Ventilation pipes for gas boilers. Exhaust chimney for a gas boiler

From time to time, the owners of the fireplaces note the deterioration of the work of their heating device. With what it is connected, naturally, they do not know. Experiments with the replacement of fuel, usually, also lead to nothing. Experts argue that the cause of poor performance of the fireplace is a weak pull.

"Classic problems":

- The diameter of the pipe is too large or too small. The pipe must be of the correct size. If its diameter exceeds certain norms, then there is a reverse thrust. Bring the fan to the chimney, if its blades start to move - then you have a reverse thrust. Too narrow a pipe leads to a reduction in thrust to critical values.

- Turning elements and bends in the pipe. The chimney must be straight, otherwise you have to put the chimney draft amplifier. Extra turns and bends significantly reduce this parameter.

- Lack of tightness. This problem is often found in brick fireplaces as a result of disrupted building technology. When a small hole appears in the wall, it starts to work on the principle of a black hole, sucking in air because of the difference in pressure. The presence of additional air adversely affects the force of traction. This is the same as putting the fan on the side of the upward air.

If not one of the above problems is not similar to yours, then in this case problems with traction will help to solve the amplifier.

Flue draft deflector

Types of Amplifiers

Deflectors Are aerodynamic devices that specialize in deflecting air currents. With their help, you can adjust the traction force to the required parameters. The ventilator of the deflector operates on a very simple principle: it sucks air from the atmosphere and directs it inside the chimney. The disadvantage of the device is its absolute helplessness in a quiet hike without the wind.

The most common and effective deflectors are the designs of Grigorovich and Volpert. At the heart of modern improved deflectors lie their prototypes. The most common designs: round nozzles on the chimney ("Vopplers"), star-shaped ("Shenards") and H-shaped (multi-tiered). When choosing a deflector, carefully look at the material from which it is made. It should be a stainless steel - a material that is distinguished by its strength and reliability.

Rotary turbines of smoke draft

Rotary turbines- are the mechanisms that are placed above the chimneys. The fan resembles the principle of operation, because it uses wind energy to increase the pressure inside the pipe. Advantages rotary turbines: they cover the chimney pipe and prevent precipitation. The device does not work in windless weather.

The most popular brands are Turbomax, Turbobent and Rotowent. Products The turbine is not suitable for installation on ducts for flue gas evacuation from furnaces.

It is also necessary to ensure that the temperature of the outgoing gas does not exceed a threshold of 250 degrees (these are standard requirements, which may vary from model to model). Rotary pipes are installed for boilers on gas heating.

Weathervane chimneys

Weathervane chimneysIs a device for protecting the chimney from the leeward side. The model is characterized by good resistance to negative effects of atmospheric precipitation, long service and the presence of protective mechanisms for the chimney. During the operation of weathercocks one of their drawbacks was noted: they do not cope with a strong wind, and weathercocks require careful maintenance - regular lubrication (especially in winter) and cleaning from soot and flue gases.

Duck and Dog weathercock - video review

The weathervane fan works on the principle of a stabilizer: reduces the effect of strong wind on the draft in the chimney or reinforces it in the absence of movement of gas masses in the atmosphere. This type of device is excellent for fireplaces that work on firewood.

Chimney smoke exhausters

Smoke exhausterIs an electric heat-resistant fan for the chimney. It is recommended to install these adjustments for traction force only for narrow pipes. It requires access to electrical network, the capacity of 220 V. Modern smoke exhausters have several upgrades, thanks to which the problems of reverse and weak traction are solved. The electric mechanism has no drawbacks, it works fine in quiet and windy weather.

Caps and umbrellas- are decorative elements for the chimney, which do not solve the problem of weak traction. Once installed, the owners heating devices noted additional problems: the formation of condensation on the surface of hoods and umbrellas, as a result of which the fan of the above mentioned devices quickly deteriorated.

Thus, a wide variety of mechanisms for enhancing traction are good at dealing with the problem posed. The above models, in addition to smoke exhausters, combine one drawback: they are too dependent on weather conditions. Therefore, to increase the thrust in the chimney, it is better to choose an electric smoke exhauster.

Manufacture of traction control devices

Manufacture of devices for strengthening traction with their own hands

Well, when a person has money and he can buy himself a few attachments to the chimney, but what if there is no opportunity to get a modern mechanism, however, in the garage there are tools and several metal plates? The answer is simple - to construct yourself.

From the tools you will need: a square, metal scissors, a tape measure, a hammer, pliers, a drill, screws (15 mm), a galvanized sheet of metal with a thickness of 0.3-0.5 mm and a few handy materials for fixing and an old fan, its blades.

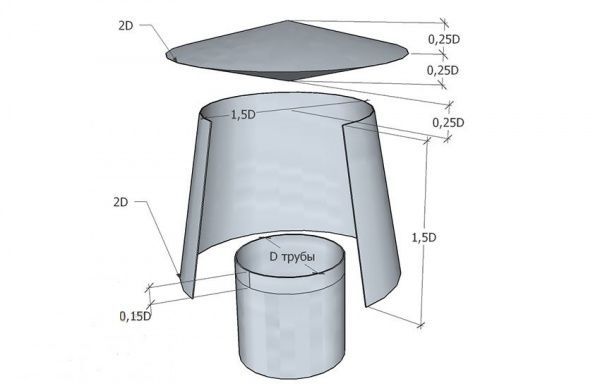

Draw a layout of devices to enhance traction

The first thing to do is draw a model of the future device. Drawings of schemes can be found on the Internet. After the exact transfer of dimensions to a sheet of galvanized steel, such actions are performed in strict sequence:

- With the help of a Bulgarian or metal scissors, the main details of the weathercock are cut out;

- The components of the weather vane are assembled according to the scheme in a strict sequence and fixed with rivets or self-tapping screws;

- Then it is necessary to fix both cones (in most schemes this item is skipped, since "masters" believe that it can be ignored). In fact, this item is highly discouraged to ignore, so as not to provoke tearing of cones in strong winds;

- Now it remains to put on the device fasteners and a fan. With the help of fasteners, the device is attached to the chimney base. The fan performs the function of strengthening the thrust.

Flyugarka

At this stage, the manufacture of the weather vane is considered finished, it remains only to attach it to the chimney. It is fixed by means of screws or rivets. Remember that these devices need regular maintenance: from time to time it must be cleaned from soot and accumulated condensate, if you do not want the accumulated moisture to get on the waterproofing layer inside the pipe.

Video: Booster of the furnace, boiler and chimney

Secrets of treating joint pain from our regular reader.

Hello!

My name is Gennady Alexeevich. I'm a stove man with more than 20 years experience. I am engaged both in repair and construction of Russian furnaces and fireplaces. The work is always performed very accurately and carefully, which negatively affects the condition of the joints. With age, the pain began more and more, right up to the point where I could no longer work. After a lot of both drug and folk ways treatment, I realized how serious my disease is, since there was no positive effect. Until I came across one tool, which I want to tell you about.

This is a unique mixture of the rarest and most powerful natural medicinal substances. This tool has proved its effectiveness not only to patients, but also to science, which recognized its effective drug. The pains in joints and back go for 10-15 days, as studies have shown. The main thing is to follow the instructions in the methodology clearly. Order the product in its original packaging , with a guarantee of quality can be on

For the heating of a private house, owners are increasingly using, not old stoves, and modern heating systems. Based on what fuel is used, there are solid fuel (coal), liquid (diesel) and gas systems.

Installing the hood is necessary for normal operation of the boiler

Gas boilers are the most convenient and efficient equipment for autonomous heating. The boiler equipment is installed in separate rooms, boiler rooms, with its own ventilation system. Air circulation is extremely important for the normal functioning of the heating and safety of the residents of the house.

Boiler rooms and ventilation system in them

At the heart of the autonomous heating system is the combustion process. During combustion, fuel, interacting with oxygen, turns into carbon dioxide and water vapor. As a result of this process, a large amount of heat is released. Gas boiler houses are equipped in attic rooms, separate rooms or in buildings far from the house. Boilers can not be installed in basements.

To maintain combustion in the gas boiler, constant circulation is necessary, exchange of contaminated carbon dioxide to oxygen-rich air. This can be done with the help of an air ventilation system. Air exchange can be natural and forced. Natural air exchange is provided by open windows, crevices in the doors, exhausts with a flow mechanism, chimneys.

Forced or mechanical air exchange is provided by the fans. Exhaust fan for gas boiler will pull the combustion products outwards, and the supply air will bring clean oxygen inside the room. Forced ventilation, an exhaust or a chimney - obligatory attributes of a boiler-house.

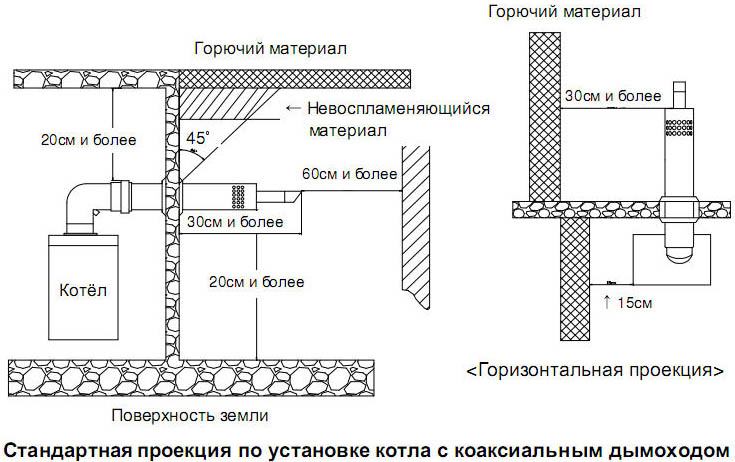

Mounting diagrams exhaust pipe in a private house, which is necessary for the safety of tenants

Ventilation is needed not only to maintain boiler operation and improve the efficiency of heating, but also for the safety of tenants at home. In the process of fuel combustion, carbon monoxide is released. At high concentrations, it causes suffocation and death, and with small drowsiness, fatigue and dyspnea. Also, when the gas boiler is operating, small leaks may occur natural gas, which is also not safe for humans. Extraction for the boiler will not allow dirty air to spread to other rooms and protect the family from harmful influences.

Boiler arrangement rules

Sanitary rules prescribe the requirements for the arrangement of domestic boiler houses and ventilation in them.

- The outlet duct in the boiler room with a gas boiler is located at the top, on the ceiling.

- At 30 centimeters below the opening for the arrangement of the chimney, an additional channel is made. He will participate in cleaning the chimney.

- Clean air must come through the vent from the street or from the adjacent room from the boiler room through the holes at the bottom of the doors.

- From the street in the boiler room should get air in the amount of 30 square centimeters per unit capacity of the boiler.

If the boiler operates at a capacity of up to 30 kilowatts, then it is not necessary to equip it in a separate room. It is installed in the kitchen, when:

- the area of the room is more than 15 square meters;

- the ceiling is at an altitude of more than 2 meters;

- windows are easily opened and equipped with a window;

- at the bottom of the door, holes are drilled for airflow from the adjoining room.

A large-capacity heating boiler is installed from the boiler room

A large-capacity heating boiler necessarily requires a boiler house. The walls in the boiler house of a private house must be made of non-combustible materials. The equipment is installed at a distance of more than 10 centimeters from the wall.

Installation of exhaust equipment

For ventilation in a room with a gas boiler, natural draft is most convenient. The diameter of the vent is 15 to 25 centimeters, depending on the capacity of the boiler. A small plastic tube is inserted into the tube. The inner opening of the tube is equipped with check valve. It prevents the drawing of clean air back to the street. Outside the house a hole is covered with a mesh, protecting vent channel from clogging.

The installation of the hood is exactly the same. The outlet part of the exhaust pipe is closed by a cone to protect the interior space from debris and sediments. The extractor is installed directly above the boiler, and the supply air duct behind the fuel compartment. The hood for the boiler houses in the house should be made of a heat-resistant material that withstands sudden temperature changes. The hood housing must be resistant to gas, sulfur, ash and rust.

The ventilation system, based on natural draft, is easy to arrange with your own hands. But it has one significant drawback. By health standards The air in a room with a gas boiler must be renewed completely three times in one hour. Adjust and control the natural traction ventilation can not. The circulation of gases is directly dependent on the time of year and the direction of the wind.

Chimneys for boiler room ventilation

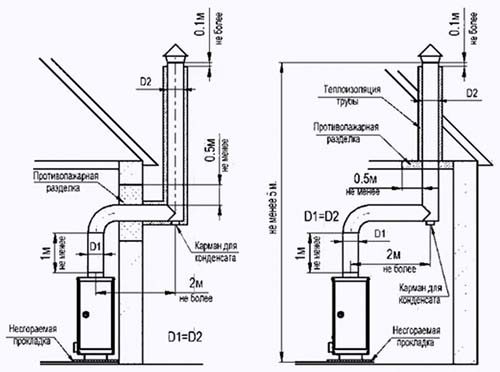

The principle of the chimney is also based on traction. On the chimney carbon dioxide and carbon monoxide, steam, ash and other by-products are released into the atmosphere. In domestic conditions, use vertical and horizontal chimneys. Household chimneys have a cylindrical shape and are made mostly of stainless steel. Chimney often build their own hands of stone, brick or concrete. Chimney ventilation must comply with sanitary standards.

- The chimney is made completely sealed, smoke and gases must not be allowed to enter the boiler room. To ensure this, the chimney pipes are plastered. Do this usually with their own hands.

- The chimney should rise 2-5 meters above the roof of the house to ensure normal draft.

- The diameter of the chimney of the boiler should be slightly less than the ventilating exhaust chimney.

- The size of the chimney pipe section is always indicated in technical characteristics boiler.

- The chimney duct must not have more than three curved sections.

Chimney for gas boiler requires periodic cleaning

The disadvantage of chimneys is that they require periodic cleaning. Chimneys are regularly clogged with soot and soot. Inspection and cleaning of pipes is carried out according to the rules before the start heating season, when they do not function.

Equipment for artificial ventilation boiler room

There are cases when natural ventilation in a room with a gas boiler can not be arranged. In such cases, a forced mechanical air exchange system comes to the rescue. Fans are used to draw out dirty air and feed clean room into the room. Most often for household needs, they use aggregates built into the ventilation duct. They are called channel. The longest-serving models are closed in cases of copper and aluminum. These materials are resistant to high temperatures.

To save, equipment that is designed only for removing or inflowing air is often installed. But for greater safety it is better to install a complete mechanical circulation system.

The exhaust fan for the gas boiler is selected depending on the capabilities of the boiler itself, the number of bends and the length of the duct. It is necessary to select a fan with a power reserve.

The most important plus mechanical ventilation system in the boiler room - the possibility of automatic control. When the boiler is turned on, the sensors start the fans. After turning off the boiler, the fans circulate the air for a while and then automatically turn off. Installation of ventilation equipment is often produced independently, but it is better to use the help of builders, because the devices are quite heavy.

The house needs high-quality autonomous heating. Proper deployment of ventilation will ensure high performance, safety and long service heating boilers.

The boiler is a wonderful and inexpensive way of heating and hot water supply of a private house. In the process of burning natural or liquefied gas, so-called combustion products are formed, which need to be removed. Complete operation of the unit is not possible without such an element as a pipe for a gas boiler.

The chimney for a gas boiler is identical to the similar structures installed on solid or liquid fuel assemblies. But there is a basic rule that treats which chimney pipe for a boiler should be. Most often it is made of stainless, enamel or aluminum.

Brick options are no less popular. But from the inside they must be protected with a metal sleeve. The thing is that in the combustion of gaseous fuels an acid condensate forms, which destroys the brickwork. Some manufacturers offer smoke condensing devices made of plastic for condensing boilers of low power.

The general scheme is identical to the typical smoke extraction channels and consists of the actual pipe, branch pipes, flanges, adapters, conical tip, fasteners and condensate collection system.

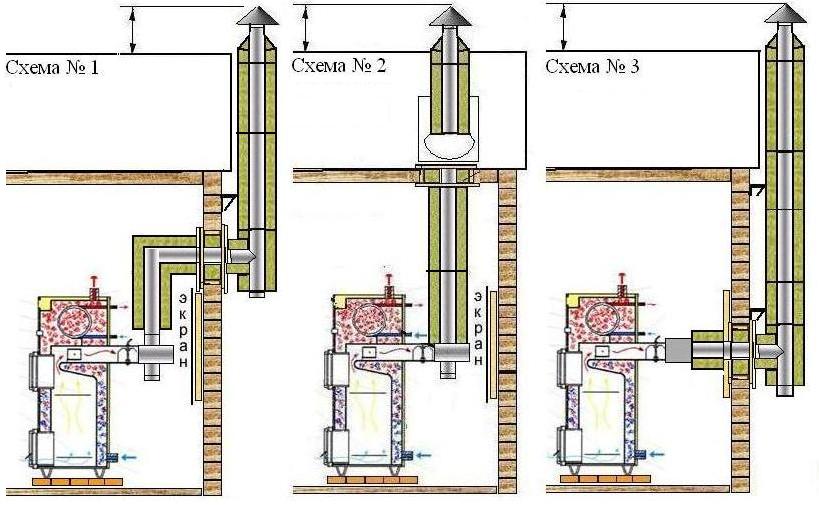

The characteristics of the exhaust chimney structures depend on the type of boiler. If it is equipped with an open type burner, the duct performs only the extraction functions and is installed strictly vertically. For indoor combustion chambers, an intake and exhaust system is made. It consists of an outer coaxial with a larger diameter, through which air enters the burner, and a smaller internal one functions as an extract for a gas boiler.

Design and installation of chimneys should be entrusted to professionals. When self-installation be prepared for the fact that the manufacturer of boiler equipment will refuse warranty repairs.

Dimensions and cost

The choice of pipes for the chimney of the boiler starts from the dimensions. The diameter is calculated based on the boiler output and the cross section of the inlet. Large manufacturers, as a rule, give recommendations on the selection of the exhaust system for each model or series.

If they are not available, the following definition can be used: the internal area of the channel must be equal to or greater than the same value for the boiler. Calculated by the formula (for a round chimney):

- S = π x Internal diameter x Chimney height.

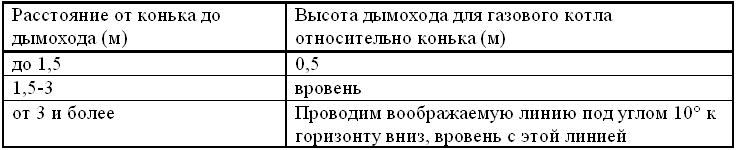

The standard length is from 2 meters. The table below gives the minimum values, depending on the position of the pipe relative to the roof ridge.

Before you buy vent pipes for the boiler, check the main parameters again. If the area is redundant, the diameter or length changes. Varying these indicators, the ideal variant is chosen.

Very often buyers of boiler equipment with a closed combustion chamber are interested in the review coaxial tubes for gas boilers. As a rule, it includes the description and advantages of the kit, but there is very little about the cost of its acquisition and installation of information.

Coaxial chimneys are sold separately for components, the selection is made directly at the point of purchase of the boiler or in organizations that specialize in engineering facilities. The price of a smoke pipe for a heating boiler depends on the material from which it is made (steel, plastic), the length and number of elements. Average running meter starts from 2 000 rubles.

Most well-known manufacturers supply ready-made kits, their price is not too different from analogs. For example, the cost of construction for a gas boiler Baxi varies from 3,000 to 5,000 rubles per 1 running meter. Accessories should be selected individually.

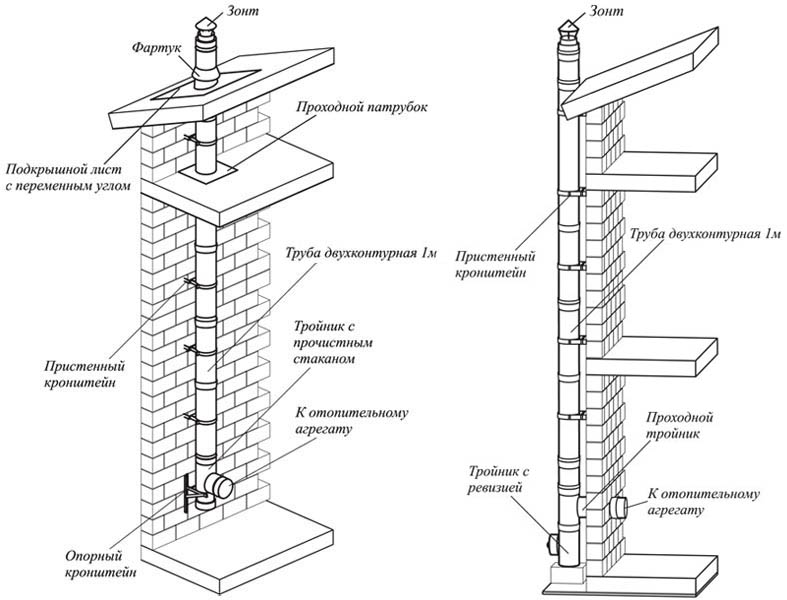

Chimney installation

Installation is carried out inside the house or outside. Schematically it looks like this.