Fittings for ventilation plastic. Smooth polymeric products. Order of ordering plastic ducts of polyethylene and polypropylene

The organization of effective ventilation in the house is not the whim of the owner, but the need dictated by health standards. For the device of such a system, plastic vent pipes for drawing, as the most simple, productive and relatively inexpensive option.

These light products, apart from the simplicity of installation, differ in the mass of other advantages: environmental friendliness, resistance to negative UV light, durability, low specific gravity, high resistance to aggressive environment, large size range and relatively low cost. The disadvantage is a low threshold of temperature stability that does not allow to use them in industrial conditions. For a private house they fit perfectly.

On the construction market there are products of different length and diameter. There is a length limitation for the PVC pipeline - 3 m minimum and 12 m maximum. Their diameter varies from 1.6 to 160 cm. For a cottage, the optimal cross-section exhaust pipe 15 x 15 cm.

Plastic pipe perfectly fits into any interior. It can be adapted to the features of the building, giving it the necessary shape

Important is the fact that the inner surface of PVC pipes are treated with an antistatic, because of which they almost do not settle the dust, which prolongs the periodicity of maintenance of the ducts. According to the type of section, 3 types of plastic pipes are distinguished:

- round;

- rectangular;

- corrugated, being a kind of round.

From the point of view of aesthetics, a rectangular section is preferable, but when the room has a small area, a tube with a section in the form of a circle is more suitable, because in this case there are no projecting parts. Marking available on square tube, gives the opportunity to orientate on the correspondence rectangular section similar round air channel.

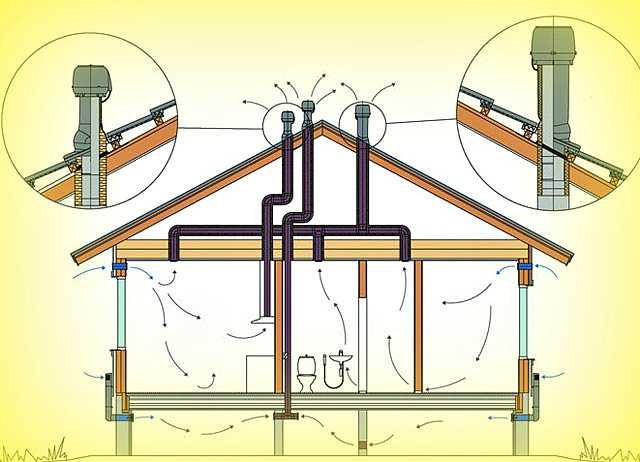

AT a country house from gas heating Through the exhaust pipe, which exits through the roof, the combustion products of the boiler are diverted. The main enemy of the design is the condensate, which appears when the temperature decreases in the autumn-winter period. The plastic pipe itself does not destroy it, but the moisture flowing along its walls can cause significant harm to the building, so the plastic duct at the outlet must be insulated.

Pipes made of plastic are contraindicated for hoods, arranged in baths and saunas, for chimneys and fireplaces, solid fuel boilers. If you still use them in these places, then it is necessary to lay pipes from this material only from the outside. In this case they will have to be well isolated from the cold.

Smooth Polymer Products

By choosing a plastic pipe for mounting the hood, you do not have to worry about the harmful corrosive effects and internal cleaning of the ventilation system. Passing through a smooth surface, the air flow does not encounter obstacles in its path and does not create much noise. To ensure that the air duct does not stand out against the background of the wall, a PVC pipe for drawing in the kitchen is laid over the cupboards.

In a pipe with a smooth inner surface, there are no stepped protuberances and relief drops accumulating fatty deposits and dirt. This greatly facilitates the care of the exhaust design. At installation use L-shaped adapters, hermetic.

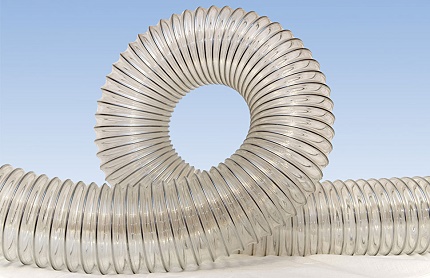

Corrugated plastic pipes

You can lay a corrugated plastic pipe for drawing in places where other pipes can not be used. Due to its exceptional plasticity, it can be bent as required by the conditions. If access to the ventilation is located at a certain distance from the plate, then the use of a corrugated air duct is the most rational solution.

Corrugated plastic pipe for drawing is not used as often as smooth. Preference is given to its analogue from metal

For their installation, neither welding equipment, nor a large number of connecting elements, nor special support structures will be required. The disadvantages are the same as for flat plastic pipes - completely unfit for high-temperature conditions. Add to the list of shortcomings can be increased noise during the operation of the exhaust system.

There are several types of corrugated tubes, but for the extractor device the most commonly used are:

- Single-layer, with increased flexibility and low mass.

- Two-layer, having high strength characteristics. They are also mechanically and chemically stable.

They are made from the same raw materials as the rest of the species plastic pipes. Products have on their surface grooves located through the same gap from each other. Corrugated 2-layer pipes made of polypropylene have a smooth inner surface and a diameter of 16 to 63 cm.

For their manufacture manufacturers use a screw extrusion process with the formation of corrugation on the entire outer surface. In the places of the depressions, the layer inside the pipe is welded.

Strength corrugated pipe is several times higher than that of smooth pipes. produce corrugated elements for the construction of hoods with varying degrees of rigidity. This parameter depends on the presence of thickening on individual rings.

Overview of the materials

The assortment of pipes, both flexible and rigid, is very large, it is not difficult to work with them, so they were appreciated by consumers. They confidently displace steel analogs from the sphere of private construction. For their production, polymers such as polypropylene (PN), polyvinyl chloride (PVC), polyurethane (PPU), fluoroplastic (PVDF) are used. The greatest demand is for PVC pipes.

Analysis of pipes made of polyvinylchloride

This inert polymer has sufficient rigidity. Its elasticity is increased by adding plasticizers to the formulation. The glass transition temperature is rather high - 75 ° C.

Under normal conditions, the decomposition of the material occurs for dozens of years, but at a temperature of 160 to 180 ° C it begins to break down very quickly. Because of this, it can not be used for ventilation in rooms such as saunas, where the temperature of the steam sometimes reaches 200 °.

A rectangular PVC pipe is connected through adapters. When air passes through it, it remains stationary, so the hood almost does not make noise

In the decay of the material, carbon monoxide (CO) is released, the inhalation of which is accompanied by suffocation, hydrogen chloride (HCl), which forms hydrochloric acid in an environment with high humidity, an invisible liquid that claims a pungent odor. The compound has a very negative effect on health, in particular, on the state of the respiratory tract. In difficult cases, vision can dramatically worsen.

From this we can conclude: PVC pipe Excellent for drawing, but only in those places where the temperature threshold does not exceed + 120 ° C. Contraindicated for these pipes and negative temperatures.

Polypropylene ventilation pipes

Polypropylene is a stable polymer, the hardest of plastics and easily transformable. Its softening occurs at 140 ° C. Poorly withstand polypropylene negative temperatures - it immediately becomes brittle, brittle, so it is suitable only for internal use.

For the extractor device take polypropylene pipes with the designation PN10. This type is characterized by such dimensions as the outer diameter - 2-11 cm, the wall thickness - 0.19-1 cm.

Polypropylene is a safe, reliable and simply ideal material for molding. On the photo, vent pipes and plastic ventilation elements

Pipes made from polypropylene are single-layered and multilayered. The first include products with the following markings:

- PPH - made of homo-propylene;

- PPB - the material for manufacturing is a block copolymer of polypropylene;

- PPR - made of a random copolymer of polypropylene;

- PPs - in the manufacture of applied igneous material.

Multilayer pipes are reinforced with foil and fiberglass. They have increased rigidity and a small coefficient of thermal expansion. Products made of polypropylene are less strong than PVC, so they have thicker walls and their cost is higher.

Pipes for ventilation from polyurethane

The characteristics of pipes made of polyurethane are similar in many respects to PVC pipes. They are plastic and wear-resistant, they can be given any shape. The main difference is the ability to remain unchanged until reaching a temperature of 280 ° C. If this threshold is exceeded, the polyurethane becomes very dangerous to health, since it releases nitrogen compounds.

On a pipe made of polyurethane, even under the influence of high stresses, cracks do not appear. It can be bent as you please, but as soon as the load disappears, the original form of the product returns

They are used in areas with complex trajectories, many turns and shifts. Several reduces the aerodynamic characteristics of these pipes, the presence of roughness on their inner surface. The cost of such pipes is quite high.

Characteristics of fluoroplastic pipes

Pipes made of this material have high strength characteristics. They have proven themselves in the temperature range from -40 to + 140 ° C. Fluoroplastic is recognized as the slippery polymer, this fact is even fixed in the Guinness book.

Fluoroplastic pipes are exceptionally resistant even in comparison with noble metals. This material does not lose its characteristics under extreme conditions

They are resistant to aggressive alkali and acidic vapors, so they are indispensable for exhaust systems on chemical industrial enterprises. The diameter of the products ranges from 15 to 60 cm. Because of their high cost, they are not used in the private sector. Also a limitation for their use is their increased gas permeability.

Plastic ventilation from sewer pipes

Experts often argue whether it is possible to do plastic hood of sewer pipes. Opponents of this idea give such an argument as the lack of antistatic coating in these products, as a result of which their inner surface is not immune from the settling of dust and dirt. Supporters say that the problem will be solved if the procedure is carried out independently.

The material for making plastic sewer pipes is the same type of plastic, except that its quality is somewhat lower. They are cheaper, so many use them for the hood device

The indisputable advantage of sewer pipes is that their price in comparison with plastic ducts is lower than the rate of 3. The drawbacks of these pipes and special ventilation products general - loss of rigidity at high temperatures.

When using pipes designed for sewerage as a supply air duct, there is sometimes a smell characteristic of plastic, but after a while it disappears. The pipes differ somewhat and somewhat larger than those of the airways with the weight. For them it is necessary to provide fastening.

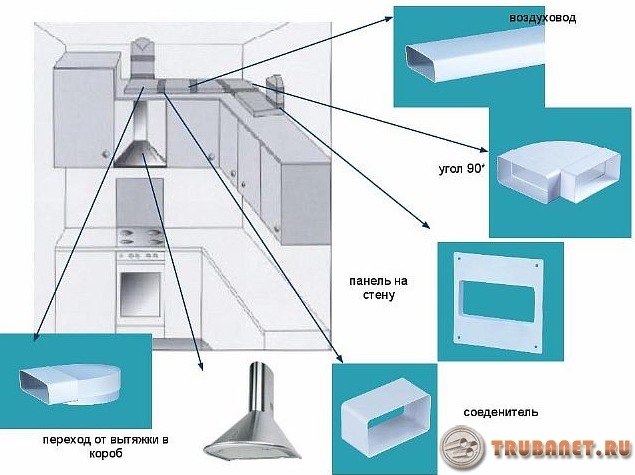

The device of a plastic airway

When installing a duct, it is important to follow several rules:

- The length of the pipe should not exceed 3 m, otherwise the efficiency of the device will decrease.

- The diameter of the hole, through which the pipe is connected to the ventilation shaft, can not be larger than the diameter of the pipe.

- Do not bend the pipe more than 90 °. This will disrupt the normal flow of air.

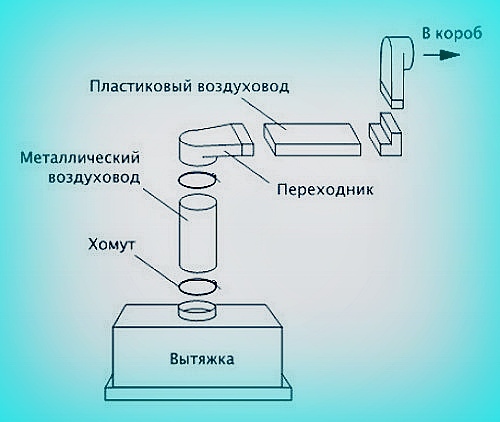

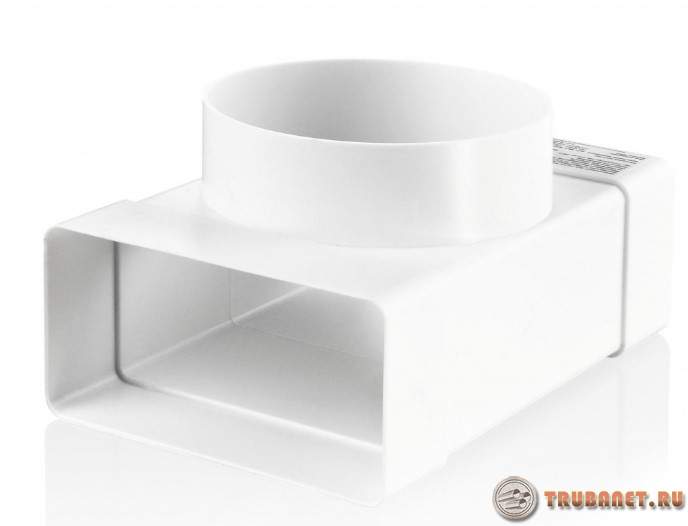

4. It is necessary to apply special valvesto prevent back draft. - At the transition point from the hood to the ventilation shaft, you must install an adapter.

Not recommended for implementation is the option, when the cooker and hood above it are on the side opposite the output in the ventilation shaft. In this case, the length of the pipes and the number of turns will significantly increase, which reduces the efficiency of the hood to a minimum.

An important parameter in the drawing device is the diameter of the pipe. If it turns out that it is smaller than the size of the outlet, the load on the engine of the hood itself will increase, the noise level will rise to an uncomfortable perception. This will be followed by breakdowns, additional costs for repairs.

At the drawing device sometimes use a combination of plastic pipes with metal. To connect them using a special adapter

Air ducts always try to hide. To this end, they mount decorative boxes, build the structure in furniture. An acceptable option is the installation of a pipeline over a suspended ceiling. The main thing is not to violate any of the safety rules.

For connection to the equipment, use a section metal pipe with a diameter of 160 mm. From this element, bends are made of plastic pipes. Increase the efficiency of the system by installing suction or blowers

If necessary, connect pipes having different cross-sections, use bends, special connectors, adapters. The internal surface of these elements must correspond to the external parameters of the duct. The tube segment is inserted into the connector and provides a seal, using the appropriate sealant for this.

There is a bell joint type. It is used when connecting pipes different sections. A smaller diameter pipe is inserted into the wider end of the pipe. Fixation takes place by means of a thread or a special rubber seal.

The role of the check valve in the system

The presence of non-return valves in the system will prevent air from entering the room from the ventilation duct. To avoid clapping, it is necessary to install the valve axis perpendicular to the floor. The valve can only be opened when the extractor is working. Among the variety of such products, the most common are 3 types of valves:

- Reverse petal. This is a series of blinds, oriented in a non-working state vertically or horizontally. They open when the forced hood is turned on. Typically, for their installation, the walls with inlet openings are selected.

- Turning. This is a simple mechanism that regulates the intensity of the flow or overlaps it completely. It is made in the form of a block with a latch located on the axis and controlled by means of a counterweight and traction system manually or by means of automation.

- Two-leaved butterfly. In the case of this product there is an axis on which there are two flaps. When the fan is on, the dampers open, when they are turned off they take their original position.

Often, connecting the exhaust structure to the ventilation duct, completely block the way of entering the building of clean outside air. Then, when the hood is not exhausted, the room is completely not ventilated.

To prevent this from happening, a special grill must be installed on the opening of the ventilation shaft. At the top of it there is a branch pipe for connecting the exhaust pipe and at the bottom there are openings through which air flows naturally.

On the picture check valve. He works well in the presence of exhaust fan and without it. Blocks the flow of air from outside

Ventilation pipes made of plastic for drawing both for a gas column and for a plate sometimes come on sale complete with the hood itself. The components of such a system are matched by color and texture, so you do not have to think how to disguise or refine the pipes.

Video about the use of plastic ventilation pipes

Well thought out option kitchen hoods:

Here everything about the installation plastic ducts with a rectangle in section:

On the merits of plastic ducts and their installation:

The best kind of pipe for retraction is plastic round. The rectangular profile, although it looks more aesthetic, but it provokes increased resistance in the ventilation system, leading to overloading of equipment.

The lightness, strength and durability of plastic materials for ventilation helps consumers to move away from metal analogues.

But, at the same time, skeptical people put forward doubts: is it true that the plastic is as durable as metal?

Plastic pipes for ventilation, the dimensions and features of which must be studied before installation, will be amazed by a vast spectrum of excellent characteristics. Due to these properties, these products enjoy the highest popularity.

The ventilation network of this material can last more than 50 years. For rapid air circulation - this is the best option.

The cost of buying and installing plastic pipes will be much lower than for metal pipes. It is also worth highlighting their aesthetic appearance and ease of maintenance.

Pipes in such systems:

- not prone to discoloration;

- do not undergo corrosion;

- easy to install;

- durable;

- acceptable price;

- flexible.

The ventilation system is difficult process exchange of air in the room. It operates in this way: the air in the room (whether it is a living room, office or production hall) is replaced by clean air - from the outside (outside).

Only now to the ventilation system can be attributed not only the process of air exchange, but also thanks to modern systems Added also conditioning, ionization, cooling and heating, humidification and dehumidification and other useful functions.

Under the ventilation system, all the so-called "material part" is understood: ventilation devices, exhausts, fans, as well as pipes (which in turn are divided into a round or square / rectangular section), which are also an element of this system.

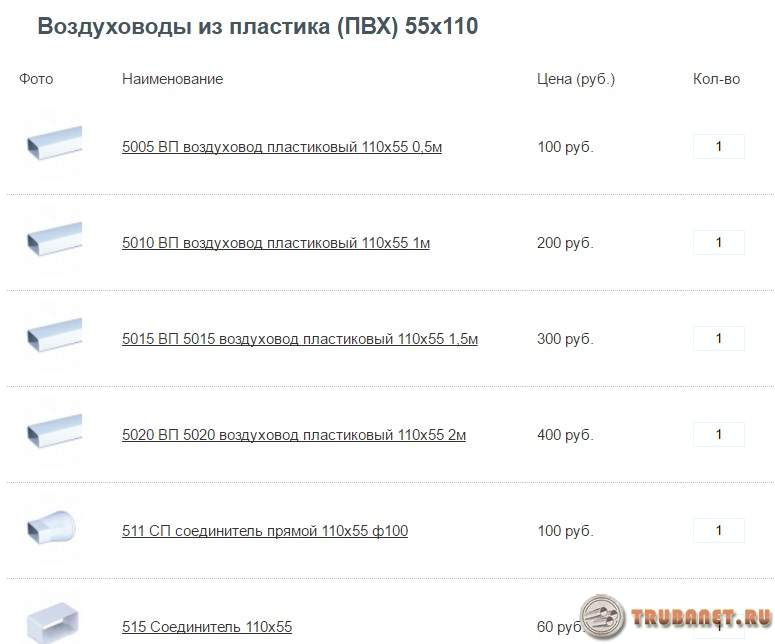

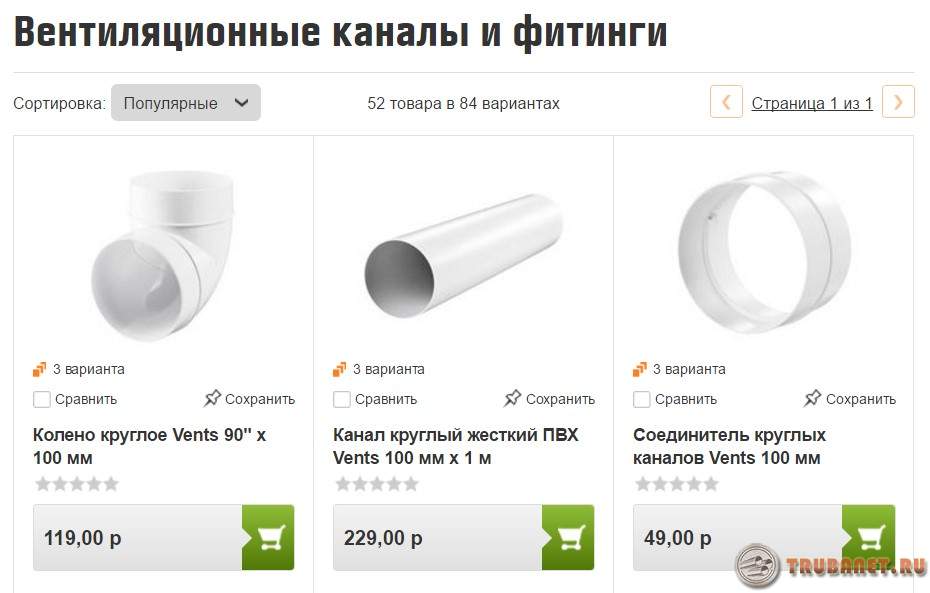

We will get acquainted with the widespread sizes and the prices for them. Dimensions of the rectangular duct: 11 x 5.5 cm; 12 x 6 cm; 20.4 x 6 cm. The diameter of the round: 10 cm; 12.5 cm; 15 cm.

Accordingly to GOST, air ducting is produced with the size of the internal section from 10 to 200 cm. The traditional size of ventilation for the kitchen hood is similar to the dimensions of a rectangular.

The price of rectangular and circular air ducts will average from 400 rubles and lower, and you can buy them in any building supermarket.

At construction companies, you can make an order for round and flexible duct. The flat PVC channel system will cost from 100 rubles.

The price of flexible and plastic version - this is about 320 rubles.

Ventilation system with a diameter of 12.5 cm

The main task of ventilation is to provide outflow or inflow air. High strength of these products is not required, but the small weight for this task is ideal.

This is very important when you have to install not on the main wall, but on a decorative partition, or over a suspended ceiling.

Pipes with a diameter of 125 mm are used in a standard length of 5 meters. Longer billets are difficult to pack and transport. Pipes for 125 are most often used for ventilation in a residential area.

Tubing materials are very easy to join - they are simply inserted into the socket of another workpiece.

The throughput in this case is 400 m / h. These are the most optimal indicators for domestic needs, in which the necessary air circulation is created and no unnecessary noise is generated during operation.

How to calculate the size and section

For laying produce different fittings, which makes it possible to connect several sites in a single whole.

Sealants help seal the joints, which do not allow air to escape outwards at the junction points.

Fastening of such a construction is performed by fasteners. On sale they are in a wide range.

Select plastic pipes for ventilation and their dimensions are recommended for the type, purpose and extent of the structure itself. Type, exponent, length and location are determined at the design stage.

At the design stage, the performance of all components of the system is calculated. If this is not done, there may be problems in the form of insufficient air circulation or strong noise during operation.

The cross-sectional area of the channel for an air speed of three meters per second is calculated by the formula: S = 0.9 x L. In it, the designation S is the cross-sectional area and L is the air speed index.

Incorrectly selected diameter will cause components to quickly fail. A repair and connected to the system will cost a decent amount.

Section

When mounting plastic ducts for ventilation, the dimensions of the section must be selected exactly. They are an important characteristic in this case. This selection is carried out depending on the location of the network.

For example, if the main overlap and ceiling separates a small distance, then a flat-oval view of the duct is recommended. Its design is not much different from the system of circular cross-section.

Purification of air passes with the same intensity. But, it should be noted that the plastic designs of the oval section do not create the proper resistance to the air flow, as a result it easily passes and the engine does not work with a high load.

The truth is the only drawback will be this is a high cost. But, this is justified by the need to use just such a form based on constructive features premises.

Ventilation channels

Plastic ventilation ducts harmoniously fit into the interior decoration of the room.

And the presence of a visor gives elegance and sophistication. This element allows you to hide not only flat, but also round channels.

They are used not only in everyday life. Such a box is often constructed by the exhaust line in offices and small commercial premises.

TO virtues can be attributed.

- Smooth surface outside and inside.

- High index of strength.

- High connection rate.

- Simplicity and ease of cleaning the surface.

- Presentable appearance.

TO shortcomings This design is its high cost, if you compare with galvanized and flexible options. This also applies to the limitation of the PVC pipe diameters being manufactured.

Flat ducts

Rectangular plastic pipes are used for laying flat plastic systems.

Their appointment is as follows.

- Creation of supply and extraction networks for small and medium-sized premises.

- To construct a flat output channel.

- For the supply of exhaust and ventilation equipment.

Design features.

- Made from environmentally-friendly material of high quality, which is not subject to burning.

- A wide range of use temperature (from -30 to +70 degrees).

- Minor resistance to the passing air flow.

- Long service life.

- A little noise when working.

- Economical use of space between the ceiling.

- A wide range of options when looking for a standard size and the nominal value of flat tube materials.

Couplings and fittings

Plastic ventilation is easy, this is facilitated by fittings, which greatly simplify this process.

The airway network is constructed in a single modular construction by means of connecting parts according to the scheme for working with the children's designer.

These modules are divided into the following types:

- Connectors. They are intended for direct fastening of parts of the same type and size. For example, this is rectangular duct of plastic 6x12 cm with a similar 6x12 cm (UPC 612). Also knee for fastening of networks of one kind and dimensions under an inclination (ККП 12,5 or КРП 612).

- Reducer. Set for a network of one type, but of different sizes.

- Adapter. This part serves to fasten different parts of different sizes.

- Splitter (tee). It is installed to divide the system into separate branches.

- Flange and overlay. Such elements are placed when attaching the system to the vent hole.

- Holder. Mounted for fastening to the wall and other surfaces.

Fittings of the modular network are perfectly adjusted to each other and do not cause any difficulties during the installation.

Fittings do not spoil the appearance of the structure in its visible areas. The connecting elements help to hide the air duct in the niches or to pass unnoticed, for example, over the suite in the kitchen.

Fittings in the ventilation network made of rectangular pipe materials allow it to be located inside a partition of plasterboard or behind suspended ceilings without any difficulties.

Correctly selected pipes allow creating a beautiful and reliable modern ventilation system. Thanks to a large number of positive characteristics of plastic, it will last a long time effectively and smoothly.

Choose the material from which the pipes will consist

So, let's imagine the situation. You moved to a new house. Ventilation in the dwelling is an important issue.

There are several types of ducts: plastic and metal (including galvanized metal and others).

Metal pipe owners of living quarters prefer to give less.

It's understandable: the material is less wear-resistant than plastic, heavy in processing, it weighs a lot and with unreliable fastening even creates a danger for others.

So metal ducts are mainly used in non-residential premises and in various industries. Pipes for ventilation from plastic - the most "running" material for the "home" system.

And the plastic for the ducts is also different. The most common materials are PVC (polyvinyl chloride), polypropylene, polyethylene, polyurethane and some other materials of this type and composition.

The advantages of plastic ventilation systems

Do not worry about the internal state of your ventilation systems - many are afraid that plastic pipes retain a static charge, and as a result, dust, dirt, fluff, debris, insects, light household waste are electrified and settle on the inside surface of the ventilation duct.

Only in reality there is no dense layer of dirt and dust, because manufacturers take care of those who will use their products in advance. How, you ask?

Everything is extremely simple - one of the most important processes of production processing is the so-called "antistatic" treatment.

Simply put, pipes made of plastic both from the outside and from the inside are treated with an antistatic to prevent any particles from sticking to the inner surface. Safety for the health of the customer is the most important aspect for air duct manufacturers!

And another "myth": the owners of living quarters are afraid that the plastic can melt under the influence of high temperatures and even will "drip" in your kitchen, creating a threat to health for those who live in the apartment.

Well, such an option seems quite fantastic, and that's why: first of all, the minimum temperature threshold that the plastic pipes for ventilation can withstand is not less than 80 degrees Celsius.

With all diligence, you can not create such high temperatures in the kitchen unless, of course, you create a threat to your health and the health of your loved ones, for example, lighting a small fire in the kitchen.

And yet - all manufacturers also take care of your safety, therefore, in addition to antistatic treatment, the processing of products with a layer of special refractory compounds is used.

Moreover, the modern production of plastic products has already reached the point where special refractory compounds are used not only in the processing of finished plastic, but also in its direct creation!

That is, a refractory layer of the substance is already embedded in the plastic product, which will create safety for you and your ventilation!

Where ventilation and exhaust ventilation is required

Now we will discuss directly where to install ventilation systems and hoods in a residential area. Without fail, exhaust ventilation is installed in the kitchen (in the dining room) and in the bathroom (and also in the toilet, if the bathroom is separate).

The logic is clear: it is necessary to remove hot air from the kitchen (which will always be there, because the cooker works there, as well as many electrical appliances), smells of food, fumes, soot, unpleasant smells and others.

In the kitchen, you can use air cleaners with various filters (including coal filters, etc.), as well as an extractor, which is installed directly above the plate (gas / electric) and piped to the main ventilation.

In the bathroom and toilet there should be no humid air and foreign unpleasant odors, so here it is also necessary. Additional devices for ventilation in the bathroom are not required, but the output for ventilation should be mandatory.

Combined air ducts

Once every two weeks, the grille of the air intake should be gently washed and cleaned of the settling dust.

By the way, when installing ventilation you can use not only plastic or metal ducts only.

First, it can be combined variants - with metal knots such as couplings, clamps or directly the grilles of the air intake.

And secondly, there is another common type of pipe for ventilation - corrugations. Gofra is used not as a single pipeline, but rather as another element of the type of adapter node.

Simply put, if the ventilation hole due to circumstances and the location of the appliances in your kitchen is not above the cooker and hood, but away from them, then it is just the corrugation that will help you.

A distinctive feature of the corrugation is its versatility and the principle of "spring", which allows you to smoothly connect pieces of pipe corrugation, turning them as you like and without making angles more than 90 degrees.

After all, if you create a too straight angle during installation, this will be a serious loss in the process of air exchange.

Each angle of 90 degrees does not just "slow down" the flow of air, but at the same time it significantly reduces the productivity of the ventilation process itself - by 10-15% or more!

Your task is to simplify as much as possible the installation of your ventilation and create ideal conditions for the air exchange process. So corrugation is an excellent "helper" for joining plastic elements.