Polyethylene pipe for gas. Pipes mfd for gas

The gas pipeline for gas is a rational solution for the construction of a gas pipeline, which makes it possible to organize a reliable and durable highway with insignificant investments. These products meet the safety standards and are characterized by a mass of advantages compared to the analogs of steel.

Pipe HDPE gas GOST R 50838-2009 PE-100 price:

* In this table we collect HDPE pipes of the most demanded sizes and technical characteristics. The full range of HDPE pipes for gas is presented after the table.

| Diameter, mm |

Thickness walls, mm |

Pressure, atm |

Packing, m | Price, m.p. | |

| 20 | 2.0 | 6 | a bay of 100 or 200 m | 20 rubles. | |

| 25 | 2.0 | 5 | a bay of 100 or 200 m | 24 rubles. | |

| 25 | 2.3 | 6 | a bay of 100 or 200 m | 30 rubles. | |

| 32 | 2.4 | 5 | a bay of 100 or 200 m | 39 rubles. | |

| 32 | 3.0 | 6 | a bay of 100 or 200 m | 44 rubles. | |

| 40 | 3.0 | 5 | a bay of 100 or 200 m | 54 rubles. | |

| 40 | 3.7 | 6 | a bay of 100 or 200 m | 65 rubles. | |

| 50 | 3.7 | 5 | a bay of 100 or 200 m | 78 rubles. | |

| 50 | 4.6 | 6 | a bay of 100 or 200 m | 96 rubles. | |

| 63 | 4.7 | 5 | a bay of 100 or 200 m | 113 rubles. | |

| 63 | 5.8 | 6 | a bay of 100 or 200 m | 142 rubles. |

Signal tape

| A photo | Name of product | Price, m.p. | Price, pcs. | |

| 10 rubles. | - | |||

| - | 2000 rub. |

Pipes HDPE GOST R 50838-2009 full range of PE-80:

Pipe HDPE GOST R 50838-2009 full range of PE-100:

Gas Pipe Pipe: Features

The LPG tube for the gas is frost-resistant, durable, not subject to corrosive formations and chemical products. The installation of the main lines is carried out underground, since the products are sensitive to UV rays, which have a destructive effect on them.

The tube of gas for gas, purchased by the company "Aqua-Engineering" - is a product of high-quality execution. In the catalog products are represented by the current assortment:

- 17;

- сдр 11;

- cd 17.5;

- 9;

- 13.6.

Pipes md for gas (to buy in the catalog of the company "Aqua-Engineering" - profitable) are mounted in the following ways:

- butt welding. The process involves placing the ends of the products inside welding machine, where as a result of high-temperature exposure, sealed connection;

- with the help of electrical couplings. Electrospiral - a heating element, which produces heating and melting of products, which makes it possible to glue them securely.

Using gas fittings for gas, it is possible to create a permanent joint of great strength, which is relevant for a pressure system.

Key positive qualities of the gas pipes for gas

Tubular products under the gas are actively used in the organization of domestic and industrial gas pipelines, positive properties. First of all, it concerns the big operational rock (more than 50 years). During the service, regardless of the conditions, they retain their original functional qualities. The only thing worth paying attention to is their vulnerability to sunlight. Thus, during the laying, it is necessary to make the appropriate insulation (the signal gas tape is fixed in a prominent place in the immediate vicinity of the communication, appearing as a sign and a signal about the flammability of the main line).

Pipes do not rot, do not rust, are inert in contact with chemical and bioactive substances. These qualities can not boast of analogs from other materials.

Pnd tube (gas) has a low gas permeability, due to the special properties of the material from which they are made. In connection with this, during installation, the use of protective casings, electrochemical protection or other special means is not required. Also worth noting that they do not need waterproofing.

The PNG gas pipe has a smooth internal surface, this increases its throughput and eliminates the settling of particles on the walls that could cause congestion. Products of low weight will not cause difficulties when moving.

Sort of pipes

The gas pipe peh gas differs according to the following parameters:

- on the nominal outside diameter (D);

- by the thickness of the walls (E);

- by the limiting deviation of the mean diameter (S);

- on the dimensional relation (SDR) - the value of the nominal diameter relative to the thickness of the walls.

For example, we take PE100 gas and PE 80 having a wall thickness of 3.5 mm and 2-3 mm, respectively, and a working pressure of 3-12 atmospheres and 4-6 atmospheres, respectively.

The values of the working pressure are directly related to the SDR parameter. For example: PE80 SDR11 and pipe PE100 gas SDR11. In the first variant the indicator is 6 atmospheres (0.6 MPa), in the second - 10 atmospheres (1.0 MPa). Pipe production pe gas is produced in accordance with GOST.

When laying the gas pipeline, a signal tape is needed "carefully gas". Its main task is to designate the location of the main road. The signal tape "flammable gas" is fixed without fail. In support of the need for its application, it is necessary to get acquainted with the rules prescribed in normative and technical documents.

The company "Aqua-Engineering", specializing in the sale of pipe products, offers to buy an alarm tape gas. Products with a long service life are characterized by high breaking load (about 90 kg) and non-adherence to decay. Is the gas tape interested? Price in the company "Aqua-Engineering" is always below wholesale market, which contributes to the acquisition of benefits.

Information for visitors:

On the site not all the items are stated and not all the prices of products that we can offer you are indicated, please send an inquiry of the items you are interested in to the e-mail address or contact the contact numbers listed on the website.

The company "Plast Torg" for more than 5 years has been selling gas pipes HDPE at favorable prices. There are products of different diameters, suitable for the construction of a reliable gas pipeline.

HDPE gas pipes

Gas pipes from polyethylene GOST R 50838-95, TU 2248-018-40270293-2002

Pipes for gas pipelines of low and medium pressure (up to 3 atm)

| Nominal outside diameter, mm | PE 80 SDR 17.6 (0.3 MPa) | PE 80 SDR 11 (0.6 MPa) | PE 100 SDR 11 (1.0 MPa) | PE 100 SDR 9 * (1.2 MPa) | Packaging | |||||

| Thickness. walls, mm | The price is 1 sq.m. VAT included | Thickness. walls, mm | The price is 1 sq.m. VAT included | Thickness. walls, mm | The price is 1 sq.m. VAT included | Thickness. walls, mm | The price is 1 sq.m. VAT included | |||

| 25 | 2,3 | 24,60 | bays | |||||||

| 32 | 3 | 39,93 | 3 | 39,93 | 3,6 | 47,31 | bays | |||

| 40 | 3,7 | 62,17 | 3,7 | 62,17 | 4,5 | 73,82 | bays | |||

| 50 | 4,6 | 96,52 | 4,6 | 96,52 | 5,6 | 114,43 | bays | |||

| 63 | 3,6 | 98,31 | 5,8 | 151,37 | 5,8 | 151,37 | 7,1 | 181,99 | bays | |

| 75 | 4,3 | 141,60 | 6,8 | 213,58 | 6,8 | 213,58 | 8,4 | 257,24 | stretches, coves | |

| 90 | 5,2 | 200,60 | 8,2 | 303,26 | 8,2 | 303,26 | 10,1 | 370,52 | stretches, coves | |

| 110 | 6,3 | 276,10 | 10 | 448,40 | 10 | 448,4 | 12,3 | 551,06 | stretches, coves | |

| 125 | 7,1 | 388,22 | 11,4 | 594,72 | 11,4 | 594,72 | 14 | 709,18 | lengths of 13 m | |

| 140 | 8 | 488,52 | 12,7 | 739,86 | 12,7 | 739,86 | 15,7 | 892,08 | lengths of 13 m | |

| 160 | 9,1 | 621,86 | 14,6 | 952,26 | 14,6 | 952,26 | 17,9 | 1161,12 | lengths of 13 m | |

| 180 | 10,3 | 796,50 | 16,4 | 1228,38 | 16,4 | 1228,38 | 20,1 | 1471,46 | lengths of 13 m | |

| 200 | 11,4 | 987,66 | 18,2 | 1515,12 | 18,2 | 1551,15 | 22,4 | 1820,74 | lengths of 13 m | |

| 225 | 12,8 | 1221,30 | 20,5 | 2238,46 | 20,5 | 1884,46 | 25,2 | 2301,00 | lengths of 13 m | |

| 250 | 14,2 | 1543,44 | 22,7 | 2358,82 | 22,7 | 2358,82 | 27,9 | 2824,92 | lengths of 13 m | |

| 280 | 15,9 | 1922,22 | 25,4 | 2955,90 | 25,4 | 2955,90 | 31,3 | 3552,98 | lengths of 13 m | |

| 315 | 17,9 | 2384,78 | 28,6 | 3668,62 | 28,6 | 3668,62 | 35,2 | 4485,18 | lengths of 13 m | |

| 355 | 32,2 | 4747,14 | 39,7 | 5707,66 | lengths of 13 m | |||||

| 400 | 36,3 | 5909,44 | 44,7 | 7236,94 | lengths of 13 m | |||||

* There is a complete package of permits for the use of pipes

| Max. Working pressure MPa, MPa | The design value of the safety factor C for the maximum operating pressure of the MPA | ||||

| SDR 17.6 | SDR 17 | SDR 13.6 | SDR 11 | SDR 9 | |

| Pipes from PE 80 (MRS 8.0 MPa) | |||||

| 0,3 | 3,2 | 3,3 | 4,2 | 5,3 | 6,7 |

| 0,4 | 2,4 | 2,5 | 3,2 | 4 | 5 |

| 0,6 | 2,1 | 2,7 | 3,3 | ||

| 1 | 2 | ||||

| Pipes from PE 100 (MRS 10.0 MPa) | |||||

| 0,3 | 4 | 4,2 | 5,3 | 6,7 | 8,3 |

| 0,4 | 3 | 3,1 | 4 | 5 | 6,2 |

| 0,6 | 2 | 2,1 | 2,6 | 3,3 | 4,2 |

| 1 | 2 | 2,5 | |||

| 1,2 | 2,1 | ||||

Product Features

For the construction of the gas pipeline system, gas polyethylene pipes of 2 grades - PE 100 and PE 80 are used, which are manufactured in strict accordance with GOST R 50838-95 and P 50838-2009.

Gas polyethylene pipes are highly flammable (at temperatures over 360 degrees). But they are completely safe for human health (non-toxic and explosion-proof).

Sphere and features of use

The scope of HDPE gas pipes is very limited. They can be used only in the construction of underground gas mains. They are also prohibited from being installed in seismic regions, under motorways, railway crossings, etc. If the system passes through such areas, the HDPE gas pipe must be placed in a special metal container.

Pros of polyethylene pipes for gas

- Increased resistance to destructive effects of the environment. HDPE gas pipes are not subject to corrosion, rot and do not deform under the influence of low (-15) or high (+40) temperatures;

- Long service life. Producers of polyethylene pipes for gas provide a guarantee for up to 50 years, but the actual lifetime can exceed this figure;

- Possibility to use for building a system with any pressure level;

- Low price. A gas polyethylene pipe costs about 40% less than a steel pipe.

Technical indicators

LPG gas pipes have many technical features. First, all pipes are marked with a special yellow stripe running along the entire length of the pipe. They can also have a yellow or orange color. The symbol always contains the word "GAZ". These requirements are determined by GOST and are binding. Therefore, if you see a 25 mm HDPE gas pipe without these signs, it is most likely a low-quality product.

The site has a table showing all the characteristics of the gas pipes. It contains the following parameters:

- D is the outer diameter of the pipe in mm;

- E is the thickness of the wall;

- S - difference between nominal and average diameters;

- SDR is the value of the diameter related to the wall thickness.

Also in the table you will find information about the cost of products. All prices for gas HDPE pipes are up-to-date.

If you want to buy a HDPE gas pipe of 25 mm or any other products, please contact the company manager who will answer all your questions and send a detailed price list. For wholesale and large buyers special tariffs are virgin, which will save on the purchase of materials.

Modern polyethylene pipes for gas supply - a practical option for underground gas pipelines. Products are made of polyethylene low pressure and are suitable for use in gas mains. Pipes made of polyethylene are also used for arranging residential and industrial transportation systems natural gas under low, medium and high pressure - up to a value of 1.2 MPa.

|

Nominal outside diameter, mm |

Thickness. walls, mm | Price 1 p / m without VAT, ₽ | Price 1 p / m with VAT, ₽ |

| PE 100 SDR 11 | |||

| 1.0 MPa | |||

| 32 | 3 | 56,04 | 66,13 |

| 40 | 3,7 | 87,25 | 102,96 |

| 63 | 5,8 | 212,44 | 250,68 |

| 90 | 8,2 | 425,00 | 501,50 |

| 110 | 10 | 630,00 | 743,40 |

| 160 | 14,6 | 1 337,00 | 1 577,66 |

| 225 | 20,5 | 2 645,00 | 3 121,10 |

| 315 | 28,6 | 5 149,00 | 6 075,82 |

Advantages of gas HDPE pipes

Plastic products for gas networks are distinguished by a number of advantages. The most important of them are high technical characteristics and easy installation of the gas pipeline. Such pipes solve the majority of construction tasks: from gasification of a private house to the construction of a gas distribution system within a large city.

The main advantages of polyethylene pipes for gas include:

- Insulating properties of the material. Gas piping from HDPE is resistant to impact electric current, since polyethylene is a good insulator.

- Strength properties. The combination of mechanical strength and high elasticity prevents damage to conventional and main pipelines. Products remain intact even in mobile soils.

- Chemical resistance. Products are resistant to transported combustible gas, do not undergo corrosion and do not overgrow under the influence of a moist environment.

- Transportability. Polyethylene pipes for gas supply systems have an allowable bend radius equal to 25 pipe diameters. This feature allows you to deliver products in the form of mobile bays in length from 25 m, which greatly facilitates installation and reduces the number of joints.

- Economical. The technology of laying gas pipelines from PE implies much less costs for installation work and, as a result, reduces the total amount of expenditures.

- Durability. The period of application of polyethylene pipes is from 50 years. Gentle operating conditions allow the use of products for much longer.

Cost of polyethylene pipes

Pipes for a gas pipeline from HDPE have a higher cost than water pipes . This is due to more stringent requirements for raw materials and end products. At the same time, the price of HDPE pipes is significantly lower than the price of steel products. Prices for products depend on the outer diameter and its ratio to the thickness of the walls.

SIS Company, a subsidiary of the Polyplastic Group, offers gas polyethylene pipes with an outer diameter of 32-315 mm and a wall thickness of 2.3-36.3 mm. The products are suitable for gas distribution and gas consumption systems. In terms of the ratio of diameter to wall thickness (SDR), Polyplastic produces products for gas systems with an SDR of 11. Such a pipe is capable of withstanding significant pressure.

For the production of pipes a special grade of polyethylene (PE) of PE-100 grade is used. The products are manufactured in accordance with TU 2248-010-73011750-2010, comply with international standards and Russian GOST R 50838.

If you want to buy HDPE pipes for the gas pipeline system, but do you have any questions - call us or leave your contacts in the feedback form. Our specialist will call you back and advise you.

The presence of a gas pipeline and the continuous supply of household gas to homes today is not a luxury, but a mandatory communal service. Even country houses basically have everything necessary for gas supply. Installation and installation necessary equipment always build specialists at the construction of the house. But even more often, when carrying out repairs in apartments or changing plates, people try to perform the installation work independently, while not knowing what kind of fittings for gas pipes are suitable and which are unsuitable.

The replacement of the old gas stove with a new one or simply a transfer to another place is always connected with manipulations on the gas pipeline. Before telling what types of fittings for gas pipes are better to use, it is necessary at least in general terms to represent the device of the gas pipeline, and what requirements it must meet.

Device and requirements for domestic gas pipeline

Pipes of the gas pipeline passing inside the house or apartment are a transitional connection from the main main flow through the flow meter to appliances operating on gas. It can be equipment such as:

- a gas column for heating water;

- kitchen stove;

- fireplace;

- converter;

- boiler.

The main components of the pipeline are pipes or hoses and connecting elements for them, that is, gas fittings. Every detail through which gas will pass must meet the following requirements:

And one more important point - before deciding on alterations in the gas pipeline, consult an expert yourself, and start working only after you are fully confident in your knowledge and skills.

The need to comply with all these rules dictates the use for gas pipelines of certain types of pipes and docking elements to them.

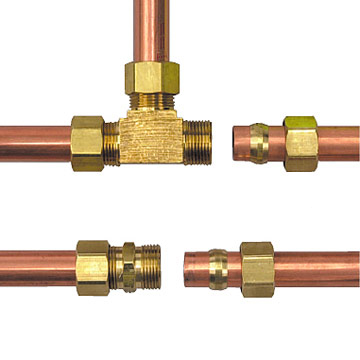

Criteria for selection and features of models of gas fittings

Of the variety of docking connections available in the assortment for the safe wiring of gas lines, only certain types are suitable that correspond to the required parameters.

Steel fittings and pipes

Products made of high-strength steel have always been famous for their quality. For the supply of household utilities, it is possible to use several types of docking elements. Complete sealing is also ensured by seamless rolling joints, both cold and hot.

Steel bends are laid to residential ladies by land. To protect from harmful external influences, a double surface coating, a primer and a paint are performed.

Butt joints for such lines are made of cast iron, steel or brass. By design, only two types are suitable:

- threaded (detachable),

- welded (monolithic).

Models of fittings designed for permanent jointing are installed during the main gas supply line. The installation features include the formation of a smooth and smooth annular weld using an electric arc method or gas soldering.

The branches leading to the meter and the devices are held together only by split threaded fittings. The tightness of the joints is ensured by the thermally stable polymer material FUM. Such a tape easily falls on the drill, but it can be damaged by the movement of the clutch in a counter-clockwise direction, which will lead to a leak. Therefore installation of gas fittings using FUM tape requires experience and skills.

Polymer Compound Models

In the event that it is necessary to conduct a branch line under the ground, metal structures can not last a long time. Polymeric components are used for wire laying in the ground.

This material is not corroded, and pipes from it remain in perfect condition for many decades. In addition, such bends are able to withstand the most high pressure, they are made monolithic, that is, without seams, while easily cut, and the docking elements can be fixed with a simple soldering iron.

The connecting parts to such lines must meet all the requirements of strength and tightness. Therefore, polyethylene fittings for gas pipes are not recommended to install. Neither compression nor press models will be able to provide a quality connection, because of the susceptibility to mechanical damage. Even the use of complete insulation, taking into account all security measures, does not provide guaranteed protection against external influences.

The best option in this case are:

- special fittings for HDPE communications, made of brass. Such parts have increased strength, and can provide the necessary tightness;

- welded structure bends are great for polymer products. For their installation low-temperature soldering devices are used;

- electric welded fittings equipped with self-melting spirals. These are the most expensive items, but they are also the most reliable.

Metal fittings for metal-plastic pipes

The main purpose of the use of products from this material is heating communications. But in their technical specifications they are perfectly suited for domestic gas pipelines. Such pipes are able to withstand up to 4.5 mPa of pressure, and this is twice the standard requirements. In addition, the metal-plastic is perfectly mounted with both threaded and crimp connection parts.

For gas wiring, the designs are ideal. Their uniqueness lies in the fact that such a dock does not lose its qualities over time. While threaded connection has a tendency to gradually unwind and lose its reliability.

Just like HDPE products, metal plastic is not corroded, and its flexibility and elasticity allows you not to select the fittings necessary bending, and use fittings or couplings.

Installation instructions for a gas fitting fittings

The advantage of the crimping mechanism is that it is able to provide high strength and reliability of the connection, and during installation there is no need to use welding or threading.

The main component of this design is a clamping ring, which is made of high-strength steel. It is able to tighten the parts tightly, and will not weaken with time, since it is additionally held by a special nut.

The rules of mounting such a joint are incredibly simple, and are available for performance by a non-professional.

- saw off a damaged piece of pipe;

- to clean edges from jags and sharp elements;

- with the caliper, check the compliance of the tube diameter and range of indicators in the instructions to the fitting;

- we mount the connecting mechanism in the following sequence:

- Nut;

- Clamping ring;

- Sealant;

- insert one end of the tube into the clamp body, but not tightly;

- at the other end, put on the seal, ring, clamp and push the casing;

- tighten the nut on the body. Joint is ready.