Rectangular plastic pipe for drawing. What are the use of exhaust pipes for ventilation?

The laying of communications in a house or apartment is not as simple as it seems at first glance. In order for the equipment to work properly, and also there were no claims of the inspection authorities, it is necessary to make the installation taking into account all norms and rules, not forgetting about the aesthetic component. Consider how diverse the pipes for drawing, understand in their technical characteristics and choose the most the best options installation.

Ventilation pipes with a set of connecting and fastening elements is usually called air ducts. They are designed to provide air circulation and are installed in those rooms where there is no access to natural movement air or there is an additional need for ventilation: in the kitchens, in the bathrooms, in the toilets.

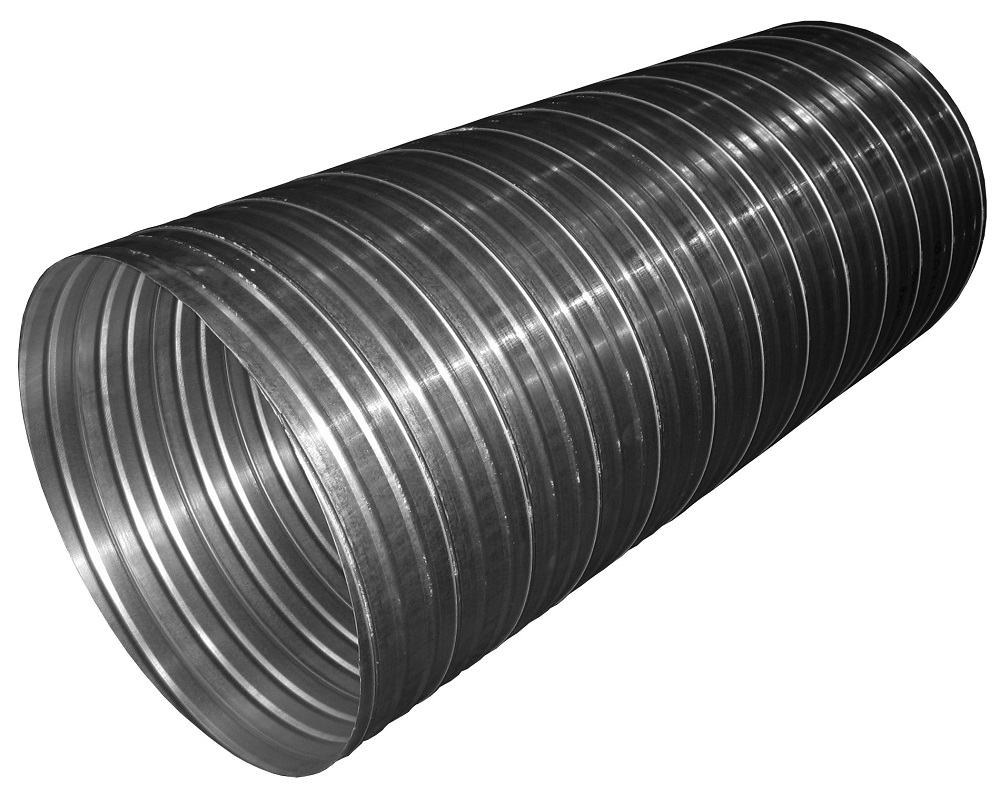

Before the appearance of plastic parts in the market, air ducts were made of galvanized metal, and they are still often found in production shops or in public catering establishments (their use is associated with high temperatures).

Stand in the supermarket with plastic elements of the ventilation system assembly for extraction: rectangular and round tubes, adapters, tees, plugs, corner pieces

But for use in everyday life, that is, for installing ventilation in apartments and cottages, polymeric products are more suitable. They have the following advantages:

- they have less weight than metal ones, so they are easier to install with their own hands;

- smooth walls have minimal resistance to air movement;

- they are hermetic, since they do not have seams;

- resistant to high humidity, do not rust;

- on the market you can always find a set of fittings suitable for cross-section.

For the sale allowed products that meet the norms of SNiP and have certificates of compliance, so we can talk about the safety of plastic elements.

Basic characteristics of plastic parts

The properties of pipes need to be known in order to properly design and install a ventilation system in an apartment or house. The characteristics of the elements may differ depending on the installation location (above the ceiling of the plasterboard, in the closet, in the attic) and from the geometry of the room. Let us consider which features become decisive in the selection.

Ductwork material

On sale, you can find products to create ventilation structures of four types of material, which in everyday life is called plastic:

- polyvinyl chloride;

- polypropylene;

- polyurethane;

- polyethylene.

Lightweight, inexpensive, easy-to-install PVC air ducts are the most common material for the construction of household ventilation structures. They are strong, tight, but have some limitations. They can not be heated up to 160 ° C, since harmful for all living chlorine starts to be released, and according to the regulations, the upper heating plate without risk to human health is + 120 ° С.

PVC pipes are suitable for installation in the kitchen or in the bathroom, their use is prohibited where there is a possibility of heating up to 160-180 ° C - for example, in saunas or in rooms with a fireplace

When the temperature drops below + 5 ° C, PVC becomes brittle, so for installation ventilation system in rooms with temporary residence it is better to choose another type of pipe, for example, from polyethylene or vinurethane.

Polypropylene is an excellent dielectric, it is not hygroscopic, it has high resistance to aggressive chemical media. The strength limit is approximately 4 times higher than that of polyethylene products high pressure. The main drawback is flammability, the maximum possible temperature is + 85 ° C. However, there is a fire-resistant version with flame retardant additives - PPS.

Polyurethane in its characteristics like PVC, but withstand higher temperatures - up to + 280 ° C.

Particularly strong is vinurethane, reinforced with a steel spiral. It is suitable for drawing, because it has excellent resistance to mechanical damage and flexibility, allowing the deployment of the duct from any angle

HDPE - polyethylene low pressure. Does not crack with time and, unlike PVC, it is easier to tolerate negative temperatures (actual for houses with temporary residence). Possible heat resistance - up to + 80ºС, cooling - up to -50ºС. Easy to handle, like all kinds of plastic products.

Polypropylene and polyethylene pipes for household ventilation are used rarely, the leading products of their PVC.

Types of pipes in terms of flexibility

There are two categories of ventilation plastic pipes for drawing - rigid and flexible. Sometimes a combined option is required, but much less often. If the hood is installed next to the vent, there is no need for a complex design.

When purchasing rigid round or rectangular cross-section pipes, it is necessary to purchase a set of additional parts to make turns or transition points.

To assemble a short duct for drawing, placed above the kitchen cabinet, rectangular PVC channels and connecting corner elements from a similar material

Along with rigid straight pipes, corrugations are used - flexible products made of polyurethane or aluminum, which allow to do without corner pieces.

Use as an air duct corrugated pipe Aluminum, which has two advantages over plastic analogues: fire resistance and higher strength

Corrugated products are more economical, but lose in design. To preserve the beautiful appearance of the interior, it is better to disguise them under suspended structures or to locate them in a "blind" zone - on cabinets near the wall.

Varieties of elements in the form of section

Depending on the configuration of the pipe, ducts of the following types are distinguished:

- round;

- rectangular;

- flat.

The cross-sectional shape greatly affects the technical characteristics and mounting method. For example, straight round tubes have better throughput and excellent noise insulation, since air, moving along smooth walls, practically does not encounter obstacles (except for the angular sectors). However, due to the cylindrical shape, installation problems may occur.

Option for installing a circular pipe leading from the hood to the vent on the adjacent wall. Elements of installation: 4 pieces of pipe, 3 round angular elbows of 90º, reducer (+)

Rectangular ducts fit tightly to any level surfaces (walls, ceiling, walls of kitchen cabinets), so it is much easier to install them. But there is one drawback - the uneven distribution of air, because of which there is a strong noise.

The optimal solution for installing ventilation over a suspended ceiling: light rectangular plastic pipes with a set of adapters and a round tube outlet (to reduce noise)

Flat ducts are the same rectangular, but having a large difference in the dimensions of the width and height of the section (for example, flat channels 110 mm x 55 mm). Due to the compactness, they are often used for installation in the presence of a shortage of free space (for example, over suspended structures or over highly suspended cabinets).

How to choose the section size

The section size is more important than its shape, since the efficiency of air exchange in the room depends on this parameter. There are standards that take into account the specifics of different rooms, and when choosing the elements of ventilation, it is better to be guided by them.

Premises with high humidity and high levels of dirt in the air (bathroom or kitchen) should be ventilated more often and intensively than relatively clean and dry (bedroom, living room) (+)

According to SNIP, the volume of air inflow in houses and apartments should be at least 3 m 3 / hour per 1 m 2 of living space, while the number of people living is not taken into account. The volume of circulating air for people permanently in the room is 60 m 3 / h, temporarily located at 20 m 3 / h (referring to places of work, for example, offices).

It is not possible to make an exact calculation of the cross section by yourself. It is better to use the services of an engineer or a special program for which the following data will be needed:

- form of air ducts;

- material for the manufacture of pipes;

- internal resistance;

- indoor temperature.

There is a way to determine the dimensions of the vent hole for the area of the room. For each square meter The room has 5.4 cm² of duct cross-section, while the pollution factor is important. For an accurate selection of the pipe cross section, we recommend that you contact the professionals who calculate the complex formulas based on the specific data.

What does the exhaust ventilation consist of?

For the installation of ducts, few pipes are needed, fittings are needed - fittings for various purposes. They serve to seal the parts in a single system, provide smooth transitions of pipes of different diameters, connect the air duct with a hood and vent, allow the creation of angles of 90º.

Shaped parts from plastic for assembly rectangular duct: connecting and horizontal elbows, plugs, holders, grilles, reducers, straight connectors, plates, tee

One of the important elements is the transition (adapter). It is necessary in two cases: when it is necessary to connect pipes of different cross-section or ducts that differ in size. Used to assemble structures in rooms of complex geometry, sometimes - for embedded fragments in cabinets.

In order to avoid the effect of return thrust and the used air does not return to the room, the air ducts are equipped with check valve. This is an integrated frame with a dynamic blade that opens only in one direction - in the direction of air flow into the ventilation shaft. The valve does not act as a connecting element, but as a part that increases the efficiency of the ventilation.

In the assembly of a small segment, two pipe segments are involved rectangular section, a wall plate, an air duct connector with an outlet and a horizontal angled elbow

To ensure 100% sealing, it is necessary to select fittings strictly according to the dimensions of the pipes: for example, for boxes 150 * 100 mm, knees of the specified size are necessary.

Variants of installation of plastic pipes

Consider two options for installing plastic pipes for exhaust ventilation. They differ both in the place of installation and in the choice of elements.

Installing the duct inside the room

Most often, plastic pipes for ventilation are used in the kitchen to connect the hood and vent located on the wall under the ceiling. For ease of operation, the hob should be positioned as close to the outlet as possible. If it is installed on the opposite side, it is better to move it closer than pulling the duct through the kitchen.

The shorter the overall length of the pipes, the better. It is estimated that each turn of a pipe with an angle of 90º reduces efficiency by 10%, and another as much as one extra meter lose systems longer than 3 meters. That there were no questions on a course of work, we make preliminary calculations and we make the drawing with the instructions of the sizes and additional details of an air line.

As a sample, let's take the often encountered variant, when the outlet ventilation hole is located slightly to the side of the installation site of the hood

You will need:

- flat channel for exhaust ventilation 204 * 60 (1,5-2 m);

- horizontal knee 204 * 60

- connecting knee;

- the plate is wall-mounted;

- round reducer with adapter;

- hacksaw for plastic;

- sandpaper;

- sealant;

- marking tool.

Preparing the pipes - from the plastic boxes cut off the blanks of the required length, we clean the edges. If the air duct is fixed in the free space, it can be pre-assembled on the floor, fixing the connecting elements with a sealant. If part of the structure is in the cabinet, first fix it (reducer + vertical pipe), then connect it to the horizontal pipe with an angular bend.

At the end, connect the pipe to the plate-shaped hole with a special fitting. For strength, anointing joints with a sealant, heating can not be used.

To mask the duct use suspended ceilings or wall cabinets. For open space it is better to choose flat rectangular boxes that become invisible if they are placed on cabinets (+)

If you need to fix the wall or ceiling, you can not use self-tapping screws. For this purpose, specially designed clamps, tightly covering the pipe. They are provided with a rubber seal and are attached using brackets or pins. Some clamps are fixed with a simple click, which simplifies the installation process.

Selecting a suspended ceiling as a masking structure, try to carry out the work qualitatively. Before starting the construction, carefully check the airtightness of the air duct - for repair or replacement it is necessary to disassemble the ceiling structure from plastic panels or plasterboard.

Thermal insulation of pipes in the attic

In the city apartment, the exhaust ventilation system is reduced to the installation of plastic ducts leading up to the hole in the common house shaft. In a frequent home, it does not end there, because there is another segment - from the heated space through the attic to the street. To prevent condensation on the pipes from the cold (the attic is often not heated), they produce insulation.

The best materials for thermal insulation are:

- basalt wool (glass wool, mineral wool);

- shells of polymeric materials - polystyrene or polystyrene;

- expanded polyethylene.

An example of basalt cotton wool is Rockwool, which is non-flammable and rugged, with a minimum air permeability of 0.3 mg / m × h × Pa, a wide range of heat resistance (from-180 ° C to + 500 ° C), hygroscopicity of about 1.5% by volume . Service life is up to 35 years.

In addition to the roll basalt cotton wool, there are other types of insulation Rockwool: thick mats or plates, rollers with foil coating

Soft rolls are wrapped around overlapping pipes, covered with foil or roofing material (if mats are used without waterproofing), fixed with a winding metallized tape or steel wire.

Styrofoam and expanded polystyrene look like rigid tubes, consisting of several segments. Some of them are covered with a layer of foil. Polyfoam has a more loose structure, so it is suitable for the insulation of curved fragments. Because of the low price it is preferred by economical owners.

The table shows comparative characteristics shells of PPP, which are made of foam plastic PSB-S and have the appearance of half-cylinders, fastened by clamps or bandage (+)

Leading positions are foamed polyethylene PenoFol, more elastic than the listed materials. The insulation has a minimum thickness, but it does not allow moisture (one or two sides is covered with a waterproofing foil), provides a low noise level and keeps the heat perfectly.

The thickness of the insulation is different - from 3 mm to 10 mm, the coefficient of thermal conductivity within 0.038-0.051 W / (m * K), water absorption - up to 0.35%. For installation it is enough to cut the material into pieces of the right size, remove the protective film and paste it on the piece of pipe. For straight pipes, large in length, you can use a roll full width, without cutting.

Particular attention should be paid to the places of joints, the outlet area of the duct to the roof, the places of contact with the outer walls.

Video materials on plastic pipes

Informative videos will help you understand the types of plastic pipes and learn more about the ways of their installation.

Installation of plastic box:

Installation procedure in plasterboard box:

Heat insulation of ventilation pipes in the garage:

General information about heaters:

As you can see, the installation of ducts made of plastic is not difficult and suitable for independent work. However, when drafting a project, we recommend that you turn to professionals who know the nuances of the installation combined extract and input ventilation and who can accurately calculate the size of the applied elements.

The organization of a ventilation system that delivers fresh air into the house and expels the waste mass outward, a necessity dictated by the provision of standard sanitary and hygienic standards. The device of supply and exhaust ventilation is a strict requirement in the presence of gas heating. The system with natural circulation air are built in small single-storey houses. Devices for the discharge of air must be installed in the bathrooms, saunas, kitchens, fireplace rooms, if any. Regardless of the method of air exchange, channel-type systems are mainly constructed using air ducts for ventilation, the characteristics of which are worth familiarizing with.

If the device of the ventilation system is made during the construction of the building, they are usually laid in the wall in order not to spoil the interiors with not too attractive communications. It is best if the ducts are located vertically next to the chimneys (no closer than 10 cm), which will contribute to strengthening the thrust. Ideally, if each room has a separate air duct, and they are all combined into one outflow channel. Other wiring schemes are allowed if the rooms are in different parts of the cottage.

If the device of the air exchange system is made in the course of construction, the ventilation ducts are laid in the walls or in the mines constructed for their installation

Attention. The intersection of air ducts with sewer, gas, water pipelines construction standards is prohibited. In the ventilation shafts, you can not lay a sewage pipeline.

Channels can be laid out with a brick or mounted using ready-made pipes for ventilation. The latter method is less time-consuming, it's easier to do it yourself. Most often, galvanized steel or aluminum pipes were used for ductwork. Metal products are now installed in offices, public buildings, in industrial premises characterized by a high degree of explosion hazard. However, with the introduction of polymer products in various areas of construction, plastic pipes for ventilation have actively replaced the metal counterparts.

Two versions of the air duct device: on the left - all air ducts are combined into a common system with one outlet pipe, on the right for each room is installed its own duct

What is better plastic or metal?

Before we start comparing products from materials with different technical characteristics, we will study the list of requirements for air ducts. After all, the function of metal zinc-coated products and pvc pipes for ventilation must perform one.

Comparison by technical characteristics

General requirements to ventilation ducts:

- Ensuring perfect tightness.

- Creation of conditions for free flow of a specific volume flow with a given project speed.

- Compliance with sanitary and hygienic standards for the composition of products and the level of noise generated.

- Resistance to burning.

- Maximum combination with the design of premises.

- High insulation characteristics.

To form sealed connections, both plastic ducts for ventilation, and metal products are equipped with special flange elements. That is, you can build a system of any complexity from both variants. PVC products and metal pipes are available in different shapes and sizes. Hence, complications with the choice of suitable pipes will not be in both cases. But the insulating characteristics of the innovative material is significantly ahead of the metal, which requires mandatory insulation in the zone of passage through the roof.

In the zone of passage through the roofing structure, the galvanized air ducts must be insulated to prevent the formation of condensate, which corrodes the metal, the plastics are not afraid of accumulation of moisture

Non-combustible galvanized pipes for ventilation are indispensable for the construction of an air exchange system in hazardous production workshops with the threat of fire. However, for the arrangement of housing with standard operating conditions, they are not required, but spoil the interior picture bulky tin ducts may well. In addition, in a metal channel in the case of turbulence, the noise negative amplifies, being reflected from the walls, which does not happen in plastic ducts.

Council. To exclude "twists" with a characteristic sound negativeness, corrugated pipes for ventilation and rigid channels should preferably be paved with a minimum number of turns. Avoid angles of 90º and sharp jumps from one pipe diameter to another.

Welded flanges for tin galvanized pipes are necessary for making sealed connections, for making turns with a certain flange model, in degrees, for wiring and changing to another diameter

On the sum of operational advantages, plastic is ahead of the metal, the only drawback of PVC is insufficient fire resistance. In case the exhaust pipe for ventilation is installed next to the chimney, from polymer products it is better to refuse.

Rigid and corrugated channels

Depending on the complexity of the system being constructed, in the process of its installation, rigid and flexible air ducts. With rigid elements everything is clear, they are in both variations with a round and square section. Round are more beautiful and compact, they are mainly used for ventilation in a country house.

Flexible pipes are needed if in a small section the channel needs to be rotated several times to connect to the main line.

- Metal flexible ducts for the ventilation system are made of multi-layer aluminum foil with a corrugated structure. You can bend them at any angle, but you need to remember that the smooth interior surface creates additional aerodynamic resistance.

The use of a metal flexible duct allows you to quickly arrange the system and use a minimum number of flanges

- Plastic flexible flexible pipe for ventilation is made of polyester and aluminum foil. The multilayered structure is reinforced with steel wire, laying turns between layers. Now PVC products with increased heat-insulating and sound-absorbing qualities are produced. They are used for laying ventilation ducts in housing.

Plastic corrugated pipes - the most common option for ventilation in suburban cottages: a minimum of connections and fastenings, the maximum pace of construction

Corrugated products are suitable for laying ventilation ducts with low pressure (800-5000 Pa) and low speed of air flow (30 m / s).

Evaluation from the installer's point of view

It is mandatory to include any ventilation ducts: their installation is inevitable and not easy, but you can choose a material that can reduce labor costs.

- Plastic is easier. This quality is in the priority and in the process of construction, both during transportation and during operation.

- To fix the channels, devices that can hold a large load are not required. The sagging of the channels should not exceed 4%.

- PVC air ducts for ventilation by one's own hands it is possible to cut freely into the size necessary for laying a complex configuration. Working with metal is much more difficult.

The plastic ventilation duct is easier to construct with your own hands, the pipes are easily cut, which makes it possible to make ventilation of any complexity; there are special elements for making corners and joints, a smooth surface does not interfere with the airflow, they need not be cleaned

Will sewers fit?

For laying air ducts, special plastic products with a diameter of 120 mm. According to the structure and composition of the material, they are similar to sewage pipes, but the cost is higher in a five-fold almost size and a diameter of 110 mm. At forums of folk craftsmen, the question of whether ventilation from sewer pipes can be built is actively discussed. Is it possible, for example, to corrugate a plastic with a diameter of 120 mm to attach to a chimney made of sewage pipe?

The scheme forced ventilation: 1) ventilation grilles on the windows for fresh air intake, 2) exhaust openings for exhaust ventilation air mass, 3) flexible air ducts, 4) control equipment, 5) output device with a diameter exceeding the dimensions of the air ducts

According to the building rules, the output device must be wider. However, many believe that a narrowed by 10 mm pass will not affect the functionality of the system. The main thing, in their opinion, is that the connection is airtight, to ensure that the joint is tightened with double-sided tape and other insulating materials. In general, it is not recommended to switch to another diameter when constructing a ventilation network. And in the place of air removal the narrowed passage will make movement difficult. But if otherwise it does not work out, the transition should be smooth without "steps".

The connection of pipes into a single channel must be smooth without sharp transitions from one diameter to another and "steps"

It's no accident that consumers are switching to plastic products. They are lighter, cheaper, in terms of technological, aesthetic, and operational parameters ahead of outdated metal options. A weighty addition to the pluses is a rare care, because on the smooth surface of plastic with antistatic properties does not accumulate a clogging air duct sediment.

At the design stage of ventilation, it is necessary to determine which pipes should be ventilated. Option two - it's plastic or metal. The quality of each material is different, but the only purpose is to ensure good air circulation. When choosing, of course, not the last value is the price, so it is important to understand what advantages and disadvantages are in plastic and metal ventilation.

Exhaust pipes for ventilation from aluminum

In practice, most often use corrugated tubes. They have high flexibility. Therefore, during installation, no special physical effort is required to "round" complex areas. These ducts are available in three versions: steel, aluminum, plastic.

Operational characteristics

Aluminum corrugated tubes are the most practical and have the following features:

- compact if you do not stretch them;

- lightweight;

- resistant to mechanical stress;

- are mounted simply and quickly;

- are fireproof;

- in the joints, the metal duct can be connected by an adapter with rectangular ventilation elements;

- takes the form of the desired angle.

Aluminum corrugation is also used to equip ventilation in production buildings. Semi-rigid corrugated pipes do not accumulate static electricity, without any problems withstand temperature fluctuations in the range of -30 C and ending with +270 C. Pressure drops and aggressiveness of the external environment are not a hindrance. Over time, aluminum pipes do not lose their original appearance. Spiral turns are stretched if necessary. This is especially true when mounting pipes for drawing over a gas or electric stove.

Important! In the cold season, condensation may form at the dew point of the duct. For aluminum pipes this is not a threat, as they are resistant to moisture and not covered with rust.

Mounting Features

- Ventkanal of thin-walled aluminum is fixed to the support with self-tapping screws and clamps. Therefore, do not first build a powerful frame.

- During the installation you can make spontaneous changes in the project, because such pipes are maneuverable.

- If the ventilation duct spoils the interior of the kitchen, it can be sewn in a decorative box for the color of the kitchen set.

- To achieve good noise insulation, the "accordion" of the metal corrugated pipe is stretched.

Attention! Aluminum corrugation can not be used for ventilation ducts of boilers and fireplaces. It has a lower melting point, compared to other metals. The corrugated tube can crack, and carbon monoxide will enter the living rooms.

Plastic pipes for ventilation

The ventilation can be used as corrugated flexible, and inflexible air ducts made of polymer materials. In the market of ventilation pipes they constitute a worthy competition to the metal. Corrugated tubes and rigid ventilation ducts on the market are represented by such materials:

- polyvinyl chloride (PVC);

- polypropylene;

- fluoroplastic (PVDF);

- polyurethane foam (PPU).

In practice, in most cases for the installation of ventilation ducts of private houses and apartments use PVC air ducts. They are relatively inexpensive, easy to use, convenient to install. Withstand the temperature ... .0 .... + 80 degrees. Pipes from this material are hermetic, the noise insulation parameters do not exceed health standards. A wide range of diameters of cross-sections and shapes allows to form the ventilation structure of any configuration. From plastic pipes and auxiliary elements it is possible to assemble a structure of any complexity.

Ventkanaly, especially rectangular shape, look very aesthetically in the interior of the house or apartment. Therefore, it is not necessary to make a decorative box.

PVDF

The strongest air ducts are made from PVDF. They are resistant to environmental influences. With the help of such pipes, the supply and exhaust ventilation is installed. They do not act on steam, most alkalis and acids. The temperature range that they can withstand from -40 to +140 degrees. Therefore, fluoroplastic pipes are used where air with aggressive substances is discharged.

PE

Polyethylene pipes are no less popular. They are also actively used in the installation of ventilation systems. They have antistatic protection. Withstand temperature regime from -40 degrees to + 80 degrees Celsius. There are polyethylene air ducts with protection from ultraviolet rays. They contain, in addition to the main material, black soot. Such pipes differ from other analogues in color.

PPU

Polypropylene ducts are also resistant to aggressive environment and moisture. Operating temperature is +1 to +98 ° C. Such pipes can not withstand frost and crack. It is advisable to use them only inside the heated premises.

Advantages of polymeric corrugated tubes

- Do not require additional connectors, which significantly saves the budget.

- The life of flexible pipes is almost 100 years.

- Low level of deformation.

- Shock resistance.

- Heat resistance.

- They bend at different angles.

Disadvantages of polymer duct

The weak point of any air ducts from different polymers is fire hazardous. therefore metal pipes In this regard, ventilation is more reliable.

Council. When choosing a pipe, it must be remembered that the duct must be thin-walled, but at the same time have high strength. The bandwidth depends on this parameter. It is also recommended to give preference to ventilation ducts with a circular cross-sectional diameter. It must be remembered that the length of the ventilation ducts should not be too large. Otherwise, the effectiveness of the air masses is reduced.

Galvanized pipes for ventilation

Ducts made of galvanized steel are round and rectangular in diameter. The ventilation ducts are made of sheet steel, the thickness of which varies in the range of 0.5-1.25 mm. The formed pipes are protected by a galvanized coating. It should be noted that this type of pipe is not afraid of water, so it is not corroded. These characteristics allow you to install ventilation ducts both inside the house or apartment, and outside.

Ducts made of galvanized steel in addition to long term service, also easy to install. The ventilation pipes are interconnected by means of special elements - flanges. This applies to ducts with a rectangular cross-sectional diameter. Such a connection ensures the necessary tightness of the ventilation structure. Also, for pipes with a circular cross-sectional diameter, a nipple connection method is used.

The main requirements for a duct with a sheet thickness of 0.5-1 mm are as follows:

- the temperature of the passing air is up to 80 degrees;

- the humidity of the passing wind masses is not more than 60%.

These metal ventilation pipes must be properly fixed to each other. Therefore, the use of rubberized gaskets with a flanged connection is mandatory. In the case of a nipple connection, additional elements are used. This will ensure the necessary noise insulation and sealing of the entire ventilation system.

Correct calculation of duct cross-section diameter

When natural ventilation, without use mechanical devices, it is easy to calculate the duct diameter. To do this, you need to know the area of the room and the section of the vent. For example:

- In a private house on 1 m2 of area, 5.4 cm2 of the duct section is required.

- In a garage room for 1 m2, 17.6 cm2 of the ventilation duct section is actual.

If a room is 30 m2 in area, an air duct with a diameter of 162 cm2 is purchased. Similarly, the ventilation of the pipe in the garage is calculated or production room. It is important to know that for normal air exchange two pipes are mounted, preferably one length. When calculating the diameter of the vent pipe section, it is also necessary to take into account the length of the pipe and the use of fans for air flow.