How to disassemble the tap on the sink. How to disassemble a single-lever ball or single-arm mixer. Features of the design of bathroom faucets

Every owner wants to know how to disassemble the faucet in the kitchen.

In the article you can find out how this is done.

First, we describe how to install a faucet in the kitchen.

Such a task, as an independent or any other types of faucets in the kitchen, requires a considerable set of tools. From an electric drill to a hex key for small screws.

In the pharmaceutical industry, various cutters, crushers and mills are used. Cutters mainly allow rough grinding of fibrous plant material. They can be levers with one or more knives. One-legged boots have a low performance and are suitable only for hard work. Multicolor more powerful knives are located in the form of a cross. The blades rotate rapidly, and their cutting surfaces cut the fabric very quickly and efficiently.

Crushers use the effect of pressure, friction, impact or impact and crush material. They are suitable for processing brittle and hard material up to 1 mm in size. Depending on the design of the working arms and the surface and the grinding process, jaw, cone and roller crushers are recognized.

In any case, you need the following:

- the adjustable wrench is not less than 35 mm, or a whole set of spanners;

- crosshead screwdriver;

- roulette;

- level;

- set for fastening the crane.

Council. In our time, the sealing of the pack and the oil paint is outdated. One of the reasons is the difficulty of disassembling if necessary in many years. It is much better to use a fluoroplastic tape, which is now sold everywhere.

The basis of the machine are two metal plates, one of which is rigid, and the other is mobile. The moving jaw is pressed against the fixed plate at regular intervals. In the reverse movement, the material to be crushed falls out of the crusher.

The size of the ground particles can be adjusted by means of an adjusting screw that increases or decreases the distance between the jaws. The surface of the jaws is smooth or with grooves, depending on the type of material being processed. Advantages of the crusher are reliability, ease of operation and easy replacement of parts. The drawback is strong bumps that occur during machine operation and uneven filling.

Use a sealer in each threaded connection. When winding, make sure that the ribbon is flat on the thread. After installing the mixer, turn on the water and check all connections for leaks and dripping.

In addition to ribbon filler, a special thread is sold in the cassette, from where it extends beyond the tip.

If the water oozes, do not be afraid to pass! Turn off the water again, unscrew the connection and do it again neater. When tightening the seals are wrinkled, so you have to use a new piece after disassembly.

Compared with jaw crushers, cone crushers have lower power consumption, higher power, more convenient and reliable filling. The material is crushed by friction, impact and pressure in the adjustable slot between the body of the device and the rotating cone. The working surface of the cone is coarse or ribbed.

Cone crusher grinds and dust, for example, root means, dry seeds and chemicals. The disadvantage is a complex design with the replacement of complex parts and the possibility of clogging the gap with a thin material. The crusher is formed by two cylindrical disks, which are equipped with interchangeable ribs or teeth on the surface. Depending on the type of device, one cylinder or both rollers rotate either at the same speed or at different speeds. The material is fed between the rollers and crushed by grinding and friction.

Council. Spread the inner thread before laying the technical petroleum jelly, this will greatly facilitate the subsequent possible disassembly after many years, and additionally protect against corrosion.

Begin the installation by carefully reading the instructions. Typically, it shows the installation scheme. Do not rush to throw out the instruction, it can come in handy when repairing.

The adjustable distance between the rollers determines the particle size. By grinding, it is possible to grind the substances to particles of 100 to 10 μm in size. Hammer, whip and ball mills are used. For a very fine grinding and homogenization, a colloid mill can also be used.

Dismantling the mixer for spring replacement

The mill consists of a storage chamber, a loading hopper and screens. The material is crushed both by hammer blows and by impact of particles on the wall of the working chamber. The particles, crushed to the required size, are sieved through a sieve forming the bottom of the working chamber.

For a hard landing, the mixer must have eccentrics to adjust the landing distance between the cold and hot water connections.

If you have flexible hoses in a metal braid, you will not have to adjust anything. However, do not save, cracked poor-quality nuts and hoses always break down at the most inopportune time.

How to disassemble a two-valve mixer

The mill is used to pre-dry the dry material. Humidity should not exceed 15%, otherwise - sticking particles and clogging the screen. The pin mill is a very efficient mill, consisting of two metal disks arranged along a vertical axis. Discs have opposite to each other the wings of metal pins, so that one of the wreaths of one of the wheels is installed between the wings of the second wheel. If only one of the disks rotates, we are talking about disassemblies.

Before tightening the nuts, lubricate the internal threads with technical petroleum jelly, as mentioned above.

Tighten the nut with a wrench carefully: first tighten with your hands as much as you can. Quality nuts should be easily twisted. After that, turn the key for one and a half to two turns, ending with the rubber seal.

Tools and materials

The disintegrator rotates both disks. Each disc has its own shaft and a separate drive. The speed of the material fed to the mill must be controlled so that the mill does not melt. That's why the valve valve is in the hopper. Centrifugal force rushes to the edge between the rows of pins, strikes them and is crushed to small particles. They are centrifugally removed from the mill chamber. The pin mill is widely used. Its advantage is considerable productivity and very fine grinding.

It is better not to tighten so that the nut does not crack. After turning on the water, you can tighten the nut until the leak stops.

Try to set the level, strictly horizontally. Do not skew, otherwise the mixer body may crack, because it is constantly subjected to mechanical stress.

Place the mixer on the sink, and screw the bottom of the hairpin, a half-washer and sealant is put on it, and the nut is pulled to the sink. Then screw the flexible hoses to the tap and to the water supply.

The disadvantage is the gluing of the particles with the walls, the wear of the pins and the heating of the material. This is partly offset by the fact that the rapid movement of the discs creates a negative pressure, which is used to cool the device and material. In addition, the reduced pressure allows you to move the particles.

The mill is suitable for grinding dry and wet substances, sticky and hygroscopic preparations, waxes, plant material and a material with a higher oil content. A ball mill consists of a hollow cylinder or drum filled with steel, stone or porcelain balls. When the roller rotates, the balls are transferred along the circumference of the shell.

Installing a two-ventilated mixer

Two-valve mixers are available with a tee or with tubes. If you have a variant with a tee, from the bottom there is a collet (a cut sleeve with a thread), a nut is screwed onto it. Thus the mixer is attached to the sink.

Mounting the mixer with the tubes is described in the previous paragraph.

Important conditions for effective grinding are the difference between the diameter of the cylinder and the diameter of the sphere, the total number of spheres, the weight of the material and the speed of rotation. It is necessary to determine the critical rotation speed so that the spheres are not transferred by centrifugal force, they do not remain on the circumference of the grinding chamber, but gravity forces come on them.

A ball mill is used for very fine grinding before micronization. The material is crushed by the action of spheres, friction and wrinkles between the spheres inside the drum. The disadvantage is the grinding time, the possibility of particle aggregates and intermittent grinding.

Now you know everything about installing the cranes, then describes how to disassemble the kitchen faucet.

Disassembly of cranes

When you look at the tap in the kitchen, it does not have a single screw. How to disassemble the water tap? There are a few secrets in this case.

First, let's define the types of cranes.

It is often possible from people far from plumbing to hear questions such as:

The colloid mill is suitable for very fine grinding. In addition to grinding, it is also used for dispersing and emulsifying in the preparation of suspensions or emulsions. The main part of the device is a conical stator, in which the rotor rotates on a vertical shaft. The gap between the two parts is very small and is regulated by a micrometer screw. The destructive material is extruded through the slot and exits through the outlet. The material is crushed mainly due to friction, to a lesser extent from the impact.

Tips for extending the period of operation of the mixer in the kitchen

A great advantage of the mill is that it allows the grinding of dry substances, as well as substances dispersed in liquids and liquids. The disadvantage of the mill is that during the grinding process, all of its parts, which need to be cooled, become very hot.

- how to disassemble the ball valve;

- how to disassemble the ball valve.

There is some confusion. People often confuse ball valves with faucets with main ball valves. Trunk cranes are used to shut off water in the main or its branches, and modern main ball valves are not collapsible.

Micronization gives very small particles with dimensions in micrometer units. The jet mill consists of a grinding chamber installed around the periphery by means of a set of nozzles arranged in a tangential direction. Compressed air or other gas is sucked into the chamber to hold up the material and give it high kinetic energy. When the particles are twisted, fragmentation occurs due to the mutual action of the particles on themselves or the walls of the vessel. Then, the ground particles are captured by the air flow into the filter.

Features of the design of bathroom faucets

The grinding performance is affected by the direction of the nozzles and the amount of material. The advantage of the mill is the high efficiency of milling, the possibility of cooling and, consequently, the grinding of thermolabile materials. In this mill, it is also possible to grind substances exhibiting a great tendency to form agglomerates. The disadvantage is the high cost of acquisition and noise.

The most common in our time cranes: single-lever. Such a mixer can have a ball or ceramic cartridge with flat-fit plates in the housing. The merit of the latter is a simple substitute.

And that version of the crane and the other can fail if solid particles fall. Therefore, it is necessary to have grid filters at the inlet of hot and cold water into the apartment.

Decorate 25.0 g of sucrose in a fine powder in a porcelain coating and pass through a 180 μm sieve. Describe the cone crusher and its use. Describe the crusher and its use. Describe the hammer mill and its use. Describe the pin mill and its use. Describe the ball mill and its use. Describe the colloid mill and its use. Describe the jet mill and its use.

- What is fragmentation and what does it serve?

- What are the main mechanisms that can crush the material?

- What equipment is used for fragmentation in a pharmaceutical laboratory?

- Describe crushing, grinding and micronization.

- Describe the jaw crusher and its use.

The two-valve mixer is more familiar to many of us. A tap with two handles - hot and cold water. All of them have two valves (crane-axle boxes). Water is blocked by rubber or paronit pads. Modern versions have priturtye ceramic discs.

Due to the frequent replacement of gaskets and buzz, the first option loses popularity. In addition, often the crane is torn off, trying to tighten more forcefully, which began to skip the gasket.

You killed yourself, and you do not know where to put meat for your family? Or do you need to store fruits and vegetables safely in the summer? It offers a clear distribution of beans and a convenient capacity of 210 liters, which shows that it will satisfy even the most demanding customers. It also outperforms energy efficiency when it is among the class A energy-efficient appliances and consumes only 227 kWh per year.

Despite a reasonable price, it offers many useful features. There is no visual warning of too high temperatures, which can affect the quality of the storage or the vacuum relief valve for easy opening. The interior is effectively illuminated to give you an ideal view and praise the freezer that stands even in noiseless mode - the maximum noise does not exceed 42 dB, so do not worry about sitting in the living room.

How to replace the cartridge in a lever mixer

If the tap with the cartridge started to flow, most likely, it's not about the gaskets, but in the hitting of solid particles between the ceramic plates or in the cracked cartridge casing.

In both cases, its replacement is required. How do I disassemble a tap with a cartridge?

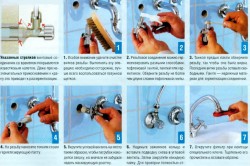

The order of disassembly (after the water is blocked and cold and hot!) Is as follows.

The freezer is equipped with a special condenser, which allows maximum use of the interior. Due to this, it is about 30 cm smaller than the standard, but its capacity is preserved. A special condenser allows the refrigerator to stand anywhere. This prevents the formation of condensation and rust. Do not be afraid to leave it in cold and damp places.

Preparation for work

For the freezer to be easily opened, it has a special vacuum safety valve. Without much effort, someone will open it. The freezer is really durable because of its design. Products are always stored with the utmost care and are perfectly frozen even at a high level of cold and humidity. Under all circumstances, you do not need to worry about the quality of their storage.

Disassembly of the ball valve

(after blocking the water and cold and hot!) is as follows.

- Unscrew the decorative cover on the handle of the lever with a flat screwdriver. Behind it is a screw that holds the handle itself.

- Unscrew the screw inside the handle, remove it. Screws are different, for different screwdrivers or thin hex keys.

- Unscrew the decorative nut, which is under the handle, it covers a large nut, which actually mounts the cartridge in the body;

- Unscrew the nut holding the cartridge. To do this, you need a wrench or a hexagonal hexagonal to the right size; These nuts are quite fragile, there are spare reinforced ones on sale;

- remove the cartridge, stirring the lever, check the condition of the plates, inspect the O-rings on its end and the body; if necessary, replace the cartridge;

- reassemble in reverse order, greasing all connections with petroleum jelly.

The house has rooms that are difficult to plan, because they need to pay special attention to their functionality. In such places there is a kitchen and a bathroom. Everyone would like the kitchen to be able to cook delicious dishes and stimulate the appetite, and in the bathroom there was a place for a quick shower in the morning, and in the evening it favored a warm bath. However, we believe that we can fully realize our idea if we adopt the right tactics. You can combine functionality with convenience and attractive appearance.

Disassembly of the ball valve

How to disassemble the ball valve?

It looks like a tap with a cartridge.

Council. There are different versions of cranes. For example, a row of mixers have small grooved indentations at the top of the dome. When disassembling, protect your fingers, so as not to get injured by metal fragments.

Before assembly, lubricate all seals with silicone grease.

Well, now you know how to disassemble the ball valve.

- Types of cranes

- Disassembly process

- Replacement parts

- Repair of machinery

All plumbing fixtures have a certain service life, which depends on the conditions for their proper operation and maintenance. Are not an exception and water taps. If you know how to disassemble the tap correctly, then you can extend the life of this device several times.

Types of cranes

To understand the device cranes, you need to know what types they are divided. At the moment there are 2 main types of water supply faucets:

- valve;

- lever.

To be able to disassemble any faucets, you need to know their device. All valve valves have different mechanisms that allow to block the flow of liquid. In older models, there is a fairly simple device that is equipped with a rubber gasket blocking the opening of the water current.

Wear of similar rubber gaskets occurs quite quickly, but also their replacement is not very difficult. The modern design of the ball valve has ceramic locking devices that are very resistant to wear and can easily be replaced.

In the lever mechanisms is a special locking device, which is called the cartridge. By its design, such a crane is a more complex mechanism, unlike a faucet mixer. The advantages of such a device are the ability to adjust the temperature and water feed rate with one hand. In the event that both hands are dirty, you can always make a crane opening with your elbow.

Moreover, such a device allows for a smooth adjustment of water and is more durable. Repair of such a crane is quite simple, you need to remove the damaged cartridge and replace it with a new one. Complexity can arise if the cartridge becomes sour, which can lead to its inability to be removed. To avoid this, you must moisten it with kerosene and wait 30-40 minutes.

Back to contents

Disassembly process

Modern faucet mixers are made of special lock boxes (crane-box). To disassemble the water tap, you need to stock up the following tool:

- adjustable wrench;

- slotted screwdriver;

- crosshead screwdriver;

Such a tool should be available in every home, so difficulties with its availability should not arise. It is better not to use other improvised means, so as not to break the gaskets and not to crush the threaded branches.

It is first necessary to remove the plastic plug, which closes the mounting screws of the valve. Then, in order to, it is necessary to unfasten the valve. It can be fixed not only with screws, but also with the help of plastic rings.

After the valve has been removed, it is necessary to use the adjustable wrench. With its help, it is necessary to unscrew the crane-axle. This is done in the opposite direction of the movement of the clockwise direction. Before, it is necessary to close the supply of cold and hot water to the risers.

In the lower part of the ball valve (axle box) a gasket of rubber should be installed, it performs sealing properties. When a faucet has a small leak, it often requires replacement. This gasket is fixed with screw connections. After unscrewing them, you can replace it.

Back to contents

Replacement parts

The replacement of such a gasket must be carried out exactly according to its dimensions, A deviation in either direction can lead to water leakage. If, however, the replacement of the ball valve padding does not help to fix the malfunction, then it is necessary to disassemble the bumper. Very often it happens that between the ceramic parts of the crane-axle are the mote, which is in large quantities in the water. Such specks can interfere closely with the ceramic parts and cause a gap between them. A gap the size of a human hair can cause the presence of large water leaks.

However, it is necessary to remove such impurities from the body of the axle box as quickly as possible so that the nadir on the ceramic parts does not form. In the event that this happened, then it will be impossible to save the crane-axle. It will need to be completely replaced.

Older ball valve designs are equipped with plastic gaskets that prevent the presence of possible water spills between the axle and the mixer. This gasket is not maintainable and requires a complete replacement.

After replacing the damaged parts or the entire box, the mixer must be assembled in the reverse order. The tightening of the entire mechanism should be carried out not very strongly, in order not to further prevent its dismantling and damage the thread.