Fugen Knauf putty plaster application. Putty specifications

Gypsum plaster is an excellent assistant when decorating concrete, brick, plaster and plastered walls in dry rooms. Experienced use it for rough finishing. This kind of putty material is popular with both masters and those who make repairs themselves.

Any wall, whether it's gypsum blocks or concrete construction, is uneven. Even if it is a question of a new high-rise building - there are still small gaps and swings. Such a putty is used to smooth out these drawbacks. And in those cases, when the base has also cracks or chips, here it is exact not to do without puttying. Gypsum composition is also used for sealing joints, leveling the ceiling. The substance binds well to the base.

Wall plastering - pledge of durability of repair

Whatever company produces gypsum putty, the composition is practically the same. The basis is a fine gypsum with the addition of components that help penetrate the treated surface. The composition of such mixtures is distinguished by ecological compatibility, which makes it possible to use gypsum putty practically in any room.

Professionals point out that this type of mixture for the treatment of walls and ceiling has a wide range of advantages. Let's highlight the list of main advantages:

- Plasticity of the material - the composition is not subject to cracking, after certain time intervals;

- Ease of operation;

- The ability to regulate the absorption of moisture by walls;

- Durability;

- Absence of components harmful to health;

- High level of adhesion;

- Extensive scope of application. It is possible to decorate walls, ceiling, other surfaces

One of the drawbacks of plaster putty is that it is afraid of high humidity. Therefore, it is better not to use the composition in rooms with permanently high humidity. And in places with periodically rising humidity (kitchen), install a good exhaust system.

With the help of putty even walls with differences of 1-2 centimeters

With the help of putty even walls with differences of 1-2 centimeters The starting putty differs from the finishing coat

What kind of putty is suitable for sealing seams and cracks? You can give an answer to this question if you study in detail the three main types of finishing materials. The puttying composition is divided into:

- starting;

- the finish;

- universal.

Starting putty is suitable for walls and ceilings. With its help, they fill up cracks and gaps, level the differences in a centimeter or two. Such a mixture is applied uniformly over the surface layer up to ten to fifteen millimeters. If the surface has impressive swings, then the use of putty is not practical because the too thick layer easily falls off the ceiling or the wall. Therefore, for the treatment of large differences, it is recommended to use plaster or sheathing with GKL sheets.

after leveling the finish the walls are ready for painting

after leveling the finish the walls are ready for painting Finishing putty is used for single-layer surface smoothing and giving it evenness and whiteness. Finishing type of putty walls is used for further painting. The composition of the final mixes visually differs from the starting with a less granularity and whiteness of the material. If after applying the starting material the walls have a gray tint, then when they cover the ceiling or walls, they acquire a milky white shade.

A universal shpatlevka is called "start-finish". It is used when leveling the walls and ceiling under the wallpaper. The universal composition allows to save on the acquisition of two types of materials, without reducing the quality of the final coating.

Note that the gypsum material is simple in operation. With observance of mixing and applying technologies, even a man without experience will be able to cope with the rough finishing of the walls.

The Starateli company produces blends in various bag sizes

The Starateli company produces blends in various bag sizes Which firms should pay attention when choosing a mixture

When it comes to buying building materials to start work, then the key factor is the choice of the manufacturer. The modern market is filled with well-known brands, and newcomers. And when choosing cheap products from such firms it is important that the quality is not worse than that of popular brands like Knauf, Ceresit, Sniezka, Perfekta, Bergauf. From the Russian representatives we will allocate already enough known companies Starateli and Axton. They will be discussed further on.

When choosing a product, pay attention to reviews about the manufacturer

When choosing a product, pay attention to reviews about the manufacturer If we are talking about Axton putty, then it is used as a universal material in roughing the walls. The composition includes fine-grained gypsum with the addition of components for high adhesion and plasticity. The viability of this mortar after kneading is one hour, so do not try to mix the entire bag at once - this amount of material is unlikely to be applied to the wall in just an hour. The drying time at room temperature is 20-22 hours.

Finishing Putty Stackers in the bag 12 kilograms

Finishing Putty Stackers in the bag 12 kilograms The Starateli company produces a filler of various compositions. The most popular are polymeric putty and gypsum plaster. They are rightfully called the leaders of the domestic construction market. Gypsum consists of fine gypsum fractions with adhesive and polymer additives.

Putty Putters are produced in bags of different volumes, which allows you to select exactly the required amount of the mixture. Consumption of material at a thickness of 1 mm per each square of the surface does not exceed one kilogram. Putty Stackers in the mixed state should be used in an hour. The setting time and hardening of the composition on the surface is 5-7 hours after application.

Remember that in the market there is also a counterfeit goods. Often in the forgery is a cast of poor quality, which is cracked after applying to the surface. Such materials may also contain harmful substances not shown on the packaging. Therefore, try to carefully inspect the goods and require quality certificates. Please note that the gypsum mixture has a short shelf life of 6 months. After the expiry date, the mixture loses some useful properties, which will necessarily affect the final result.

In contact with

Gypsum putty is a powder or paste-like material, the basis of which is gypsum. This finishing material is used for leveling surfaces that are pre-prepared with plaster mixtures and primed. This building material is very popular, as gypsum is an environmentally friendly product, and the displayed values of putty are quite high.

The technical characteristics of such a putty allow it to pass air sufficiently well, which allows it to be used in a room for internal work. The material is perfectly combined with plaster moldings, plasterboard slabs, and is also widely used on wooden, cement and concrete surfaces.

Advantages of Putty Putty

Due to the fact that the recipe correctly combines polymer additives and other fillers, it is possible to create a really reliable and high quality filler. It dries very quickly and a smooth and durable film forms on the surface, which reduces the subsequent consumption of facing materials. In addition, the natural ecological components that are part of this putty provide the following technical characteristics:

1. Water vapor permeability, as well as the ability to create a good microclimate.

2. Crack resistance, because the mixture has a sufficient level of plasticity.

3. Absence of discontinuities on the surface, ease of application and grinding.

4. High hardness, strength and durability.

5. A variety of applications. Suitable for, cracks, leveling and the like.

6. Excellent adhesion with many materials. Adhesion can be strengthened by using a primer, which also will prevent conflict between materials.

7. Uncertainty.

8. Ecological compatibility.

9. Affordable cost.

Among the main drawbacks, it should be noted the inability to use this putty in damp areas. In most cases, it is used inside buildings and structures.

Preparation of materials and surfaces before applying putty

In the course of the work, the following materials may be required:

1. spatula metal;

2. to mix the drill mixture with the mixer;

3. packaging for putty;

4. Water sprinkler to moisten the surface;

5. Scapula to remove the past coating.

In the process of puttying it is important to observe the safety measures so that the composition does not get on the skin and eyes. If this happens, then rinse thoroughly with warm water. To conduct work is recommended in specialized clothing, because in the course of work, it will necessarily get a building mixture.

Putty gypsum can be of different types:

1. Putty plaster universal;

2. putty starting;

3. putty finishing.

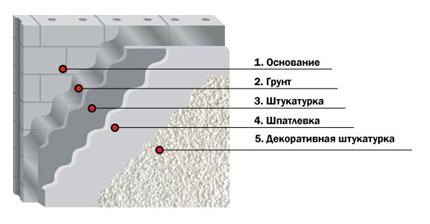

The starting variant will approach to the plaster mixtures, because the purpose of the putty is in the finish alignment. Then putty is mainly used for leveling, and then smoothing plasters and surfaces.

Universal gypsum mixture is used to seal gypsum board joints, puttying cracks. With it, you can glue the GCR to the surface, in addition, it can be processed by combined panels.

Finishing putty is used to create a fine thin layer flattening of flat surfaces, it perfectly matches with the materials of the plaster layer.

Each of them is selected depending on the work. In order not to get confused, all the information, including the characteristics, is on the packaging of the putty.

However, before applying any of them, the base must be carefully prepared. If this is not done, then soon on the surface will appear cracks. The first thing to do is remove the old coating (decorative plaster, paint, paper wallpaper and the like). Then, from the walls you need to remove dirt, stains of rust and grease. If there was mold, it is also eliminated. In stores today, they sell different compounds that allow them to be removed.

Then the walls are treated with a suitable primer. She is selected for a certain type of foundation. Primer is applied in 1-2 layers. Then prepare the mixture for - dilute 1 kg of the formulation with 0.5 liters of water. All mix thoroughly. Then leave the minutes for 5 and mix again. The resulting mixture will need to be consumed in the next 2 hours. In the process of work, the composition is stirred, sometimes water is added to eliminate drying and maintain plasticity.

It is advisable to use proven compositions that have proven proven among buyers, for example, plaster filler Fugen Gips, Knauf, Primer and others.

1. The mixture on the walls will be applied with a spatula. The tool is kept at a certain angle to the surface. Press the base with a spatula and spread out the putty. Movements should be both vertical and horizontal. If the walls have many irregularities and defects, then two layers of the mixture should be applied.

2. The next step is to apply the filler plaster finish. The mixture is prepared in accordance with the recipe. Finishing putty apply a thin layer (1-2 mm).

3. The coating should dry for a certain time. On average, it takes 1-2 days.

4. Mandatory grinding is then performed. It is necessary to produce a leveling of the coating. For this, sandpaper is used. It is desirable to use fine-grained sandpaper.

5. At the last stage, the decorative facing material should be applied. Among them can be: wallpaper, plaster, whitewash, paint and the like. If the works listed above were made in accordance with the instructions and as true as possible, the facing materials will be kept securely and for a long time.

Also

In the process of carrying out repairs, you can invest in a rather large amount, and therefore you should try to make repairs in such a way that it would serve for many years. This can be achieved through the use of putty, thanks to which the uniform adhesion of tiles, floors, wallpaper, various decorative elements, also helps to get rid of cracks and cracks, which can get water. It is for the implementation of these purposes, in most cases use gypsum putty.

Putty on gypsum provides an opportunity to level any surfaces in the room and increase the level of adhesion to paintwork materials or building glue.

Gypsum - a mixture, which is an excellent basis for applying decorative substances that are made on different bases. The astringent component of such a substance is gypsum, it also contains a variety of polymers and fillers that give the material elasticity and strength. Use a dry mixture to mix with water until a uniform mass is formed. The prepared solution can be used for forty minutes, although it completely hardens in three hours. During the repair work, each applied layer of gypsum must dry for at least two hours.

Gypsum-based fillers are used for such surfaces, brickwork, concrete, plaster, natural stone, gypsum boards and others. Surfaces that strongly absorb moisture, before applying plaster putty, it is necessary to primer. If this is not done, it will sit down, and a perfectly flat surface will not work. Due to the use of the primer, the putty is reduced and its adhesion to the surface increases.

The most common for the repair work used gypsum putty finish, which is used for the final coating and before the beginning of decorative works. The layer of putty filler plaster after drying turns white, perfectly smooth and shows a high level of adhesion to the glue for tiles. Gypsum putty finish is used in rooms with continuous heating in the cold pores of time and with a normal level of humidity.

The most popular manufacturers of gypsum putties are the company Scala and the company Starateli.

Rock putty gypsum is produced by the well-known company TD Skala-Trade, which, in addition to manufacturing its products, sells construction materials from other companies.

Rock putty gypsum is used in rooms, the level of humidity in which is at the optimum level. This building material is reinforced with cellulose, which contributes to its better solidification. The only drawback of the Rock putty gypsum can be considered inadmissibility of its use in rooms where the humidity level is increased, and also in the cold time of the goal in those rooms that are not heated.

After applying the clay putty, the gypsum surface turns out to be white and perfectly even.

Very convenient in application are plaster fillers. In the construction market, they can be found packed in buckets or in waterproof bags.

To prepare a ready-made mortar of gypsum fillers, you need to mix the dry mixture with water in the proportions specified in the instructions on the package until a uniform mass is formed. Such a solution is needed for three hours.

Gypsum Putty The Erasers, thanks to the fact that it contains environmentally friendly material, is safe for the environment and human health.

The consumption of gypsum putty depends on the thickness of the applied layer, and is approximately one and a half kilograms per square meter.

Gypsum putty, which is not very high, is used by many professional builders for repair work in various premises.

Gypsum putty: application / ооо арнада / г. новосибирск

Putties belong to the most, perhaps, diverse kind of building materials. They are designed in order to carry out finishing, leveling ceilings and walls before starting or pasting wallpaper on them.

Scope of putty

Gypsum putty is used to smooth out various defects on the surface, such as cracks, seams and large depressions. It also produces a continuous shpatlevanie of various materials: gypsum boards, lightweight concrete, brick, as well as other surfaces.

Composition of putty

The mixture for leveling includes gypsum, mixed with mineral plasticizer and a complex of modifying additives.

Preparation of the surface for treatment with putty

The surface to be treated must be cleaned in advance from contamination, as well as grease and oils, as well as it must be firm and dry. If the surface is absorbent, it must be primed before processing.

Application of putty

On the base plaster putty is applied with the help of a rubber or steel staple, you can use a steel ruler - the main thing is for the tool to level the surface well. Dry shpatlevku if necessary can be treated with abrasive materials and any kind of coatings, glue on top of it or lay ceramic tiles.

Storage of putty

A mixture for putty can be stored in a dry room for six months. After it is better not to use, as the gypsum putty can lose its properties, and the quality of the coating will become unsatisfactory.

Purchase shpatlevku

Please contact Arnada. Our experts will advise you which brand of filler is best suited for your purposes, and the quality of our building materials will ensure the reliability and durability of your building.

Universal plaster putty

The proportions of the mixture are 0.30-0.34 l of water per 1 kg of the mixture0,90 - 1,02 l of water per 3 kg of the mixture

1,50-1,70 l of water per 5 kg of the mixture

3.00-3.40 liters of water per 10 kg of the mixture

7.50-8.50 liters of water per 25 kg of mixture The usefulness time of the solution

to use about 1.5 hours Open time about 15 minutes. Adhesion min. 0,50 MPa Cooking temperature from + 5 ° С to + 25 ° С Base and ambient temperature from + 5 ° С to + 25 ° С Density in dry condition approx. 1.1 g / cm³ Max. single layer thickness2 mm

Finishing putty gypsum bolars, putty finishing. finishing materials bolars

Shpaklevku used for external work. Leveling compounds are used to seal large cracks and prepare the surface for decorative finishing. Putty plaster, cement or used in rooms with high and normal humidity. To prepare the substrate for painting, the final putty is used. It hides small defects, forming a smooth surface. For exterior surfaces of buildings use façade fillings. They withstand changes in temperature and atmospheric influences. Putty TM is applied on the surface of concrete, brick, stone, aerated concrete and plaster.

Advantages of putty

- elasticity,

- moisture resistance,

- economy,

- frost resistance,

- resilience.

Application technology

The treated surface is cleaned of dust, oils, paint residues and moisture. Finishing putty is applied with a metal spatula at an angle of 30-35 ° C. It is distributed over the surface by a layer from 0.2 to 3 mm. Putty finish is leveled with a smoothing pad or grater. If necessary, a second coat is applied. When the layer thickness of the applied solution is 1 mm, the flow rate of the mixture is 1 kg / cm2.

Kinds of putty

Putting on shingles is putty:

- cement. Fillers are made on the basis of white or gray cement with the addition of sand. Designed for finishing non-deforming substrates (concrete walls or facades of buildings) and preparing the surface for painting or wallpapering. The catalog shows BOLARS (based on white cement) and BOLARS Facade Finish (based on white cement), BOLARS Universal, BOLARS Leveling, BOLARS Water resistant.

- gypsum. The basis is gypsum and modifying polymer additives. It is used for finishing walls and ceilings, for leveling or joints of GCR with cut or semicircular edges. Gypsum plaster is used for final finishing of ceilings and walls. It includes "BOLARS Gypsum (white)", "BOLARS Gypsum-Elastic (white)" and "BOLARS Gypsum (white)";

- polymeric. Produced on a mineral basis with polymer additives and marble flour. Putty filler is used for interior and exterior finishing, eliminating microcracks. In the catalog are putty fillers "BOLARS Finishing (white)", "BOLARS Universal (gray)" BOLARS Imperia, and BOLARS Imperia-Fasade.

In the field of application, putties are distinguished:

- universal. For the main and final leveling of surfaces in order to eliminate unevenness and microcracks;

- leveling. For basic alignment of bases;

- finish. For final alignment, the thickness of the applied layer is 0.2-3 mm;

You can get additional advice and order cement, polymer or gypsum by using the feedback form or the toll-free hotline phone 8-800-100-71-17.

The technical characteristics of the FUGENFULLER putty and its advantages make it possible to carry out not only finishing works, but also restorations.

1. Putty Fugenfüller is a white powder.

2. The flexural strength is 2.6 MPa.

3. The compressive strength is 5 MPa.

4. It is possible to work with the finished solution for a maximum of one hour.

Preparation of mortar mixture

For mixing dry mix, use water from drinking water supply. Mixing ratio: 0,34 - 0,40 l of water is required per 1 kg of dry putty mixture. Dry mixture to fill in a pre-measured amount of water at room temperature and mix for 2-3 minutes with an electric mixer or electric drill with a nozzle, with a speed of no more than 600 rpm, until a uniform consistency is obtained. Allow the solution to stand for 5 minutes and mix again. With repeated stirring, it is allowed to add water to the maximum value of the above ratio. The time of use of the finished mortar mixture is not more than 2 hours.

Operating procedure

The products are allowed for use in all types of civil engineering (Aeff

Fugenfueler putty

Fünfüller joint filler (Fugenfuller) is prepared on the basis of gypsum and in combination with a reinforcing tape it is intended for sealing joints formed by gypsum boards (GKL) with a thinned or semi-circular and thinned edges, using reinforcing tape (this is in contrast to the gypsum plaster Uniflot); sealing of cracks and other defects on them, for gluing gypsum boards and combined panels to the flat surface, for sealing seams, shells and unevenness of concrete elements, for gluing and plastering gypsum elements.

APPLICATION:

Gypsum plaster Fugenfuller is ideally suited for thin-layer plastering of concrete substrates and previously plastered surfaces, for filling and leveling joints of prefabricated elements from concrete, installation of PGP, gypsum blocks.

Fugenfüller is suitable for gluing to flat substrates of sheets or gypsum panels. Fugenfüller is used as a gluing material for any gypsum products.

Fugenfueler putty is made on the basis of gypsum and is used exclusively for work.

PREPARATION OF THE SOLUTION:

To prepare a solution of Fugenfüller putty, it is necessary to fill the dry mixture in a container with cold clean water, evenly spreading it over the surface until the appearance of "dry islands" (maximum 2.5 kg per 1.9 liters). Then it is necessary to allow the mixture to get wet for 2-3 minutes, and mix with a trowel with a trowel until a uniform creamy consistency is obtained. After this, the addition of a dry mixture is not allowed. Use clean containers and tools.

Do not add any other components to the mortar, this impairs the properties of the putty. Also, it is not allowed to add water to the thickened solution - this does not restore the original properties, but worsens them. The thickened solution is no longer suitable for work. The working time (before the beginning of the thickening) is at least 30 minutes, but the contamination of dishes or tools can lead to a faster curing

CONSUMPTION RATE:

Approximately 250 g of dry material are used to seal joints per 1 m2 of installed gypsum boards.

SURFACE PREPARATION:

Preparation of the surface for puttying is carried out in the following order. Gypsum boards must be firmly mounted on a supporting frame or other base. The surface intended for puttying should be dry and free of dust.

The surface itself should not be cold (not less than + 10 degrees).

If there are contaminants - they must be removed, it is possible to wash off (after that, dry well), with the removal of the residual formwork grease. Joints drywall, which will be putty and the surface of the sheets must be cleaned of dust by dry methods. Surfaces that strongly absorb moisture must first be primed with a brush, roller or spray. If the surface is smooth or concrete, it should be treated knauf primer Contactless, this is necessary to increase adhesion. After applying the primer, dust should not be allowed to enter the prepared surface.

In order to putty Knauf Fugenfüller behaved well and did not form any kind of defects and cracks in the process of operation, all work should be carried out at the same temperature and humidity regime as will be during operation. This precaution is necessary to avoid linear deformations due to temperature changes and saturation with moisture.

OPERATING PROCEDURE:

Time from the moment of filling the Fugenfüller putty into the water before the setting begins is about 30 minutes. Dirty tanks and tools shorten this time. Work should be done when there is no significant change in the temperature and humidity regime in the room, which excludes any linear changes in gypsum boards. The minimum temperature of the base and the room during work is + 10 ° C. If there is a filling or asphalt floor in the room, then the putty should be laid after laying the floor.

To putty joints GKL (shpaklevanie usual seam) with a spatula, apply the first layer on the seam area, then stack the reinforcing tape by pressing with a spatula (you can not allow the formation of bubbles or creases). This layer needs to be allowed to dry, after applying a leveling layer. It is most convenient to make these manipulations with a spatula about 150 mm wide with a handle adapted to screw the screws. This will quickly eliminate the defects in the installation of drywall.

Continuous puttying of surfaces is also carried out in two stages. The first layer is applied with a wide spatula, and after drying, a finer leveling coat of Knauf Fugenfüller is applied.

After the second layer dries, the surface is corrected using a grinding tool (grates with grinding mesh). If the surface is prepared for painting, then for high-quality painting it is necessary to apply a layer of finishing putty on the finished surface.

Before the application of the decorative coating (paint, wallpaper, decorative plaster), the surface is treated knauf Tiefengrund primer.

In order to carry out all the work quickly and efficiently, you will need a tool:- Filler box for mortar preparation;

Spatula trowel metal for kneading the putty Knauf Fugenfüller;

Spatula metal (width 152 mm);

Spatula metal wide (width 200x300 mm);

Spatula metal for external and internal angles;

Grater with grinding mesh for grinding a dry, clogged surface.

All tools must be of stainless materials. After completion of work, the remnants of Knauf Fugenfüller should be washed off with water.

SPECIFICATIONS:

1. layer up to 5 mm;

2. The size of the fraction is not more than 0.15 mm;

3. yield of a solution of 1 kg of a mixture of 1.3 liters;

4. compressive strength of 5.2 MPa

5. The bending strength is 2.7 MPa.

STORAGE:

Keep bags in a dry place on: pallets. Material in damaged bags should be used first. Shelf life - 6 months.