Laying of sewerage inside a private house. Plastic sewer pipes can be docked with cast iron. What kind of slope is needed?

Make a plastic sewer yourself, much easier than plastic water supply and much easier (physically) than to disassemble the old cast-iron sewers. The main thing is to observe a few simple rules, set out below.

Fundamental rules:

These rules are formulated on the basis of principle of gravity (non-pressure) drainage , and if any of the provisions set forth below are not sufficiently clear, then for clarification you can refer to this article.

1. The fewer joints and turns you make when laying pipes, the more reliable the system will work.

Each joint or swivel is a potential leakage location for substandard connection and, in addition, additional resistance for liquid and especially for solid waste.

2. Sockets of vertical pipes (risers) and horizontal pipes should be directed towards sewage water movement.

This is done in order to minimize the risk of sewage leakage. And it is unlikely that you will be able to lay horizontal pipes in a different way. Sometimes in the case of sewer pipe repair, it is allowed to install connecting (sliding) couplings, in which one branch pipe (socket) is directed along the sewage flow, but it is generally desirable to avoid the use of couplings, if you cut the pipe incorrectly, better buy a new one.

3. Cutting and shortening of shaped parts (sockets) is prohibited. The installation is not allowed:

- all pipes, branch pipes and fittings that have chips, cracks or incisions;

- shaped parts, having an internal brim with sharp edges;

- rubber rings and cuffs having tears, shells and unsuccessful extrusion, as well as rings in which there are no plastic spacers provided for in the design;

- metal fasteners, whose elements have sharp edges and burrs at the junction with pipes and shaped parts.

It is logical and without comment.

4. The diameter of the pipes depends on the number of connected sanitary devices and on the slope.

Of course, there are formulas for calculating the diameter of the pipe, depending on the slope, the number of joints and turns, taking into account the number of sanitary devices or, to put it more simply, wash basins, bathtubs, sinks and toilets. But in practice, these formulas for intra-apartment wiring are rarely used, and there is not much need for this. And besides, the exact calculation of the required diameter of the pipe - the topic of not one scientific dissertation.

On the riser and on the connection of the riser to the well put pipes with a diameter of 100 or 150 mm, and if you had a cast iron pipe with a diameter of 200 mm (although it is very rare - if the number of connected sanitary devices is more than 1200, I do not think this is your case, although everything is possible) , then a new plastic pipe should be put in the same diameter. The exceptions are their homes. There the sewerage was laid not from those pipes that are needed for technical specifications, but from those that managed to get it.

With internal horizontal wiring usually put pipes with a diameter of 100 mm when connecting the toilet to the riser, all other pipes with a diameter of 50 mm (sometimes 40 mm).

If you have some incredibly complex layout, and you doubt that a diameter of 50 mm will be enough for the normal operation of the sewer, then you need a hydraulic calculation of the pipelines. And to understand the intricacies of the movement of sewage and waste of life through a sewer pipe, sometimes one higher technical education is not enough. If you still want to try for yourself, then look in SNiP 2.04.01.85, or read the main provisions of hydraulic calculation of sewer networks.

You can also find out the water flow and the number of drains from any sanitary and technical device and, accordingly, the minimum diameter of the connected sewage system, and determine if the main conditions are met: a flow velocity of at least 0.7 m / s and a pipe filling (ratio of water height to diameter) no less than 0.3; what to do if these conditions are not respected, and many other interesting things that I try to summarize in this article in this article.

5. Horizontal sewer pipes should be laid with a slope to the riser.

Since the sewage system is non-pressure, and pressure losses due to air resistance and friction of the pipe walls occur, a certain slope of the pipes is required to maintain the flow velocity. And that the pipes do not melt (there was a self-cleaning of the sewage system), the flow rate should be at least 0.7 m / s - to ensure turbulent flow of the liquid, and the filling of the pipes should be h ≥ 0.3d. Like the diameter, the slope of the sewer pipes is determined by calculation. When the volume of wastewater is not sufficient to meet both conditions, the turbulence of the current is placed first. When carrying out the standard intra-apartment wiring or the sewage system of a small private house, the following requirements must be observed:

The minimum slope of the sewage pipe is i = 0.025 for pipes with a diameter of 50 mm, the recommended slope is i = 0.035

The minimum slope of the sewage pipe is i = 0.015 for pipes with a diameter of 100 mm, the recommended slope is i = 0.02

i is the ratio of the height difference between the center of the pipe diameter and the pipe length. Translated into normal human language, this means that if you have a sewage pipe 1 meter long, then if the bottom of one of its slices touches the floor, then the bottom of the second should be above the floor level by 2 cm, of course, provided that the floor is horizontal and The increase in diameter on the pipe connection socket is taken into account. In this case, the slope of the pipe is assumed to be equal to the hydraulic slope of the fluid flow, thus ensuring a constant flow rate.

Maximum slope for horizontal sewer pipes i = 0.15

For large inclines, the speed increases significantly, which in turn increases the force of the hydraulic shock and can lead to clogging of the pipe in areas with high local resistance (changes in the trajectory of the fluid - the turns of the sewer pipes, the connection point to the riser). Although such a restriction is conditional - it is unlikely that you will be able to lay a 10-meter-long pipe with such a bias (external work does not count). With a pipe length of less than 1.5 m, this restriction does not apply, since in such a relatively short section of the pipe, the wastewater does not have time to develop a high speed.

The floors may not be horizontal and determining the slope of the sewage pipe by the floor level may lead to an error, the foundations of the houses may sag, which may cause the pipe incline to change for the better. To avoid problems with sewerage, it is desirable to make a slope of 4-7 cm per meter (for pipes with a diameter of 50 mm). The more on the sewage route there will be turns and joints (see point 1), the greater the slope to compensate for local resistances.

If the pipes are laid without a slope or even with a counter-curlon, then such pipes will be clogged quite often. The correct solution to the problem will be the removal of counter-rubble or other causes leading to clogging of the sewer, but this is not always possible, in such cases, a reverse shut-off valve will help.

6. For normal operation of the sewage system, the pipes must be fixed to the floor or to the wall.

Plastic pipes, unlike cast iron, are easily deformed and long loose areas can sag, which will lead to a change in the slope. To prevent this from happening, the pipes must be fastened to the wall or to the floor with special fasteners (sold in the same place as the pipes) every 50-100 cm, depending on the diameter of the pipe. Fastening the riser pipes to the walls is also necessary to reduce the weight of your own weight. In addition, it is recommended to fasten the pipes in the places of turns, connections to partially absorb the load from the hydraulic shock.

7. Presence of fan ventilation.

The ventilation pipe, which is output to the roof of the building or to the attic, is designed to equalize the air pressure in the drain pipes, which can drop dramatically if a large volume of water is discharged from the riser, for example from a toilet bowl. A sharp decrease in the air pressure in the riser sucks the water out of the siphons plumbing fixtures, thereby destroying the water gate. And this leads to free access to the sewer gas apartment with extremely unpleasant smells.

In addition, these gases can cause dangerous diseases. As a rule, in all houses with the number of floors more than two and often even in two-story stalines, there is fan ventilation. Moreover, if you, living on the last floor, want to redevelop (and change the riser route - this is redevelopment) remove the pipe leading to the roof, then no one will officially allow you, and unofficially - options are possible.

With a small volume of sewage, the use of a non-vented sewer pipe is allowed. Those. in the attic or on the roof of the riser is not output. In this case, at the place of connecting the horizontal wiring to the riser (according to building codes and rules), it is necessary to do a "cleaning" and close it with a plug (so that the sewage does not flow out). And if you do, apart from cleaning, you will also make a vertical withdrawal for the reverse air valve worth $ 4-10:

(of course, if you want, you can buy a branded valve and for $ 100), then in the future you will save time, money and nerves necessary for cleaning the sewerage.

If for any reason you can not put the check valve directly on the riser (this sometimes happens when repairing the sewerage in your houses), a 50 mm diameter check valve can be placed on any part of the horizontal pipe, but it is desirable that the valve is located on the height 30-50 cm from the axis of the sewer pipe. The options for installing a return air valve can be as follows:

Option A is the correct one. Option B - permissible in their homes, so, for example, in the country, I installed a check valve option B four years ago. Option C is also permissible in their homes, when it is not possible to put a non-return valve on the riser, so for example I put a sister living in my house about 5 years ago, a 50 mm reverse valve in option C, I put the tap under the check valve under the bathroom (The matter is that the sewer was made by other people and the ventilation was not provided for by the sir, and then it was easier to insert the tap for the air valve under the bathroom). The taps for cleaning are not shown on the diagrams.

The essence of the operation of the reverse air valve is that it transmits air only in one direction - into the sewage system, when the water in the toilet is flushed, then in the sewer pipe on the section to the toilet and in the riser (if there is) the air pressure decreases and the valve opens. When the air pressure in the sewer pipe is the same as in the room and more than in the room, the air valve is closed - this prevents the gases from escaping from the sewage system, so that when correct installation No odors in the room where the air valve is installed should not be.

Put the air valve on sewer pipes After the toilet it does not make sense, in this case the valve will not work properly. When the water comes down in the toilet, and the toilet is the sanitary appliance that creates the maximum flow of sewage, the air pressure in the sewer pipe after the toilet will be increased. The higher the return air valve from the sewer pipe axis, the less is the risk of clogging the valve with sewage when the sewage system becomes clogged, so option A is the most correct.

8. It is necessary to install "cleaning" in the places of turns, changing the angle of inclination and connecting the sanitary device to the sewer pipe.

A good rule, but it was observed for a long time, when installing cast-iron sewers. In old houses, you can still see somewhere under the sink appendix of a sewer pipe with a wooden chop sticking out of it on a good 20 cm. Now plumbers involved in the installation of plastic sewage, do not install a "cleaning" (I have not met at least) for several reasons.

Firstly, sewer pipes are often sewn from aesthetic considerations. Secondly, the modern plastic sewage system unlike the cast iron can be easily disassembled and, if necessary, it is always possible to disconnect some sanitary device, for example, a washing machine or a sink, and insert a cable for cleaning through the opening.

9. The inspection (inspection hatch) should be installed no more than 15 m.

In five-story houses, audits were installed on the first and last floors. If your sewer stand at a height of about 1 m from the floor there is some iron plate bolted with powerful bolts and causing unpleasant associations with the kingstones, then this is a revision. The audit for plastic sewer looks much more aesthetic:

If you are going to sew up a riser, then make an inspection hatch to access the revision.

10. Plastic sewer pipes can be docked with cast iron.

If you have a cast iron riser, it is not necessary to change the cast-iron pipes to plastic pipes, if the riser is in good condition. In addition to considerable physical effort, you will also need a lot of moral to convince neighbors not to use the sewers for several hours and, as usual, someone will forget. But even if you completely change the cast-iron riser to plastic only in your apartment, you still have to join plastic and cast-iron pipes.

11. When moving risers into a horizontal pipeline, it is forbidden to use a 90 ° elbow.

A good rule, compliance with which allows you to reduce the force of the hydraulic shock, the turbulence of the flow of liquid waste and thereby avoid frequent clogging of sewerage. If your multi-storey house is often clogged with sewerage, go down to the basement and check whether the rule is not violated by builders when installing sewerage.

And if you have your home and connected to the sewerage 5-6 sanitary devices, you can not pay attention to this rule.

12. It is allowed to lay plastic pipes in the ground in the absence of additional external loads.

13. Inspection wells are arranged at a distance of not more than 50 m, as well as in the places of turns, changes in the angle of inclination and the drop in the pipeline heights.

The first observation well is arranged at a distance of no more than 8 m from the axis of the riser - with a diameter of 50 mm, 12 m - with a diameter of 100 mm, 15 m - with a diameter of 150 mm or more. In general, the last two rules are relevant for owners of private houses engaged in laying the sewer. Usually these people are smart and they do not need additional comments. But just in case, I'll give a link to the article, which briefly describes the installation of sewerage wells.

1. Sometimes rubber gaskets (gaskets) are sold separately from pipes and can not provide tight pipe joints during installation.

When purchasing pipes and gaskets, insert one gasket into the socket and try to connect two plastic pipes. If one tube enters easily into the socket of another, it is advisable to immediately change the gaskets or look for another seller.

Since a quality pipe must fit very tightly into the socket of another pipe, the use of shampoo or liquid soap (they are usually always on hand) greatly facilitates the process of joining.

3. When the pipes are joined together, one tube enters the other 47 and 36 mm socket with the diameter of the pipes and fittings 100 and 50 mm, respectively.

4. When installing plumbing, pipes of standard length are used.

But do not change the design of the apartment due to the modular dimensions of the pipes, and the modular step is not very pleasing: 150 mm, 250 mm, 500 mm, 1000 mm, 2000 mm, 3000 mm. If you need a pipe of a different size, you can always cut it smoothly and neatly, as a result you will get a cut pipe sometimes better than the factory one.

When building any modern home, you need to take care of the sewage system. The installation of pipes for sewerage should be carried out in compliance with all norms and requirements. This will make it possible to avoid in the future the replacement of deformed pipes, labor-intensive cleanings, excessive noise during the movement of sewage and other troubles associated with the operation of sewerage.

Sewer installation at home

When installing it, pipes of gray color, made of PVC or PP, are used for it. These pipes have a strength class lower than that of orange for outdoor sewage, since they are not subjected to such a high load as the latter.

Use gray pipes for installing outdoor sewage is strictly prohibited. For the sewerage of a house, pipes with a diameter of 40, 50 or 110 mm are most often used. The gasket internal sewerage can be divided into two stages. The first is the installation of vertical and horizontal pipes under the floor or in the basement. Simply put, there is a design of pipe routing.

Before starting work, it is necessary to make a marking of the axes of the pipelines and the places where the fasteners will be located. Next, mounts are assembled and assembled assemblies from branch pipes, fittings and pipes. Finished nodes are connected with each other, check the correctness of their location relative to the vertical and horizontal, and then fixed in clamps.

When installing sewerage It should be taken into account that it is not possible to locate the bell-shaped connections in places of passage through floors and other building structures. It is also forbidden to change the slope on the off-shore horizontal sections. The installation of vertical risers must be done from the bottom up without any vertical deviations. When this work is done, you need to design the risers and horizontal flowlines. This stage is completed by installing in the attic of the exhaust part of the pipeline.

Piping installation

The next stage is the installation of horizontal pipelines along the floors of the building with their connection to the releases of sanitary equipment and siphons. At carrying out of these works it is allowed to mechanically process pipes and branch pipes with the help of manual hacksaws on metal and hacksaws on a tree with small teeth.

The next stage is the installation of horizontal pipelines along the floors of the building with their connection to the releases of sanitary equipment and siphons. At carrying out of these works it is allowed to mechanically process pipes and branch pipes with the help of manual hacksaws on metal and hacksaws on a tree with small teeth.

Saw a pipe strictly perpendicular to its axis. The resulting burrs must be removed and chamfered using a file with large serifs. All the above treatments can also be carried out using special tools. It is prohibited to process shaped parts (tees, turns) mechanically. Lubricate pipes when installing with engine oil, solidol, etc. are also prohibited. Only the use of soap solution or special lubricants is allowed.

When installing fittings and pipe fittings, against the movement of sewage.

Sewer installation prices

Use the convenient search system →Name of works | Description | units measurements | Cost |

|---|---|---|---|

| Installation of the connection point to the sewage system | Installation, connection to the sewage system | pC. | 1500 |

| Installation of internal / external sewage pipes (open) | |||

| diameter up to 50 | m. | 200 | |

| diameter from 50 to 110 | m. | 400 | |

| diameter more than 110 | m. | individually | |

| Installation of internal sewage pipes in a fine (brick, gypsum) | Pipe laying with spigot connection | ||

| diameter up to 50 | m. | 400 | |

| diameter from 50 to 110 | m. | 650 | |

| diameter more than 110 | m. | individually | |

| Installation of internal sewage pipes in a fine (concrete) | Pipe laying with spigot connection | ||

| diameter up to 50 | m. | 600 | |

| diameter from 50 to 110 | m. | 900 | |

| diameter more than 110 | m. | individually | |

| Installation of the sewer riser | Installation of riser, revisions and tees | m. | 600 |

| Installation of the ladder | Plumbing installation in the lower floor level | pC. | 1000 |

| Installation check valve sewage systems | Installation of check valve with bell joint | pC. | 1000 |

| Sewer installation pumping unit sololift | Installation in place, connection to the system | pC. | 4000 |

| Installation of a drain pump | Installation, connection | pC. | 2000 |

| Installation of a drain pump | Installation, connection | pC. | 2000 |

| Installation of a septic tank from concrete rings | pC. | individually | |

| Installation of a septic tank (Tank, TOPAS, etc.) | Selection necessary system, excavation, installation work | pC. | individually |

| Installation of VOC - Local Treatment System | Selection of the necessary system, excavation, installation work | pC. | individually |

| Mounting СБО - Biological Cleaning Station | Selection of the necessary system, excavation, installation work | pC. | individually |

Installation of sewerage inside the house

It must be designed in such a way that the possible lengthening of the pipeline during operation associated with the change of temperatures is compensated. Pipes can be extended by a maximum of 10 mm per 2.5 meters of pipe. To compensate for such elongations, the socket joint is installed in such a way that the pipe with a smooth end does not reach a stop exactly 10 mm.

For pipes from 2.5 to 10 m in length, special compensatory couplings are used to compensate for up to 60 mm of elongation. Now, when the installation inner tubes for sewerage is completed, let's talk about outdoor sewage. For the installation of pipes for external sewage smooth pipes of orange outer surface made of PP (polypropylene) and PVC (polyvinylchloride) are used.

Sewer pipes of red color do not undergo destruction and corrosion, being underground, as gray. This is because they have a very smooth internal surface. In production, special additives are added to these pipes, which makes them more rigid and allow them to withstand large external loads. The laying of such pipes is possible even at a depth of 3 m.

If a very high load is planned for sewage pipes (namely, the location under the roadway or their deep lying), then use pipes with increased rigidity, namely, two-layer corrugated pipes, made of PE (polyethylene) or PP. Most common among sewer outdoor plastic pipes - pipes with a diameter of 110 mm. In suburban construction, these pipes are widely used for drainage from one small building and from a whole group of buildings to sewage treatment plants. Used and sewage pipes of large diameters - for wastewater disposal of a larger number. When designing a sewage system for connecting plastic pipes, use special shaped elements.

Mounting the pipe in trenches

The second way is to lay the trench manually. When installing pipes with a diameter of 110 mm (the most common), the width of the trench should be the same as in the first case. The installer, who will perform the work on the laying, should stand with two legs (freely) in the trench. Upon completion of work, it is necessary to align the bottom of the trench and set the required slope to it. The trench needs to be digged so that its depth is about 50mm more than the depth at which the pipe should lie on the plan. This is necessary in order to prepare a sufficiently dense sand base. In both cases, sand is poured to a height of 50 to 100 mm and compacted by hand.

When the trench is excavated and the sand cushion is covered, the sewage pipes of orange color are prepared. The inner elements of the funnels must be freed from contamination and check for the presence of o-rings in the pipes.

Begin the installation of sewage from the basement. In case the pipe was removed from the house even when laying the foundation of the building, then the outer sewer pipe is put on the smooth end of the outlet pipe. Otherwise, the pipe is inserted under the foundation or a hole is drilled for it (using diamond drilling).

Sewer pipes and fittings are connected by means of silicone grease or liquid soap. The smooth end of the pipe is smeared and inserted into the socket with an elastic band.

Then, on a prepared base of sand, lay a sewage pipe with a slope of 2cm per 1m (pipe diameter 110mm). The first pipe of external sewerage is connected to the sewage pipe of the internal sewer leaving the house. To change the direction of movement of sewage, smooth (15, 30, 45 degrees) bends for pipelines of external sewage are used.

If the length of the sewage route is more than 15 m, then at each turn it is necessary to provide for the presence of a revision.

It is necessary that the pipes, unlike the pipes of internal sewerage, be connected to the stop, because it is possible to expand the pipes, due to the temperature change.

Pipe joining is always done manually. To ensure that the pipes are easily and tightly connected, the smooth end of the pipe is carefully peeled off the sand and dirt and the flares and sealing ring are cleaned. The ends are lubricated with soap or silicone grease.

After the pipes have been connected, check their slope and backfill them with sand with layered tamping from the sides. Directly above the pipe, sand is not trampled.

The entire length of the pipe should be 2 cm per 1 m. This is explained by the fact that only with such a slope is a smooth flow of liquids along with the substances present in it, and the probability of the appearance of clogs in the pipe decreases substantially.

To insulate the sewer pipes, use a specially designed for this heat insulation (or stenoflex) - it's foamed polyethylene.

Energoflex is put on pipes along the entire length of the sewerage route. Heat insulation on pipes is used to prevent freezing of sewage.

Warming of sewer pipes is necessary if they are laid within the depth of freezing of the soil.

When the powerflex is clad on pipes, make a control measurement of the slope of the pipes. Further, the filling is made from the sides with a ramming and the final filling with sand.

After this, the pipe must finally be filled with earth, which remains when digging out the trench. The soil is poured with a slide (to a height of 10-15 cm), because over time, its shrinkage occurs. Usually, after the pipes are filled with sand, the electrical cable, intended for feeding the sewage treatment plant, is also traced into the trench. The cable must be laid in a protective corrugation. The pipe is connected to the septic tank according to the installation instructions of the used station.

After all the above actions have been performed and the station has been prepared for operation, the treatment plant is ready for operation. Wizards must check the operation of the compressor and the pump, and also check the performance of the airlift.

The purification plant is put into operation, the pipeline is checked for operation of wastewater and, accordingly, the removal of treated water. When all this is done - the sewer system is ready for use.

All land works in the construction of sewerage, water drainage, fixing the walls of trenches, dewatering should be carried out in accordance with the regulations of SNiP 3.02.01-87. With a list of some requirements from the regulations you can find out below.

AT country houses there is no centralized sewerage, so owners of such houses have to independently build on their site an autonomous water disposal system. Laying sewers in the ground is not very difficult, but there are certain rules and regulations that need to be taken into account when working.

Today almost every household has the necessary set of amenities for comfortable living: a wash basin, a sink, a toilet, a shower or a full bath, a washing machine and other benefits of civilization. Many houses are equipped not with one, but with several bathrooms and bathrooms.

All this farm with full-time work gives out a large amount of waste and sewage per day (according to the standards, the amount of liquid waste per day per person is from 5.4 to 9.5 liters), which must merge somewhere.

Usually, country houses, where people live permanently, have many different plumbing devices, which makes it necessary to equip an autonomous sewage system

Therefore, the water disposal system is an obligatory part engineering communications individual house. It consists of internal sewerage, discharge from the residential structure and an external sewerage network laid on the site.

Many owners of private houses, giving special attention house system, for some reason not always properly refer to the arrangement of outdoor networks. Indeed, the process of laying the pipeline seems simple, it is enough to dig a trench, connect the pipes with each other, the house-building system and the collector, and then cover everything with earth.

But this is only at first glance. In fact, in this, as well as in any other work, there are many nuances that must be taken into account. Failure to comply with technological standards and improper laying of the pipeline may lead to siltation and other significant problems in the future.

In order for the sewage system to function properly and for a long time, when it is installed, it is necessary to adhere to building and technological standards (+)

The wastewater disposal system must ensure the drainage of all wastewater, eliminate the possibility of flooding the structure in the event of emergency situations, and ensure that wastewater is purified when discharged into a body of water. When adjusting the system, it is necessary to take into account such parameters as the material of manufacture and the diameter of the pipes, the type of soil in the locality, the depth of the sewer pipes, the certain angle of inclination.

The autonomous sewerage of private households can be made in the form of separate or joint diversion and purification. In the first case, two separate pipelines are made for wastewater from wash basins, bathtubs and sinks and for fecal masses from the toilet. In the second case, all liquid and solid wastes are combined into one common stream and enter the septic tank where the purification process is carried out and then exported.

Selection of pipes for laying

Previously, when laying the sewer, only metal pipes were used: cast iron or steel pipes. Indeed these materials are like any other suitable for laying in the ground. They are durable, durable, have low cost, easy to assemble. However, along with the merits, metal structures have significant drawbacks. The minus steel pipes is the possibility of corrosion, and cast iron - a lot of weight.

For strength and durability, cast iron pipes are not equal, this material can lie in the ground for decades without losing its qualities, but because of their severity, the laying of the water conduit is significantly complicated

A certain complication is the sealing of the joints of the cast-iron pipe, as well as its internal surface, which due to the nature of the material will never be perfectly smooth. The latter characteristic influences the speed and quality of the movement of waste inside it, over time, clogs can form in the pipe.

Asbestos-cement pipes can be used for sewerage. They have a smooth surface, which excludes the possibility of blockages, they are simply connected by means of special couplings, their weight is much less than that of metal structures. But they also have a significant minus - a great fragility, which complicates their transportation and packing. Ceramic pipes also have the same fragility.

Reinforced concrete structures have many advantages: they have exceptional strength, water resistance, frost resistance. From reinforced concrete it is possible to produce pipes of large diameter, which can not be made from other materials. But the laying of such pipes is big problem. Because of their large weight, it is necessary to use special equipment, which is not always advisable in the conditions of individual farming.

Today, with the provision of sanitation for private households, polymer pipes, which, for all their strength, have a low weight, which allows them to be laid to one person. They are very simple and easy to connect, with excellent leak-tightness.

For the arrangement of external sewerage, orange polymer pipes are used. They have an increased strength in comparison with the gray pipes intended for the internal pipeline, and also have the ability to withstand heavy loads

Polymer pipes are of three types: from PVC, polyethylene and polypropylene. PVC structures, in addition to the above advantages, are also distinguished by their resistance to UV radiation and a slight change in the parameters for temperature changes. However, they do not withstand very low and very high temperatures, and they can also deform under mechanical loads.

Sewage system during its operation is subjected to dynamic loads, which best withstand corrugated polyethylene or polypropylene pipes. Even with freezing, the integrity of the pipe will not be disturbed, but deformation of its walls may occur.

The diameter of the pipes is chosen based on the number of sanitary equipment installed in the house. So, for a country cottage with two toilets, there will be enough pipes with a cross section of 110 mm. If there are three or more bathrooms in a house building, a pipe with a diameter of 160 mm should be used.

Depth of laying sewage system

Some mistakenly believe that the deeper the sewerage will be, the more effectively it will work. However, it is not. The system's performance will not increase from this, the only thing that will increase is the cost of its installation. In addition, the sewerage network will become more complicated. And the biggest trouble can happen if, as a result of punching or scouring the soil, the pipes will not withstand its pressure and burst.

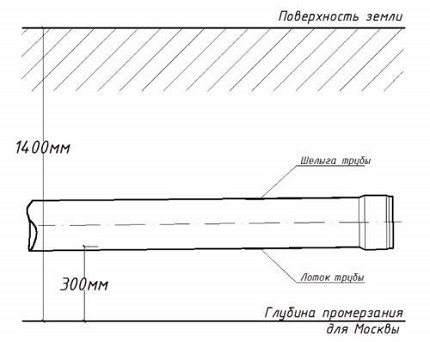

When laying sewer pipes, it is necessary to adhere to the norms and rules stipulated in SNIP 2.04.03-85. An important parameter to consider when installing a pipeline is the depth of its laying in the ground. Despite the fact that in normative act The precise parameters of the depth of the pipe laying are not given, the document indicates which criteria are the determining factors for the laying of the sewer pipe.

Usually in middle lane Russia pipes are laid at a depth of 0.8-1.4 m, which is quite enough for the effective operation of sewerage

According to the SNIP, it is necessary to be guided by the climatic conditions characteristic of the region, in particular the level of freezing of the soil, and the experience of the operation of the sewerage networks that has developed in the given area. If there is no information on the operation of the sewage system, the minimum depth of the pipeline should be 30-50 cm above the freezing level.

At the same time, from the surface of the earth to the top of the pipe there must be a distance of at least 70 cm. If the highway passes under a concrete platform or in traffic areas, it is necessary to increase the minimum recommended depth of the pipeline to 0.9-1 meters.

In addition, with the arrangement of the external network, the pipe material and soil composition must be taken into account, since the depth of freezing of different types of soil is not the same. Clay and loamy soils in the same area freeze less than fine sand and sandy loam. The highest level of freezing is of coarse and gravel sand.

From the table shown, it is clear how different the depth of freezing of different types of soil in the same city

Do I need to insulate the pipeline?

The efficiency and longevity of the operation of external sewerage largely depends on the properly executed insulation. This is especially important in the northern regions and when the pipes are laid above the freezing level. To understand the importance of warming, you need to imagine how the system works in the cold season.

During the passage of a liquid, which always has a positive temperature, the pipe is partly filled with liquid runoff. Water vapor also fills the pipe. In winter, at sub-zero temperatures, a part of the pipe closer to the surface cools, which leads to the formation of condensation, and then a frost that rushes to the center of the pipe, which often causes blockages.

Formed insulation is chosen based on the diameter of the pipe, before laying the sewer pipe, it is simply put on top

Avoid the formation of frost and blockages, as well as protect the system from freezing allows high-quality insulation of the pipeline. You can do it with different materials, which today are abundantly represented in the market: foamed polyethylene, foam plastic, isover, heat insulation and others.

Heaters are rolled and molded. The first are wound on the pipe during its laying in the basement. A similar application for thermal insulation shells made of foamed polyethylene.

They are not used as a thermal insulation of underground lines. Generally used are molded insulation, which are made for a specific pipe diameter. Thermally insulating material of the required diameter is simply placed over the sewer pipe.

One of the most popular heaters is Energoflex, which is made from extruded polystyrene foam. The closed structure of the cells of the material excludes penetration groundwater, which can significantly reduce the insulation properties. Enhances the effectiveness of the foil sheath

If the temperature in the region is very low, then one heater is unlikely to become a reliable protection of pipes from freezing. In this case, a heating cable is usually used, which is laid along the outside of the pipe inside the heat-insulating material. When using a heating cable, care must be taken to ensure that the joints are completely sealed, so that moisture does not seep inside.

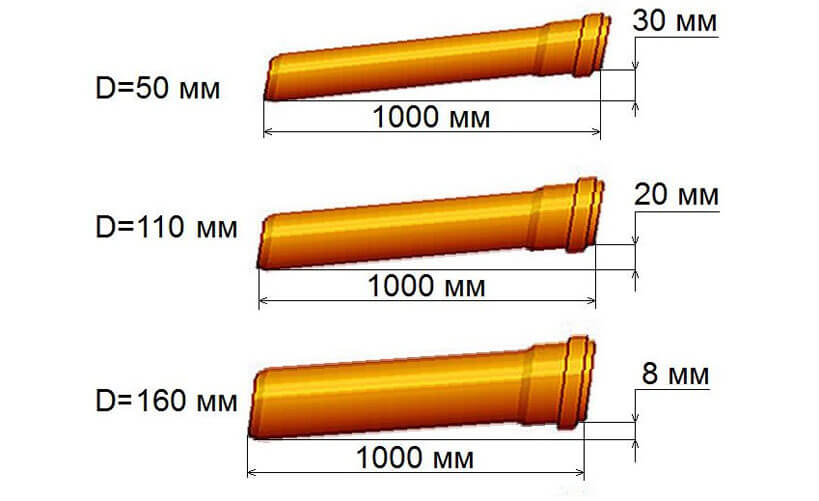

What kind of slope is needed?

When laying the pipeline, it is necessary to provide a slope towards the septic tank. According to technological standards, the slope of a pipe with a diameter of 110 mm should be 20 mm for each meter of the pipeline. Pipes having a diameter of 160 mm should be laid with a slope of 8 mm per one meter of the laid line.

When laying pipes, the slope is calculated per one meter of the pipeline. The figure shows how much should be the difference between the sides of pipes with different diameters

The presence of bias is the determining parameter for the successful functioning of the system. The closer the pipeline performance to the normative, the more efficient the sewage system will work. A complete lack of bias, like an excessive slope of the pipeline, will lead to siltation of the system. In the first case, the waste will not be transported through the pipes at the required rate, which will serve as the formation of clogs.

In the second case, the liquid will move too fast, which will ultimately reduce its transport capacity, and the waste will remain in the pipe, which will also lead to clogging and further siltation of the pipeline.

The slope of the pipeline should always be directed from the outlet from the apartment house towards the septic tank. This condition is especially important when using the non-pressure drainage system, which is most often used for private households

The level of the entire trench can be checked with the help of special device - Level. If the device is not on the premises, then the grading test is carried out using the building level.

- At the beginning and at the end of the foundation pit, the pins are driven into, to which the cable ties.

- The construction level is applied to one end of the rope and the horizon is adjusted.

- The height of the trench is measured from both sides to the rope.

- Simple mathematical calculations are performed.

For example, the total length of the trench is 50 meters, using a pipe with a diameter of 110 mm. From the exit from the house the depth of the excavation is half a meter. In this case, at the end point of the pit, its depth should be equal to one and a half meters.

If there is natural bias, exceeding the recommended standards, it is possible to lay a sewage system with several vertical transitions. In this case, on the horizontal sections of the pipeline, it is necessary to observe the normative indicators.

In sections with a large slope, the pipeline can be laid in a stepwise fashion. If the angle of incline is slightly higher than the norm, they are limited to one vertical transition (+)

Another option - to leave the house to lay vertical pipe to a considerable depth, and already from it to lay the pipeline with the necessary bias. In this case, the depth of the trench will be greater than when stacking the first way. For the same purpose, it is possible to use a well that falls into which the sewage flows smoothly to a lower level of the pipeline.

Pipeline construction works

Technologically, the process of laying the sewer is not particularly difficult. First, it is necessary to dig a trench, the depth of which corresponds to the normative indicators characteristic of this region. Before laying sewer pipes, sand is poured onto the bottom of the ditch. The height of the sand base is 10-15 cm, so the depth of the trench must also be increased by these values.

Sand pillow allows you to level the bottom of the ditch. Before laying pipes, sand must be carefully compacted to prevent subsequent shrinkage

The width of the trench is laid approximately 40 cm more than the diameter of the pipe used. In the places where the pipes approach the septic tank and at the outlet from the house sewage system, the trench is made a little wider, so that it is convenient to carry out the installation work.

To prevent wetting of the foundation and walls of the house, the septic tank is installed at a distance no closer than 5 m from the building.

After the trench and the base has been prepared, it is necessary to connect the pipes together and then to lay them. Long sections of the trunk can be laid flat and correctly to one person is beyond the power, therefore it is desirable to attract several assistants to this work.

At the ends of the pipes there are special sealing rubber bands. Before they mate with each other along the perimeter of the pipe, a silicone lubricant is applied, which facilitates the joining process and makes the joint more reliable. But here you can not use force, excessive force on the pipe can damage the rubber or tear it from the seat, which will lead to a breach of its tightness.

Before laying the prepared pipeline, the outlet from the house drain is put on the branch pipe, which has the required angle. The other edge of the trunk lies in the hole in the septic tank. If the storage well is made recently, it is advisable not to immediately fill the hole with concrete, since the shrinkage of the septic tank may cause the pipe to burst.

The branch pipe, put on the pipe leaving the house, allows to direct the pipeline in the right direction

Backfilling of the sewer pipe is carried out as follows: first poured sand in such a way that the pipe was completely covered by it. Then it is watered with water, and after it shrinks, another batch of sand is poured. After that, the highway is completely covered with earth.

By technical standards In places where the turns of the route are to be installed, rotary wells are to be installed, and on the straight sections of the pipeline, manholes are equipped for every 35 meters. In addition, every 15 meters of a straight line is set up for revision or cleaning.

The installation of the audit is a simple procedure, but it allows you to monitor the condition of the sewage network throughout the pipeline and, if necessary, clean the desired area with a cable or water jet

The audit can be made from the same sewer pipe, which is installed vertically on the right sections of the pipeline using a tee. From above it is closed by a plug. With this rather simple device you can get quick access to the clogged section of the highway.

What to do when the sewage freezes

If you have not insulated the sewer pipes, or have insulated them insufficiently, and they have frozen, first of all, you need to determine the damaged section of the pipeline in order to choose the method of solving the problem. Metal pipes can be heated with a blowtorch.

If the pipeline is made of plastic, open fire can not be used. You can pour hot water into the sewerage system, in which to dissolve the salt (2 kg per 10 liters of water). You can send a jet of steam or hot water in the closest to the frozen section of the audit.

If the damaged pipe is in the middle of the main line, you can use the steam generator to warm up the soil. However, this process can take quite some time. It is best not to allow freezing of the system, and when laying pipes to conduct their quality thermal insulation.

Useful video about the laying of the highway

In this video, the process of laying external sewerage is described in great detail, as well as the normative indicators that must be adhered to during installation:

This video shows how the sewer pipes are laid in the ground:

Despite the seeming simplicity, the work on laying sewer pipes requires a competent approach and knowledge of the regulatory rules of laying. Only with the observance of the necessary indicators and the proper performance of works, it is possible to equip a really effective and durable sewerage system.

From the internal pipelines, the drains are transported through the external to storage tanks or septic tanks. In order for this function to be carried out at the proper level, it is necessary to ensure the correct laying of the pipes.

Most often, polymer pipes made of polypropylene, polyethylene and polyvinylchloride, painted in orange, are used for mounting the sewage network.

In the presence of dynamic loads on the pipeline network. It is worth choosing corrugated polymer pipes, consisting of two layers of material. The connection is made with the help of shaped parts, usually in the socket. Such pipelines are less exposed to corrosion, durable and due to low wall roughness they do not create blockages and fouling. They are laid to a depth of less than 3 m.

Sequence of pipes laying

- Excavation. First you need to properly excavate the trench, only then begins the laying of sewer pipes in the ground. The technology of this process is as follows:

- Determination of the depth of the trench - according to normative documents it should be greater than the depth of freezing of the soil in winter, and also the location of groundwater

- Preparation of the trench - leveling of the bottom surface, slope is performed according to calculations (usually 1-2 cm on running meter), the substrate is filled from rubble with a thickness of 15 cm and its seal, as well as in the moments of the connection of pipelines and shaped parts, small pits

- Construction works. Lay pipes should start from the foundations of buildings:

- Piping the pipelines in the trench down and cleaning their edges

- Lubricate the edges with a special substance and install the pipe into the socket until it stops

- Connection of all other parts

For convenience of work execution, correct and reliable connection of pipelines, it is necessary to measure the depth of pipe entry into the socket in advance and apply the appropriate marks.

Turns on the main line are constructed by the value of 15, 30 and 45 degrees. Every 15 meters the pipes are equipped with a revision or cleaning.

- Backfilling of the trench is the final stage construction works, after the laying of sewer pipes in the ground. The backfill technology involves checking the slope of the system after connecting all the elements. In order to fill the trench, the soil formed in the process of excavation, which is formerly ground and disposed of large inclusions, is used.

For backfilling, it is forbidden to use soil that contains stones or solid blocks larger than 30 cm, since they can damage sewage pipes.

The trench is gradually filled with earth, each layer about 5 cm thick ramming the embankment only in the lateral part of the pipelines. It is forbidden to tamper with them, as the possibility of deformation or damage to the pipe is not ruled out.

Warming of sewer pipes

Pipelines that need thermal insulation are usually those that are located above the freezing point of the soil or releases from the internal sewage system. Usually for these purposes, polymeric heaters such as stenoflex or powerflex are used. Thermal insulation is placed around the pipelines and is well fixed by screeds or wire. Only after installing the heater and checking the slope of the network can backfill the trench.

It should be remembered that in the presence of breakdowns in the sewer network, it will be more expedient not to change a separate element that failed but to completely dismantle the system. It will be more reliable and economical.

A process that can be performed independently is the construction of a system and the laying of sewer pipes in the ground. The technology is simple, and if you follow all the recommendations described in this article, the lifetime of the sewage system will be long, and its reliability is high.