Air ducts for the extraction of PVC. Plastic ducts for kitchen hoods

Systems forced ventilation practically in every apartment or private house. They consist of an air intake device and a duct for drawing, which can be made of different materials. Plastic version It is widely used because of cheapness, durability and ease of installation, which can be carried out independently.

For the normal operation of the ventilation system using the hood, you need to correctly calculate the duct parameters. In most cases, for household purposes, you can pick up plastic boxes of typical shapes and sizes.

Rules for choosing the duct section

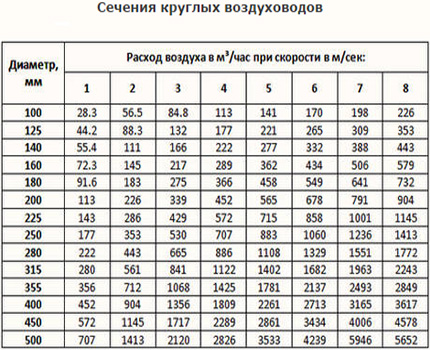

The main parameter of the vent box is its internal section. The speed of the flow along the channel depends on it and on the drawing power. The cross-section is selected based on the maximum volume of air to be passed. Normative documents, regulating the speed for domestic plastic air ducts is not, therefore, they are guided by the values tested in practical terms, equal to 3-7 meters per second.

The size of the section of the duct is taken equal to or slightly larger than that of the duct of the exhaust duct, the size of which is indicated in the passport of the device. If regular operation of the maximum mode is not planned, then in this case a proportional reduction of the section of the vent box relative to the size of the outlet opening is permissible.

For small kitchens, you can not use the maximum output power. This enables the adapter to use a smaller diameter airway than specified in the instructions

So, if S is the area of the duct section of the exhaust duct, N is the volume of air to be passed at the maximum mode of the device, M is the volume of air to be passed in the planned mode, then the required sectional area of the box is calculated by the formula:

P = S * (M / N)

Insufficient value of the section of the box leads to significant air velocities, an increase in the friction force and, as a consequence, to the following negative effects:

- there is an increase in the load on the ventilation mechanisms of the hood, which leads to a decrease in the service life of the device and additional costs of electricity;

- due to the increase in resistance there is a decrease in maximum capacity, which reduces the air circulation in the room;

- as a result of the occurrence of aerodynamic effects in the ventilation duct, the noise level during operation increases;

- there is an increase in air pressure from the inside to the elements of the system, as well as the occurrence of vibrations, which requires a more reliable attachment and sealing.

If the section of the box is more than necessary, this will not adversely affect the operation of the forced ventilation system, but will lead to unnecessary financial costs. In addition, ventilation ducts and other large-sized units are more difficult to install and integrate into the design of the premises.

The table for calculating the dependence of the flow rate on the drawing power and the diameter of the circular duct allows the correct choice of the size of the ventilation duct

Kinds of shapes and sample sizes

Plastic ducts for ventilation have a round or rectangular shape. The circumference has the least perimeter in comparison with other geometric figures with the same area. Therefore, from the position of minimizing the resistance of the inner surface of the duct to the movement of the air flow generated by the hood, a circular channel shape is preferred.

On sale for household purposes, the most common round plastic boxes of the following diameters:

- 80 mm, cross-sectional area of 50.3 square meters. cm;

- 100 mm, the cross-sectional area of 78.5 square meters. cm;

- 125 mm, sectional area of 122.7 square meters. cm;

- 150 mm, cross-sectional area of 176.7 square meters. cm.

Ventilation ducts of a rectangular shape are easier to fit into the interior of the room, and also placed in niches above the kitchen cabinets, above the suspended or stretched ceiling. The most common boxes are the following sizes:

- 110 x 55 mm, cross-sectional area of 60.5 square meters. cm;

- 120 x 60 mm, the sectional area of 72 square meters. cm;

- 204 x 60 mm, sectional area of 122.4 square meters. cm.

If necessary, you can find elements of a larger ventilation system. This plastic boxes for household purposes are round in shape with a diameter of 200 mm and a rectangular size of 220 x 90 mm. However, before making a choice in favor of non-standard sizes, you need to make sure that you can purchase all the elements that allow you to build a duct to draw the desired geometry.

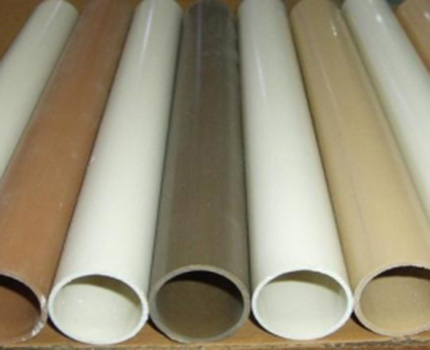

Extensive color scheme plastic pipes and boxes for ventilation of residential buildings allows you to easily fit the air duct into the interior of the room

Plastic Fittings

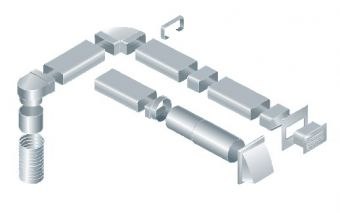

Ventilation systems from the hood to the mine have different geometry and topology due to individual approaches to kitchen layout. Therefore, special elements are provided for the realization of almost any configuration of the plastic box.

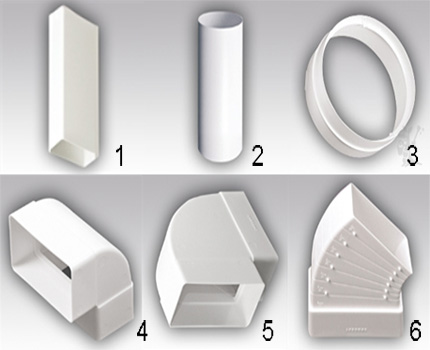

The ventilation ducts are straight duct elements of rectangular or circular shape. Their standard length is 0.35; 0.5; 1; 1,5 and 2 meters, but you can independently cut a piece of the required size with a hacksaw or a grinder.

If it is necessary to obtain a straight section of more than two meters in length, then it is mounted with several standard lengths using special connectors for plastic channels. In this case, the increase in the length of the section due to the size of the connector does not occur.

Another necessary element is the knee, by which the duct is rotated through an angle of 90 or 45 degrees. For boxes of rectangular shape, the elements for changing the direction along the horizontal and vertical are distinguished. To rotate at angles not multiples of 45 degrees, use the so-called razogouglovoe knee. Depending on the required angle, one of the sides of the connector is cut off.

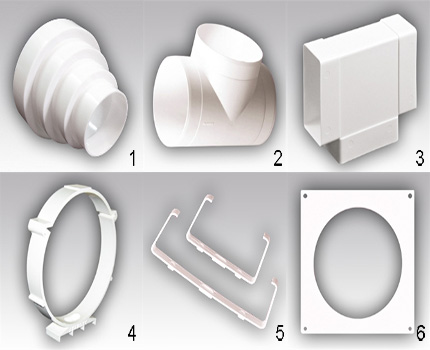

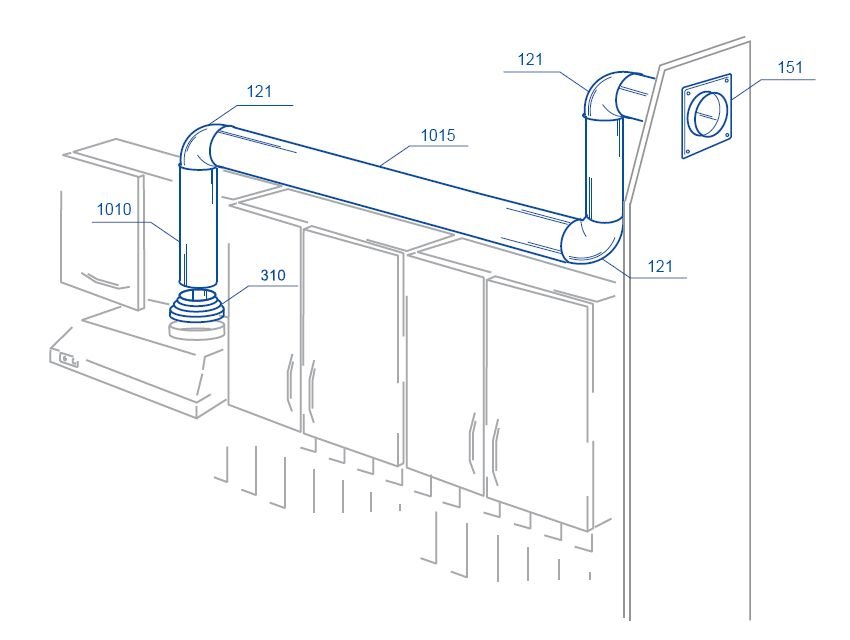

Shaped elements: 1 - rectangular channel; 2 - round channel; 3 - round duct connector; 4 - knee vertical; 5 - the knee is horizontal; 6 - angular elbow

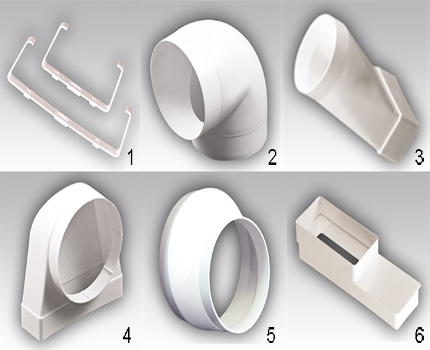

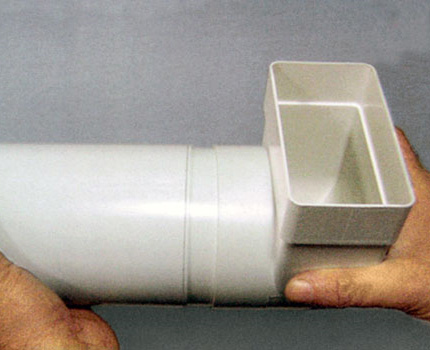

To change the shape of the box from round to rectangular (or vice versa) use special adapters. Their use, as a rule, is due to the difference in form ventilation ducts with the outlet funnel of the hood or a hole in the grille. They can be either straight or angular. The following transition options are the most common on offer:

- from a diameter of 100 mm to a size of 110 x 55 mm;

- from a diameter of 100 mm to a size of 120 x 60 mm;

- from a diameter of 125 mm to a size of 204 x 60 mm.

If it is necessary to carry out the transition to another dimension of the plastic box without changing its shape, then the reducers are used. For round variants, there is a special universal adapter that can be used to connect all standard sizes.

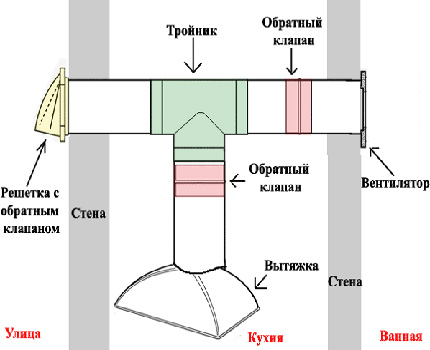

For designs with a complex topology, tees are provided that can be used to connect air flows from several hoods, for example from the kitchen and from the bathroom, towards the exit. They can be rectangular, round, and also a combined shape.

Shaped elements: 1 - flat channel connector; 2 - the knee is round; 3 - straight line adapter; 4 - corner adapter; 5 - the reducer is round; 6 - rectangular reducer

Fastening of the elements of the box to the wall occurs with the use of holders. Since plastic constructions differ from metallic ones with low weight, their installation is not a difficult task. These factory-made parts are inexpensive and fit well into the interior of the premises, so the use of homemade structures it is inappropriate.

A wall plate or grate is attached over the hole in the wall leading to the ventilation shaft or to the street. The grille, if necessary, may contain additional slots for natural ventilation. In this case, it is necessary to provide protection from penetration through these openings of the generated airflow back to the room.

To prevent the emergence of reverse traction when the exhaust hood is used check valve. It can be integrated into a plastic duct connector, or the ventilation grilles can perform its function. In the absence of such a device, air may enter the room from the street or from the ventilation shaft.

Shaped elements: 1 - reducer universal round; 2 - the tee is round; 3 - rectangular tee; 4 - the holder is round; 5 - the holder is rectangular; 6 - the overlay for round channels

Features of design and installation

Installation of a plastic box for ventilation from kitchen hoods You can do it yourself without involving specialists. In this case, it is necessary to take into account some simple features of design and installation of such systems.

Nuances of choosing the geometry of the ventilation system

A wide variety of structural elements makes it possible to realize practically any geometry of a plastic ventilation duct. However, in order to maintain the functionality of the air-pass system at the proper level when designing the duct, the following rules must be observed:

- If possible, minimize the length of the box. A distance of less than 3 meters is considered the optimum distance from the hood of the hood to the ventilation grille.

- It is desirable not to use a large number of elements that change the direction of air movement. Bends, constrictions and various transitions create additional aerodynamic resistance.

- It is necessary to minimize the number of knees with a turn of the box by 90 degrees. They create the greatest resistance to flow, generate noise and accumulate deposits in the form of fat and adhering to it dust.

In the case of placing the box near the heating stand or other heat source, it is necessary to prevent the plastic from heating up to a temperature above 50 degrees Celsius.

To do this, you need to either bypass the hot object or build a thermal insulation between it and the duct. As an insulating material, it is easiest to use foam because it has low thermal conductivity, and also will not create noise when the box vibrates.

Implementation of heating circuit bypass with four knees with a 90 degree angle. With a different orientation of the channel, if a narrow part was turned to the wall, it would be possible to manage angles of 15-20 degrees with the help of a multi-angle knee

Check Valve and Grille

A necessary element of the ventilation system is the non-return valve. If the box goes only from the hood to the shaft and has no branches to other sources of air intake, then the valve is installed at the end of the duct or use a special grill with "blinds" to prevent air return.

In the case of several sources of air intake into the ventilation system, a check valve is installed near the connection of each branch with the main duct and another one near the grid.

A typical solution for placing check valves in the ventilation system in the presence of two points of air intake and an external grate

If there is a need to support natural ventilation when the hood is turned off, there are three solutions:

- separate outputs for forced and natural ventilation, and they should not go into one ventilation shaft;

- to establish near the exit the tee "exhaust hood - grate - check valve";

- use a ventilation grille with slots for natural movement air and protection against reverse traction.

Birds or rodents inhabiting the ventilation shaft sometimes penetrate into the air duct. Once in the bends of the plastic box, they can die, as a result of which the decomposition products fall into the room. To prevent such a development, the grid leading to the street or to the mine is often provided with special protection that is insurmountable for animals.

Protection of the ventilation grill from the penetration of birds and rodents significantly narrows the cross-section, which must be taken into account when calculating the diameter of the hole

Fixing and placement of air ducts

The sections of the plastic duct from the hood to the ventilation grill can be fixed in different ways depending on their position relative to the cabinets, walls and ceiling. In any case, the installation is not difficult and it can be done independently. However, it is necessary to approach this procedure responsibly, in order to avoid occurrence of noise from vibrations, as well as sagging or other deformations of the box with possible subsequent depressurization.

If the box is located inside the cabinets, then it is fastened to the back of the cabinet using clamps. Also fix the places of passage of the duct through the walls with the help of foam or polystyrene inserts. These materials do not make noise when in contact with the vibrating elements of the system.

In the case of the location of a part of the duct above the cabinets, it is easiest to fix it to the cabinets with the help of holders and screws for a small length of wood. The plastic box in this position does not create any significant lateral pressure.

When fixing the duct to a wall or ceiling, the holders are recommended after 1 meter. Fixation occurs with the help of special clamps, which can be purchased under the shape and size of the box to be purchased. The weight of the entire plastic structure is small, so its fastening is simple enough.

A plastic box can be completely hidden behind a suspended ceiling and plasterboard. In this case it is permissible to carry out sealing and fixing of the entire structure without taking into account its visual perception

If the plastic box is closed by a tension or suspended ceiling, it is necessary to check the reliability of its fixation when the extractor is operated at maximum power. In other cases, the fastening can be easily strengthened after the detection of weak points.

Sometimes, during operation of the ventilation system, rattling or knocking may occur, caused by the vibrating elements of the plastic box touching with solid objects such as a cabinet, wall, etc. In this case, instead of additional fastening, it is sufficient to lay foam or foam between them.

Ensuring the tightness of the plastic box

Elements in the ventilation system made of plastic parts do not have a sealant. The joint dimensions are well adjusted, but after some time due to deformation, the density of some joints may decrease.

In the event of a leak in the joints of structural elements, it is possible to penetrate the air from the ventilation system to the outside. In this case, odors and moist air spread through the rooms through which the air duct passes. In addition, when air passes through the cracks, there is sometimes considerable noise.

Despite the fact that all the elements of a quality plastic box fit tightly to each other, it is better to devote some time to sealing joints

To prevent depressurization of the plastic ventilation box, there are two solutions:

- Spread the joints of the structure with a special silicone or acrylic sealant. It is applied a thin layer on the edge of the element before it is inserted into the system.

- Wrap the joints with self-adhesive tape. Such a method can be applied after the installation of the system in case of detection of the places of depressurization.

The first method is more reliable, but serious problems may arise if you need to analyze the vent box for repair, cleaning, or changing its geometry. Over time, the sealant binds the structural elements so tightly that in some cases one has to sacrifice one of the parts to begin the parsing of the system.

The method of external sealing, on the other hand, allows you to easily analyze the plastic box. However, this method affects the appearance of the structure, so it is not practically used if it is located in view.

Video examples for selection and installation

Installation of the kitchen box. Elimination of cracks in joints of structural elements with the help of silicone sealant and self-tapping screws. Preventing vibration with a mounting foam:

Installation of a plastic duct for extraction in the kitchen. Fastening of elements among themselves, fixing to a ceiling by means of holders:

The operation of a non-return valve for the operation of natural ventilation is exemplified by the tee-off "exhaust hood - grill - natural ventilation":

The information presented by us on the selection, the methods of the device and the main components of the plastic ventilation ducts will help us to build a reliable box for kitchen ventilation by our own hands.

Ventilation in the kitchen performs not only a practical, but also an aesthetic function. Installing a plastic duct for a kitchen hood allows you not to breathe fumes that inevitably accompany the cooking process, and ensure the safety of kitchen furniture. The extractor is installed directly above the plate, and the ventilation shaft can be located at some distance. To connect them, you use special pipes - air ducts.

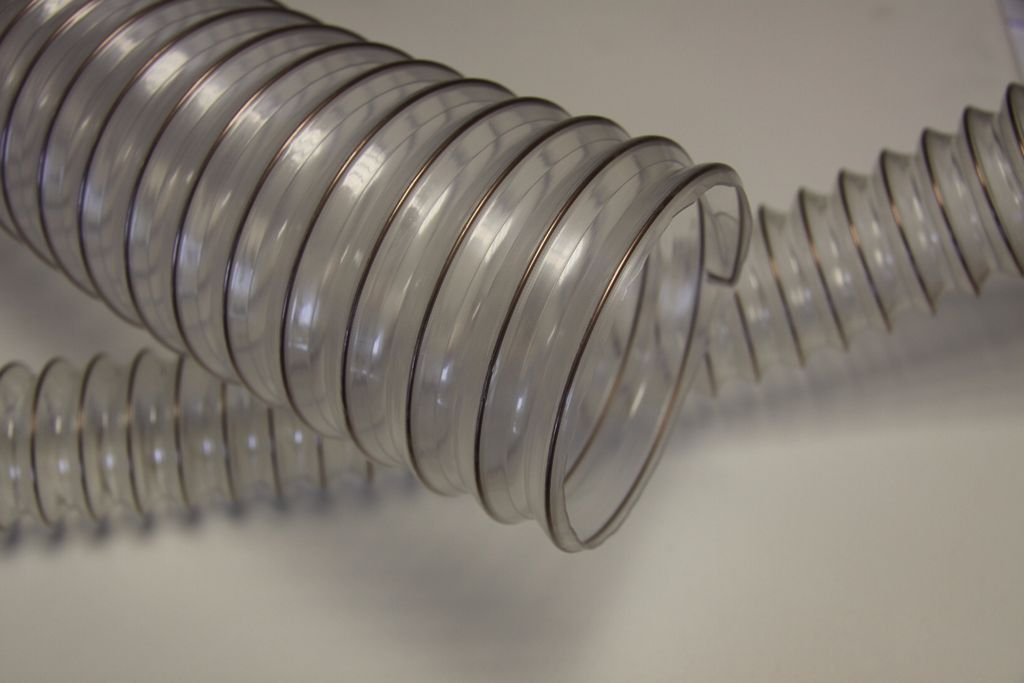

Varieties

Air ducts that are used for kitchen hoods can differ in material of manufacture, shape and level of rigidity. The best option To ensure ventilation in the kitchen are corrugated air ducts made of PVC.

The plastic pipes are characterized by a long service life and easy installation. In addition, PVC products are safe in terms of ecology and hygiene. These products for kitchen hoods can be made of smooth plastic. In addition, air ducts can have different sizes, rectangular or circular cross-section of the pipe. Rectangular plastic ducts are more convenient in terms of installation, but round ducts for stretching have greater throughput.

Dimensions and design features

Remember that when purchasing air ducts from PVC, you need to stock up on adapters. They are needed to connect the plastic pipe and the hood. Also adapters are used for duct bends and connection to general ventilation. The recommended number of adapters is not less than three. If a plastic corrugated air duct is used for the hood, it is possible to save on adapters for pipe bending.

Length pVC pipes should not exceed three meters. Otherwise, the performance of the hood will fall with each additional meter. Each bending of the pipe also has a negative effect on the functionality of the kitchen hood. When installing the duct in the kitchen, try to avoid angles of 90 degrees. This will cause overload of the hood, which will significantly reduce the service life of the product. The maximum number of knees and bends allowed must not exceed three.

The diameter of the plastic pipe must match the size of the vent.

Dimensions of rectangular kitchen ducts from PVC are standard. In general, the following values are used: 110 * 55, 120 * 60 and 204 * 60 mm. Dimensions of round plastic pipes vary from 110 to 150 millimeters in diameter.

You can buy these products in almost any construction shop. It is worth noting that flexible air ducts cost more than flat PVC channels.

Installation

The most practical and convenient for installation are corrugated products. They are cut into pieces of the right size and combined with the elements of the hood and the ventilation shaft in the kitchen. It is recommended to replace the conventional ventilation grill with a special - with a built-in connecting branch pipe. The connection is made by means of crimp clamps. For greater tightness, the joints must be treated with sealant. It is worth noting that corrugated pipes are set in the maximally stretched position. This approach ensures the nominal throughput of kitchen ventilation.

PVC ducts are installed in the same way. The pipe is cut by a hacksaw over the metal into pieces of the right size and fixed to the elements of the hood with the help of adapters. The pipe should enter the nozzle approximately 50 millimeters. Joints are treated with silicone.

Advice! Installation of the hood is done taking into account the direction of air movement. Otherwise, the service life of the PVC duct is significantly reduced.

If you have installed a powerful hood, the reverse traction effect may appear. In other words, the kitchen will have fragrances from the general ventilation shaft. This applies to powerful models, whose capacity is about 600-700 cubic meters of air per hour. To avoid such a phenomenon, it is recommended to install a non-return valve. These devices can be of two types: film type or as a plastic disk on the axis. The valve should be installed vertically, otherwise it will operate under its own weight.

You can do the same in another way: take the hood directly to the street. For this, a hole of the required diameter is made in the wall of the house. You should know that before starting such work, you need to get permission in the housing and utilities sector.

To avoid such difficulties, it is recommended to consult the seller about the power of the hood and correlate these parameters with the area of the kitchen. For the needs of the average family living in a typical high-rise building, there is enough low-power stretching.

How to hide the air duct in the kitchen

Plastic ducts more organically fit into the design of the room than the metal. But even they can spoil the look of the kitchen, so most people prefer to hide this element of the hood. There are several ways of such camouflage.

- Kitchen hoods are well hidden under multi-level, hinged or tension ceilings. To do this, a special box is made that hides almost all exhaust system. But this method is suitable only in the event that a major overhaul in the kitchen is started with a ceiling replacement. If the hood is installed after repair, then it is unlikely to hide it under the ceiling.

- For camouflage exhaust pipe you can buy or make a special PVC box. This decorative element can be selected in a tone finish. In addition, in the box you can cut additional lights.

- If the kitchen will be purchased furniture made to order, you can put the hood directly in it. To do this, it is enough to inform about the desire to the master for furniture installation. The air duct can be permanently embedded in the kitchen cabinets or made in an advanced version.

- Finally, you can simply paint the airway pipe. If you show a certain imagination, you can get quite an original decoration for the kitchen.

To ensure that all elements of kitchen ventilation are the same color, it is recommended to purchase ready-made sets. Some manufacturers sell their products according to the scheme: hood + duct + additional element = high-quality ventilation in the kitchen. Special attention it is worth giving to the quality of materials. Remember that hoods made from poor quality raw materials or with a violation of production technology, will not last more than 5 years. While PVC products from proven manufacturers are designed for at least 30 years of operation.

Ventilation is an integral part of the life support system of any residential, administrative or economic building. With the help of it, excess moisture is removed from the premises, carbon dioxide and foreign smells. Ventilation ensures the influx of fresh air into the room, creating a comfortable microclimate.

The ventilation system consists of several elements, each of which performs a certain task. One of these elements is the air duct. The purpose of the duct is to transfer air from the suction fan to the ventilation shaft of the house or to the street. The best material for manufacturing ducts are plastic ducts for ventilation. These products have proven themselves in the process of operation ventilation systems in different conditions.

Advantages and advantages

To produce plastic boxes for drawing PVC is used - a unique material that combines a lot of positive qualities.

So, ventilation plastic boxes made of polyvinyl chloride have such necessary and useful properties:

- environmental Safety;

- mechanical strength;

- elasticity;

- resistance to chemically active and organic liquids;

- resistance to temperature changes;

- small specific weight;

- the possibility of creating almost any form of air duct;

- simplicity of installation;

- ease of maintenance;

- the possibility of dismantling for the purpose of washing or repair;

- incombustibility;

- a wide range of colors;

- a variety of shapes and sizes;

- affordable price.

One of the biggest advantages of plastic ventilation ducts is their ability to organically occupy space in the premises of any destination. These products, after installation, no additional finishing is unnecessary. Pleasant appearance and smooth forms of the duct will look good, both in living quarters and in administrative buildings.

The smooth internal and external surface of the PVC duct ensures almost unimpeded passage of air through it. On such a surface, mechanical particles are not retained. Fat, which, one way or another, settles inside the pipe, is easily washed off with a warm soap solution.

Important to know: Plastic exhaust ducts are used in rooms with high humidity, such as bathrooms, kitchens and toilets.

Types, sizes and equipment

In form, ducts for the manufacture of air ducts, there are round, rectangular and square section. The most popular products are rectangular shaped. They easily fit into any interior and are in harmony with any furniture. Today, there is a wide choice of shapes and sizes for plastic ventilation boxes. This allows them to find their use in rooms with different area and volume.

Having a standard wall thickness of 3-4 mm, rectangular plastic ventilation ducts have the following parameters:

- section - 110 × 55 mm, 120 × 60 and 204 × 60 mm;

- the length of the channels is 50 cm, 100 cm, 150 cm, 200 cm and 250 cm.

The color of the products can be as follows:

- white;

- solid color;

- under the tree.

If none of the color options is suitable, then you can do the following:

Elements of plastic duct

- paint the air duct;

- cover the box with wallpaper or duct tape for the color of the interior of the room;

- make for the air main a plasterboard box with the subsequent finishing;

- to cover the air duct with sheets of PVC plastic under the color of the ceiling;

- place the ductwork under the plastic suspended ceiling.

For ease of installation and shaping the air duct, manufacturers offer a large selection of additional elements.

So, in a complete set with pipes it is possible to get such details:

- Wall plates. To connect the duct to the ventilation shaft and the decorative hiding of the mounting hole.

- Angles for rectangular tubes. Are intended for their connection at a right angle. There are vertical and horizontal performances.

- Angles for rectangular and round boxes. Used to connect round and flat sections of the trunk at right angles.

- Angles for different boxes. They serve as a joint for rectangular parts of different cross-section.

- Clutches for rectangular boxes. To connect pieces of rectangular lines.

- Couplings for rectangular channels with a valve. For connecting rectangular plastic parts. Have a check valve to prevent air from entering the ventilation shaft or from the street into the room.

- Muffs universal. Are intended for connection of ventilating plastic rectangular boxes in the size 55 × 110 mm and 60 × 204 mm at any angle.

- Clutches for rectangular and circular fragments. Used to connect rectangular and round boxes.

- Holders. They are used for connection to walls or ceiling of plastic ducts for ventilation with dimensions of 55 × 110, 60 × 122 and 60 × 204 mm.

Box installation

Having decided on an exhaust plastic box, certain preparatory work to install it.

These include:

- Drawing up the design of the duct.

- Selection and purchase of material.

- Tool preparation.

Drafting

The design of such an uncomplicated design as an air duct will not be difficult. To do this, enough 1-2 sheets of paper and 20-30 minutes of time.

The diagram of the passage of the air main is shown, which takes into account:

- the metric of each type of channel;

- number and type of knees, connectors, transitions and tees;

- the type and size of the wall plate;

- number of holders and fixing material.

After determining the material requirements, you can proceed with the purchase.

Procurement of material

Despite the fact that construction shops have a large selection of goods, not all can buy a complete list of necessary. Prices for absolutely identical products can be quite different. Therefore, it is recommended before going to the store to carefully read the websites of the city's shops. This will save time and money.

Choice and purchase

You should buy a set of products from the same manufacturer. In this case, the additional elements and ventilation ducts of the dimensions have the most appropriate dimensions.

When you purchase a material, you should pay attention to such nuances:

- availability of a quality certificate for the goods;

- absence of mechanical damage on products;

- geometric correctness of forms of boxes and components;

On a note: The reliability of the connection of individual parts can be checked directly in the store. The parts must fit into the grooves tightly, but without effort.

Instruments

Even such a simple job as installing a plastic duct for ventilation requires a minimum set of tools.

Required Tools

This set includes:

- perforator;

- hacksaw for metal;

- roulette;

- building level;

- marker or pencil.

Having prepared and checked up serviceability of the tool, it is possible to start installation of an air line.

Installation of ventilation plastic box

The airway can be placed in 2 ways. The most common is its placement on furniture. If the installation takes place in the kitchen, the air duct simply fits into the hanging cabinets. The free running of the joints allows you to precisely adjust the dimensions of the plastic duct for drawing.

If the installation of the box on the furniture is not possible, then it is laid on the walls or ceiling.

In this case, the procedure is as follows:

- a suitable plastic transition is installed on the hood;

- wall plate is fixed on the wall;

- measures and cuts the vertical fragment of the box, taking into account its attachment in the grooves of the upper and lower transitions;

- the vertical section of the box is inserted into the hood, an angle is fixed to it;

- measured, cut and joined by couplings (if several sections) horizontal fragments of the duct;

- after fitting a single horizontal run, it is fixed to the surface with the help of holders;

- the next run of the air channel is made, inserted into the plastic corner and fixed by holders;

- the duct is inserted into the wall plate.

The work is finished. Now the room will be free from smells and dampness.