Check valve for pumping station: what is needed and how to install. How to properly install an air check valve.

Bookmark this site

This can create a noticeable noise and expel air with water when the crane is opened. If the pump is vibrating, then check valve It is installed to the receiver anywhere in the pipeline, where it is convenient for the user.

The way of installation is standard: connecting the device directly in front of the station through the drive in case of replacement. When connecting immediately after the ratchet, the suction pipe is not required. When installing a non-return valve on an existing pipeline, we choose the place for installation between the pump and the pump station or receiver, we break the pipeline, put the device on one part, connect it by means of a drive to another part. If the water supply is intended for use only in the summer, then the lowest point of it is desirable to provide a tee and attach to it a water tap for draining water for the winter.

The device of the return valve for the water drain and its installation

The non-return valve in the sewerage individual network is designed to protect against return flow of sewage water and fecal matter. Overflow of toilet bowl threatens to spill over the apartment if there is no device preventing the return movement of sewage water, when the total sewage system is blocked. Device construction is extremely simple, despite the importance of the functions performed. It consists of a clamping movable circular plate attached to the body, with a rubber gasket tightly covering the outlet opening. The plate rises horizontally from the outlet hole of the outlet hole, and after its weakening is lowered into place, preventing the return current.

The non-return valve to the sewer can be made of:

- bronze;

- cast iron;

- of stainless steel;

- polyvinyl chloride (PVC);

- polypropylene (PP);

The diameter of the outlets can be 100, 50 or 70 mm. The housing is provided with a removable cover for cleaning the locking plate. With the help of the handle, it is possible to close the outlet hole manually. Installation of this plumbing fixture Supports both vertical and horizontal frames. The cut-in is made to the existing or newly installed sewer system in the areas where the pipes of the corresponding diameter are joined. Docking of cast iron with plastic is carried out by means of adapters from pig-iron to plastic or vice versa. When the frame is installed, maintenance must be provided and maintained.

Do I install a check valve for heating?

A non-return valve is only needed if the bypass is installed on the free circulation water heating systems. Free circulation means the movement of water in heating system due to heating. This heating is produced heating appliances, in which there is no provision for the installation of pumps for forced circulation. Bypass is an English word for parallel feed. If we put a pump for forced water pumping in parallel to the heating system with free movement of the coolant, we need a check valve.

Forced heating is much more efficient, more economical and more efficient. Therefore, the overwhelming number heating devices It is manufactured with built-in pumps for forced heating. With free circulation, more thermal energy is needed. With this type of heating, in addition to the energy consumption for heating the water to heat the room, it also requires an additional flow rate to ensure fluid movement.

With forced movement, this work is performed by the electric motor, reducing fuel consumption. In addition, due to the small difference between the temperatures on the supply and return pipes, the heating efficiency increases, and as a result, the temperature in the system can be reduced, which provides additional savings.

Installing the bypass of forced heating is extremely beneficial. But then the tie-in of the check valve becomes necessary, as it is designed to shut off the circulation of water over a small circle when the electric pump is turned on. The device is installed between the suction and discharge pipes of the pump. When the engine is turned on, the rubber ball of the check valve, under the influence of the suction force, return pipe, forcing the fluid to move through the pump.

When the pump is turned off or there is no electricity, the opening is opened by the force of water movement, automatically resuming the free circulation of the liquid. It is only necessary to block the movement of water through the pump, closing the valve installed on the suction pipe during installation. The diameter of the suction and discharge bypass pipes must be less than the diameter of the heating pipe to ensure the least resistance to water movement.

A non-return valve will relieve many of the problems that await the user on the way to autonomous water supply, heating and sewage, will bring considerable benefit and cost savings.

One of the most important elements of the system autonomous water supply is a check valve for water. It performs the function of protecting against such interruptions in the operation of the water supply, such as lowering the water pressure, switching off the pump or leaking.

The check valve has a simple design in the form of a brass cylinder with a spring built into it and a round overlapping plate. The valve is only able to flow water in one direction.

Where to install the check valve: in the well or in front of the pumping station?

The installation of a non-return valve is possible either at the inlet of the suction pipe itself, or immediately before.

Installation of a check valve at the entrance to the pump station

A non-return valve connected to the system does not allow water to flow from the suction pipe back into the well or into the well after the pump is disconnected. This very useful function of the non-return valve is indispensable for organizing flows in heating and water supply: for all subsequent pump starts, there is no need to re-fill the entire system with water. And this not only facilitates the work of the pump itself, but also provides an almost instantaneous supply of water to the consumer. The choice of the valve should be based on the diameter of the pipe, in the section of which the installation of a non-return valve is planned. Keep in mind that the non-return valve creates additional resistance to the water flow in the system, so that the pump pressure can drop by 0.5 atm.

How to install a check valve for water correctly?

The design of the non-return valves used in household plumbing with the spring-loaded membranes installed in them makes it seemingly possible to install the valve with any orientation in space. After all, the check valve in any case, regardless of whether it is horizontally mounted, vertically or otherwise, should work normally. In fact, so it is, it is possible that you will never have such a problem. But it will be superfluous and be safe, because what the devil does not joke, as they say ...

The spring installed in the check valve is so weak that it can not withstand various dirt and deposits. But in the course of operation they inevitably form on the walls of the check valve and the membrane! But if the spring of the check valve was more powerful, then the sense of using a check valve would also be lost, because then it would be very difficult to pass water in one direction, and in the other it would not pass at all.

So, if you are not a masochist and do not want the water supply system to bring additional problems and costs in the future, install a check valve for water with an up arrow, i.e. strictly vertical. And the more accurately you do it, the longer the check valve will last without any failures and censures.

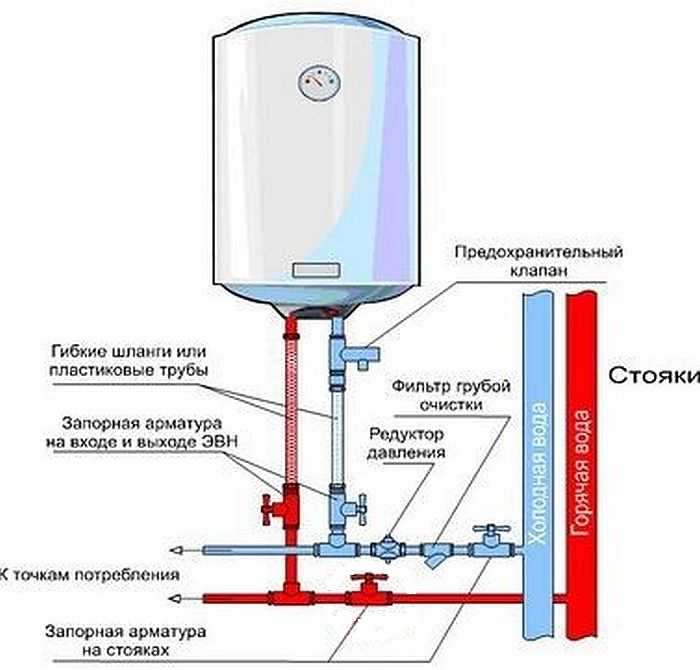

From proper tying electric water heater storage type (boiler) depends not only the life of the equipment, but also the safety of tenants. That's the way things are. And its proper tying is a safety valve for the water heater on the supply cold water.

What is it needed for

The installation of a safety valve prevents the pressure inside the device from rising above the norm. Because of what the pressure rises? As is known, when heated, water expands, increasing in volume. Since the boiler is a sealed device, there is no surplus to go - the valves are closed, the return valve usually is on the supply. Therefore, heating the water leads to an increase in pressure. It may well be that it will exceed the ultimate strength of the device. Then the tank breaks. That this does not happen, put a safety valve for the water heater.

Maybe you do not need to put a safety valve, but just remove the return valve? With a sufficiently high and stable pressure in the water supply system, such a system will work for some time. But the decision is fundamentally wrong and that's why: the pressure in the water pipe is rarely stable. Often there are situations when the water is barely running out of the tap. Then hot water from the boiler, pressure is forced out into the water supply system. In this case, the heating elements are bare. Some time they will warm the air, and then burn out.

But the burnt TENs are not the worst. It is much more terrible if they are heated, and at this time the pressure in the water supply system rises sharply. The water which has got on the heated heaters evaporates, there is a sharp increase in pressure - a jerk - that leads to the guaranteed rupture of the bulb of the boiler. At the same time, a decent amount of scalding water and steam, under great pressure, bursts into the room. Than it can threaten - it is understandable.

How does it work

A safety valve for a water heater would be more correct to call a valve system, since there are two valves in the device.

They are located in a brass or nickel-plated case, which looks like an inverted "T" (see photo). In the lower part of the body is a non-return valve, which prevents the outflow of water from the water heater when the pressure in the system decreases. In the perpendicular branch there is another valve, which, when the pressure is exceeded, allows the discharge of part of the water through the union.

The mechanism of work is as follows:

- As long as the pressure in the boiler is less than that in the water pipe (with filling or with the tap open), the plate of the check valve is wrung out by the flow of water. As soon as the pressure level, the spring presses the plate against the protrusions of the body, blocking the flow of water.

- When the heating is turned on, the water temperature gradually increases, and with it the pressure also increases. While it does not exceed the limit, nothing happens.

- When the threshold level is reached, the pressure compresses the safety valve spring and opens the outlet to the union. Some of the water from the boiler is discharged through the nozzle. When the pressure drops to a normal spring, the passage closes, the water stops draining.

According to the principle of operation it is clear that the water from the nozzle will constantly undermine. This happens when the water is heated, when the pressure in the water pipe decreases. If you see water from time to time, then everything is working fine. But the confluent liquid must be diverted. To do this, put a suitable diameter pipe on the branch pipe, always fix it with a yoke. The normal working pressure of the boiler is from 6 bar to 10 bar. Without mechanical fastening, the tube will tear off in two counts, so that the collar is selected high-quality, tighten well. Take the tube to the nearest sewer.

One more thing: the tube on the choke needs a transparent and preferably reinforced (so-called "Christmas tree"). Why reinforced is understandable - because of pressure, and transparent - for the ability to control the operability of the device.

Types and varieties

If it is a question of usual safety valves for a water heater, they look almost the same, only the nuances differ. But it is these small parts that are responsible for the ease of operation.

In the photo above two safety valves with drain arms. They are needed for periodic testing of operability. The flag of the lever is lifted upwards. He pulls the spring behind him, freeing him to dump the water. This check should be conducted about once a month. You can also empty the boiler tank - raise the checkbox and wait until everything drains.

The difference in the models presented is that the model in the photo on the left has a lever fixed with a screw. This eliminates the possibility of accidental opening and complete discharge of water.

Two more differences are striking. This is an arrow on the body, indicating the direction of movement of water, and an inscription showing the pressure the device is designed for. It seemed to be minor details. But if the direction of the water movement can be understood (see which way the poppet valve is deployed), then the face value is more difficult. How to distinguish, for example, 6 Bar or 10 Bar? Only checks. And how will the sellers distinguish them? No way. On the boxes. And if you put it in the wrong box? In general, it is better not to take without marking on the case. This is usually the cheapest of Chinese samples, but the difference in price is not so great as to be worth the risk.

Also pay attention to the shape of the nozzle for water discharge. The model on the left has a long, non-linear nipple. It is quite easy to get a hose and length is enough to install a yoke. The shape of the fitting on the right of the model is different - with an extension to the end, but more importantly, the union is short. You can still pull the hose on it, but the yoke is questionable. Is that the wire crimped ...

On the next photo, safety valves without a forced pressure relief flag. The one on the left, at the top, has a threaded cover. This is a serviced model. If necessary, you can unscrew the lid, remove blockage, scale and other impurities.

Safety valves - serviced and not

The model on the right is the worst of the options. No designation, forced reset or maintenance. This is usually the cheapest available, but this is their only advantage.

All the above models are suitable for water heaters up to 50-60 liters. For boilers of a larger size, there are other models, many of which are equipped with additional devices. Usually this ball valve and / or a pressure gauge to control the pressure.

The outlet for water discharge here with a regular thread, so there will be no problems with the reliability of the fastening. Such devices already have a fairly high price, but the quality and reliability of their much higher.

Not all in appearance like these devices. For those who attach great importance to aesthetics, very attractive devices are produced. Their price, however, is comparable to the price of a cheap water heater, but beautiful.

Can I put other valves

Sometimes, instead of a special safety valve for the boiler set subversive, which is intended for emergency discharge of water on heating. Although the functions they have and are similar, but the main mode of operation differs in the root. Subversive should only work in emergency situations. It is designed for salvo discharge of a large volume of liquid. For the constant bleeding of small portions of water, it does not fit. Accordingly, it will not work correctly.

Another case is the installation of a non-return valve. It will not drain water when the pressure in the water pipe decreases, but it will not save you from raising the pressure in the boiler. So this option is also not workable.

How to choose and install

Select the safety valve for the water heater according to the pressure to which the unit is designed. This figure is in the passport. The choice of tank capacity also affects the choice. Issue devices with a limit of operation at 6, 7, 8, 10 Bar. In general, all units are designed for this pressure. So everything is simple.

The installation is simple: a flaxen fiber or a tape tape is wound on the thread, after which the valve is wound up and the branch pipe. Until the stop is twisted by hands, then another one or two turns with the keys. It is much more important to choose the right place for its installation. When this valve is installed directly on the inlet pipe of cold water.

Further, there may still be a check valve, which is called still shut-off. But this is already reinsurance - the same device is available in the safety, and even often after the water meter at the entrance. The wiring diagram is shown below. This is one of the normal options.

The diagram has a ball valve. It is necessary for emptying the tank before conservation for the winter (in cottages) or before dismantling for prevention and repair. But more often put it on the tee, which is wound directly on the inlet pipe of the water heater. A safety valve is wound on the tee from below, and a ball valve is placed in the lateral branch.

Actually, these are all normal options.

Breakdowns, causes, elimination

In principle, the safety valve for a water heater has only two faults: water often flows from it or does not flow at all.

First of all, I must say that bleeding water when heated is the norm. This is how the system should work. Water can also be drained when the boiler is turned off, if the pressure in the cold water supply pipes is higher than the limit of the valve operation. For example, the valve is 6 bar, and in the water pipe is 7 bar. As long as the pressure does not drop, the water will be drained. If this situation is repeated often, it is necessary to install a reducer, and preferably on the water in the apartment or house, but there are compact models of reducers that can be installed at the entrance to the boiler.

How to check the serviceability of the valve? If there is an emergency reset lever, this is easy. When the boiler is switched off, it is necessary to raise the lever several times, releasing the excess pressure. After this, the drops stop and do not resume until the heating starts.

If the water continues to drain, the spring might be clogged. If the model is serviced, the device is disassembled, cleaned, and then put in place. If the model is not demountable - you just need to buy a new valve and put it.

This is how the reducer looks - to stabilize the pressure on the boiler

Constantly dripping water - it's unpleasant and "hits" the wallet, but not dangerous. It is much worse if you do not have water in the nozzle when you have heated the water. The reason is that the valve is clogged or the outlet fitting is clogged. Check both options. Did not help - change the valve.

Employees of the Ministry of Emergency Measures, fire protection, housing and communal services, manufacturers of household electric heating appliances do not get tired of warning that the installation of devices should be carried out in strict accordance with the requirements for their safe operation.

Surprisingly, there are people who try to ignore the rules, simplifying the installation scheme, ignoring the installation of a special safety valve.

The explosion of an electric boiler is extremely dangerous, both for people's lives and for the building itself. And the causes of such incidents are most often the absence or malfunction of a small, inexpensive and rather simple device - a safety valve.

To understand the importance of this safety device, you need to familiarize yourself with its device and the principle of operation.

How the safety valve is arranged

The safety valve for the water heater is quite simple. Structurally, these are two cylinders with a common cavity, located perpendicular to each other.

- Inside the large cylinder there is a poppet valve, pressed by a spring, ensuring free flow of water in one direction. In fact - it's all familiar. The cylinder at both ends ends with a threaded part for connecting the valve to the heater and the pipe system.

- The second cylinder, located perpendicularly, is smaller in diameter. It is drowned from the outside, and a drainage pipe is made on its body. Inside it there is also a poppet valve, but with the opposite direction of operation.

Often this device is equipped with a handle (lever), which makes it possible to forcefully open the drainage hole.

By what principle does the valve

The principle of the safety valve is simple.

The pressure of cold water in the water pipe squeezes the "plate" of the check valve and ensures the filling of the heater's capacity.

By filling the tank, when the pressure inside it exceeds the external one, the valve closes, and as the flow of water again ensures its timely replenishment.

The spring of the second valve is more powerful, and is designed for increased pressure in the boiler's capacity, which necessarily increases as the water warms up.

If the pressure exceeds the maximum permissible value, the spring contracts, opening the drainage hole, where excess water is drained, thereby equalizing the pressure to normal.

The importance of normal operation of the valve

Perhaps the description of the device and the principle of the valve did not fully clarify the issue of its extreme importance. Let's try to simulate the situation, which can lead to his absence.

So, let's say at the entrance to the heater there is no valve blocking the return flow of water supplied to the tank.

Even if the pressure in the water supply system is stable, the device will not work properly. Everything is explained simply - according to the laws of thermodynamics, when the water in a tank with constant volume is heated, pressure necessarily increases.

At a certain point, it will exceed the supply head, and the hot water will be discharged into the water supply system.

At a certain point, it will exceed the supply head, and the hot water will be discharged into the water supply system.

Hot water can go from cold taps or enter the toilet bowl.

The thermostat in this case continues to work properly, and the heaters consume expensive energy for nothing.

Even more critical is the situation, if suddenly the pressure in the water supply system falls for some reason or another, which is practiced quite often, for example, when the load at water stations at night is reduced.

Or if the pipes are empty as a result of an accident or repair work. The contents of the boiler tank are banally merged into the water pipe, and the heating elements warm the air, which inevitably leads to their rapid burning out.

It may be objected that the automation should prevent the heater from idling. But, firstly, not in all models such a function is provided, and secondly, and automation can fail.

It may be objected that the automation should prevent the heater from idling. But, firstly, not in all models such a function is provided, and secondly, and automation can fail.

It would seem that to avoid such situations, you can confine yourself to the installation? Some "clever" do so, not realizing to the end, that by this they literally "pawn the bomb" in their dwelling.

It's scary to imagine what could happen if the thermostat fails.

Water reaches the boiling point in the tank, and since there is no way out of the closed volume, the pressure rises, and when increased pressure the boiling point of water becomes much larger.

Well, if it ends with the cracking of the enamel on the inside of the tank - this will be the least evil.

When the pressure drops (crack formation, open valve, etc.), the boiling point of water drops again to normal 100 degrees, but the temperature inside is much higher.

Instantaneous boiling of the entire volume of liquid takes place with the formation of a huge amount of steam, and as a result - a powerful explosion.

All this does not happen if an operating valve is installed. So, we summarize its direct purpose:

- Do not allow the return flow of water from the heater to the water supply system.

- Smoothen possible pressure jumps in the water pipe, including - hydraulic shocks.

- To discharge surplus of a liquid at its heating, keeping thus pressure in a safe framework.

- If the valve is equipped with a lever, it can be used to drain water from the heater when carrying out maintenance.

How to install the valve on a water heater

Choose the model you need

As a rule, good boilers are supplied to the consumer with a complete safety valve of the required parameter.

As a rule, good boilers are supplied to the consumer with a complete safety valve of the required parameter.

If not, or if you need a replacement, you will have to buy it yourself. They are inexpensive, 250-400 rubles depending on the model.

If there are no special problems with the threaded part (almost all valves have a ½ inch thread), then the working pressure of the valve is the value that is paid special attention.

The correct pressure value should be specified in the operating manual for your heater.

If you buy a valve with a lower pressure rating - it will constantly flow from it. If you choose a value higher than the allowable value - the valve may not save you from big trouble when the boiler overheats.

How to install correctly

- Before installing the safety valve for the boiler, the appliance itself must be switched off and the water drained from it.

- The valve is installed at the inlet of cold water into the heater. The process is simple - the usual "wrapping" with a 3-4-turn key, using seals (fum-tape or pakli, as someone likes). The second threaded end is joined to the cold water system.

It is mandatory to check the direction of incoming water - on the valve body it is marked with an arrow.

- If the pressure in the water pipe is not stable, it can be excessively increased, it is better to put a water reducer before the valve.

- Not everyone likes the fact that from time to time water leaks from the valve. It is quite normal phenomenon, saying that the device is coping with its direct task. It will be reasonable to connect the drainage pipe with a flexible hose with a sewage system. The hose must be transparent so that the valve can be visually evaluated.

Sometimes attempts are made to hide the valve from the eyes, placing it away from the heater. This approach is also possible, but under two conditions:

- It is strictly prohibited to install shut-off devices between the valve and the boiler inlet.

- A long vertical section of the water pipe will in itself increase the pressure on the valve, and absolutely unnecessary "idle" leakage can begin. In any case, between the valve and the boiler should be no more than 2 meters.

What if the water flows through the drainage pipe is too abundant, even without much heat?

Perhaps the pressure in the water pipe is too high (although this is extremely rare) - in this case the installation of the reducer will help.

It should also be checked - it is possible that a valve with a too low pressure indicator, which does not correspond to the heater model, was purchased. If everything is still normal here, then the valve spring has "sat down", and it should be changed.

More worries should be caused by the fact that the valve is always and under all circumstances dry.

Even if maximum heating From it never showed a drop of water, with a high degree of probability it is possible to talk about its malfunction, clogging or jamming. It is better not to take risks, and get a new one.

Uncomplicated installation of this absolutely inexpensive device and secure the life and health of the owners of the house, and keep their property, and prolong the period of accident-free operation of the water heater.

A technically competent arrangement of such a system as a private house water supply with an individual source necessarily requires the installation of a non-return valve in the system, a device responsible for maintaining the required water level in the water supply. Rather, it allows to maintain this level before water enters the capacity of the boost pump.

Why use a check valve

In a private house individual system water supply is most often fed from an aquifer located at a depth of 4 to 8 meters. This indicator is comparable with the depth of the well or a small well, at such a depth, with a difference of 1-1.5 meters, there is also a water intake, in other words, a pipe filter sucking water into the water supply system.Regardless of the pump's capacity and aquifer productivity, water should be raised to the surface height, which is 4-6 meters and transported to the house, even if it's a small clone of only 5-10 degrees, but the distance can also be decent - up to 10 meters or more. With a constantly running pump, this task is solved simply - under the influence of immersed idi surface pump water rises and fills the whole water system. But if the non-return valve is not installed, immediately after the pump has been shut off, the water will flow by gravity, back to the well or well in the same pipelines. And if necessary, for example, to wash the dishes, you will have to turn the pump back on and wait again for the water to fill the water supply system.

In order for this situation not to be repeated again and again, a non-return valve is installed in the system, which ensures the passage of liquid in one direction and blockage in the event of a change in its direction of outflow, and thus the water that has entered the water pipe system remains in the pipes, rather than flows back in the well.

Where to install the check valve correctly

Installation of such a water supply system design element is most often required directly at the water intake site, that is, at the end of the pipe. This arrangement of this unit is applicable both for a pipe in a well and in a well when installing a suction surface pump.The valve, corresponding to the diameter of the pipe, is installed by means of an adapter to the lowest part of the pipe, and thus prevents the outflow of water from the water pipe.

The peculiarity of this option is the need for a mandatory addition to the valve to install on it and a screen filter, to prevent the device from entering the device of small stones and other debris. Such foreign objects can block the operation of the closing mechanism and, thus, cause the valve to be inoperative.

For Immersed People centrifugal pumps, the permanent installation of the valve in the water is done immediately after the pump, but in this case it is recommended to install flow filter with hermetic casing. Such a design will ensure a constant supply of water, since the water column will be above the body of the device, and the filter space and the pump chamber are constantly under the water column.

Another similar option for installing the valve may be the option of installing it in conjunction with deep-water pump membrane type. Here, depending on the design of the pump, it can be installed both on the outlet pipe and as an insert in the pipeline or hose.

The device of the return valve

In principle, there is nothing unusual in the arrangement of the check valve. The body is a cylinder of metal, most often bronze or brass, inside which there is a chamber, which closes the valve. The sealing density is provided by a plastic or rubber gasket, and the work is provided by the presence of a spring that tightly presses the valve.

Cases, as a rule, are produced today by teams, because the installation inside the body of the valve group and the spring is carried out by disassembling the parts of the body and then assembling them. All parts are made of high-quality materials, because the permanent place of installation is most often in the water environment.

The body at both ends is threaded for easy assembly. But the direction of the flow of water can be determined by the arrow on the body, it indicates the direction of the flow. For cold water mains, standard valve models are available in standard sizes from 50 to 300 millimeters in diameter, or from 2 to 12 inches. All dimensions are standardized and comply with the established technical standards.

By the type of valve design, it is customary to distinguish between check valves and reverse shutters. The difference between them is that the former have a latch in the form of a metal disk, while the latter work on the principle of a spool with a spring and seals. Valves having gate valves are usually divided into shock (the principle of operation is associated with impact closure of the valve) and unstressed, ensuring a soft closure of the valve.

The main types of check valves for a water supply system

In plumbing communications of a private house, a non-return valve of the lifting type is most often used. This element ensures a reliable retention of the water column a few meters. It works perfectly both for borehole type water intake, and when installed in a well. Under the action of the water flow there is a compression of the spring and the opening of the space for the passage of water.The ball check valve in the base of the construction has a conical chamber in which a ball is used as a shutter. The cone with its base is located in the direction of the water flow. Under the action of the flow, the ball moves inside the cone and opens the space for the liquid. When the water supply stops, the ball moves in the opposite direction, overlapping the neck of the cone.

A non-return valve using a swivel plate that swings when the liquid passes through the housing and blocks the opening when the direction of flow changes.

Each of the designs of such a device is successfully applied in practice, as in water supply systems private houses, and urban communications. The peculiarity of the installation of one or another type of equipment is determined by the need for the project and technical parameters, starting from its mass, the material of the shell manufacturing and ending with the application in specific conditions, for example, in hot water pipelines.

Specific places for installing check valves in the private water system

For a private house using an individual source of water supply and including such elements as pumping equipment, a hydraulic accumulator, filters, household appliances, the installation of check valves is also possible in other places that require a strictly directed direction of the water flow. A non-return valve is usually installed in front of the filter unit, in addition to the suction device in the well or well. This place is due to the need to ensure the constant presence of water in the filter housing.

The check valve installed in front of the boiler guarantees the correct direction of the water flow, and serves as an additional insurance for the work of the built-in standard element of the boiler itself.

Another option for installing a non-return valve may be to install this element further in front of the pumping station with a large water supply path from the well or well. This arrangement additionally insures the lower check valve at the water intake point.

And, of course, such a device is installed in front of the water meter, so that changing the direction of the water flow does not cause the meter to be restarted. This situation involves the use of one source and one pumping equipment to provide several private consumers.

Possible malfunctions and methods of their elimination

Despite the high reliability of such devices, they, like any technical element, have operating features and can also break down and fail.Most often the check valve stops working:

- When the garbage and stones hit the body;

- If the spring is damaged;

- When wiping off the surface of rubber or plastic seals;

- Gradual aging and loss of elasticity of plastic and rubber;

- The effects of water and chemicals dissolved in it.