Do you need ventilation in the kitchen? Connecting the exhaust fan. Rules for installing natural ventilation

The air in the apartment, especially in the kitchen, should be clean and regularly updated so that all members of the family can breathe comfortably. Ensure its regular flow is called upon to natural system ventilation, which is laid at the stage of construction of the facility. However, for various reasons: shortcomings in construction, design errors, constantly increasing demands for the comfort of living - one is not enough. To effectively clean the air in the kitchen, you need to install a system forced ventilation. It is necessary that foreign smells from cooking, combustion products, which are often eaten into furniture, be removed as quickly and efficiently as possible. In addition, ventilation in the kitchen will keep the ceiling, the suite, walls and household appliances clean.

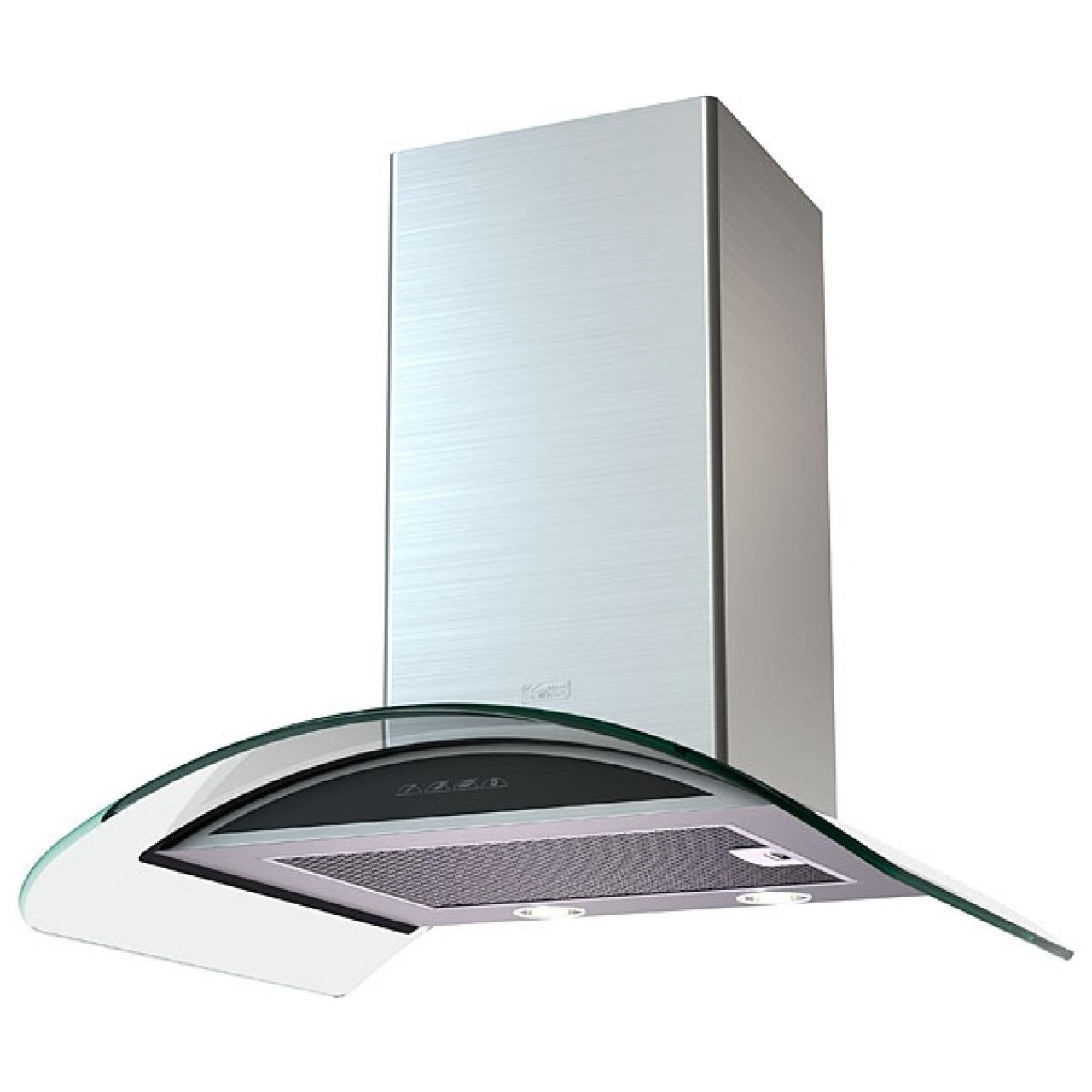

The kitchen hood is mounted directly above the cooking plate, since most odors during cooking and combustion of gas emanates from there. Outwardly, it does not spoil the interior, but, on the contrary, complements it, creating a finished look and emphasizing the owner's consistency. Kitchen hoods are produced by many manufacturers, they differ from each other in cost, appearance, service life, productivity, availability of certain options and many other parameters. Thanks to them, quality ventilation in the kitchen becomes easy to organize.

Types of kitchen hoods

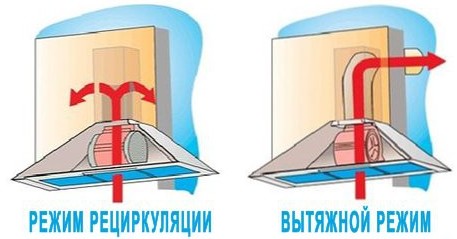

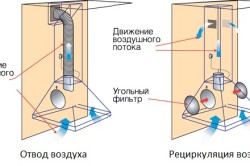

Hoods differ from each other in many ways. According to the type of work they are circulating and flowing.

Circulating

Hoods circulating have installed filters coarse cleaning. They successfully cope with the removal of particles of dust, grease and soot. The peculiarity of such exhaust devices is that they return the polluted air back to the room immediately after the filtration. In addition to the coarse filters in the circulation hoods, there are filters fine cleaning. They catch even the smallest particles of soot, so ventilation in the kitchen remains at a high level.

Plus the hoods of the circulation type in that they do not need to be connected to the duct system. It is convenient and less expensive. And they have a low noise level within 30-40 decibels. The drawbacks include a weaker performance and inability to clean the filters, in comparison with the flow hood, they need only be changed, as indicated by the indicator light in advance.

Flowing

Flow-through hoods are connected to the ventilation system by means of an air duct. They divert the polluted air that has accumulated in the room, into the street. Some models have metal coarse filters that prevent the fat and soot from settling inside the duct and on the walls of the ventilation system. After a certain amount of time, they must be removed and thoroughly rinsed. Models without filters should also be kept clean to prevent clogging of the fans and reduced performance.

Flow-through hoods can operate in two modes of tap and air intake. They have more performance than circulation ones. The installation of such devices in the existing kitchen set is problematic, so it is better to buy them simultaneously with the purchase of a new kitchen for furniture.

According to the design of hoods are:

- Embedded;

- Suspended (horizontal and vertical);

- Dome (insular).

Built-in

Built-in hoods differ from conventional hangers in that they need to be connected to ventilation system in the apartment. Therefore, the process of their installation is more complicated, requires special knowledge in this area and is more expensive. But such hoods can almost completely be hidden from view by installing them in suspended cabinets or under the countertop. Some air purification devices have a retractable panel, due to which it is possible to increase the "capture area" and more efficiently remove smells.

The productivity of built-in hoods is higher, since more powerful motors are installed inside them, their number can be from one to two. Filters in such devices are multi-layer, washable, they filter air much more efficiently. Other advantages of built-in units include:

- Several speeds of work. Modern built-in compulsory purification devices can have 1, 2, 3 or even 4 operating modes. You can independently adjust the speed of suction of fumes and smoke, resulting in the required ventilation of the kitchen;

- Presence of illumination. The considered models of hoods are equipped with powerful lamps, the light of which does not interfere with cooking.

Suspended

Suspension hoods - an excellent purchase for those who are used to monitor their health and their loved ones, but prefers not to overpay. They have a simple design, low cost, convenient to install, attached under a suspended kitchen cupboard to the wall. Their distinctive feature from other extracts is that they do not remove the polluted air from the room. It simply passes through the filters installed inside, and is cleaned. Usually it is a carbon filter or acrylic filter, as well as a grease trap. The power of the motors located inside the housing is small, since they operate in a recirculation mode. But in general the hoods successfully cope with the task set before them, as a result of which the necessary ventilation for the kitchen is created.

Advantages of suspended hoods:

- Affordable price (from 3000 rubles). Due to its low cost, the popularity of suspended hoods is very high;

- Ease of installation. To connect the hood, you do not need to connect it to the house ventilation system, which necessarily entails additional costs for the call of the master. Instead, it's enough to fix the hood on the wall, plug it into the outlet - and that's it, it's already working;

- Low noise level during operation. Since suspended hoods are low-power, they do not create any noise during operation. Modern devices are produced with a noise level of 25-30 decibels;

- Durability. The work of the cooker hood consists in passing contaminated air through a system of filters installed inside. If they fail, then replacing them will not be difficult. Thus, it is possible to prolong the working capacity of the ventilation system for as long as possible.

Suspended hoods are horizontal and vertical. They practically do not differ from each other, except the location of the hull, and the possibility of installing more powerful motors in vertical models.

Island

Island hoods are mounted above the stove to the ceiling and this is different from the previously considered hoods. The plate is located at the center of the headset. The installation of such extracts is advisable in the kitchens of a large area, where they look most practical and aesthetic. Externally, the island exhaust units are cylindrical, T-shaped, manufactured in metal design or with inserts of glass. They have high productivity, at least a thousand cubic meters per hour.

Requirements for hoods and their installation

All the hoods, including their installation, are subject to certain requirements. Here are the most important of them:

- The size of the working surface of the hood should correspond to the dimensions of the hob. In this case, removal of odors and impurities in the air will be most effective;

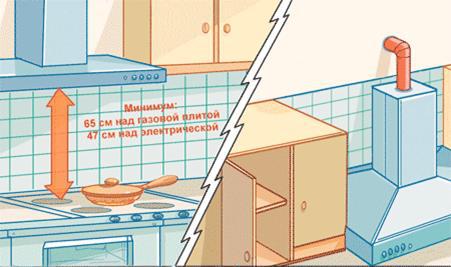

- The mounting height of the hood above the hob must be at least 50-60 centimeters. The main condition is that the hostess should work comfortably and not be distracted while cooking. Too low to install the hood can not be, it will overheat, and there is a possibility that the fat accumulated on its walls will ignite;

- The performance of the hood should be such that it ensures the air change in the room at least 10 times in sixty minutes. In order to accurately calculate the required amount of processing of cubic meters of air, it is necessary to take into account the square of the room and its height, and then calculate by the formula: V = SxHx10x1.3, where S and H are the area and height of the room, 10 is the minimum air exchange value per hour with a margin of - 12), 1.3 - correction factor. Based on the received value, you can always find the right hood for your kitchen;

- If the house does not have a special ventilation duct, then in the kitchen it is better to install hoods with adjustable capacity and air recirculation. Connecting flow-through hoods to a natural ventilation system will result in the work of the latter being broken. It is also not recommended to include such devices at full power for a long time.

Mounting the hood

We offer to consider the installation in the kitchen of a simple hood, which will be installed between the kitchen cabinets, at a height of 60-70 centimeters. The process itself is not complicated, and with certain skills in working with the tool and the elements of the ventilation system major problems should not arise. Before starting the installation, it is necessary to consider the following:

- Thoroughly plan the location of the hood;

- Check its operability;

- Determine the height of its suspension;

- Beforehand, install a socket with a grounding contact for extraction (preferably if it is located slightly above it), ground.

Tools required for installation:

- Drill;

- Dowels, screws;

- Electric jigsaw;

- Pencil;

- Roulette, level.

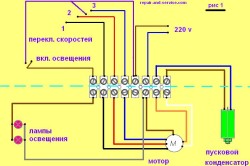

The installation scheme for each particular hood is always available in the instructions to it. However, it does not cover all the nuances of installation and connection. Therefore, we will consider in more detail each stage of the installation:

- Fixing the hood on the wall

The hood is attached to the wall using self-tapping screws. To do this, perform markup. To do this, measure the distances between the fixing holes on the hood and transfer them to the wall, or simply draw a straight line at a pre-selected height, flush the work surface of the device flush with it and make marks through its back panel. On the made marks drill holes, depth of 5-6 centimeters, install in them dowels, apply once again the hood and fix it permanently with screws. Doing work on the suspension is better not alone, but with a partner.

- Docking the hood with ventilation system

To solve this problem it is necessary to prepare the following additional elements:

- PVC air duct or aluminum corrugation;

- Ventilation grating at the entrance of the mine;

- Several clamps, a special flange on the grate (if corrugation is used);

- Special connectors, sealants (if a PVC duct is used).

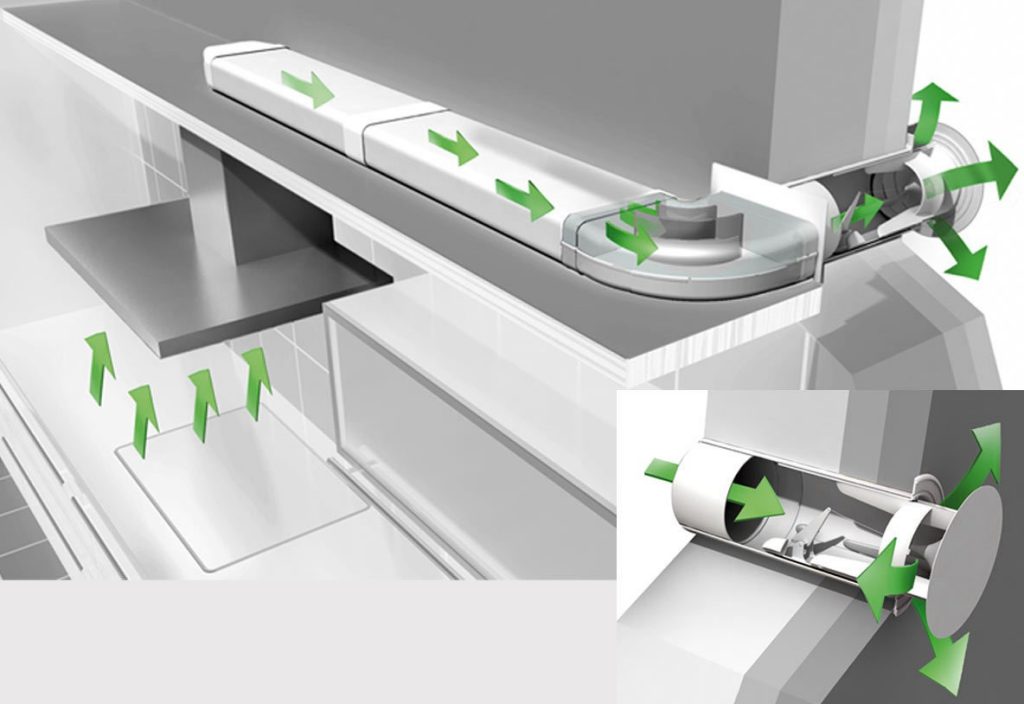

The bypass channel should be tried so that it contains the minimum number of joints. What to choose - a PVC duct or corrugation is a private matter for everyone, but the plastic channel looks aesthetically pleasing.

When the duct and all its elements are selected, it remains to properly connect them. With aluminum corrugation everything is simple: a flange is attached to the opening of the ventilation system with the help of a sealant, similar to the one on the other side - on the hood. With the help of the first clamp, the corrugation is attached to the exhaust outlet of the extractor, is laid along the required line and is joined by the second end with the flange of the ventilation system.

If PVC air ducting is used, all joints in the course of its laying are greased with a sealant. To change the direction of the hose laying, straight or corner connectors are used, which can have different outlets (circle, square, rectangle). This is convenient when it is required to move from a round pipe to a flat one or vice versa, which often has to be done in conditions of lack of free space.

Rules for the use of hoods

Kitchen exhaust - a device of increased danger, therefore it is important to know the rules of its use and strictly observe them:

- Closely monitor the device during operation;

- Do not allow children to operate the device;

- Clean the grease filter every two months, otherwise there is a risk of burning off the deposited grease;

- Never operate the hood without a grease filter;

- Do not turn on the gas hob if there are no dishes on it. After a certain time, the extract is heated, which will provoke the inflammation of the fat deposits;

- Avoid prolonged burning of 2 burners with high flame (more than 15 minutes), this can cause overheating of the hood;

- If the appliance does not breakdown, do not repair it yourself, call for specialists;

- Do not clean the extractor controls with a damp cloth to avoid electric shock;

- Do not use abrasive or caustic cleaners when cleaning the surface of the unit.

To ventilation system in the apartment worked without failures, it is necessary that its installation was handled by highly qualified specialists. Incorrect installation of the hood, gasket and docking of the corrugation, connection of the outlet, its grounding and other defects can cause serious problems during operation electrical appliance. Remember this and do not make mistakes.

The kitchen is a room exposed to strong steam, grease, soot and high temperatures. Cooking here is accompanied by sharp smells, spreading throughout the apartment. To avoid this, install hoods of different types. Remember, only experts know how to make ventilation in the kitchen efficient and qualitative, dividing it yourself, you risk the exact opposite result. The most effective is a mixed type of ventilation, which includes the correct natural air exchange and exhaust operation. Therefore, you will learn in this article how to make mixed ventilation in the kitchen.

The design of the ventilation system must begin with the calculation of the power of the future drawing, its type and method of installation. When calculating the power, two parameters must be taken into account:

- Kitchen area

- Ceiling height

Multiplying these figures and multiplying their product by 12, you get an approximate power necessary equipment. Hence it can be concluded that with ventilation of a small kitchen can handle and extracting a small capacity, but for spacious premises it is better to purchase a more efficient exhaust system.

All kitchen hoods are of two types:

1 suspended - installed directly above the gas stove;

2 built-in - located inside the cabinets, so easily adaptable to the design of any kitchen.

Suspended exhaust ventilation can also differ by the installation method. It is mounted:

- on the wall above the stove (wall hood) - can be of different shapes and uses different methods of work

- in the corner of the kitchen - corner. Are you interested in how to make angular ventilation in the kitchen? The installation method is similar to the wall

- in any part of the room - island (fixed not on the wall, but on the ceiling, so suitable for kitchens with a central location of the plate)

According to the method of operation, the listed systems can be:

1 Circulating - do not connect to the ventilation shaft. Air purification with their help is due to replaceable carbon filters. Such equipment requires regular costs for the replacement of filters and constant monitoring of their condition. If you forget to replace the cartridge in time, your hood will not be able to fully perform its functions to clean the air in the room. 2 Flowing - connected to the ventilation shaft and are more reliable, economical and functional equipment, compared with the previous version.Whatever the ventilation system you have chosen, regardless of the design or installation method, only proper installation ensures a good result.

How to organize ventilation in the kitchen

The process of ventilation is based on the withdrawal of soiled by soot, steam and odors, air and replacing it with a new one. When a correctly designed system is operating, the fresh air flow must equal the outflow of the old one. Therefore, to achieve the desired efficiency, it is not enough to buy equipment and install it in the proper place.

You should take into account that originally forced-type ventilation systems were designed for rooms with wooden windows. Such windows easily pass air, and so with the influx of necessary cubic meters there are no problems. But in modern buildings everywhere are installed sealed metal-plastic windows, preventing the air flow into the room.

You turn on the hood, and it actively starts pumping out the air in the kitchen, creating a rarefied atmosphere. And since it is known that air flows easily flow from zones with more high pressure in areas with low, in a few minutes the atmosphere from your apartment will be pumped out through the ventilation shaft. But that is not all. In each apartment there are at least two air ducts. One is in the kitchen (our hood is connected to it), and one or two are located in the bathroom zone.

When all the air reserves in your apartment are exhausted, the remaining free mines will join the ventilation system. Through them, your home will start to receive air from outside, replenishing the missing cubic meters. This would not be a problem if only fresh air flows from the street were pumped through the pipe. However, not only your home is connected to the ventilation shaft. It comes out air ducts from the apartments of neighbors located above and below your apartment. And the more floors in the house, the more such ducts will be in the ventilation system. Accordingly, air flows will come from neighbors' apartments, bringing with them new unwanted odors.

Hence it follows that the installation of ventilation should be accompanied by correct calculations of air exchange in the room and installation of an additional air duct in the kitchen. Optimum ways of arrangement of the duct:

- Connect the hood above the opening of the ventilation shaft. The exhaust pipe must be charged directly into the shaft and directed with a turn upwards. If you follow this rule, the flows will not mix, and the airflow can be carried out below its outflow.

- Addition of grating by non-return valve. In this case, the hood pipe does not have to be charged directly into the shaft. When the system is shut down, the valve will be permanently open.

- Installation of supply valves in the outer wall. You can install these valves on any wall facing the street, but it is better to place them directly behind the radiator. The air coming from the outside can immediately heat up, passing through the radiator, so you will avoid a perceptible difference in temperatures and drafts in your kitchen.

Only correctly drawn up scheme of the ventilation system allows to fully exploit both electric hoods and natural ways of ventilating the room.

Installing the hood with your own hands

The kitchen ventilation system can be very different, that's why the installation process is also different. Now you will learn how to organize ventilation in the kitchen with your own hands using the example of a flow-through hood, built into the cabinet. We chose this type, because it is the most common.

I stage - installation of anti-return valve

To make a reliable ventilation system, start the installation with the installation of the cork for the cracker. You can make it at home using tin, galvanized sheet or aluminum. All you need to do is take 4 metal sheets and connect them with screws.

But if you do not want to mess around, you can just buy an anti-return valve in the store. It is installed in front of the ventilation shaft and opens like a butterfly flies. And yet in this article you will learn in detail how to make ventilation in the kitchen:

- For you to work comfortably, place the valve body on the wall cabinet. Then secure it tightly to the cabinet and fill all the slots with mounting foam.

- Try on the case of the firecracker and mark the cabinet for the holes.

- Next, remove the cabinet from the wall and using an electric jigsaw cut into the bottom wall a hole for the lower frame. First of all, drill a hole with a large drill inside the marking area. After that, insert the saw into the resulting hole of the jigsaw and cut out the hole of the desired shape.

- Work to perform better imported tools, if quality is important for you. By the same principle, make holes in the shelves in which the air duct is located. And leave a margin of 3-5 mm.

II stage - air duct connection

After installing the anti-return valve we will tell you how to make a conclusion in the ventilation in the kitchen. The duct is connected in this way:

- In the drilled holes, insert the corrugation. Push the corrugation through the top wall of the cabinet, give it a rectangular shape.

- Trim the corrugation so that the stock remains. Incline the corners and bend them outwards.

- Now you can hang the cabinet with the corrugation on the wall. Do not forget to treat the joints of the duct sealant, so as not to lose the exhaust power.

- At the next step, fix the box to the cabinet, which provides the connection of the corrugation and the ventilation shaft. You can also put the box on the silicone, while covering the large cracks with foam.

- Then fix the hood in the cabinet with the help of self-tapping screws.

- Corrugate very firmly attach to the hood and fix it with a clamp.

These rules for installing ventilation in the kitchen will help you return clean and neat air to the room, which is pleasant to breathe!

Features of natural air exchange in the kitchen

With not too active use of the kitchen, you can only manage the natural air exchange, but it is better to accelerate the outflow of air through the ventilation shaft. To do this, you must improve the ventilation in the kitchen, that is, upgrade the mine with a special fan. Such a fan is built right into the vent, the power is calculated based on the volume of the kitchen.

As with exhaust hoods, the fan pumps out polluted air from the kitchen, so you should take care of an additional supply, especially if you have a kitchen with a gas stove. Fire quickly burns oxygen, dilutes air and lowers atmospheric pressure. In order to ensure a sufficient air supply, it is possible to use supply valves in the outer wall, as in the case of forced exhaust ventilation. But you must remember that the main goal is to achieve a balance in the calculation of air exchange in your apartment.

Heavy, unsuitable air, entails the appearance of many diseases. Therefore, a quality ventilation system is a guarantee of health and the best way to get rid of your unpleasant smells. But you now know how to make ventilation in the kitchen and solve this problem!

Did you like the material? Thank the likes.

Installation of the hood in the kitchen involves its connection to ventilation and power supply. The device for cleaning the air is installed, both above the electric furnaces, and over the gas. The main thing is to consider the height of the canopy when installing the structure. This work can be done by yourself, without recourse to specialists whose services are expensive.

Kitchen hoods with connection to ventilation

These are supply air hoods. They work in the mode of air discharge into the air duct. Such models are 100% cope with the removal of smells and steam from the food being prepared. Also in retail chains, one can find modern air-cleaning devices of a combined type. They can work in the mode of air recirculation, and discharge air into the ventilation system.

Classification of hoods by installation method

- Built-in. Mounted in the kitchen cabinet, installed above the stove.

- Suspended. Installed on the wall.

- Island. They are fastened to the ceiling. Located in the middle of the room.

- Corner. Mounted in the corner.

Any of the selected models for adaptability to a particular room and structure must comply with the current safety regulations.

What tools will be required?

- Punch.

- Spanners.

- A hammer.

- Screwdriver.

- Roulette.

- Level.

Mounting Features

A flat recessed hood is attached to a prefabricated cabinet without a bottom. Mounted at the level of the middle shelf. The dimensions of the cabinet and the hood must match. To connect the air duct in the cabinet, two holes are made in the middle shelf and on the roof of the built-in headset.

Measuring the required distance (not less than 75 cm) the distance from the surface of the plate to the hood, you can start mounting the hood. On the wall, you need to mark the fixing points. Using a puncher, holes are made for plastic dowels. With the help of 2 self-tapping screws flat exhaust. The dome construction will be reliably fixed with at least 4 fasteners.

What capacity should be drawn?

The required operational capabilities of the air-purifying device can be calculated by the formula:

Q - optimum drawing power

S is the area of the room,

h - ceiling height of the kitchen,

Note! According to the requirements, air in the kitchen should be changed 12 times per hour (requirement health standards) - which is why the formula contains the indicator 12. Digit 1.3 - the minimum stock factor. It involves the account of the number of storeys of the building, the length and contamination of the vent, the length and bend of the ventilation duct.

Also for calculations you can use the special one on our website.

What should be the air duct

When installing the built-in hood, plastic or metal (corrugated) ducts can be used.

Inexpensive duct is a goffer

Plastic

More often install plastic pipes - they are light, with good noise insulation, easy to assemble. Pipes made of PVC can be either circular or rectangular. The installation of the ventilation duct is made at the top above the hanging cabinets of the kitchen set. At the time of buying plastic pipes It is necessary to purchase "G" -shaped transitions and sealant.

Gofra

Also, to connect the extractor hood with ventilation in the kitchen, corrugated air ducts are used - this is a more budget option compared to PVC materials. Corrugations are made of thin-layer aluminum. On noise insulation this material is much worse than plastic. Adapters do not need to be bought, so fixing is provided by means of clamps. Gofra stretches to the desired size. When installing it is better that the "accordion" is well stretched - the noise level will drop significantly.

Features of the device ventilation ducts

The diameter of the hood must match the diameter of the duct. If chimney it will be less, then the extractor will work in the enhanced mode, and this will lead to a breakdown of the fan motor. A pipe of smaller diameter also affects noise insulation - when the equipment is operating, the noise level will increase many times.

It is necessary that all angles of bends during installation of ventilation ducts are more than 90 degrees. The work of ventilation depends on this. And the number of these very curves should be minimized. The efficiency of the exhaust device for air purification depends on this. It is better to give preference to plastic systems with a circular cross-section. In them not only will not settle dirt and dust, but also resistance is less when passing the air masses.

Important! In the scheme there is also the installation of valves - plastic or film.

Installation of the socket

Before connecting the hood to the ventilation it is necessary to take care of the presence of the outlet. Ideally electrical installation works a certified specialist should be engaged. However, in practice, as is known, quite often it is necessary and to carry out it independently. In this case, besides the rules of personal security, it is mandatory to comply with such standards:

- The socket is mounted in a place above the hanging cabinets of the kitchen set-at a distance of 5 cm or near the ventilation shaft - at a distance of 20 cm.

- Do not install the outlet at a distance less than 2 m from the floor covering.

- A grounding device with a current strength of at least 15 A is mandatory.

- The socket outlet intended for extraction must be 15-ampere and larger.

- When connecting to an additional outlet, the total power of all connected devices is calculated (no more than 4 kW). If the indicators are higher, then the hood should be placed on a separate line.

Important! It is forbidden to install the outlet at the sink or gas / electric cookers. Do not install the outlet behind the hood. Do not install an outlet with a current of less than that required for this device. The wires must be double insulated.

How to connect the hood to the ventilation duct

- Before connecting the hood to the ventilation box, it is necessary to pre-purchase the corrugated section diameter, which is suitable for this model, clamps, sealant.

- The corrugation is inserted into the pre-made holes in the enclosure.

- A cabinet with a ducted duct is fixed to the wall.

- The duct of the hood is connected to the ventilation duct.

- To draw the hood to the ventilation, it is necessary to bend the corrugation at the output of the hanging cabinet of the kitchen set. You can also use plastic connecting elements for pipes.

- To seal the joints are treated with silicone. Sealing the ventilation system allows you to operate the hood without additional costs.

Important! The corrugated pipe or PVC pipe is fixed to by means of adapters or clamps. Sealing in this area can not be made. The main thing is that the adapter corresponds to the size of the hood.

The connection of the hood in the kitchen to the ventilation is done taking into account certain parameters, namely the distance between the gas stove and the hood should be 90 cm. If an electric stove is used, then 70 cm. These standards should not be neglected. The minimum distance from the gas stove should be 75 cm, and for electric ovens minimum 65 cm.

When installing vent pipe in the ventilation it is important to make sure that the vent hole does not completely overlap, so you need to install a special grate. It has special valve, and also the fixing point of the air duct. When the hood is operated, the valve closes, and when the hood is turned off, the valve opens, facilitating natural ventilation. If it is impossible to mount such a grate, then the duct is installed check valve.

How to connect the hood in the kitchen to ventilation so as not to spoil the interior? All ventilation should be hidden under a protective cover, which can be made to match the color of the kitchen unit. Often, thin plastic is used for this purpose. The final step is to check the operability of the equipment. All elements during installation must be secured securely, so that the hood does not rattled while working.

- What is the need for air exchange?

- Hood Construction

- How to choose a kitchen hood

- Types of kitchen hoods

- Process of the device of kitchen ventilation

Most people try to equip their kitchen in such a way as to avoid the appearance of unpleasant odors. Everyone who decides to save himself and his loved ones from this problem, asks how to do ventilation in the kitchen. Thanks to the materials outlined below, you can get an answer to this question.

The kitchen is ventilated using a rectangular plastic duct.

There are several types of ventilation:

- natural;

- created by a mechanical method.

Natural ventilation, as a rule, does not cope with the purification of air from extraneous unpleasant odors. This is why an additional source is needed that promotes air exchange in the room.

If the air exchange is carried out in sufficient volume:

- rooms with high humidity do not dry for long;

- in the whole house (apartment) the normal level of humidity of air;

- at heating period windows do not get fogged.

How often should the air exchange be carried out?

In order to maintain the freshness of air, air exchange should be carried out at intervals of several hours. If your house has recently been renovated or you have purchased an apartment in a new building, air exchange will need to be done hourly until the humidity level improves and the chemical smells emanating from the building materials disappear.

What is the need for air exchange?

Fresh air positively affects the health of people living in the room.

With it, you can remove unpleasant odors and lower the humidity level. Due to the fact that natural ventilation can not perform air purification, an additional source of air exchange is required. With high humidity in the living room may appear mold.

If you have arranged additional ventilation, remember some important points:

- when opening windows in the room penetrates street dirt and dust;

- audible extraneous, sometimes loud sounds, because of which it is impossible to fully relax;

- in the heating period, it is not necessary to ventilate the room frequently with the help of open windows, since a lot of heat is wasted.

No modern kitchen can be imagined without drawing over a stove or hob.

What are the functions of the kitchen ventilation?

It cleans the air in the kitchen from the impurities contained in it: soot, the smells of cooking food, particles of fat. Even the most common smells can cause a healthy person to be allergic. It is extremely uncomfortable to be in such a room.

If your kitchen-dining room is integrated with the living room, smells will be spread over long distances. The modern market of household appliances is ready to offer the widest range of products for every taste and prosperity. Some models can clean air in a record short time almost 100%.

Main ability kitchen hoods Is performance. It is measured to m³ / h. From this technical characteristics depends on the speed of air purification. The maximum level of productivity is 750 m³ / h, and the minimum 100 m³ / h.

For the kitchen, air exchange during cooking should be made much more often - at least 5 times per hour.

Back to contents

Hood Construction

The hood is a body made of metal, plastic or other material. It can be decorated with additional decorative elements, for example, from the darkened glass.

The price for hoods varies from the minimum and can reach a very high level. Inside the case, as a rule, there is an engine and a filter. They can be either one or several.

Back to contents

How to choose a kitchen hood

![]()

In order not to be mistaken with the choice of an air cleaner for the kitchen, the room volume should be multiplied by 5 or by 10.

The resulting figure and there is a suitable for your kitchen performance. But it should be remembered that the hood is hung at a certain distance from the surface of the plate. It is about 70 cm. But 85 cm are allowed.

For more powerful units, the distance to the plate can be increased.

The kitchen hood is connected to the ventilation. And for this it is required to mount a chimney. The level of efficiency of the cooker hood depends on such factors as the length, internal state of the pipes and the number of bends.

Tip: when the oven is on, you can lower the temperature of the indoor air in the kitchen, if you turn on the hood.

Virtually every second device is equipped with a phased air-cleaning system. It can be switched from the minimum level to the maximum level. If you do not use all the burners, you can turn on the power to a minimum, and if cooking is active, the maximum power will be required.

On sale there are extracts with an economical mode of use. They clean the air in the room through internal filters and do not throw it through the ventilation to the outside. This allows you to reduce energy costs during the heating season.

Another no less important factor in choosing a cooker hood is the noise level produced by the appliance.

Of course, it is much more comfortable to use an air cleaner with a minimum noise level. It is worth paying attention to sound insulation, as well as on internal engines.

Back to contents

Types of kitchen hoods

Now manufacturers offer hoods that work in one of 2 modes: air extraction and recirculation.

Kitchen hoods are divided into two types:

- circulating;

- flowing.

The first involves purifying the internal air and returning it back to the room. Not used so often.

The second option is more common. These extracts absorb polluted air and are vented to the outside through ventilation.

If possible, the appliances are divided into:

- wall, they are attached to the wall directly above the surface of cooking;

- built-in, they are inserted into the hanging cupboard, without standing out from the general interior of the kitchen;

- suspended, they can be attached to a cupboard located above the stove;

- corner, they are installed in the corner of the kitchen.