How to make steam heating. Stages of mounting the device. Video - Installing the boiler

1.

2.

3.

4.

5.

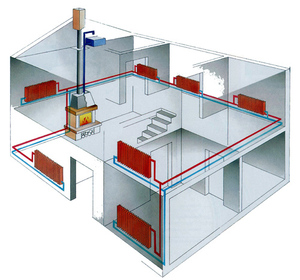

Steam heating is still in demand in the private residential sector, with the help of effective scheme steam heating heating country cottages, holiday homes. Thus, property owners prefer to use steam as the heat carrier.

At one time the principle of operation of steam heating was used for heat supply of large buildings. Steam for this purpose was obtained as a result of the operation of special devices - steam generators or it was a by-product of some production processes. Now this type of heat supply is successfully used in own households.

The scheme of steam heating of a private house consists of heating boilers of compact sizes and its structural elements are notable for availability, therefore it is able to make a worthy competition to the traditionally used water systems.

Features of steam heating

At present, the scheme of steam heating in a private house is an inexpensive and at the same time an effective solution to the problem of heat supply to a suburban building.Such heating systems have a lot of advantages, among which I would like to highlight the following:

- high efficiency. The equipment can work for a long time without losing its original characteristics. Use it is beneficial because of high performance;

- in the design there are no heat costs. These positive moments are achieved as a result of the use of pipes with a smaller cross-section. Steam, unlike water has good heat-accumulating characteristics, it perfectly transfers heat through radiators;

- even the largest room warms up very quickly. According to the instructions attached to the steam equipment, the steam is characterized by low inertia, and therefore the rooms with high efficiency are heated in a short time.

Principle of operation of steam heating

Before installing the steam heating yourself, you need to understand the principle of its operation. First, the water in the steam boiler is brought to the boiling point, and it begins to evaporate. Then the steam enters the pipes and radiators, and thanks to the condensation it returns back to the heating boiler.The air in the pipes of steam heating structures is not delayed, since it is displaced by the steam supplied under high pressure, and therefore there are no problems with air-quenching in them. Outside the air is discharged through the air vent pipes.

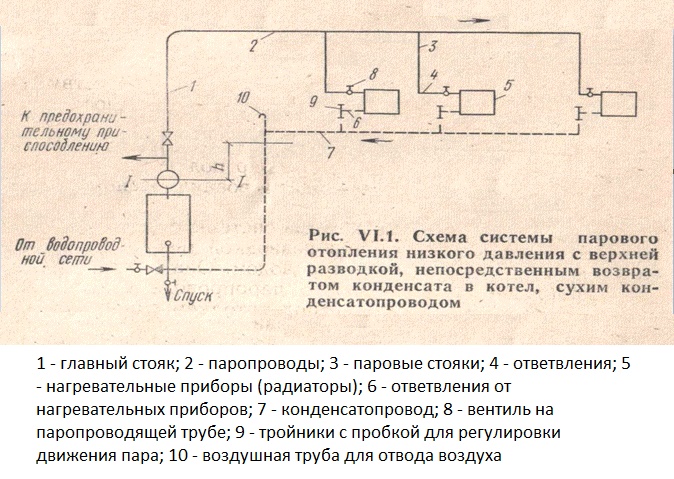

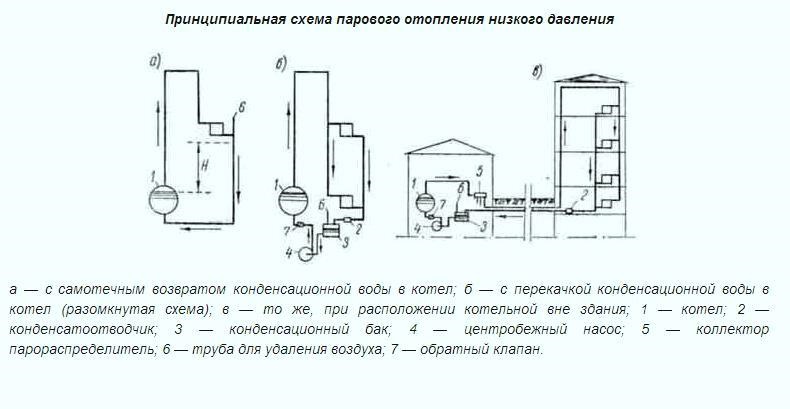

Variants of steam heating schemes

Currently, there is a large number heating circuitsoperating with a heat carrier such as steam. Naturally, the price of building a heat supply system and its efficiency directly depend on which type of steam heating system is involved.Small cottages and their own homes often use heating systems with steam at low pressure, about 100-170 kg / sq. M. Not less popular are vacuum-steam structures - in them the pressure reaches 100 kg / m 2.

When the household is large, it will be prudent to install a system that operates with high pressure of such a coolant as steam. If steam heating is created - a scheme of this type provides that the pressure in the mains can reach 600 kg / m 2.

![]()

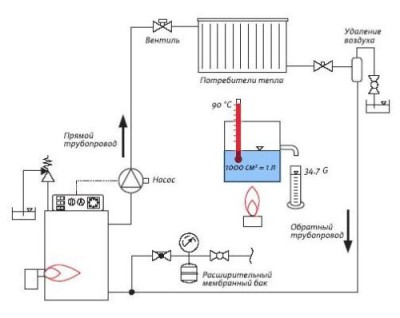

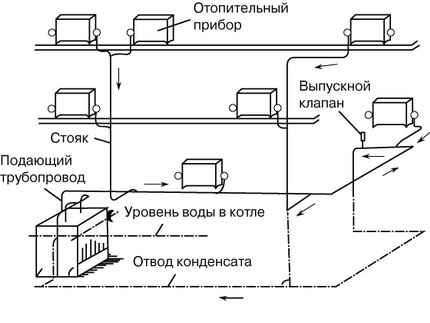

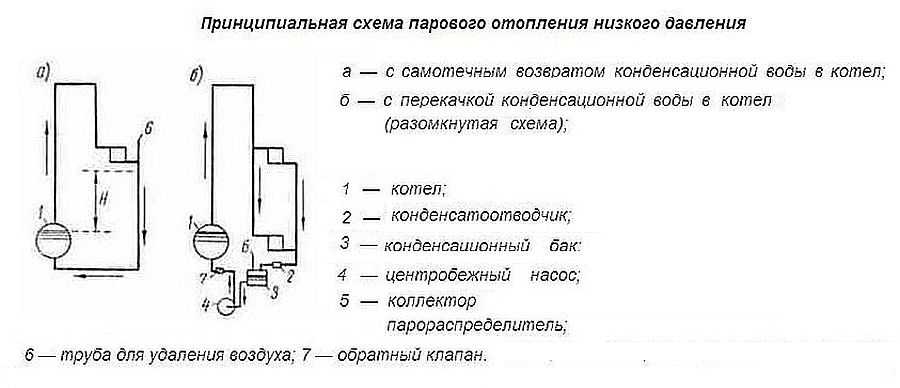

Also, steam heating systems differ in the way the condensate returns to the heating boiler.

They are:

- open (open) - the condensate is collected in a special tank and pumped after cooling into the boiler for subsequent heating;

- closed (closed) - they mount a wide diameter pipe, through which the condensate returns to the heating unit by gravity.

Self-assembly of the steam system

It is not difficult to build a steam heating system on your own. The main thing during work is to pay attention to every detail and adhere to certain rules.The creation of steam heat supply is carried out in stages:

Drafting. This document must be approved by the relevant state control agencies. It indicates the location of the radiators, intake valve, heating boiler. A drawing of the heating structure and calculation of the steam heating will also be required.

Preparation of the boiler room. As you can see in the photo, it is important to ensure its protection when building a room. For this purpose, the walls are covered with non-combustible material, for example, sheet asbestos can be used. At this stage, the foundation for the installation of the boiler is also poured.

Boiler installation. It is placed below the level of the pipelines and radiators. This allows you to move the steam along the heating structure upwards. Simultaneously, the condensate will be sent to the boiler by gravity.

Installation of pipelines and installation of heating radiators. The main thing that you must pay attention to is the right choice of the type of pipes (it is preferable to give copper products) and the diameter of the articles. They need to be mounted in the building. It is forbidden to use plastic, which is not able to withstand high pressure in the system.

When creating steam heating in a private house - the scheme provides for the installation of radiators by using welding or threaded connections. The main thing in this matter is the adherence to tightness, otherwise pipes, under high pressure, will let steam pass.

Installation of a heating boiler and sensors. A heat meter must have a pressure gauge and other adjusting devices.

Testing the working capacity of the heating system. Usually for such work should be invited professionals. Specialists of the appropriate qualification will perform correctly the procedure of the first start-up of the unit and the heating system in full compliance with existing norms and standards.

When there are problems during the startup process, then they are urgently required to be eliminated. Otherwise, the construction of heat supply is prohibited. On each battery, two cranes should be installed - one for temperature adjustment, and the other - for system shutdown.

Types of steam systems

Boilers that are used when the scheme of steam heating is arranged single-story house or a higher-storey building, are on the market today in a wide range.With their use, you can equip two types of circuits:

- single-circuit system - provides heating of the house by steam;

- double-circuit design - steam is used not only for heating the house, but also for heating the water. These schemes are convenient, practical, functional and productive.

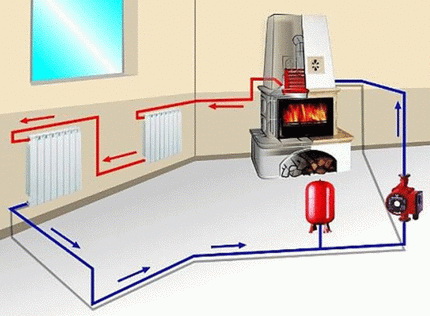

There are many ways to heat your home. You can use the Russian oven and fireplace, solar collectors, steam and heated water. But those who decided to live in a private house constantly, often choose a water or steam heating system. And this has a reasonable explanation.

When heating the premises with water and steam, a stronger and even warming of the air, as well as walls and floor, takes place. In addition, such a wide distribution of these kinds of heating systems is affected by the peculiarities of our severe climate, as well as the prices for gas and electricity available (for example, in comparison with the member countries of the European Union) to the average citizen - the main resources used for heating water.

Steam heating is well known and has been used successfully already 100 years.

Steam heating is well known and has been used successfully already 100 years.

What does it look like?

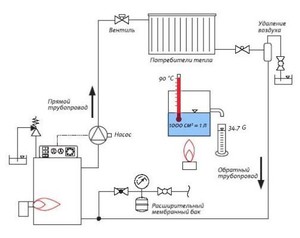

Steam heating is steam heating system, which is formed when boiling water in the boiler, and then enters through the pipes in the radiators installed throughout the perimeter of the premises.

Required components of the system of steam heating:

- the boiler - heats up and accumulates water;

- exhaust valve;

- radiators;

- pipes;

- pump;

- firebox.

There are open and closed systems heating. In the first case, the pump helps to return to the boiler. When closed system heating, the resulting condensate itself falls back into the heating boiler under the influence of gravity and because of the small technological slope of the pipes.

There are systems with high(from 170 to 600 kg / m2), with lowsteam pressure (from 100 to 170 kg / m2), as well as vacuum-steam (up to 1 kg / m2). This division is not accidental. It depends on many technical specifications system, for example, from the total length of the pipes from the boiler to the radiator furthest from it.

In addition, the following types of pipes are used:

- Single-tube- when both steam and return condensate pass back and forth through one pipe. But for this reason, there is one drawback - extraneous sounds in the system.

- Two-tube- one pipe passes through the system, and the other formed condensate, returns to the boiler. Both pipes are closed in a single cycle.

Owners of private homes are more likely to choose two-pipe system. Why? The fact is that this type of wiring allows you to adjust the temperature in the system with a valve. In the case of single-tube operation, this is only possible with a decrease in capacity or productivity of the boiler, which entails a risk of underheating in the winter.

Types of fuel required for the operation of a steam heating system:

- Solid (firewood, coal),

- Liquid (fuel oil, diesel oil),

- Gas (natural).

Currently, there are the following types of steam boilers:

- Gas tube (low power, but increasing it can lead to an explosion).

- Water tube (more modern and safe).

The second type of boilers is increasingly common in private homes. Such devices are divided into the following types:

- Vertical - characterized by the presence of two or more drums, located at different levels.

- Horizontal - here to the drum still join the drainage channels, called collectors.

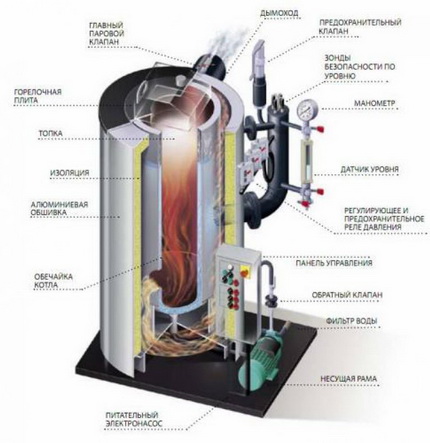

Components of a standard heating boiler:

- Burner.

- The furnace.

- An ashtray.

- Drum.

What do I need to know when choosing and installing?

Those who build their own house and intend to install a steam heating system (or to replace the existing one), it is important to know about the prohibition of use plastic pipes. The fact is that because of the very high temperatures of water and steam (over 100 degrees Celsius) all the components of the system are subjected to enormous loads, which can withstand only the metal pipes.

Since this is a complex system, it is always necessary to remember its reliability. Homeowners need to purchase only materials and equipment manufacturers (not "underground" production), and the installation of the system should produce experienced profile professionals. When choosing a boiler, it should take into account its power, which directly depends on the number of rooms in the house, the height of the ceilings in them and the winter temperatures in the region. But you do not have to overdo it, so as not to pay more money for electricity or gas, which uses a boiler to heat water. It is equally important to clarify the amount of steam produced by the boiler (calculated in kilograms). This affects the speed of heating the rooms.

Thus, if you have a big house somewhere near Yakutsk, then choose a more productive and powerful boiler.

Normative requirements for rooms where the steam heating system will be installed:

- Fire resistance of walls - from 75 min. (brick or cladding with ceramics).

- Fire resistance of the door - from 30 min.

- The presence of doors and windows on the street.

- The distance from the walls to the boiler is more than 1 meter.

- The height from floor to ceiling is 2.20 m.

- Presence of ventilation (serviceable).

Advantages and disadvantages of steam heating

Benefits of the system:

- warming up the premises in the shortest possible time;

- the possibility of heating the house in several floors (because of its lightness, the steam has the ability to independently rise to any altitude, cooling down, it turns into a heavier condensate, and descends back into the boiler, which excludes installation costs additional equipment, for example, pumps);

- fuel economy (in comparison with other heating systems) due to high heat transfer;

- cheaper materials.

The disadvantages are:

- too high temperature of heating devices;

- short service life of equipment and pipes (due to very high temperatures it is necessary to make replacements on time).

If you analyze all the pros and cons of this system, it becomes clear that in many cases, its use is fully justified. First of all, this is economy (cheaper materials and savings on fuel), secondly performance because of higher speed and volume of heating.

If you analyze all the pros and cons of this system, it becomes clear that in many cases, its use is fully justified. First of all, this is economy (cheaper materials and savings on fuel), secondly performance because of higher speed and volume of heating.

Thus, the advantages of this system not only make all its shortcomings insignificant, but also prominently steam heating from a number of other heating systems in private households.

It is not recommended to install a steam heating system only to people who are afraid of such equipment in mind explosion risks, and who in the house small children- due to possible burns due to the high temperatures of the heating devices (but even in this case there is a way out - the installation of protection systems within the reach of children).

The main competitor of the steam water system heating. But the latter is different the greatest cost for materials.

No matter how comfortable and comfortable the apartment is, almost every one of us dreams if you do not completely replace it for an individual house, then at least have a private property outside the city. And comfortable and comfortable. It is clear that in vacation home water must be supplied, it is necessary to properly arrange the sewage system. And, in addition, in the house you need to create an efficient heating system. In this case, it can be confidently stated that steam heating is the fastest and most affordable option for its creation. Steam heating in a private house, despite the variety of other options for heating the building, does not lose its relevance. And this is a simple explanation: its functionality and reliability are verified by practical experience - it has been used by various consumers for many decades. Such a system is simple and understandable, that is, any person can even equip steam heating with their own hands, even without special knowledge in this area.

Steam heating in a private house can be performed:

- Single-loop.

- Two-circuit.

A single-circuit system is designed exclusively for heating the building, and a two-circuit system not only heats the house, but also provides it with warm water for domestic needs. Pipelines of steam and radiator batteries are characterized by a high temperature of heating - in some cases it can reach 100 0 C or more. The piping system includes horizontal and vertical pipes. The layout can be lower or upper - depending on the features of the room.

Choosing a heating boiler

Important! The heating system is the key element of the heating system. It is for this reason that the main emphasis should be placed on his choice. In order for the boiler to perform its direct function as efficiently as possible, it must be properly selected according to the size of the heating area of the building's interior.

In other words, the heating boiler should have enough power. Proceeding from this, we choose:

- for an area of 60-200 square meters. m - 25 kW;

- for an area of 200-300 square meters. m - 25-30 kW;

- for an area of 300-600 square meters. m - 35-60 kW;

- for an area of 600-1200 square meters. m - 60-100 kW.

The heating boiler of steam heating can work on fuel of such types:

- solid;

- liquid;

- combined;

- natural gas.

The pressure in the steam boiler is commensurate with the atmospheric pressure. That is, its indicators may be lower in the case of a vacuum-vapor system or higher up to 6 atm.

The constituent elements of the heating unit are:

- firebox;

- an ash pan;

- burner.

The key role of the design is assigned to the drum, to which the measuring instruments, automatic fuses and the pipeline system are attached.

Steam boilers can be gas-tube with a division into such subspecies: smoke, fire-tube, smoke-flame. In everyday life, most often there are water-tube boilers, because they are distinguished by high potential.

Pipes for steam heating - features of choice

In this case, it increasingly depends on the individual wishes of the landlord. Steam heating in the country, in a cottage or a house can be made of several types of materials.

Steel pipes

Installation implies implementation welding works. The steel heating pipeline is reliable and durable, but has one obvious drawback - low corrosion resistance.

Stainless and galvanized

Do not have the above disadvantage, they are connected threaded connections, however are not cheap "pleasure".

Copper variant

Copper piping for steam heating

They are considered very reliable - they behave well under high pressure and elevated temperatures. Mounting is performed by high-temperature soldering. Copper pipes without fear can be embedded in the wall. The copper heating pipeline is one of the most expensive options and is most often performed in luxurious mansions built under an exclusive project.

Important! If you decide to arrange steam heating with your own hands, then when designing the project, the material from which the pipes are made must be taken into account.

What does the design of such a system take into account?

One of the variants of the scheme of the device of steam heating

The scheme of steam heating really competently will be designed if it takes into account such features:

- Length of the pipeline.

- Number of adapters, tees, adapters.

Note! Do not flatter yourself that the scheme - it's very simple. Even if you have a small house all the same on the outline of the heating pipeline route, you need to identify all the turns, trivialities and branches.

How does this all work?

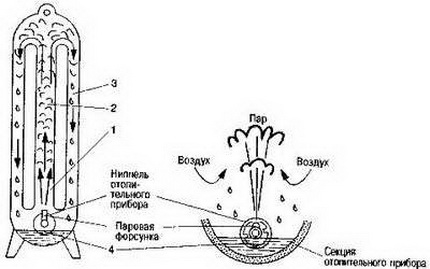

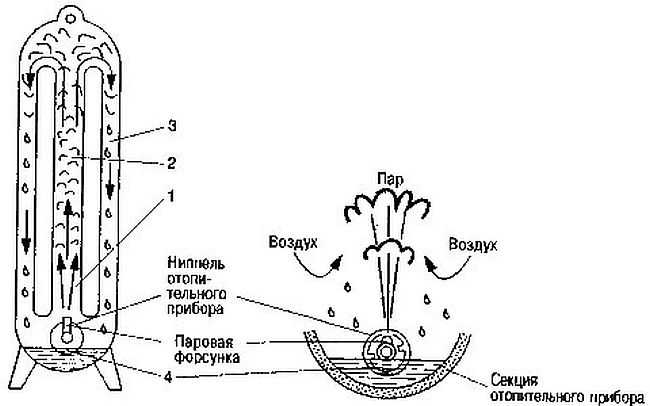

So, in a steam heating system, the boiler serves as a source of heat, and heating devices - radiators, convectors, smooth or finned tubes. The steam is taken from a steam turbine or a reduction-cooling unit (DOC). In the operating system, the formed steam, transformed into condensate, returns by gravity to the source of heat - in closed systems, in open systems - by means of a pump. To create a steam-heating pipeline, pipes of small diameter are used. And in thick walls there is no need.

Important! When creating a house heating on the basis of a steam boiler, it is necessary to use certified equipment. From this will depend not only on its reliability, but the safety of the operation of such a system.

Video with an example of the operation of such a system

How to make steam heating? We hope that after reading this article, you will no longer doubt that you will be able to independently perform steam heating in your home. If you have any additional questions about this topic, you can easily find answers to them on other pages of our website.

Every house must be warm, otherwise it will be very uncomfortable to live in it, even if it is very spacious and beautiful. Owners solve the problem of heating in different ways, based on their own capabilities and climatic conditions. Some equip steam heating in their homes: it is quite easy to assemble such a system with their own hands. How to do it? Let's try to understand.

Many confuse the system of steam and water heating. Indeed, outwardly they are very similar. In both cases there is necessarily a boiler, pipes and radiators. But for the steam system, steam acts as the heat carrier, water for the water system.

This is the fundamental difference between the two systems. The boiler does not heat, but evaporates the water, the resulting steam moves through the pipes to the radiators.

The principle of operation of the steam heating system is very simple: as a heat carrier, steam produced in the steam generator

Inside of them, cooling and condensation of steam take place. In the process of condensation of a kilogram, steam releases more than 2000 kJ of heat, while cooling at 50 ° C gives only 120 kJ of water. It is clear that the heat output of steam is several times greater, which explains the high efficiency of heating of this type. The condensate formed inside the radiators flows down to the bottom of the parts and gravitates towards the boiler.

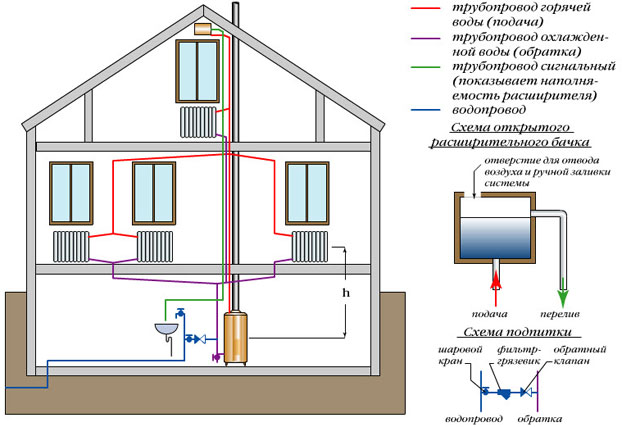

By the way of return of the heat-transfer agent turned into condensate, all kinds of steam heating systems are divided into two varieties:

- Closed. In this case, there are no ruptures in the circuit, and the condensate flows down the pipes laid at a certain angle directly into the boiler for subsequent heating.

- Open-ended. The system is characterized by the presence of a storage tank, where condensate from the radiators enters. From this tank, it is pumped back into the boiler with the help of a pump.

According to the methods of assembling and distributing pipes, steam heating circuits are divided into species that are absolutely analogous to water systems.

The contours of steam heating are constructed according to the principle of water systems. Steam rises on the riser, moves along the mains to heating devices. Only instead of the return condensate is collected, formed during the transfer of steam thermal energy to the consumer (+)

According to the parameters of the absolute pressure of the heating system, the ferry is divided into varieties high pressure with an excess of\u003e 0.07 MPa; low pressure with an excess pressure in the range of 0.005-0.07 MPa; vacuum with absolute pressure<0,1 МПа. Если в контурах низкого давления есть участки или приборы, сообщающиеся с атмосферой, их относят к категории открытых, если нет — закрытых.

Why choose steam heating

It must be admitted that steam heating systems can not be classed as very popular. Such heating, rather, is rare. Let's consider in detail its merits and demerits. Among the first, indisputably, are:

- Efficiency of the heating system. It is so high that a small number of radiators will suffice for heating the rooms, and in some cases you can do without them: the pipes will be enough.

- Small inertia of the system, thanks to which the heating circuit heats up very quickly. Literally a few minutes after starting the boiler, the rooms begin to feel warm.

- There is practically no heat loss in the system, which makes it very economical compared to others.

- The possibility of rare use, because the system does not defrost due to the small amount of water in the pipes. As an option can be installed in the cottages, where they come from time to time.

The main advantage of steam heating is considered to be its economy. The initial costs for its arrangement are rather modest, during operation it requires relatively small investments. However, even with so many advantages, the system's shortcomings are very significant. They are primarily connected with the fact that water vapor is used as a coolant, the temperature of which is very high.

Condensation of water vapor occurs inside the radiator of steam heating. During this process, a large amount of thermal energy is released, which explains the high efficiency of the system

Due to this, all elements of the system are heated up to 100C and even higher. It is clear that any accidental contact with them will cause a burn. Therefore, all radiators, pipes and other structural parts must be closed. Especially if there are children in the house. The high temperature of radiators and pipes provokes active circulation of air in the room, which is quite uncomfortable, and sometimes dangerous, for example, with an allergic reaction to dust.

When using steam heating, the air in the rooms becomes too dry. He overdies hot pipes and radiators. This requires additional use of humidifiers. Not all the finishing materials with which the rooms heated in this way are decorated stand the neighborhood with hot radiators and pipes. Therefore, their choice is very limited.

The most acceptable option in this case is a cemented plaster painted with heat-resistant paint. All the rest is in question. There is a steam heating one more affecting the comfort of living in the house shortcoming: the noise that produces passing through the pipes of steam. To more significant disadvantages can be attributed to poor controllability of the system. The heat transfer of the structure can not be controlled, which leads to overheating of the premises.

Steam heating belongs to potentially hazardous systems, so the choice of equipment must be treated very responsibly. Pipes for the system must be only metal

There are solutions. The first is the installation of automation, which will include the boiler when the premises cool down. In this case, living in the house will be quite uncomfortable from the constant temperature fluctuations. A more "sparing", but time-consuming way - arrangement of several parallel branches, which will need to be put into operation as needed.

The main disadvantage of steam heating, because of which it is used little, is its increased emergency danger. It should be understood that if there is an explosion from the pipe or radiator under pressure, hot steam will be beaten, which is extremely dangerous. That is why such systems are now banned in apartment buildings and less commonly used in production. In private houses they can be arranged under the personal responsibility of the owner.

The main elements of the steam system

The composition of the steam system includes several mandatory elements. Let's consider each of them in more detail.

"Heart" of the system: steam boiler

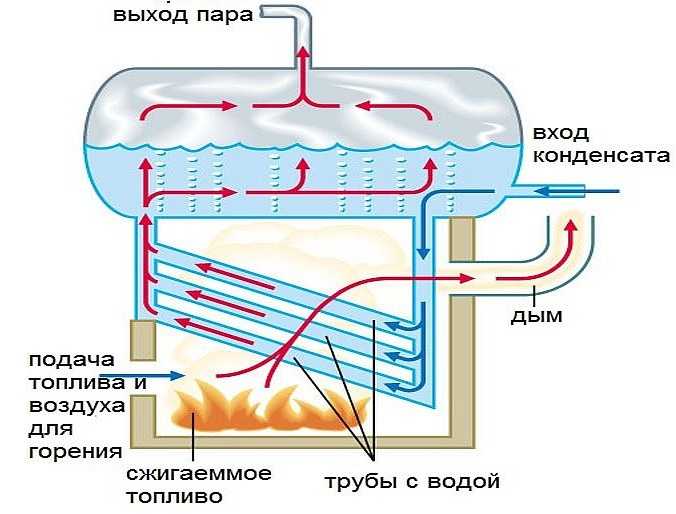

The main function of the heater is to convert the water into steam, which then flows into the pipeline. The main structural elements of the device are collectors, a drum and pipelines. In addition, there is a container with water, which is called a water space. Above it, during the operation of the device, a vapor space is formed. They are separated by the so-called evaporation mirror.

The figure shows schematically one of the varieties of a domestic steam boiler

Inside the vapor space, additional equipment can be installed to separate the steam. At the heart of the boiler is the principle of heat exchange of flue gases, water and steam. There are two types of steam heating devices: fire-tube and water-tube. In the first case, heated gases move through the pipeline inside the water tank.

They give off the heat of the fluid that reaches the boiling point. The water-tube species work somewhat differently. Water flows through the pipes laid inside the chamber with flue gases. It warms up and boils. Water and steam inside the boiler can move forcefully or naturally. In the first case, the pump is switched on in the design, in the second case, the density of water and steam is used.

In all varieties of steam boilers, the same principle of water conversion into steam is used:

- Prepared liquid is supplied to the tank located in the upper part of the boiler.

- From here, the water flows down the pipes into the collector.

- The liquid from the collector rises to the upper drum, passing through the heating zone.

- Inside the pipe with water, steam forms as a result of heating, which rises upwards.

- Steam, if necessary, is passed through the separator, where it is separated from the water. After that he enters the steam line.

A steam boiler can use a wide variety of fuels. Depending on this, certain changes are made to its design. They touch the combustion chamber. For a solid fuel, a grate is arranged on which coal, firewood, etc. are placed. For liquid and gaseous fuels, special burners are used. There are also practical combined options.

Among domestic craftsmen, the use of steam heating with the use of a stove is very popular. The photo shows one of the possible options for converting the furnace

Depending on the heated area, the boiler output is selected. This can be done based on the average values:

- 25 kW for buildings up to 200 sq. M. m;

- 30 kW for homes ranging from 200 to 300 square meters. m;

- 35-60 kW for buildings from 300 to 600 square meters. m.

If you need more accurate data, use the standard calculation method, where for every 10 sq. Km. meters account for 1 kW of power equipment. Do not forget that the formula is used for houses with a ceiling height of 2.7 m or less. For higher buildings, the power needs to be taken more. Particular attention when choosing a boiler should be turned to its certification. Any system of steam heating is potentially dangerous, therefore testing of equipment is mandatory.

Pipes and radiators for heating

The temperature of the coolant in steam systems ranges from 100 to 130C, which is much higher than in liquid systems, where it is from 70 to 90C. Therefore, it is strongly recommended not to use similar equipment for the arrangement of systems. First of all, this applies to metal-plastic and polypropylene pipes. The limiting operating temperatures for these materials range from 90-100C, so their use is strictly prohibited.

Ideal for equipping a steam heating system with copper pipes. They are not susceptible to corrosion, can withstand high temperatures, but are very expensive

For main pipelines of steam systems, three types of pipes are usually used. The cheapest option is steel. They easily withstand the temperature of 130C, which is more than enough, and are characterized by sufficient strength. However, the condensate formed inside the parts breaks down pipes rather quickly, because steel is prone to corrosion, and the corrosive medium formed by steam only strengthens this defect.

Another drawback of steel elements is the need to weld by welding, which takes a lot of effort and time. The pipes made of galvanized steel are much more resistant to corrosion. They also withstand high temperatures well. For their connection, a threaded method is usually used, which greatly simplifies the process. The main disadvantage of galvanized pipes is their high cost.

Copper pipes are considered an ideal option. The material withstands high temperatures, is flexible enough and thus is durable, is not subject to corrosion. Soldering is used to connect copper parts. Copper pipelines are very durable and durable, but their cost is very high. Thus, the most acceptable option for the ratio of quality and price is steel pipes with anti-corrosion coating or galvanized.

The best choice for steam heating is cast iron radiators. They can withstand the serious stress caused by the presence inside the batteries of hot steam

Radiators for steam systems are selected according to the principle of strength. It is important that they would withstand high temperatures and be resistant to corrosion. Proceeding from this, the best option can be considered massive cast-iron batteries, the worst - steel panel. Given the high efficiency of the system, in some cases it is perfectly permissible to use finned steel pipes.

Block of control and measuring equipment

The system of steam heating is characterized by increased emergency danger, therefore the presence of control devices is mandatory. The pressure in the system is monitored, if necessary, it is normalized. For these purposes, a reducer is usually used. The device is equipped with a valve through which excess steam is removed from the system. For powerful installations, you may not need one, but several such valves.

Types of heating system

In practice, you can meet a fairly large number of variations of steam heating. By the number of pipes, one and two-tube varieties of steam systems are isolated. In the first case, the steam moves continuously through the pipe. In the first part of his journey he gives heat to the batteries and gradually turns into a liquid state. Then it moves like a condensate. In order to avoid any obstacles in the coolant path, the diameter of the pipe must be sufficiently large.

It happens that steam does not partially condense and breaks into the condensate line. In order to exclude its penetration into the branch intended for condensate drainage, it is recommended to install steam traps after every radiator or group of heating devices

A significant disadvantage of a single-pipe system is the difference in heating of radiators. Those that are located closer to the boiler, are heated more. Those that are further are less. But this difference will be noticeable only in large-scale buildings. In two-pipe systems, steam moves along one pipe, condensate leaves on the other. Thus, it is possible to equalize the temperature in all radiators.

But this significantly increases the consumption of pipes. Like water, steam heating can be one or two-circuit. In the first case, the system is used only for heating the premises, in the second case it is also used for heating domestic water. There is also a distribution of heating. There are three options:

- With top wiring. The main steam pipe is laid above the heating devices, from it the pipes to the radiators are lowered. Even lower, at the very floor is laid the condensate line. The system is the most stable and easy to implement.

- With bottom wiring. The mainline is located below the steam heating appliances. As a result, along the same pipe, which should be somewhat larger than usual diameter, steam moves in one direction, and in the opposite direction - condensate. This provokes water hammering and depressurization of the structure.

- With mixed wiring. The steam pipe is mounted slightly above the level of the radiators. All the rest is like in a system with an upper wiring, thanks to which you can save all its advantages. The main drawback - high traumatic danger due to easy access to hot pipes.

When arranging schemes with natural compulsion, it must be remembered that the steam pipe is installed with a slight slope in the direction of steam movement, and the condensate line is condensate. The slope should be 0.01 - 0.005, i.e. for each linear meter of the horizontal branch there should be 1.0 - 0.5 cm of slope. The inclined position of the steam and condensate pipes will eliminate the noise of the steam passing through the pipes and ensure the free flow of condensate.

Steam heating systems are built on a one-pipe and two-pipe scheme. Among the single-tube variants, horizontal connections to heating devices predominate. In case of constructing a circuit with vertical connection of devices, it is better to choose a two-pipe version (+)

The level of internal pressure of the system is divided into two main types:

- Vacuum. It is assumed that the system is completely hermetic, inside which a special vacuum pump is installed. As a result, the vapor condenses at lower temperatures, which makes such a system relatively safe.

- Atmospheric. The pressure inside the circuit exceeds atmospheric pressure by several times. In the event of an accident, this is extremely dangerous. In addition, the radiators operating in such a system warm up to very high temperatures.

There are many options for arranging steam heating, so everyone can choose the best option for their home, taking into account all the features of the building.

The figure shows a diagram of an open steam heating system

How to equip the boiler room

A steam boiler operating on any fuel must be installed only in a specially equipped room. The standards developed for standard steam appliances with a pressure of up to 0.07 MPa, producing steam at a temperature of 120-130 ° C, provide for a number of requirements for such boilers:

- the distance from the walls to the heater can not be less than 100 cm;

- the height of the room must be at least 220 cm;

- the minimum level of fire resistance of doors is 30 minutes, walls - 75 minutes;

- availability of high-quality ventilation;

- the presence of doors and windows facing the street.

The boiler house is best equipped in a separate room, but it is also possible to block out a suitable room. Inside it it is necessary to finish with incombustible materials. Ceramic tiles are best for these purposes.

The walls in the boiler room must be finished with non-combustible materials, for example, with ceramic tiles

Preparing for the installation of the steam system

To properly make steam heating, you need to start with the preparation of the project. Its development is a difficult task, which is best solved by specialists. A lot of things should be taken into account in the finished project. First of all, thermal loads are calculated for each of the rooms and the building as a whole. The source of steam is selected, and the mechanism and degree of automation of the system is determined.

In addition, it is necessary to determine the consumption of steam, on this basis, the equipment and the scheme of its use are selected. Once the project is ready, you can begin to compile an installation plan. To implement it, you need a plan of the building, to which the location of the equipment is applied. They usually start from the boiler. Its location is determined. If the system has a natural circulation, the boiler must be below the battery level.

In this case, it is usually lowered to the basement or to the basement, so condensate can drain itself to the device. Then the layout of the entire heating system is applied to the house plan. And it notes all the necessary equipment. Experts advise to carry out this operation directly on the spot, being in the room where the equipment will be located. Only in this way can you notice and take into account all the protrusions and obstacles that will have to be circumscribed.

Before starting the installation, it is mandatory to carry out a layout of the future system, on which all equipment and places of fastening of radiators

All transitions and angles are necessarily marked on the diagram. After it is completed, you can go to the calculation of the amount of material necessary for its implementation. Once again, you should pay attention to the importance of the right choice of equipment. The steam system is potentially unsafe, so do not save on materials and appliances. Everything must be of high quality and certified, otherwise serious problems can not be avoided.

Technology of installation of steam heating

Begin work with the installation of the boiler. It is mounted in a pre-prepared premise on a concrete base. In some cases, a separate small foundation is prepared for the equipment. The device is installed on the base strictly horizontally, the correctness is checked by the building level. The detected errors are immediately eliminated.

The boiler placed on the base is connected to the exhaust gas removal system. The connection must be strong and completely sealed. The next stage is the suspension of radiators. To do this, in the locations indicated on the installation diagram, special hooks are hammered into the wall, onto which the batteries are fastened. If the use of finned tubes is assumed, then they are fixed.

Orebrene pipes can be used in steam heating systems instead of radiators. High heat transfer parameters of the system will be significantly enhanced due to the increased area of the heat conducting surface

The strength of the heat radiators is checked. Then you can proceed with the arrangement of the expansion tank. It is fixed at the highest point at a slight distance from the boiler, it is best that this distance is as small as possible. Now you can install a group of control devices. They are mounted at the outlet of the boiler. Here, at least, a manometer and a discharge valve must be located.

All installed equipment is connected with each other by pipes. The method of connection depends on the material from which they are made. In any case, you should carefully check the correctness and reliability of the connections. For open systems, a condensate collection tank is installed at the end of the line and the pump is mounted. The branch pipe that goes from it to the heating appliance should have a smaller diameter than the rest of the pipes.

The steam boiler is connected to the heating circuit. At the same time, it is necessary to install all the necessary shut-off valves and filters, which will detain large particles of dirt that can be contained in the water. If the equipment is running on gas, the fuel line is connected. Flexible hoses can not be used in this case - only a rigid line.

All connections are carried out exactly according to the regulations, in order to avoid an emergency in the future

Then you can conduct a test run. For this, water is poured into the circuit, after which the equipment is put into operation. First, at the minimum operating temperature, then gradually increase it, while monitoring the correct operation and integrity of the system. If any shortcomings are detected, the equipment will stop and eliminate all malfunctions in its operation.

Useful video materials on the topic

How to remake the oven in a steam boiler:

Principle of operation of the steam boiler:

Homemade steam heating:

Steam heating is a very simple and economical way of heating the house. Many people are attracted by its minimal heat loss, high efficiency and low operating costs. However, one must remember that steam heating is potentially dangerous, and an emergency situation in this case can lead to serious injuries. Therefore, to take into account his calculation and arrangement should be very serious.

One of the most important life-support systems in our rather unpleasant climate is heating. There are several different ways to make a heating system. And one of them is steam heating. The system is effective, but it is used very rarely - there are too many minuses.

What is it and what is different from the usual water systems

Many people believe that steam and water heating are one and the same. This is a misconception. With steam heating there are also batteries and pipes, there is a boiler. But the pipes are not moving water, and water vapor. The boiler is required completely different. Its task is to evaporate water, and not just heat it to a certain temperature, respectively, its power is much higher, as well as the requirements for reliability.

Several steam boilers

Elements of the system

During steam heating, water vapor flows through the pipeline. Its temperature is from 130 ° C to 200 ° C. Such temperatures impose special requirements on the elements of the system. First, the pipes. It's just metal pipes - steel or copper. And they should be seamless, with a thick wall.

Secondly, radiators. Only cast-iron, registers or a pipe with finning are suitable. Cast iron under such conditions is less reliable - in the heated state from contact with a cold liquid they can burst. More reliable in this regard registers of pipes, coils or pipes with attached ribs - a convector type heater. Steel is more tolerant to the ingress of cold water onto its heated surface.

Service life and scope

But do not think that the steel system of steam heating will serve for a very long time. Very hot and humid steam is circulating in it. And this - the ideal conditions for corrosion of steel. Elements of the system quickly go out and build. Usually they burst in the most rusty places. While inside under pressure is steam with a temperature of more than four degrees, the danger is obvious.

Therefore, steam heating is recognized as dangerous and is prohibited for heating public places and apartment buildings. It is still used in some private homes or for heating production facilities. In production, it is very economical, if steam is a derivative of the technological process. In private houses, steam heating is mainly used in houses of seasonal residence - in cottages. All due to the fact that it normally tolerates freezing - there is little water in the system and it can not do harm, and also because of its cost-effectiveness at the stage of the device (in comparison with water systems) and high heating rates of the rooms.

Advantages and disadvantages

Steam heating is not the most popular, but it has both positive and negative aspects. And the pluses are quite significant:

The disadvantages of steam heating systems are even more impressive:

- The high temperature of the steam causes all the elements of the system to heat up to 100 ° C and above. This leads to the following consequences:

- very active circulation of air in the room, which is uncomfortable, and, at times, harmful (with dust allergies);

- air in the room dries up;

- hot elements of the system are traumatic and must be closed, and the pipes too;

- not all building materials normally tolerate prolonged heating to such temperatures, therefore the choice of finishing materials is very limited (in fact it is only cement plaster with subsequent staining with heat-resistant paints).

- Simple steam heating has very limited possibilities for regulating heat transfer. There is only one way to change the temperature - make several parallel branches and turn them on as needed. The second way is to turn off the boiler in case of overheating and turn it on after the room has cooled down. This process is controlled by automation, but this method is by no means the most comfortable, since constant temperature fluctuations are observed.

- The system is noisy. When the steam moves quite a lot of noise. In production workshops this does not really hinder, but in a private home it can be a problem.

As you can see, steam heating is not the best choice, although it is quite inexpensive in the arrangement.

Types of steam heating systems

By the method of the device, two types of steam heating are distinguished: with a closed and open system. In a closed system, the condensate flows into a special intake tube, which is connected to the corresponding input of the cat. It is laid with a slight bias, so that the condensate moves through the system by gravity.

In an open system, the condensate is collected in a special container. When it is filled, it is fed to the boiler using a pump. In addition to the various construction of the system, different steam boilers are also used - not all of them can work in closed systems.

In general, there are systems of steam heating with a pressure close to atmospheric or even lower. Such systems are called vacuum-steam systems. What is this attractive arrangement? So that at low pressure the boiling point of water decreases and the system has a more acceptable temperature. But the difficulty in ensuring tightness - the air is constantly sucked through the connections - have led to the fact that these schemes are almost not found.

More common is steam heating with low pressure. Available domestic steam boilers can create a pressure of no more than 6 atm (at a pressure of more than 7 atm, the use of equipment requires a permit).

Types of wiring

By type of wiring, steam heating happens:

When laying the steam pipe is made with a slight slope (1-2%) towards the movement of steam, and the condensate line - in the direction of the movement of the condensate.

Boiler selection

Steam boilers can work on all types of fuel - gas, liquid and solid fuels. In addition to the choice of fuel, it is necessary to correctly select the power of the steam boiler. It is determined depending on the area to be heated:

- up to 200 m2 - 25 kW;

- from 200 m2 to 300 m2 - 30 kW;

- from 300 m2 to 600 m2 - 35-60 kW.

In general, the calculation method is standard - for 10 square meters take 1 kW of power. This rule is valid for houses with a ceiling height of 2.5-2.7 m. Then follows the choice of a specific model. When buying, please apply for a certificate of quality - the equipment is dangerous and should be tested.

Which pipes to use?

Temperatures for steam heating can normally be carried only by metals. The cheapest option is steel. But for their connection, welding is required. It is also possible to use threaded connections. This option is budgetary, but short-lived: steel in a damp environment quickly corrodes.

More durable galvanized and stainless pipes, but their price is not modest. But the connection is threaded. Another option - copper pipes. They can only be soldered, they are expensive, but do not rust. Because of their higher thermal conductivity, they transmit heat even more efficiently. So such a heating system will be super-efficient, but also very hot.