for this purpose to use a membrane dilator, as it is designed for t up to 85 ° C.

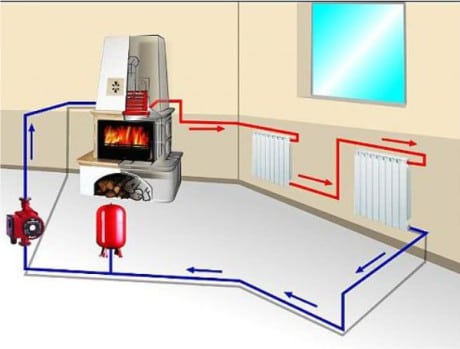

In the forced circulation system, in the return pipe, a pump is installed in front of the furnace.

Nuances when using steam heating from the furnace

In brick kilns with a heat exchanger, more soot is produced in the chimney than usual, and it must be cleaned more often.

With a gravity system, the furnace will have to be built in the basement so that the condensate can flow freely to the lowest point.

Do not neglect the installation of valves - they are necessary for safety and prevent accidents. Since the pump requires electricity, it must be borne in mind that in the event of a disconnection from the mains, it will be impossible to stop the furnace operation.

Steam heating in wooden house installed on the same principle as in the brick. It is only necessary to comply with fire safety measures - to protect wooden surfaces from overheating.

Video: combined heating system of a private house

By steam heating is meant a system in which heated water acts as a heat carrier. Such heating was widely used in the nineteenth century in residential buildings. Soon the steam was replaced with water, but the name of the system (in our case, erroneous) remained the same.

Water vapor efficiently transports and transfers heat, but was refused such heating due to the strong heating of the heating equipment (its temperature exceeded 100 ° C). Any contact with the surface of the device caused a burn, and the rupture of the main line led to serious injuries and even death.

Note! In view of all this, to date, steam heating (in its original form) is prohibited for use in public residential areas.

However, the ban does not apply to private houses, so anyone can do as they wish. But before making such a serious decision, you should weigh the pros and cons.

- The price of such a system is quite low.

- Steam heating does not defrost, therefore it is possible to use it year-round without the risk of freezing the coolant.

- Heat losses in heat exchangers are practically reduced to zero.

- In such a system, energy is transmitted by radiation and convection. For comparison: it is the convection component that prevails in the water component, while the heat transfer from the radiators is rather low.

- During installation, radiators and pipes of smaller size / diameter can be used.

disadvantages

But there are also disadvantages that you need to know before installing.

- The steam circulating in the system creates noise.

- The temperature of the heating equipment may exceed 100ᵒС.

- In the event of a breakthrough, an increased emergency hazard occurs.

- Susceptibility to corrosion.

Principle of operation

The heat generator in the steam heating is a boiler operating at low pressure - it forms hot steam and passes it on highways. When moving, steam condenses and settles on the walls of the devices, giving off a large amount of heat - this is the secret of high system performance.

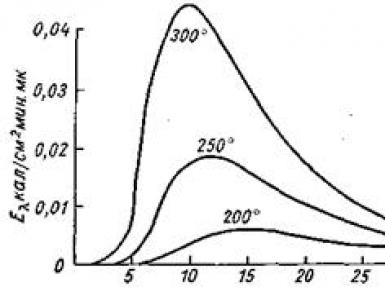

Note! During the condensation of 1 kg of steam, more than 2,400 kJ of energy is released, while cooling down the same amount of steam to 50 ° C produces only 110 kJ. The condensate itself after sedimentation flows down and enters the heat generator in a natural way or with the help of a circulation pump.

Vapor pressure depends on the type of system:

- in conventional steam heating it is above atmospheric, but does not exceed 6 atm .;

- in vacuum systems it is below atmospheric.

Adjustment of heat is carried out by changing the intensity of vaporization. If the need arises, the flow simply overlap, which creates conditions for cooling the house.

Heating equipment here are traditional radiators made of cast iron or steel, as well as finned pipes.

According to another classification, steam heating can be:

- closed - in this case, the condensate returns naturally, for which pipes of larger diameter are used;

- open - here water accumulates in a special tank and is pumped through with a pump.

DIY steam heating

Arrangement of steam heating consists of two stages - design and actual installation.

Stage 1. System design

Once again we remind you of the peculiarities of using steam as a coolant - this is a high temperature of the pipeline and radiators, as well as an increased accident rate. When all the pros and cons are weighed, you can begin work. First, a future system project is created.

First, the required power of the heat generator is determined. This takes into account the area of the house - if it does not exceed 200 m², then a device with a power of 25 kW is enough, but if it varies between 200 m² and 300 m², then a minimum of 30 kW will be required. Based on this information, the boiler is selected. When buying, consider the following factors:

- the type of fuel to be used;

- the possibility of heating water for domestic needs.

Note! The choice of a heating boiler is one of the most important stages in the arrangement of steam heating.

Heating scheme

![]()

![]()

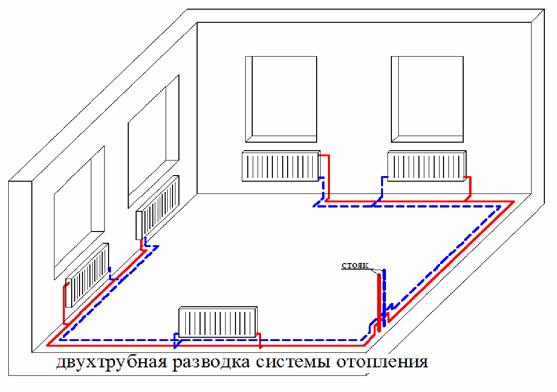

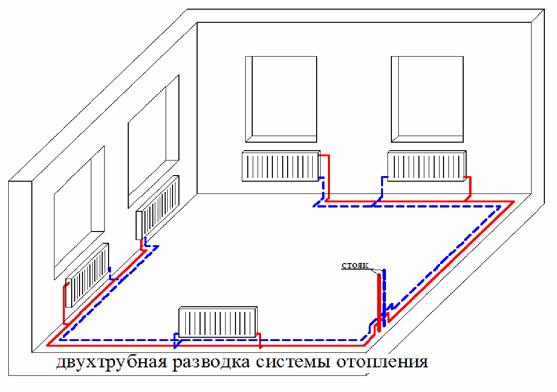

With the scheme also need to decide in advance. The choice of one or another option depends on:

- the location of the boiler;

- the area of the heated room;

- conditions for installation heating appliances;

- the required number of these devices.

In short, this is quite a difficult choice, which will help the video below.

Video - Features of working with steel pipes

Pipes

For steam heating is not allowed the use of conventional plumbing pipes in view of high temperature the whole system. For this reason, the choice of pipes should be given great attention, even if it is small.

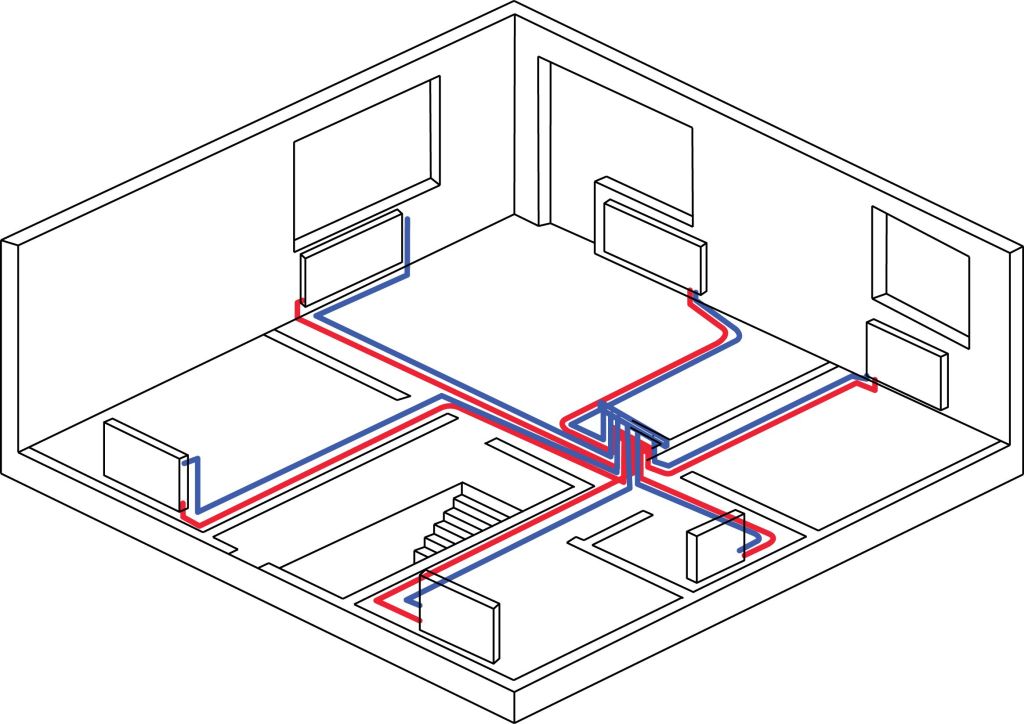

In order to facilitate assembly work at the design stage you need to determine:

- radiator location;

- pipeline length;

- installation sites of distributors, branching lines, adapters and so on.

Note! All this data is transferred to paper. A rough sketch of the steam heating is made, where all the necessary details are indicated.

Issue price

After drafting the project, future costs are determined. It is difficult to say how much the equipment of such a system will cost, without reference to heating devices, scope of work and specific conditions. We note only that, according to experts, steam heating in any case will be cheaper than ordinary water.

Stage 2. Installation

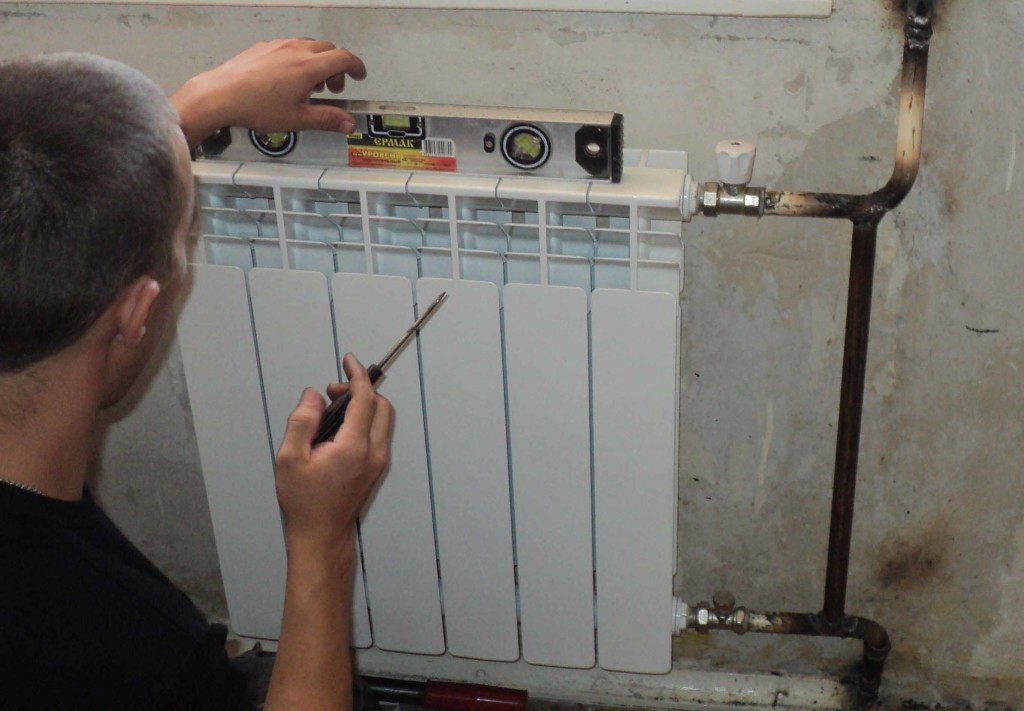

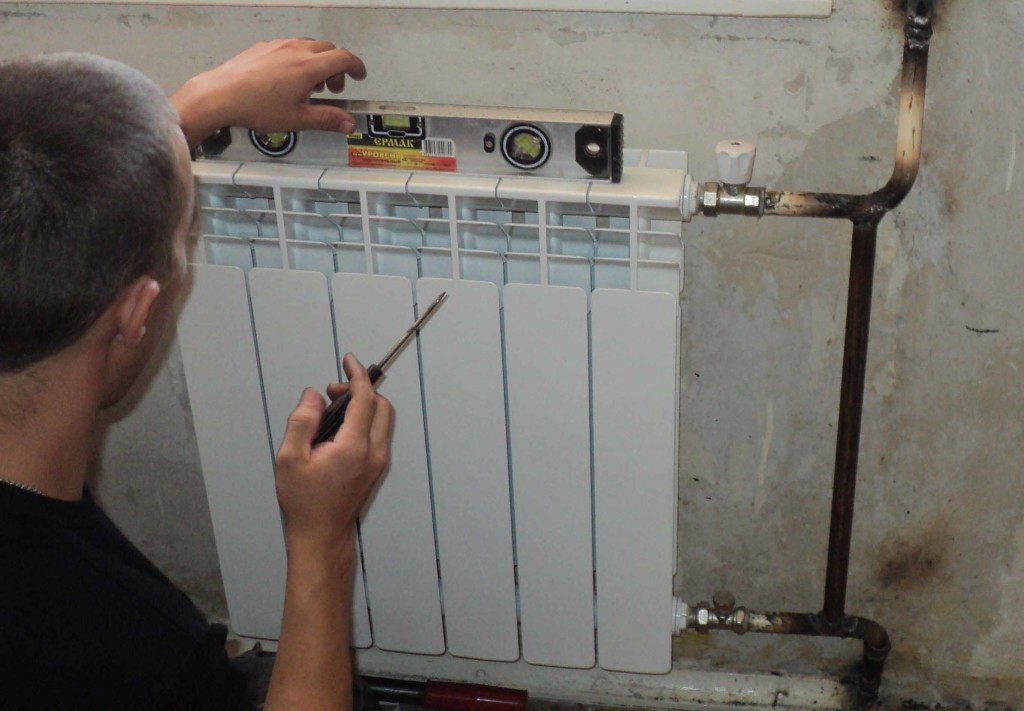

Step 1. First, an exact layout is drawn based on the sketch.

Step 3. The expansion tank is attached. It must be connected to the pipeline leading from the heat generator to the radiators. Another important point: the tank must be installed at the highest point of the heating system.

It can be closed and open, with and without overflow.

Note! Professionals advise installing an open tank, moreover, in the maximum proximity to the heating boiler. Although this scheme may well be suitable for a closed-type device.

Step 4. Installation of pipelines. This happens as follows: the pipe is supplied to the radiator, cut off if necessary, after which the leads and inputs are connected. Then the pipe is likewise supplied from the first radiator to the second, then from the second to the third, and so on.

Note! It is recommended to equip each radiator with a Mayevsky crane to remove air plugs that have formed.

Step 5. The circuit closes, that is, it is brought to the beginning - the heat generator. It is important that the boiler is equipped with a filter and (if necessary) a circulation pump.

Note! Hot water vapor can go from the boiler, mounted in any convenient place - in the garage, summer kitchen or in the house itself. This will not affect the quality of heating, and the financial side of the issue fully depends on the required length of the pipeline.

In this case, the installation of the heat generator is no different from a similar procedure in a residential area. At the same time, the bay / drain unit can be equipped on any part of the highway. This node is necessary to drain the coolant at the end heating season or before repairing the system.

Video - Installation of a heating boiler

Step 7. Testing of all heating devices is carried out. If they are new, then for a trial run, it is advisable to invite a specialist.

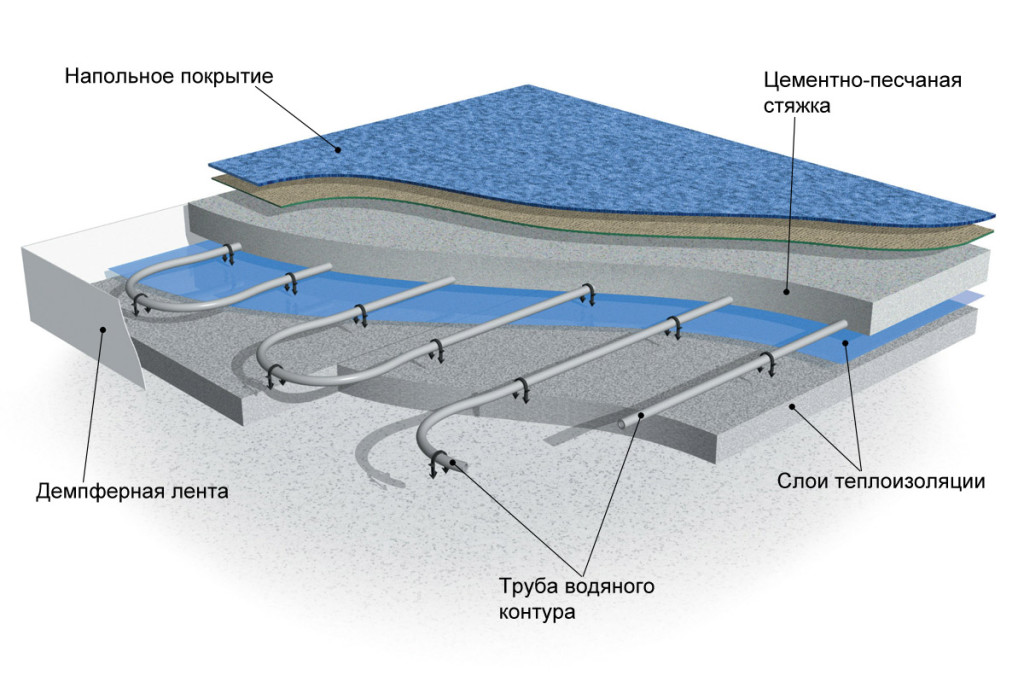

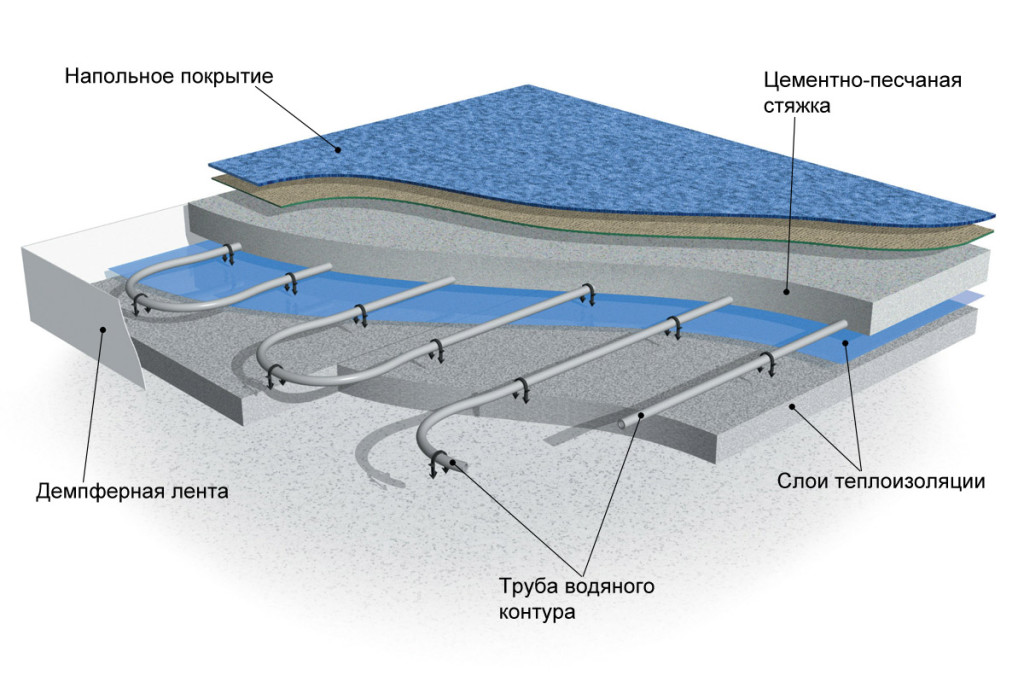

System "warm floor"

"Heat-insulated floor" gains the increasing popularity recently. Often it is created on the basis of electric heating, but if desired, you can use water. Installing such a system is a complicated and time-consuming procedure. Under the flooring stacked polypropylene pipes (it is possible to use also metalplastic) on which the hot heat carrier will circulate.

The layout and installation of the regulator

Such a variation of the “warm floor” system has a lot of advantages in comparison with the electric one, the main of which are low cost and low power consumption.

findings

The use of hot steam can hardly be attributed to the popular types of heating, moreover, according to the current legislation, it is prohibited to use it in residential and public buildings. But sometimes in order to save it is still installed in garages, outbuildings and even in private homes.

Despite the emergence of modern building materials with high technical characteristics, some private house owners choose water heating from the stove on the wood, not modern.

Water heating from the wood-burning stove is chosen not only because of the availability and financial advantage, but also because of the large choice of fuel, stylish appearance and the ability to use heat units in conjunction with other heating schemes.

Schemes of water heating from the stove

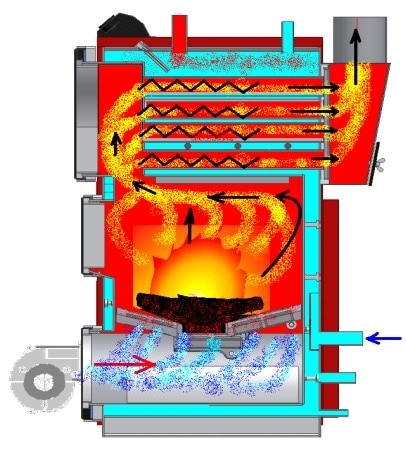

Traditional heating is a construction built of brick and having a chimney, a furnace niche, as well as an ash box. Attention should be paid to the chimney system, since the heating of the room takes place due to the heat, which the carbon monoxides, which have passed through the channels of the system, “emit” as it were.

Such a scheme is suitable for small houses, as a traditional stove is not capable of heating a large area (water heating from the stove will be relevant here).

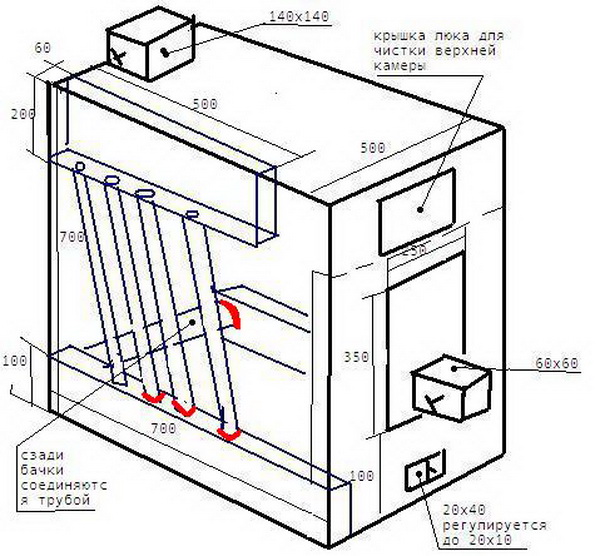

In order to build such heating, a heat exchanger is placed in the furnace niche, which will heat the coolant. In general, this kind of system can increase the efficiency of heating and increase the heating area. The U-shaped design of the stove is the simplest - the heater is made from a sheet of metal with a thickness of at least 4 mm.

- scheme: a coil is installed in the form of a register, which is made by welding pipes. Conditions: pipe diameter is 50 millimeters, the minimum wall thickness is 0.35 centimeters. A register with a heat exchanger is heated in a firebox from a burning flame, after which the combustion products flow upwards and make three strokes, heating the brick walls.

Two-purpose Cooktop Pattern

This design does not have long chimney channels, as heat is supplied from the combustion products by means of a water boiler. Heater power should be about 9 kW, and the size of the heat exchanger - 1030x650x780.

In the process of burning wood, the coil is directly heated, which flue gas receives additional heat, after which the flue gases enter the canal, which is located between the oven and the hob, round the oven and exit through the chimney.

"Two-chamber furnace with water heating K.A. Dmitriev "is the most common scheme of all. Such a system is endowed with separate chimney channels and two fire chambers, one of which is designed to heat the oven, and the second - to provide water heating from wood stove. unite in one. The furnace parameters in this version are 1500x680x770 (the last indicator is height), and the power is 9.5 kW.

When the first furnace niche works, the flue gases envelop the oven and then go to the gas duct located under it. The water heater, however, does not participate in the process, which is very convenient for the summer period. The second chamber begins to sink with the onset of cold weather, when it is necessary to warm the house effectively.

Installation

Install a stove with a water circuit in two ways:

- "From scratch" (laying a new furnace on the size of the heat exchanger).

- The installation of the heat exchanger can occur in an existing niche. Unlike the first option, the heat exchanger is made according to the size of the structure, and not vice versa.

It is important to know that the size of the radiator (in both cases) along the internal contour should not exceed 3 cm - this is necessary in order to avoid boiling water in case circulation is weak. The thickness of the walls of the radiator should be in the range of 3 to 5 millimeters. If the thickness is less, the walls may burn out, and the radiator will stop working. The fuel used is only coal and firewood.

Between the wall and the boiler should be a distance equal to one centimeter. If the radiator is made of steel, then the distance can be reduced by 50 mm. If pipes were used for the manufacture of the radiator, the gap should be equal to 1.5 cm. You should also take care that the plate can be removed to clear the register.

Heat exchanger installation

To install the heat exchanger in the erected furnace in two ways:

- Without parsing top part. This method is relevant in cases where it is possible to remove the hob, the structure itself, while not disassembling at all. In order to do this correctly, it is necessary to make holes in the fire box walls for water heating pipes that would be connected to the boiler.

- By disassembling the top of the structure. After installation of the boiler, installation and restoration of the structure to the previous form is carried out.

The number of chimneys and their direction during installation can be changed, the main thing here is not to overdo it. If the thrust rate is normal, then nothing needs to be changed.

It is quite possible to dismantle the furnace with your own hands - for this you must first draw a sketch of the location of the bricks in all the rows, which is necessary so that later you can easily assemble the structure back.

- In the construction of private houses, the construction of a boiler room is of particular importance, since it must fully comply with various building codes and regulations ....

- Natural gas is not only the most economical and efficient, but also the most risky type of fuel from the point of view of fire safety and explosion safety - that is why the device ...

For a long time and until today successfully solves the problem of heating rooms in a private house. However, having a living area of more than fifty meters, it is hardly possible to achieve a comfortable indoor air temperature. It can not do without additional heat exchanger and radiators. Steam or water can circulate as a coolant through the pipes (hence the name).

Differences of steam system from water

Some people think that water and steam heating are one and the same, although they have significant differences. And the most important thing is that according to the norms of SNiP, steam heating is prohibited for use in residential buildings.

What is the advantage?

When using steam as the heat carrier heat transfer heating appliances much higher, and the room warms up 3 times faster. Such heating is very easy to start even after a long absence, because pipes do not freeze and do not need to fill them with water or other coolant

The steam heating system has another significant advantage - it is cheaper than water heating due to compact and ergonomic equipment, for example, pipes of smaller diameter are used than for a water system.

Negative sides

The most important negative feature is a short service life. Due to the inability to smoothly adjust the operation of the system, the rooms warm up with different intensities, which creates certain inconveniences.

Pick up best option work is very difficult. Among other things, when pipes and radiators are filled with steam, an unpleasant noise appears. When steam heating pipes heat so much that you can easily get burned.

Principle of operation

The heat source can be a stove or boiler, where the water is heated to 100 ° C and begins to evaporate. Then the steam enters the batteries in the batteries and cools to form condensate. The resulting water is return pipe flows into the heat exchanger.

When choosing a boiler as a water heater, its performance should be taken into account, which depends on the area of the room. In other words, the larger the heated area, the more powerful the boiler must be.

In those houses in which steam heating is already installed, the solid fuel boiler is most often used. Gas heat generator has the highest efficiency, but to use the electric boiler for heating a private house or other premises is economically unprofitable due to high electricity costs.

Bake

If a private house already has a stove, it can be successfully used as a heat source. First, the dismantling of the furnace equipment may entail additional expenses for repairs. Secondly, coal and firewood are cheap energy. And thirdly, the operation of the furnace does not depend on the centralized gas and electricity supply.

As a steam generator, a heat exchanger is used, which needs to be made independently or ordered. The design itself consists of metal pipeswelded to each other. The key point is to check the heat exchanger for the stove for tightness.

For this purpose, kerosene is poured into the device, and the places of the seams are circled with chalk. If the chalk has darkened, it means that kerosene has penetrated there and it is impossible to use such a device for a steam heating system.

Type of circulation system

Steam heating at home does not always require a pump, as with natural circulation the pipe layout allows water to move in a closed circle according to the law of gravity, without the forced action of electronics.

The location of the radiators and the outgoing pipeline is at its highest point relative to the incoming one. The difference in water temperature causes it to constantly move around the system. Forced heating system operates with a pump.

Forced heating system.

Ways of implementation

Steam heating in private or country house can be built on a single or two-pipe scheme.

Monotube

In the first case, the batteries are connected in series. Steam passes through pipes from one radiator to the next, heating the first battery more than others. By virtue of this particular one pipe system suitable for small rooms (up to 80 m²).

Twin tube

The two-pipe heating scheme will cope with the main task in large houses. It heats all the batteries evenly, since the inlet and outlet pipes are connected to the radiators in parallel.

Installation of heating from the furnace

Steam heating is much more difficult to install than hot water, especially if you organize it from a wood-burning or coal-burning stove. Therefore, security measures during installation and during operation will have to be given special attention.

Necessary equipment

Those who still decided to do steam heating with their own hands, will need the following equipment:

- radiators that are installed under each window;

- water boiler or steam generator (depending on the type of heating);

- heat-resistant copper or galvanized pipes through which steam and condensate will be drained;

- connecting and transitional elements (clamps, elbows);

- fasteners (brackets);

- shut-off devices (exhaust valves for air exhaust, valves);

- a hydraulic valve with which the steam line is dried;

- pressure reducing valve (reduces steam pressure in the system);

- cooling mechanism with gear;

- container for condensate;

- pump;

- welding machine.

Installation of system elements

During the laying of the furnace, a heat exchanger is integrated into its furnace. Further, following the schematic drawings, radiators with air release valves and pipes (inlet and outlet) are fixed under the window openings.

At the beginning of the steam heating system, they usually install a cooling structure and a pressure reducing valve, and in the case of forced circulationput a pump in front of the stove. The container for collecting condensate is installed at an angle to the end of the heating chain. From it, water flows back into the tank.

A brick stove chimney with an integrated coolant tank needs to be cleaned more frequently.

When arranging natural circulation, it is better to make a furnace in the basement of a private house. This will allow free draining of condensate to the lowest point.

Do not ignore the installation of valves. They ensure the safety of the entire steam heating system and prevent emergency situations.