The diameter of the pipe for water supply. On additional requirements. Typical solutions for determining the diameter of pipes

The old water pipe in the apartment has rotted. Evaporated on tubes, fistula behind fistula; shut off the water, and then apply again - rust gushes from the taps. And it is planned to repair the kitchen with a bathroom, and old pipes are not something to touch or breathe - look at them scary. It is necessary to change, but the work is expensive. Is it possible to replace the apartment water supply with their own hands? Yes, you can, and without any permits, decorations. It will only be necessary to agree with the locksmith of the Deez to cut off the supply of water to the risers for a maximum of an hour; most likely, manage to manage for 10 minutes. Or warn neighbors, if not harmful, and cut / reapply yourself.

Replacement procedure

Replacement of the water pipe is carried out in a certain sequence. The work "by eye" and "along the way" in unprofessional execution often ends with a leak. The plan of production is approximately as follows:

- Selection of material for new pipes.

- Selection of wiring diagram for hot and cold cold water.

- Development of the scheme of water supply of the apartment.

- Calculation of pipe diameter for the selected material and scheme.

- Preparation of the mounting tool.

- Procurement of materials.

- Assembling of selection-accounting units, their installation on risers and registration.

- Dismantling of old pipes and sanitary equipment.

- Connection of HMS and aqua-stop, if provided.

- Connection of the filter (with SMS is mandatory).

- Installation of water pipes for hot and cold water.

- Installation and connection of plumbing, old or new.

- Trial water supply; elimination of identified defects.

- Installation and connection of the boiler.

HMS, bottle filter and aqua-stop

HMS, or hydromagnetic system, has long been used in the industry to prepare water for filtration. In everyday life, this device, without going into details, transfers the impurities in water into a thin slurry, which then settles in the filter in the form of slime and is periodically removed. HMS is absolutely harmless, does not require power supply and maintenance during operation, but it necessarily requires the installation of a water meter in antimagnetic execution (such more expensive) and, after it, the current of water, a combined flask filter.

The flask filter consists of three successively connected sections: the first collects sludge, the second removes chlorine, the third takes place fine cleaning water and its softening. The last (no one drinks water from the tap for a long time) is especially important for a boiler of a washing machine.

GMCs and bulbs are worth a lot, but they take good care not only of equipment, but also of health. Complain or not, resent - do not be indignant, but drinking water firmly holds in the top ten of the world's most scarce resources, and global programs that can bring its quality to the level of at least the middle of the last century are not and are not expected. In general, the salvation of drowning people is the work of the drowning themselves.

AQUASTOP is also a useful device, it also does not require power and maintenance, but its function is different. With a sharp increase in the current (breakthrough) of water, akvastop is triggered and its valve cuts off the entire apartment from the riser. Aquastopes come in different systems, including electrodynamic ones, so antimagnetic counter is also needed when installing aquastope.

Pipe Selection

The new water supply in the apartment starts with the selection of pipes. Steel in everyday life has outlived its, and it is necessary to choose from metal-plastic, plastic and brazed copper. This stage of work, perhaps, is the most responsible - the wrong choice will bring to nothing all diligence, expenses and troubles.

Copper

About copper water pipes can be said at once: their propagandists do not know what they are saying. Or they know, but they do not put themselves. First, on copper in contact with water, copper oxide is formed - the same copper-eyed flesh that Tom Sawyer interpreted to Huckleberry Finn. Yes, copper is needed for man, but in minute quantities in the form of a trace element, and not in the composition of a strong poison. As a counterargument lead, they say, copper with chlorine from water forms a protective film. Absurd for anyone who remembers at least school chemistry.

About copper water pipes can be said at once: their propagandists do not know what they are saying. Or they know, but they do not put themselves. First, on copper in contact with water, copper oxide is formed - the same copper-eyed flesh that Tom Sawyer interpreted to Huckleberry Finn. Yes, copper is needed for man, but in minute quantities in the form of a trace element, and not in the composition of a strong poison. As a counterargument lead, they say, copper with chlorine from water forms a protective film. Absurd for anyone who remembers at least school chemistry.

Secondly, tin is included in the copper for copper. White tin, soft metal, eventually turns into another it, as the chemists say, allotropic modification - gray tin, crumbly powder. That is, having put copper tubes in our houses (very expensive), we thereby guarantee 100% leakage. And payment for the work of a company specializing in copper pipesah, since it is impossible to properly solder them.

Metal-plastic

Metal-plastic pipes are quite expensive, but they can be combined with their own hands without having experience. Metal-plastic water supply is assembled on special threaded assemblies with gaskets or under compression fittings. In addition, the metal-plastic pipes can be smoothly bent. The hydrodynamic resistance and pressure loss in the metal-plastic are very small.

To insert the pipe into the fitting, you need a pipe cutter, press pliers and a set of reamers (rimers) along the diameter of the pipes. With their help, the work goes on playfully, and improvised means - a full guarantee of leakage. In addition, the life of the gaskets in the fittings is limited, and with time the joint begins to drip. Therefore, it is unacceptable to immerse the metal plastic in walls, and it is strongly recommended not to hide it in strobes.

It is recommended to conduct plumbing with metal plastic in separate open areas, where the minimum resistance to the water flow is important and the possibility of a simple and quick cross-over of the joint is important: when connecting a boiler, washing machine, washing, etc. Adapters from metal-plastic to other types of pipes are always on sale.

Plastic

Plastic apartment water supply has now become the standard, but plastics are different. For the right choice you need to know their properties and features.

Polybutylene (PB)

Folding plastic with good, for plastic, thermal conductivity. Holds the temperature to 90 degrees. The correctly soldered joint is absolutely reliable. Quite expensive. Applicable for the installation of a warm floor.

Polyethylene (PE)

Cheap, but for GVS need polyethylene reinforced pipes; ordinary polyethylene does not hold 60 degrees already. It is impossible to bend and glue, the solder joint keeps the pressure no more than 3.5 atm, and the water pressure in the city water supply can be up to 6 atm (0.6 Mbar) for cold water and 4.5 at for hot, so that the probability of a sudden breakthrough. Hydraulic resistance, however, is the smallest of all.

It seems to be bad for everyone polyethylene pipes, but they have a virtue that can cost all their shortcomings: they are not afraid of freezing. The ice jam breaks them, but as they melt, they shrink again, and they do not burst, even if you crack. Therefore, the installation of polyethylene water pipes is highly recommended in premises not heated, seasonal and in the ground. There is no alternative to polyethylene. But with a constantly filled system, you need aquastope.

PVC (PVC)

The properties of polyvinyl chloride (PVC) are well known: chemically stable, inexpensive, heat resistance up to 80 degrees, easy to glue, but not very durable and afraid of ultraviolet. Joints, both soldered and glued, come out more fragile than solid material, so the danger of breakthrough remains and you need akvastop. Replacement of individual sections of glued PVC, of course, is more difficult than for demountable metal-plastic, but easier than for soldered joints: warming up the connection with a household hair dryer, the joint can be separated and then glued together again. In general, the variant is budgetary or for a beginner master with the length of the main branch from the riser to the farthest point of water extraction is no more than 10 m and with no more than 7 sampling points.

![]()

Propylene (PP)

The laying of apartment water pipes with polyisopropylene pipes (propylene) is now generally accepted. The material is not very expensive, durable, stable, solder joints retain all the qualities of the base, heat resistance - up to 130 degrees, properly welded holds up to 12 at. The hydraulic resistance is higher than that of PVC, but still the accumulation of plaque in the lumen is minimal, and with HMS is excluded. There are only two disadvantages in self-implementation:

- It is not glued, but soldering requires special equipment and exact compliance with the technology.

- Has a fairly high coefficient of temperature expansion. Stuck in a wall or hidden in a barrel can bend and break out the tile, so each pipe in the laying must be worn with a stocking from a mortar or sintepon, which increases the cost of work.

However, the propylene pipeline is by far the only one that can be done once and for all and forgotten. Therefore, we will focus on soldering propylene separately, especially since the soldering of other plastics differs only in a lower temperature (110-130 degrees for polyethylene and about 150 for PVC).

Propylene Soldering

The soldering of propylene by an artisan soldering iron-an "iron" to the back (see the figure on the right) is inadmissible:

- On the "sausage" inside the accumulated pollution, and the pipeline assembled in this way is more prone to clogging than steel.

- The pressure of water, breaking the pipes, tends to break the joint. At 16 degrees in the pipe and 20-25 outside in about three months, the fatigue threshold of the material is exceeded, and the joint flows.

The assembly of the propylene pipeline is carried out at soldering fittings - straight (for connecting pieces of pipe), angled, tees, crossings. The tube preheated to softening is inserted into the casing of the also heated fitting, and the joint freezes. In this case, the water pressure, on the contrary, presses the tube from the inside to the cage, providing strength, and only the sealing remains for the fused zone. The rather high rigidity of propylene does not allow the casing surrounding the tube to expand elastically. It is this design of the joint, combined with the properties of the material, that makes the propylene pipeline suitable for walling in walls for decades.

Note: more or less a decent soldering iron for propylene costs at least 2000 rubles. and for something else is unsuitable, but does not wear out from work. Therefore, you do not need to buy it, it's better to rent it.

- For hidden wiring in a standard apartment in strobas or pinned - uniquely propylene.

- For long branches with a large number of water extraction points - metal plastic open or in channels with removable covers.

- For holiday homes, seasonal housing for rent, country houses with remote farm buildings, greenhouses, etc. - polyethylene.

- For budget repairs or in areas with water shortages, weak pressure in the water supply system, with water of poor quality - PVC.

Layout diagram

Collector-combs

There are two schemes of water distribution in the premises: sequential and parallel. When sequential circuit The points of analysis are connected to the common pipe through tees. This scheme is the most economical, but with a long wiring length, a large number of disassembly points and / or a weak water pressure is not suitable, since it greatly reduces the pressure.

In this case, the water is taken in a parallel circuit from the collector "comb", see Fig. A comb is an assembly of bypass gates, each of which runs a single branch to its point of parsing. The valves regulate the pressure separately from the points. Branches on the points are made of metal plastic or polyethylene: in this case their low hydraulic resistance plays a role, and when laid with a solid piece they are completely reliable.

Development of the scheme of pumping

The layout of the water mains in the apartment is needed primarily for yourself, so as not to get confused, do not miscalculate and then know exactly where - that special permission is not required for this work. But when registering the counter, the water can inspector can ask to look at the diagram, so you need to draw correctly.

A complete scheme according to all the rules - the work is serious and for a knowledgeable specialist; for example - on a large figure the scheme of water supply of a private house with a summer kitchen, necessary for the project to be approved. But to replace the pipes in the apartment so do not need to bother, enough that the scheme was clearly visible and understandable:

- Pipes of hot and cold water, their type and diameter of the lumen.

- Accounting devices.

- Emergency valves and plums.

- Stop valves.

- Points of parsing indicating consumers.

- Backup branches and devices.

- Direction of water flow.

That all this was clear not only to itself, or to itself after a year, certain rules at drawing out it is necessary to observe. Let's analyze it with examples, see Fig. On the left - more or less come down, but with comments, on the right - wrong:

- The scheme on the right is made in isometric - for beauty, or what? Intersections of pipes entangle her, and she does not give an idea of the real location of the points of analysis: the washing machine with the boiler goes out under the floor.

- There are too many arrow-pointers there where it is clear where it flows, which also confuses the circuit.

- In the same place - it is indistinct and not according to the rules shown stop valves with meters.

- In the same place - the pipe type and diameter are not specified.

- In the same place - who, where and when saw that the water in the boiler was fed from above, and the toilet bowl was washed through the ebb?

- But in the scheme on the left even it is not clear to the specialist that the boiler (6) is a backup boiler. The remark will be: "And where is the check valve on the hot one? Without it, when the supply is stopped, the boiler will run into a hot riser, if the valve (10) is not blocked. " But this is essentially the case and with full understanding.

The correct simplified scheme of water supply in the apartment

An example is arbitrary, not according to the rules for the design documentation, but it is perfectly clear and without excesses of the completed scheme of water distribution is shown in the following figure. This is also an example of a parallel tap; where the combs, it is understandable.

Pipe counting

Before finally choosing pipes, you need to calculate at least approximately their diameter. This is not necessary for "cleverness" - the narrower the pipe, the cheaper it is, on the one hand. On the other hand, too small a pipe diameter for a water pipe will cause turbulence of the flow in it. At the same time, the throughput of the pipe drops sharply, and at normal pressure at the inlet from the tap it will hardly trickle.

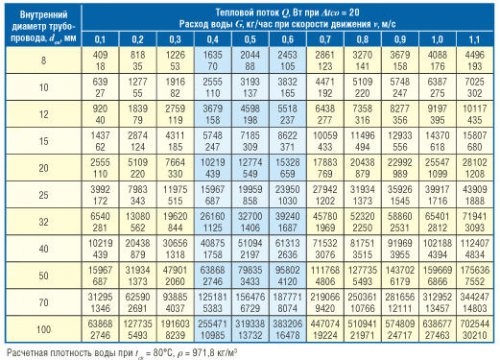

Exact calculation of the pipeline is a matter of highly qualified specialists, but for a city apartment to flow normally, you can estimate yourself. Initial data are as follows:

- The minimum allowable pressure is 0.3 at.

- Loss of pressure at 1 m propylene pipe 16 mm - 0.05 at.

- The average loss of pressure for a room wiring per unit of fittings and fittings is 0.15 at.

- The loss of pressure in the selection-accounting unit is 0.25 at.

- At normal values of the head at the inlet to the riser of 1.5-4.5 atm in a 12 mm pipe, periodic turbulence is unavoidable, and in 16 mm pipes it is not observed.

- The headroom for the furthest point is at least twofold.

It remains to find out the pressure (pressure) at the input, and you can determine if sequential wiring such, the most running, a pipe, pressure for the furthest crane, or have to take a wider and more expensive. The pressure at the bottom of the riser can be determined from the manometer in the basement or from the building's operator; then we take 0.6 atm per floor. You can also estimate the neighbors based on the same 0.6 at / floor: if, say, three floors up the faucet is still flowing, then we have a good 2 at. But in high-rise buildings such a focus does not pass: in order not to increase the cost of excessively flat wiring, separate risers are made there on the lower and upper and even lower, middle and upper floors.

Example calculation: the second floor of the nine-storey building; tenants on the upper floors do not complain about water. We have at least 4 am pressure. 11 units of armature (5 tees, 6 angles, 1 valve) give 1.65 atm losses. The length of the pipe from the riser to the far wall of the kitchen is 6.5 m, this is another 0.325 atm loss. In total, with a selection-accounting node, we have 0.325 + 1.65 + 0.25 = 2.225 at loss. It is a bit too much, you need to check the pressure with a manometer and, most likely, take the main pipe 20-25 mm, or divorce in a parallel scheme from the comb, otherwise you can remain "dry" in summer.

Note: hence it is clear how important it is to straighten the pipes and how undesirable it is to lengthen them and clutter up the armature.

Dependence of losses in pipes and fittings is nonlinear: they depend on the flow velocity, which, in turn, depends on the cross section of the tube lumen. A slight increase in the diameter of the pipe sharply reduces losses, so the usual 20 mm wiring for pipes with a pipe to the 16 mm points in most cases works well. In difficult cases, accurate calculations can be made according to SNiP, internal water supply and sewerage of buildings. There are all the necessary formulas and nomograms; The calculation can be done by a person with an engineering education of any profile.

One need only bear in mind that there are as many as three SNiPs with the same index: 2.04.01-85, 2.04.01-85 (2000) and 2.04.01-85 * "(Domestic water supply and drainage systems in buildings) ". Correct - SNiP last.

Tool, materials, dismantling of the old

Special tools for assembling apartment pipelines are described above. For the purchase of materials, of course, you need to calculate the footage, nomenclature and quantity in place. Dismantling of old pipes is done in the usual ways. It is better to do it after installing and registering the water meter, so as not to disconnect water for a long time on the floors.

We give only one piece of advice: do not take the valves with the lever. It is made of silumin or plastic and has the property of breaking off at the most inopportune moment, just when it is necessary to close it urgently. Take the ball valves with a butterfly handle. Round knurled handles, too, do not break, but wet or sweaty hands on them slip.

Accounting and control

The selection-accounting unit consists of a shut-off valve, a filter coarse cleaning, water meter and check valve. Gathered as shown. On each of the devices indicates the direction of the water flow for it, it must be observed when assembling.

The assembly is assembled with the waterproofing of the joints with a tape of the FSM and also connected to the riser, covering the water beforehand; Before supplying water, it is necessary not to forget to close the shut-off valve. This is the only operation, and a short-term one, which requires shutting off the water supply to the neighbors in the riser.

For cold and hot water separate nodes of counters are needed. It is highly desirable that the counters and hilt of the valves be highlighted. The meter readings should be clearly readable without any additional operations (taking out the hatch, etc.), so it is often necessary to pre-assemble a part of a single pipeline, sometimes a rather bizarre configuration, to connect meters to the riser. In addition to pipes and a soldering iron for this you need couplings from plastic to metal MRV - a coupling screwed internal. The plastic is connected to the metering nodes with the help of MRN - clutches of threaded outer ones.

Counters are sold sealed, but this does not mean that you can immediately call the water canal and pay for water at a cost. The factory seal is for that (the craftsmen have something Russian land is rich in), so that no one gets into the counter and does not twist or file there anything. The factory seal should be protected; without it the counter is considered unfit, as well as without a certificate for it.

The installation of water meters must be declared in a water canal and call its inspector. It is possible to use water before it arrives, the inspector does not need zero readings, he will write down the initial ones, seals the counter and drains the filter with his seal. Payment for water on the flow will go after registration of meters.

ГМС, аквастоп, the filter

Although the design of the HMS is indiscriminate and does not allow it to steal water, and this device is not sealed, the connection of the HMS to the meter is unacceptable: the turbine of the counter can be blocked with slurry. HMS with a bulb filter is connected after the meters; filter - immediately after HMS. AQUASTOP can be connected immediately after the filter, but if it is electrodynamic, the magnetic field of the GMA can cause its false triggering, but there is no sense to refer the aquastope far from the riser: it does not react to a breakthrough to it.

Video: an overview of the options for the layout of water supply elements

Installation of pipelines

So, now we are doing the water supply. The assembly of pipes has already been described, but the installation of the entire system also has non-structural features, such as the installation of channels in the screed. The latter should pass no more than 150 mm from the wall and not closer than 200 mm to the furniture. Of course, before the beginning of laying the pipes, the plumbing equipment is removed.

First of all, it is necessary to install arcs - plastic slats with MGB corners for mixers. They are attached to the main wall by screws in dowels. When attaching, you need to consider the thickness of the finish: plaster and tile or other decorative coating.

Without a lot of building experience, it is very difficult to achieve the location of the outlet nozzles flush with the wall. It is better to make them advance over the finished wall half the width of the edge of the decorative hoods of the mixer: if the hoods are unregulated, they can be easily carried on an emery wheel or manually on an emery bar.

The next point is the assembly of sections of pipelines. The most convenient way - assembly on the table and laying in the strobis entirely. But then the question arises: how to pipe through walls? With metal-plastic there are no problems, it's all on split fittings, and for brazed pipes you can offer two ways:

- With the help of adapters MPN / MPV and metal-plastic inserts. In the apartment it is quite reliable, and in the corners above the shrottles it is possible to make removable hatches for inspection and repair of threaded connections.

- Mount the piping in place. This requires a compact soldering iron. This is more expensive, and you need to work in cotton gloves to not accidentally burn yourself.

The fourth point is soldering. 15 mm of pipe is required for one soldering. That is, if between two fittings exactly 1 m, cut off 1030 mm; if 0,6 m - 630 mm etc.

The fifth point is the bending of metal plastic pipes. The minimum permissible bending radius is 5 outer pipe diameters. You can meet the recommendations: they say, put the spring there, fill the sand, and you can bend at all to the angle, and pull the spring and sand the wire with a wire hook. In no case: the coating of the pipe deteriorates, the residual stresses in it are much higher than permissible, and the metal-plastic pipe acquires the properties of a very poor steel rust.

And, finally,. This is a separate production cycle, and it is done after the water supply is put into operation. Pipes for the boiler are made in advance, but the valves on them (they are necessarily needed on both) overlap immediately after the installation of the pipes, and in addition the nozzles are muffled.

Video: example of an installed water pipe

The result

Now you know how to make a water pipe with your own hands. We emphasize - this work is not their complex or difficult, but negligence and hack-work does not tolerate.

Given the recommendations of the masters, you can choose the appropriate types of water pipes that withstand the required load. If we are talking about private buildings, then we take into account the resistance of the material to low temperatures.

The production of pipeline valves offers customers the main types of such products. Pipes differ in chemical composition and performance characteristics. On these grounds, the cold flow is selected.

Products from metalloplastika - a modern and economical offer of the construction market. The material is lightweight and focuses on the possibility quick installation. When choosing a metal-plastic, the owner of the house will be able to cope with the installation and start-up new system, correctly determining the diameter of the product.

Assembling such a wiring will require the presence of nuts and compression fittings.

Fittings and tees for connection metal-plastic pipes

For work you can use standard plumbing tools:

- keys suitable for the diameter of the nuts used;

- perforator;

- rectangular triangle, graphite pencil and level.

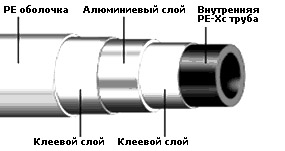

Design features of metal-plastic products white is an inner layer of aluminum. Thin metal protected from contact with water by a layer of plastic. Such reinforced pipes withstand hydraulic shocks and allow a sufficient flow of water. And specially produced for them swivel joints and tees provide convenient wiring.

Such types of water pipes "do not collect" dirt and debris on the inner walls, excluding the entry of unnecessary bacteria into the water. This property is also observed in wiring.

Photo: metalloplastikovye pipes "in a cut"

Choosing, the buyer receives products from durable and high-quality plastic, which can be laid in the premises and on the street. Absolute dielectric, PP "does not collect" plaque, which reduces the internal diameter and pollutes the water entering the taps in the apartment.

Affordable, the pipes are used together with fittings that form an integral structure without leakage at the joints. Correctly matched diameters of spins on PP will provide perfect wiring around the apartment or in the house.

Distribution from polypropylene

Taking into account the properties of the assortment presented by the producers, such water pipes can withstand internal pressure up to 20 Am at maximum load in residential houses up to 6 units.

The hot water is supplied through polypropylene pipes for a water pipe that can withstand an internal environment heated to 95 ° C. A smaller coefficient of thermal expansion is distinguished by special reinforced PP pipes that do not sag when feeding water.

Installation of PP pipeline in the apartment is performed by means of special devices:

- a) soldering iron for PP materials;

- b) keys for plumbing installation;

- c) the level at which the water pipes for cold or hot flow are put in the right position.

Copper is a rather expensive water pipe, for which fittings of a similar material are used. All compounds are cooked with pipes by the method of special soldering, carried out welding machine. To mount the structures, the wizard uses:

- a) the gas welding plant itself;

- b) buys flux and solder;

- c) Rolling.

Attention! Installing a hot water pipe or installing a cold copper pipe requires certain safety rules. The welding process in the apartment should take place in an empty room to avoid a fire from burning.

Copper wiring is aesthetically pleasing and long service. Such systems will last half a century without requiring repair.

Compound metal pipes using a layer of impregnated bacon

Interesting! Finely mounted in an apartment for cold or hot supply is not subject to repeated dismantling without repair work. Therefore, "deploy" in another line is quite problematic.

Polyethylene systems will be a universal summer residence option. The material is characterized by sufficient plasticity of fibers, capable of stretching and recovering to the original forms. Similar in properties to PP pipes, polymers are installed outdoors, without taking into account the freezing level of the soil. If the water in the system is frozen, then the formed ice will simply stretch the walls of the wiring, without exposing the product to cracking. As the ice melts, the pipe "returns" to its forms.

Polyethylene pipes

Attention! Such pipes are not suitable for supplying cold and hot supply to apartments.

Differing from the performance characteristics of PP products, polyethylene systems are designed for an internal flow temperature of about 40 ° C. Therefore, hot water supply will "warm up" the material, forming a sagging wiring. Masters use polymer systems only for cold water.

Correct cross-section selection

Bandwidth installed home The wiring is influenced by the correct diameter of the pipes. Before choosing polypropylene pipes of a particular section or structure from another material, it is recommended to consult the master.

Using general rules selection of the type of pipeline fittings for cold and hot supply, take into account the following parameters:

- the risers are laid by pipes with a section of 25 mm;

- for distributing water to the washbasin and in the kitchen, armored products made of PP material, whose diameter is 10-15 mm, are suitable;

- if a complicated wiring arrives from the riser or the system is laid with bends and bends, then a main line with a large diameter is installed; this will help to avoid congestion and high pressure in different parts of the joints.

According to the rules of selection of pipes, the complexity of the wiring is directly proportional to the value of the cross-section of the product made of material, metal-plastic or copper. Connecting hot water, choose PP reinforced products that "do not ask" when interacting with a medium whose temperature is above 40 ° C. If the water flow exceeds the standard standards for the tenants, it is recommended to install a wiring with a large cross-section.

Size determination parameters

The appropriate diameter is calculated according to such technical parameters:

- length of the whole system;

- number of rotary joints;

- number of joints according to the drawings;

- pressure in the pipeline.

Choosing, take into account the physical characteristics of products from different materials.

- The entire system must have a single internal diameter. Such a principle will exclude pressure drops in the wiring and possible hydraulic impacts on various pipelines. This condition applies to the selection of fittings.

- The same cross-section of the conditional pass for all pipes should be selected.

- Pay attention to the thickness of the walls, which in technical characteristics is denoted by S.

- The length of the pipe is selected.

A wiring made of PP (or other material) of the correct size will ensure a noiseless supply of water to all consumers. Correctly calculated diameter and thickness will eliminate the turbulence of the internal medium or high pressure in the system. And the latter condition exerts an additional load on the material of products, prematurely "wear out" the structure.

All long connections must be fastened with quality fittings and tees. The absence of leakage and the reliability of the pipeline depend on the operational parameters of the connecting elements.

Fitting Design

Correlation of length and diameter

In the sanitary ware shops you can find products from PP or metal-plastic material, folded into coils. Some retail outlets sell pipes chopped pieces.

Add to bookmarks

Application of polypropylene pipes

Polypropylene pipes for water supply in the building materials market have appeared relatively recently, but have already gained great popularity among consumers both in private buildings and in industrial production.

Polypropylene pipes are popular, as they are not susceptible to corrosion, they are resistant to aggressive environment, with zero electrical conductivity, and are very affordable for money.

The reason for the great popularity of this product is the following factors:

- non-compliance with corrosion;

- resistance to aggressive environment;

- low cost;

- lack of electrical conductivity - this means that the system of water supply or heating will not break down aluminum radiator and the owner of the faulty washing machine will not suffer a shock;

- easy installation;

- beautiful appearance.

In this article we will consider the following points:

- by what principle is selected diameter of a pipe made of polypropylene in the construction of a water supply network;

- what are the features with pipes that have a large diameter;

- what is still needed is the diameter of the polypropylene product for installing a new private water pipe.

Field of application of polypropylene products

Due to their excellent characteristics, polypropylene products are used not only for the construction of internal water pipelines.

They can also be used:

- For installation of ventilation. Polypropylene is a very light material and does not create a significant load even on a partition made of plasterboard.

- For the construction of sewage. Excellent resistance of the product to an aggressive environment here as anywhere by the way

- For installation of an external water pipe from polypropylene with cold water supply to several private buildings.

Of course, polypropylene has less mechanical strength than its main competitor in this field - cast iron. If the polypropylene water pipe is laid under the road, it needs additional protection - a box of reinforced concrete. But it does not overgrow with sediments. In addition, the elasticity of this material will keep the product intact even at a very low temperature: it is just slightly deformed (stretched), and after thawing will return to its previous form.

Classification of polypropylene product

A variety of the most common polypropylene products:

- RRV - marking of a product with increased mechanical strength. As a rule, it is used in the construction of a floor heating system and in a cold water supply system;

- PPH - marking of a product having a large diameter. Used for mounting ventilation system and a water main with cold water;

- PPR - the most common and popular brand. It is valued for its universality. The product tolerates high temperature, which allows using it not only for cold, but also for hot water supply, as well as for installing a heating system.

All of the above products differ primarily in the type of plastic used. Small additives make polypropylene more heat-resistant and much more elastic.

Reinforcement of polypropylene product

There is another way to change the mechanical property of the pipe - reinforcement.

Reinforcement methods:

- Aluminium foil. The aluminum foil layer can be located outside the product or between layers of polypropylene.

- Fiberglass. This method provides for the existence of a middle layer of a three-layer pipe, which is made of a mixture of polypropylene and fiberglass fibers.

The reinforcement of the pipe makes it possible to make the product more durable and to reduce the coefficient of thermal expansion.

According to experts, it is better to choose the product reinforced with fiberglass. Such a pipe will not separate under any circumstances. In addition, the installation of a polypropylene water pipe with the use of fiberglass reinforced pipes does not require the stripping of the product.

The permeability of pipes made of polypropylene

The internal diameter of the product determines how much water it can pass in a certain time unit. The outer diameter is not important for the calculation of cross-country capability, but nevertheless, the strength and ability of the pipe to withstand the water pressure is determined by them and, accordingly, the thickness of the walls of the article.

To calculate the desired internal diameter of the product, there is a simple formula:

D = square root of (4-Q-1000 / PV)

- Q - total of your building:

- P is equal to 3.14;

- V is the water velocity. For P = 1.5 - 2 m / s, for a small diameter of P = 0.7 - 1.2 m / s. The difference is that the smaller the diameter, the greater the ratio (surface / lumen) of this product. It is worthwhile to focus on the speed with the maximum values, since the surface of polypropylene is very smooth. This means that the water pipe made of this material, the loss of water to friction against the walls will be minimal.

Such an accurate is relevant only if the water supply system is projected apartment building. Because in the case of using a pipe with a diameter that is less than necessary, in the evening time (peak consumption) the upper floors can remain without water.

Of course, you always want to be safe and install a pipe, the diameter of which will be larger. But here we should not forget about the economic side of the project: the more the diameter of the product is bigger, the more its value. If we add to this the more expensive fittings, then in the end result we will get a very considerable amount, and these expenses can be easily avoided.

Polypropylene products of large diameter should not be used where products with a smaller diameter can be dispensed with, for another reason, which is again associated with savings. Suffice it to recall how you wash your face in the morning. Very often it is necessary to drain the tap water for a long time before the hot water goes. And the larger the diameter of the pipe, the greater this number will be. In the absence of pumping, all the heat of the water (hot) that fills the pipe, is senselessly dissipated in the atmosphere.

According to professional plumbers, if you make the circulation system of your hot water supply, then you can avoid the need for a long drainage of water before it warms up. In a private structure for this, it will be sufficient to install a simple circulating pump and a return pipe.

For five-story buildings, as a rule, pipes with a diameter of 25 mm are used, for nine-storey buildings and more - a product with a diameter of 32 mm is sufficient.

Products with large diameters are usually used to supply water and only cold to one or more structures of structures. The pipelines are never piped using polypropylene, since there is a very high water temperature on the supply pipe. And no one will be able to test the heating main, made of a relatively soft polypropylene, with huge pressure, since the consequences can be deplorable.

Cold water does not cause such problems: constantly low temperature, relatively low pressure. Proceeding from this, the public utilities have recently refrained from the construction of highways made of steel and cast iron in favor of polypropylene. These products with a diameter of 500 mm or more are often found in pipelines that supply water to entire areas of cities.

Product diameter for a private house or apartment

However, when designing a water pipe for a small private structure or own apartment, such a complex calculation is absolutely unnecessary. Since you have a small number of water pumping points, and the difference in the cost of pipes of different diameters, given the relatively small amount of procurement, will not significantly undermine your even a small budget.

If you pay attention to the body of the mixer, you will see that the water holes are thin enough and through them it gets into the sink. Polypropylene pipes should have a sufficient internal diameter so that the bottleneck of your water pipe is the same holes in the mixer. We recall: the patency of a polypropylene pipe is equal to the patency of its narrowest part.

Proceeding from this, the owners of apartments and private houses, without wasting precious time on complex calculations, simply purchase and install polypropylene pipes with a diameter of 20 mm. With any quantity, within reasonable limits, bidets, bathtubs, sinks and washbasins, this will be more than enough.

Proceeding from the above, it can be concluded that it is absolutely not difficult to choose the required diameter of a polypropylene pipe for an apartment or a private house. In the priority of most cases, it is sufficient to take a pipe with a diameter of 20 mm.

For apartment buildings designing of a waterpipe is a rather complicated task.

After all, there are a lot of factors, without attention to which it is impossible to solve it.

The correct choice of geometry and - just one of these indicators.

It depends on them how the system will be durable and reliable, will it be able to support the required parameters. Complicating is all due to the fact that there are a lot of sizes available on the market.

Like materials, each of which is radically different from the other. Therefore, the water supply requires only meaningful, thoughtful solutions. And a thoughtful answer to the question, which is better for water supply in the apartment.

Water pipes for apartments. What are the requirements they must meet?

- Points of consumption should be uninterrupted in obtaining liquid. The main thing is that the quantity, pressure is sufficient. To do this, it is necessary to determine the thickness of the walls, the cross-section of the pipes themselves. Calculations are carried out at the same time as the house is designed. If it is necessary to make modifications and partial replacement, use these calculations.

- Internal resistance at the minimum level. For this, the need arises to create a smooth smooth surface. Then the rust precipitates and accumulates in less quantity. Vortex flows also decrease. If this requirement is not met, additional noise and vibrations appear during operation. Gaps will find themselves an ideal environment for education.

- Great operating time. Provided due to resistance to corrosion, water hammer, the very material with high mechanical strength. The leakage is increased when possible to create reliable fasteners with knots. Under normal operating conditions, the cold water line must serve a minimum of fifty years. 25 years is the life expectancy at work with hot water. It is important that during this period the starting material retain its properties.

- Unproblematic installation, replacement of sites.

- Possibility of concealed, open wiring. Good adhesion to other materials and high decorative properties are mandatory for outdoor installation. If a hidden installation is required, it is important to maintain the minimum level for the coefficient of thermal expansion. The reliability must always comply with the building codes.

- An acceptable ratio between price and quality. Communications should ensure trouble-free operation at any price.

- Compliance with hygiene and sanitation standards. This is always required, regardless of the answer to the question, which pipes are better for water supply in the apartment of a multi-storey building.

About additional requirements

Heat carriers often maintain temperatures up to 75 degrees above zero. Therefore, rather tough demands are made.

Even at such a high temperature it is important to maintain tightness. Attention is also paid to the absence of deformations.

Inside and outside the pipes, there is often a difference between the temperatures. Therefore, the minimum level of heat dissipation should be. Only in this case condensation will not form on the surface.

Given the Russian operating conditions, experts advise selecting materials with a margin of interest for 20. Then the supply of heat and water will be uninterrupted, even if the city services do not comply with the standards for one reason or another.

It is inadmissible to form a coating inside, even when water is used with a chlorinated compound. The same rules apply to the ability to resist the appearance of bacteria, harmful microorganisms.

Pipes get a heat stroke if they stand for a long time without work, when after a short break inside, water is sharply fed. Because of this, the temperature of the materials sharply increases, several times.

A consequence of this situation is the ruptures on the pipeline. In this regard, reliability even in the strongest analogues suffers. An important role is played by reinforcing layers together with chemical structures.

When high pressure The probability of a rupture increases. This often affects the apartment, which is located below. It is necessary to reach a certain compromise between plasticity and strength of structures.

Diameter of pipes. Which to choose?

The efficiency of the systems is often determined by the same diameter of the pipes, inside and outside. These two parameters are usually selected with particular care.

The structures are endowed with a capacity that depends on the inside. The main thing is that it does not change throughout the site. Permissible reduction, but only in small limits.

For example, there is no sense in increasing the input pipe, if initially its diameter is 3/4 inches. But is it worth it to reduce the size to save money? After this action, several outcomes are possible:

- At the output, the head raises the level.

- In a unit of time, water passes in a smaller volume.

Sometimes there is a need to install a special heater in the bathroom. The sense of reducing is, if one or two cranes are connected to the system.

In this case, the performance is enough to solve all the main problems. Thanks to such solutions it will be easier to hide communications inside the walls.

Space inside the premises will be used with greater efficiency. But it's better not to change the size if you connect a consumer with very high expenses.

Without attention, you should not leave the wall parts. Its choice is determined by the operating pressure, which is maintained by water. The main thing is that the walls themselves guarantee tightness.

This parameter is the most critical for products made of plastic. He will help to find the answer to the question, which pipes are better for water supply in an apartment, the diameter should not be overlooked either.

Materials

Steel

Models from this material are often used in pipelines and systems. Only partially put them for sewage systems. In old houses almost a hundred percent of the cases are steel pipes.

They have the following advantages:

- The ability to create a complex system with a high degree of reliability. After all, a lot of fittings for such systems are produced.

- A small level of value.

- Resistance to mechanical damage.

But steel is not without its shortcomings:

- It is not allowed to use aluminum, copper radiators. Otherwise, a galvanic pair is formed, which leads to the appearance of weak currents. Because of what the process of corrosion at the joints is accelerated.

- A drawback is the good ability to conduct electricity. In the event of an accident, it is for this reason that electric shocks occur.

- Tubes with cold water often narrow the lumen due to the large amount of contaminants.

- Mounting is impossible without special welding equipment, which increases labor intensity. You can choose threaded connections, but they are also quite complicated in execution.

- Rapid occurrence of corrosion. Coloring and protective surfaces can protect from problems only the outer part.

Steel with galvanizing

When calculating a suitable diameter, it is important to take into account the inlet pressure, as well as possible losses throughout the entire line. Completing the point that is most distant from the riser.

To maximize the exact measurement of pressure, it is recommended to use manometers. But you can take into account and indirect indicators.

Surely the pressure level does not exceed two atmospheres, if neighbors from the nearest three floors do not experience any problems with pressure. But this is only an approximate value, not capable of giving accuracy at a high level.

What influences the pressure decrease:

- Number of turns.

- The length of the entire route.

- Connections and fittings, number.

0.6 atmospheres - permissible minimum pressure for any. If you work with a point as far from the entrance as possible - you need a minimum of two times more stock.

Practically one hundred percent is equal to the probability that operating parameters will decrease, for example, if articles made of polypropylene with a diameter of up to 12 millimeters are installed. This probability decreases with a diameter of 16 millimeters.

The optimal parameters are computed by fairly complex methods. But such methods are more often used by professionals.

Here are just some standard solutions used for wiring in ordinary apartments:

- The wiring is 3/8 or 1/2 inches.

- 3/4 or 1 inch for risers. It can be 20 or 25 millimeters.

There are other nuances that should be considered when choosing:

- The pipe dimensions, measured in inches, are not actual. They reflect only the actual diameter of the internal surfaces. This is important if you want to connect the plastic to the metal.

- When installing polypropylene pipes, the internal and external diameter parameters do not depend on each other. Half-inch types of products are supplied with 11-13 mm gaps.

Pipes without additional reinforcement

Most often these options are used in systems with cold water supply. Because the materials in such are able to withstand a maximum of 40 degrees.

Pipes sag and soften, if you heat them more. After that, the tightness of the compression fittings is lost. The working pressure parameter depends on the specific brand.

Solvents and petroleum products for plastic pipes are unacceptable. The internal surface of pipes is too quickly deformed under the influence of such substances. But pVC pipes allow you to use all kinds of connections at the time.

Compared with PVC, polypropylene is lighter and stronger. Can withstand a maximum of 95 degrees of temperature. Only at 120 degrees is it softened.

Optimal polypropylene pipes

It is this material that many experts consider optimal for the pipeline in the apartments.

As for manufacturers, in this case, many prefer Germany.

Turkish and Czech models can become the best choice for those who want to save without losing quality.

The pipe markings are usually indicated by the operating pressure at which the product works without problems.

If you need to choose a structure for transporting hot water - without reinforcement is indispensable.

For such pipes, the coefficient of thermal expansion will be small. And the tensile strength, on the contrary, is high.

It is also important to take into account the particularities of the installation when one or another type of pipe is selected. Plastic products are good in that for them there is a wide range of fittings, other accessories available.

Threaded connections are used, which do not require additional efforts. Even women can easily cope with the work of replacing an element if necessary.

But the soldering in this case will not bring much trouble. It will help ensure a high level of tightness.

There is almost no ideal option. Each species has its own peculiarities of practical application. This also applies to corrugated models made of different materials.

For the right choice, you need to consider what technical parameters the system itself has. Do not forget about the requirements listed in the construction norms.

Only in this case there is a chance that the number of emergencies will decrease. And the normal level in the pressure will be maintained. Water will flow to consumers in the required quantity.

The main thing is that everything should correspond to individual requirements and operating conditions. Some also try to achieve an optimal combination between price and quality.

Found an error? Select it and press Ctrl + Enterto let us know.

To the selection of pipes for water supply, should take into account such important indicators as:

- the maximum possible temperature of the transported water,

- features of the material used in their production,

- rated operating pressure,

- diameter of water supply pipes.

If to ignore the last indicator, in the future it can threaten with such negative consequences as decrease in efficiency work of the entire water supply system, insufficient network capacity, breaks and breakage of water pipes.

The diameter of water supply pipes made from different materials is selected according to the classification of measurements.

Dimensions steel pipes In inches, they correspond to the inner diameter. For example, a two-inch or one-and-a-half inch steel pipe has a diameter in millimeters of 24.4 and 12.7, respectively.

However, the installation of water supply and sewage should be carried out taking into account the outer dimensions of the pipe, since it is on the outside of the pipe that the thread is located. To determine the outer diameter of the pipes, one should take into account the inner and wall thickness. To understand this you will help a special thread system. For example, for metric threadM14 outer diameter of water supply pipes is 14 mm, for thread M12 - 12 mm. For pipe threading, everything is a little different. In a half-inch (1/2 ") pipe with different threads, the outer diameter will be 12.7 mm.

Of course, the distribution of water supply pipes can not be performed by pipes whose diameter is larger than the riser. The larger the pipe size, the better the pressure. Only accurate calculation can guarantee the correctness of the choice.

Complex installation of water supply, which involves a lot of turns and joints, as well as laying pipes for long distances, may face a problem insufficient pressure in system. In this case, it makes sense to carry out installation using pipes of larger diameter.

Video instruction how to choose a pipe for heating.

The modern market offers a wide range of materials that uses installation of water supply and sewerage. The most popular are metal-plastic and plastic pipes. As a result, the question arises as to how to correctly determine the diameter of water supply pipes before everyone who decided to equip their home, especially if the water pipes are to be joined from different materials.

When mounting, replacing one-inch steel pipes with plastic necessarily, take into account that the designations in inches and names in this metric size do not meet.

For joining steel pipes with plastic standard adapters, which are made taking into account the size of the pipes for each type of material. But if you need to replace aluminum and copper pipes, they are made according to metric standards. In such a situation it is necessary to take into account their actual metric size of inner and outer diameter.

Choosing pipes for water supply, it should be borne in mind that copper and polypropylene pipes are recognized as the most reliable and durable. And copper is also the most expensive. To install a water supply system using plastic pipes, you will need soldering iron. The construction of a water pipe from metal-plastic pipes is made on threaded connections, which greatly simplifies and speeds up the installation process.