Heat supply systems. Systems of closed and open heat supply.

Gives the following definition of the term "Heat supply":

Heat supply - a system for providing heat to buildings and structures designed to provide thermal comfort to people in them or to be able to fulfill technological norms.

Any heat supply system consists of three main elements:

- Heat Source. This can be a CHP plant or boiler house (with a centralized heat supply system), or simply a boiler located in a separate building (local system).

- Thermal energy transportation system(heating network).

- Consumers of heat (radiators (batteries) and heaters).

Classification

Heat supply systems are divided into:

- Centralized

- Local (they are also called decentralized).

They may be water and steam.The latter are not used very often these days.

Local heat supply systems

Here everything is simple. In local systems, the source of heat energy and its consumer are in the same building or very close to each other. For example, in a separate house a boiler is installed. The water heated in this boiler is subsequently used to meet the needs of the house in heating and hot water.

Centralized heat supply systems

In a centralized heat supply system, the heat source is either a boiler house that generates heat for a group of consumers: a quarter, a district or even the whole city.

With such a system, heat is transported to consumers via mains heat networks. From the mains, the coolant is supplied to central heating stations (TSCs) or individual heat points (ITPs). From the central heating center, heat is already flowing through quarterly networks to the buildings and facilities of consumers.

By the way of connecting the heating system, the heat supply systems are divided into:

- Dependent Systems - The heat carrier from the source of thermal energy (CHP, boiler room) comes directly to the consumer. With such a system, the scheme does not provide for the presence of central or individual heat points. In plain language, water from heating networks comes directly to the battery.

- Independent systems -cTP and ITP are present in this system. The heat carrier circulating through the heat networks heats the water in the heat exchanger (the 1st circuit is red and green lines). The water heated in the heat exchanger circulates already in the heating system of consumers (2 circuits - orange and blue lines).

With the help of make-up pumps, water losses are replaced through leakage and damage in the system and the pressure in the return line is maintained.

By the way of connection of the hot water supply system, the heat supply systems are divided into:Open.In an open heat supply system, water for hot water needs is taken directly from the heating network. For example, in winter you use heating and hot water "From one pipe". For such a system, the picture of the dependent heat supply system is valid.

Heat supply is the provision of heat to buildings and structures. It is necessary not only for heating residential houses, public buildings and industrial facilities, but also for organizing hot water supply, ventilation, and for various technological needs of production facilities. According to the way of delivery of the coolant to the consumer exists today open and closed heat supply system. The existing heat supply scheme can be both centralized, serving entire areas, or settlements, and local, for servicing one or a group of buildings.

Open system

With this type of heat supply, the delivery of hot water needed by the consumer is carried out directly from the heat network. From the system, consumers can disassemble hot water completely or partially. The entire flow of water is constantly compensated by the supply of water from the heating plant, and all the remaining in the heat network the water is coming for heating or ventilation. The main advantage of such a scheme is its cost-effectiveness, which is why until the early 1990s, up to 50% of all heating systems in the territory of the former Soviet Union were of an open type.

But there are drawbacks to this system. Hot water in an open system can not meet strict standards of sanitary hygiene, it is of a rather poor quality and does not have transparency and purity. Extensive piping networks, through which water circulates, heating devices with signs of corrosion and rust, give it an unpleasant smell, color, and often in the water there are even various impurities and pathogenic microbes and bacteria.

All attempts to purify water make such a heat supply network less economical, since the huge length of the pipeline networks significantly increases the costs of water purification activities, without achieving an effect.

Closed system

A closed heat supply system is characterized by the fact that all water in pipelines is used only as a coolant, and for the needs of hot water supply, water from such a system is not taken. This communication completely corresponds to its name and is isolated from the environment, it usually has a constant volume of water, and in the event of a coolant leakage losses are automatically compensated with a special make-up regulator. Under such a heat supply scheme, the heat carrier of the required temperature from the centralized heat supplier is sent to the heat points, where it is brought to a certain temperature before the water is taken up by consumers.

Such a system makes it possible to obtain water of a very high quality and saves energy for water heating, but the measures for water treatment in such a heat supply system are technologically complicated, the heat points are usually located at a remote distance from the centralized supplier of heat, and from each other, which significantly increases the cost of water delivery

Open and closed system heat supply to a centralized heat supplier can be connected in a dependent or independent way.

There are two types of heat supply - centralized and decentralized. With decentralized heat supply, the heat source and consumer are close to each other. There is no heating network. Decentralized heat supply is divided into local (heat from the local boiler house) and individual (stove, heat from boilers in the apartments).

Depending on the degree of centralization of the district heating system (TCC), it can be divided into four groups:

1. group heat supply (TS) of a group of buildings;

2. District - TS of the urban area;

3. Urban - TS of the city;

4. intercity - TC of several cities.

The TCC process consists of three operations - preparation of coolant (TN), transport of VT and use of VT.

The preparation of VT is carried out at the heat-preparation plants of CHP and boiler houses. Transport VT is carried out by heat networks. The use of VT is carried out on heat-consuming installations of consumers.

A complex of facilities intended for preparation, transport and use of a coolant is called a district heating system.

There are two main categories of heat consumption:

To create comfortable working and living conditions (communal-household load). This includes the consumption of water for heating, ventilation, hot water (DHW), air conditioning;

To produce products of specified quality (technological load).

By the level of temperature, the heat is divided into:

Low-potential, with temperature up to 150 0 С;

Medium-potential, with a temperature from 150 0 C to 400 0 C;

High-potential, with a temperature above 400 0 С.

refers to low-potential processes. The maximum temperature in the heat networks does not exceed 150 0 C (in the direct pipeline), the minimum temperature is 70 0 C (in the reverse one). To cover the technological load, water vapor with a pressure of up to 1.4 MPa is usually used.Heat sources of heat power plants and boiler houses are used as heat sources. Combined heat and power generation is carried out at the CHPP based on the heating cycle. Separate generation of heat and electricity is carried out in boilers and condensing power plants. With the combined output, the total fuel consumption is lower than when the fuel is divided.

The whole set of equipment for the heat supply source, heat networks and subscriber units is called the centralized heat supply system.

Heat supply systems are classified according to the type of heat source (or method for preparing heat), the type of coolant, the way of supplying water to hot water supply, the number of pipelines of the heat network, the way of providing consumers, the degree of centralization.

By type of heat source There are three types of heat supply:

Centralized heat supply from CHP, called heat fication;

District heating from district or industrial boiler houses;

Decentralized heat supply from local boiler houses or individual heating aggres.

Compared with centralized heat supply from boiler-houses, heating has a number of advantages, which are expressed in fuel economy due to the combined production of thermal and electric power at the CHPP; in the possibility of widespread use of local low-grade fuel, burning of which in boiler houses is difficult; in improving sanitary conditions and purity of the air basin of cities and industrial areas due to the concentration of fuel combustion in a small number of locations located, as a rule, at a considerable distance from residential quarters, and more rational use of ny modern methods flue gas cleaning from harmful impurities.

According to the type of coolant heat supply systems are divided into water and steam. Steam Systems distributed mainly in industrial enterprises, and water systems are used for heat supply of housing and communal services and some industrial consumers. This is explained by a number of advantages of water as a coolant in comparison with steam: the possibility of central qualitative regulation of the heat load, lower energy losses during transportation and a greater range of heat supply, no loss of condensate of the heating steam, greater combined energy production by CHP, increased storage capacity.

By the way of supplying water to the hot water supply Water systems are divided into closed and open systems.

AT closed systems The sealed water is used only as a coolant and is not selected from the system. The local hot water supply plants receive water from the drinking water pipe, which is installed in special water-water heaters due to the heat of the grid water.

AT open systems The water is directly supplied to the local hot water installations. This does not require additional heat exchangers, which greatly simplifies and reduces the cost of the device for the subscription of the input. However, water losses in the open system increase sharply (from 0.5-1% to 20-40% of the total water flow in the system) and the composition of the water supplied to consumers is deteriorated due to the presence of corrosion products in it and lack of biological treatment.

The advantages of closed heat supply systems are that their use ensures the stable quality of hot water entering hot water supply installations, which is the same as the quality of tap water; hydraulic isolation of water entering the installations of hot water supply from water circulating in the heat network; simplicity of checking the hermeticity of the system in terms of the amount of make-up.

The main disadvantages of closed systems are the complication and cost of equipment and exploitation of subscriber inputs due to installation of water and water heaters and corrosion of local hot water installations due to the use of non-aerated water.

The main advantages of open systems heat supply are concluded in the possibility of maximum use of low-potential heat sources for heating a large number of make-up water. Since in closed systems, make-up does not exceed 1% of the flow of network water, the possibility of utilizing the heat of waste and purge water at the CHP with the closed system is much lower than in open systems. In addition, deaerated water is supplied to local hot water installations in open systems, so they are less exposed to corrosion and longer-lasting.

The disadvantages of open systems are: the need for devices at the thermal power station of powerful water treatment for heating system supply, which increases the cost of station water treatment, especially if the raw water is too stiff; Complicating and increasing the amount of sanitary control of the system; complicating the control of the tightness of the system (since the value of the sub-feed does not characterize the density of the system); instability of the hydraulic mode of the network.

By the number of pipelines differentiate single-, double- and multi-tube systems. Moreover, for an open system, the minimum number of pipe-wires is one, and for a closed system-two. The simplest and most perspensive for transporting heat over long distances is a single-pipe open heat supply system. However, the scope of application of such systems is limited due to the fact that its implementation is possible only if the water consumption equals to meet the heating-ventilation load, the consumption of water for hot water supply to consumers is given. district. For most regions of our country, the flow of water for hot water supply is significantly less (3-4 times) than the supply of heating water for heating and ventilation, therefore two-pipe systems have become more prevalent in the heat supply of cities. In a two-pipe system, the heat network consists of two lines: supply and return.

By the way of ensuring heat consumers are distinguished one-

step and multistage heat supply systems. In one-

step systems, consumers of heat are directly connected to the heat networks. Nodes of connection of consumers to the network

are called subscriber inputs or local thermal points (MTP). At the subscriber input of each building, hot water heaters, elevators, pumps, instrumentation and control valves are installed to change the heat transfer parameters in local consumer systems.

In multistage systems Central heat stations or sub-stations (TSC) are located between the heat source and the consumers, in which the parameters of the coolant change depending on the consumption of heat by local consumers. At the central heating station there are central heating water hot water supply system, central mixing plant for network water, pumping cold water pumps, autoregulatory and instrumentation devices. The use of multi-stage systems with TSC allows to reduce the initial costs for the construction of a hot water supply system, pumping units and auto-regulating devices due to an increase in their unit capacity and a reduction in the number of pieces of equipment.

The optimal design capacity of the central heating station depends on the layout of the district, the mode of operation of consumers and is determined on the basis of technical and economic calculations.

By degree of centralizationheat supply can be divided into group - heat supply of a group of buildings, district heating - heat supply of several groups of buildings, city heating - heat supply of several districts, intercity - heat supply of several cities.

Design and construction of heating networks.

The main elements of heat networks are the pipeline, consisting of steel pipes, connected together by welding; The insulating design, perceiving the weight of the pipeline and the effort arising from its operation.

Pipes are responsible elements of pipelines and must meet the following requirements:

Sufficient strength and tightness at the maximum values of pressure and temperature of the coolant,

Low coefficient of temperature deformation,

Providing small thermal stress at a variable thermal mode of a thermal network,

A small roughness of the inner surface,

Anticorrosion resistance,

High thermal resistance of the pipe walls,

Contributing to the preservation of heat and coolant temperature,

The invariance of material properties under long-term exposure to high temperatures and pressures, ease of installation,

Reliability of joining pipes, etc.

The steel pipes do not fully meet all the requirements, but their mechanical properties, simplicity, reliability and tightness of the joints (welding) have ensured them an advantageous application in heat networks.

Pipes for heating networks are made mainly of steels St2sp, St3sp, 10, 20, 10G2S1, 15GS, 16GS.

Heat networks use seamless hot-rolled and electrically welded ones. Seamless hot-rolled pipes are produced with outer diameters of 32 - 426 mm. Seamless hot-rolled electrically welded pipes are used for all methods of laying networks. Electrowelded pipes are used for all methods of laying networks. Electrowelded with a spiral seam are recommended for use in channel and overhead laying of networks.

Supports. For structures of heating networks, two types of supports are used: free and fixed. Free supports perceive the weight of the heat conductor and ensure its free movement under temperature deformations. Fixed supports are designed to secure the pipeline at the characteristic points of the network and perceive forces arising at the fixation point in both the radial and axial directions under the influence of weight, temperature deformation and internal pressure.

Compensators. Compensation for temperature deformation in pipelines is made by special devices called compensators. According to the principle of action, they are divided into two groups:

Compensators radial or flexible, perceiving the elongations of the heat conductor by bending or twisting curvilinear pipe sections or by bending special elastic inserts of various shapes;

Compensators axial, in which the elongation is perceived by telescopic movement of pipes or compression of spring inserts.

The most widely used in practice are flexible compensators of various configurations, made of the pipeline itself (P - and -S-shaped, lyrical with folds and without them, etc.). The simplicity of the device, the reliability, the lack of maintenance, the unloading of the fixed supports - the dignity of these compensators.

The shortcomings of flexible expansion joints include: increased hydraulic resistance, increased pipe consumption, transverse movement of deformable areas, increasing the width of non-passable channels and making it difficult to use zasypnyh insulation, non-channel pipelines, as well as large dimensions that make them difficult to use in cities with the saturation of the route by urban underground communications .

Axial expansion joints are made sliding type (gland) and elastic (lens compensators).

Packing box It is made of standard pipes and consists of a casing, a glass and a seal. When the pipeline extends, the glass moves into the body cavity. The tightness of the sliding connection between the body and the glass is created by a stuffing box packing, which is made from a penetrated asbestos cord impregnated with oil. Over time, the packing wears off and loses its elasticity, so periodic tightening of the stuffing box and replacement of the packing are required. From this disadvantage are free lens compensators, made of sheet steel. Lens compensators of welded type find the main application on pipelines low pressure (up to 0.4-0.5 MPa).

The constructive execution of the elements of the pipeline depends also on the method of its laying, which is selected on the basis of the technical and economic comparison of the possible options.

It happens that private houses located within the city are located next to the paved central heating networks, and some even are connected to them. Of course, at the present time in the priority - individual heating, and centralized gradually disappears into the past. But if the house is already connected to the network or there are problems with an autonomous system, then it is necessary to use what is available. To work together the heat source with consumers, a dependent and independent heating system is used. What they are, as well as the pros and cons of both schemes will be outlined in this material.

Dependent (open) heat supply system

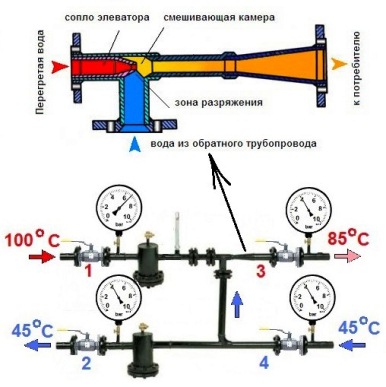

The main feature of the dependent system is that the coolant flowing through the mains networks directly enters the house. Open it is called because from the supply pipeline the heat carrier is selected to provide the house with hot water. Most often this scheme is used when connecting to the heating networks of multi-apartment houses, administrative and other public buildings. The operation of the dependent heating system is shown in the figure:

At a coolant temperature in the supply line up to 95 ° C, it can be sent directly to the heating devices. If the temperature is higher and reaches 105 ° C, then at the entrance to the house a mixing elevator unit is installed, whose task is water coming from the radiators, mix in a hot coolant to lower its temperature.

For reference. The centralized dependent heating system has a calculated and real temperature schedule. The calculated graph characterizes the maximum water temperature and in the open system it is 105/70 ºС or 95/70 ºС. The actual schedule depends on weather conditions and can be changed daily, it is maintained in the central heating station. When there are no severe frosts in the street, the temperature of the coolant is much lower than the calculated temperature.

The scheme was very popular in the times of the USSR, when very few people worried about energy consumption. The fact is that a dependent connection with elevator mixing units works reasonably reliably and requires almost no supervision, and installation work and materials costs are quite cheap. Again, no need to build additional pipes for supplying hot water to houses, when it can be successfully withdrawn from the heat main.

But on this positive side of the dependent scheme ends. And the negative is much more:

- dirt, scale and rust from the main pipelines safely fall into all the batteries of consumers. Old cast-iron radiators and steel convectors did not seem to care, but modern aluminum and other heating appliances were not exactly good;

- due to the reduction of water repair work and other reasons, there is often a pressure drop in the dependent heating system, or even a hydraulic shock. This threatens the consequences for modern batteries and polymer pipelines;

- the quality of the coolant leaves much to be desired, and it goes directly to water supply. And, although in the boiler room water passes all the stages of purification and desalting, the kilometers of old rusty roads make themselves felt;

- regulate the temperature in the premises is not easy. Even full-flow thermostatic valves quickly fail because of poor quality of the coolant.

Independent (closed) heating system

At present, when installing new boilers, an independent scheme for connecting the heating system has become more frequent. It has a main and additional circulation loop, hydraulically separated by a heat exchanger. That is, the coolant from the boiler or CHP goes to the central heat point, where it enters the heat exchanger, this is the main circuit. An additional circuit is a house heating system, the heat transfer medium circulates through the same heat exchanger, receiving heat from the network water from the boiler room. The scheme of the independent system is shown in the figure:

For reference. Previously, in such systems, bulky shell-and-tube heat exchangers, which occupied a lot of space, were installed. This was the main difficulty, but with the advent of high-speed plate heat exchangers this problem ceased to exist.

![]()

But what about the centralized supply of hot water, because now you can not take it from the highway, there is too high a temperature (105 to 150 ºC)? It's simple: an independent connection scheme allows the installation of any number of plate heat exchangers connected to the main pipelines. One will provide heat heating system at home, and the latter can prepare water for household needs. How this is implemented, shown in the diagram:

To ensure that hot water always comes at the same temperature, the DHW circuit becomes closed with the automatic return water supply. AT apartment buildings The DHW circulation circulation line can be seen in the bathroom, towel warmers are connected to it.

Obviously, the operation of an independent heating system has many advantages:

- the home heating circuit does not depend on the quality of the external heat carrier, the condition of the mains networks and pressure drops. All the load falls on the plate heat exchanger;

- it is possible to regulate the temperature in the rooms with the help of thermostatic valves;

- the coolant in the small circuit can be filtered and cleaned of salts, the main thing is that the pipes are in good condition;

- in the DHW system there will be water drinking quality, entering the house along the water main.

However, due to a poor quality coolant in central network It will be necessary to periodically flush an independent heating system, or more precisely, a plate heat exchanger. Fortunately, this is not so difficult. Another disadvantage is the higher costs of acquiring equipment, namely heat exchangers, circulating pumps and shut-off and control valves. But the closed system is safer and safer open, it more meets modern requirements and is better adapted to new equipment.

Conclusion

If, for some reason, you choose to connect to a centralized network, then an independent home heating system is preferable. Even if the temperature in the highway is low, it is still not worthwhile to supply this water to your system, it is better to separate it hydraulically from the central one. Provided that this possibility exists in the material plan, and if not - it is necessary to crash directly, according to the dependent scheme.

Provision of heat with the help of a coolant (hot water or steam) of heating, ventilation, hot water supply for residential, societies. and prom. buildings and technological. consumers. The most perspective is the centralized heat supply, which provides heat supply to many consumers located outside the production site. Such a center can be: a boiler room in the basement of the house, serving several buildings; a separate boiler-house providing heat for a quarter, several blocks or a city district, prom. enterprise or ind. node; city or industrial. cogeneration plant (CHP). The creation of centralized heat supply is the main direction of T.'s development in the USSR.

District heating system consists of a heat source (boiler or CHP), a system of pipelines (heat networks) that supply heat from the source to the consumers. Boiler installations as heat sources in heat supply systems serve to heat water (up to 200 ° C) or steam production (up to 20 am). Heat production for district heating on the basis of electricity generation is carried out at the CHPP, where special heating turbines are installed for this purpose. According to the nature of the satisfaction of thermal loads, there are communal, industrial and district thermal power plants. According to the initial steam pressure, CHP plants are: medium, high, high and over high pressure (35, 90, 110 and 240 am).

The steam produced in the boilers of the CHPP is supplied through the internal steam lines to the heating turbine, where the rotor of the turbine rotates and through it and the rotor of the electric turbine. generator. In this process, part of the thermal energy of the steam is converted to electricity, and steam with the remaining part of the heat energy leaves the turbine and is used for heating purposes.

If consumers require steam as a heat carrier (for technological needs), the last turbine enters heating network directly through a steam compressor or steam converter. Through the steam converter, steam is supplied to such consumers, who can not return the condensate satisfying the requirements for supplying high-pressure boilers to the CHP. Steam, which has given its heat to consumers (or in the steam converter when receiving the secondary steam), turns into a condensate, which is sent to the boiler, where it again turns into fresh steam and enters the turbine.

If consumers need hot water as the heat carrier (for heating, ventilation and hot water supply), steam from the turbine is sent to the water heaters, where it heats the water circulating in the heat supply system to the required temperature. In the heat supply system, closed circulation of water is carried out with the help of centrifugal (network) pumps.

On the subscriber inputs of district heating systems, communication is established between heat sources and consumers. Consumers select heat from the T system due to installed heat exchangers: heating appliances (in heating systems), air heaters (in the ventilation system), water-water or steam-water heaters of tap water in hot water supply systems and heat exchangers of various technologies. consumers.

Water as a heat carrier, in comparison with steam, has a number of advantages: the possibility of implementing a central quality control of heat supply; maintenance necessary on hygienic. conditions of temperature of heating devices (including below 100 ° C); a decrease in the average daily vapor pressure for heating water circulating in heat networks, and the next. reduction of fuel consumption for heat supply from CHP; uncomplicated connections to heat networks; Simplicity of service and noiselessness in work.

Depending on the way of connecting the hot water supply systems of buildings to water, heat networks, closed and open heat supply systems. If the building's hot water supply systems are connected to the heating networks through water heaters, when all the network water from the T system returns to the T. source, the system is called. closed; in the case when direct water withdrawal from the heating network is made for hot water supply, it is open. Water heating systems of buildings can be connected directly via the elevator or via an independent one via a water heater. Closed heat supply systems require a device from consumers of heat exchangers to heat tap water supplied for hot water supply, and sometimes water treatment. Heat exchangers and water treatment equipment, depending on the water consumption of the subscriber, can be installed in individual heat points (ITP) or central (TPP). ITP are arranged only at large facilities. In the absence of cellars, TS.P. is arranged for a group of houses or a quarter of the city, which leads to the construction (from these TsTP to consumers) of expensive four-tube systems T.

When the T system is open, the water treatment for hot water supply is centralized in the boiler room or CHP and is carried out necessarily, which excludes the possibility of corrosion and scale formation in the heat networks. For open system T. is economical and promising is the transition to a single-pipe direct-flow system with the use of a coolant - water for heating and hot water supply without returning to the T. source (boiler or CHP), if there are accumulator tanks.

Steam systems of heat supply are arranged for the needs of technological. consumers. For prom. enterprises the use of a single heat carrier - steam, to cover all loads, including heating, is allowed with the appropriate technical and economic. justification.

If you want to meet the technology. of consumers by the ferry and the availability means, loads of heating sometimes are satisfied with mixed T. systems with water supply for heating, ventilation and hot water supply and steam for technological. needs. Depending on the technical and economic. Justifications for hot water supply and ventilation can also be supplied by steam.

Technological. consumers, systems steam heating and ventilation systems are connected to the steam networks of the heat supply system directly, if the vapor pressure in the network and at the consumer is the same, or through the reducer, if necessary, to lower the vapor pressure. Condensate returns to sources of heat supply from consumers through its pumping or by gravity. Hot water systems are connected to steam systems T. through steam-water heaters of tap water. In the event that it is required to arrange for water heating systems in steam heating systems, water heating is also carried out through steam-water heaters.

REFERENCES Kopyev SF, Kachchanov NF, Fundamentals of Heat Supply and Ventilation, Moscow, 1964.

Heat supply buildings for various purposes are carried out by heat networks from a single heat and power center: a quarterly or district boiler house or a combined heat and power (CHP).

System heat supply, which uses the warmth of the earth's interior with the help of heat carriers - hot water or steam.

In our country, about half of the operating systems heat supply open. However, when passing through heating appliances, air heaters, will connect, piping san hygienic. quality ...

Systems of water heating and hot water supply. CHP. Heat supply... … Heat supply. Hot water supply. Valves and gates Cork and ball valves, valves Shut-off valves ...

Circulating in the system heat supply water is used only as a coolant. Passing through the hot water heaters, heats up. devices of heating systems and air-heater ...

Ensuring the heat of consumers, implemented by the system heat supply. Heat is transferred by means of coolants, which are used as hot water or...

Heat supply. Hot water supply. Section: Gen. Economy. ... 1.10-1. Closed Systems heat supply. In closed systems, water for HV needs is obtained by heating a cold water supply ...

Their ability to produce, transport and distribute among ... The concept of system reliability heat supply is based on a probabilistic assessment of the work ...

heat supply Heat supply...

Contact water heaters for heat supply and hot ... Systems of water heating and hot water supply. CHP. Heat supply...

Heat supply. Hot water supply. Heating Sanitary equipment Valves and gates Cork and ball valves, valves Shut-off valves.

If heat for heating, hot water supply and technological needs comes from a combined heat and power plant (CHP) ... Centralized heat supply buildings from heat and power plants has ...

Contact water heaters for heat supply and hot ... ... Heat supply. Hot water supply. Valves and gates Cork and ball valves, valves Shut-off valves Heating ...

Heat supply. Hot water supply. Section: Gen. Economy. ... Heat supply. Hot water supply. Heating Sanitary equipment Valves and gates Cork and ball cocks, valves ...

Contact water heaters for heat supply and hot ... Systems of water heating and hot water supply. CHP. Heat supply...

Heat supply in cities and towns with buildings built above two floors is carried out centrally.

Heat supply buildings of different purposes are carried out by ... two-pipe systems all the time the coolant circulates between the source .... block thermal node for systems ...

System heat supply, in which water vapor is used as the coolant. It consists of a source that generates steam, steam pipelines, through which it is transported to consumers ...