Choice of individual water supply system. Individual water supply schemes

Water supply systems can be divided into two types. Individual water supply and centralized water supply.

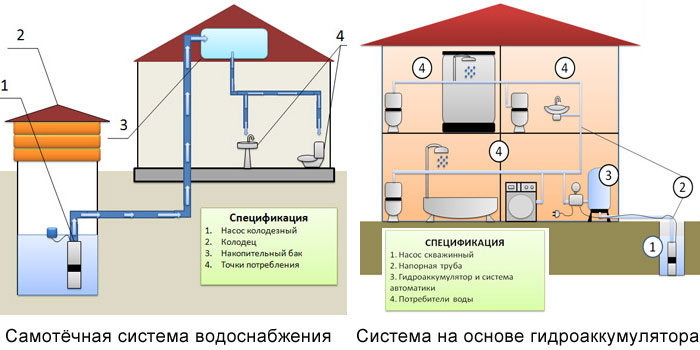

Individual, it is self-contained, water supply is designed to provide a small number of consumers with water or can be made exclusively for private consumption. Individual water supply can include water supply with a membrane tank, which is called a hydroaccumulator and water supply using a storage tank.

Centralized water supply is designed for a large number of consumers. With central water supply, all consumers are connected to a common source of water supply. The system of centralized water supply in cities and towns is used. It is rarely used in villages and cottage settlements. In the absence of centralized water supply, private source water supply.

This system of water supply is used for the individual construction of cottages, private houses and dachas. The principle of its work is the following.

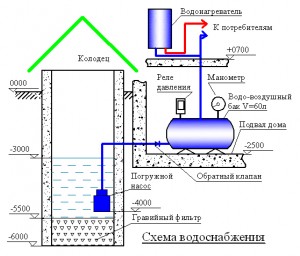

In a pre-made well or well, submersible pump, the pipeline system is connected to the pump. Pipeline system is laid and put into the house. In the house, the pipeline is connected to the cleaning filters, then to the accumulator and the automatic relay, which maintains the required pressure. This symbiosis is called the water supply management system. From the control system, the pipeline distributes water between the points of consumption (demountable points).

Thanks to a hydroaccumulator in this system is constantly maintained high pressure. Possibility to cut the accumulator into any place water supply system and the installation of a large capacity hydro accumulator allows maintaining a high pressure in the system for a long time, even with electricity cut off. So what is this hydroaccumulator?

Hydroaccumulator in the system of individual water supply

The hydraulic accumulator is a metal container into which the submersible pump, through the purification filters, pumps water. In the accumulator there is a rubber pear. Between the pear and the body of the tank, air is pumped under pressure. Water, entering the tank, compresses the injected air, which in turn expands the rubber bulb. When the set pressure in the system is reached, the automatic relay, in the control system, turns off the pump pumping water. Done! The system is under pressure, a good stream of water flows from the faucets.

As the water consumption, water levels in the accumulator decrease. Reducing the water level leads to the expansion of the injected air. The air, expanding, compresses the rubber pear. Expanding, the rubber bulb increases the pressure in the system.

But this can not happen forever. When the lower level, preset pressure is reached, the automatic relay switches on the submersible pump and water is pumped back into the accumulator and everything is repeated anew. The operating pressure of such a system is 2.5-4 atmospheres. Since the water supply system with the use of a hydraulic accumulator is the most popular and convenient for private houses, cottages and summer cottages I will necessarily write a separate detailed article about it.

An alternative to hydraulic accumulator water supply is a simpler water supply system with the use of a storage tank.

Well construction project and its role in the arrangement

Before starting any construction works it is necessary to draft a project. And a well for water is no exception. To water well has functioned without problems for many years, a well construction project is needed, that is, a scheme of the water supply system (different schemes exist for different wells). In the development of the technological chain, all significant characteristics of the cottage's water supply in this area are taken into account, as well as related measurements, including depth groundwater, the number and classes of filters used, the estimated capacity of the pumping unit.

Equipment for well construction

In order to equip the well, a number of special devices will be required. The main types of equipment that is used in the arrangement of a well for water include:

Submersible pump, uidrokakumulyator, hiele pressure, gult pump control, resonnon for the well - metal or plastic.

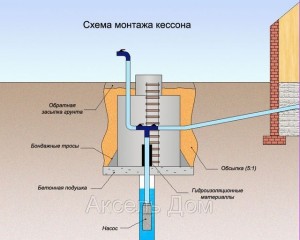

Well construction with caisson

Well construction may include installing a caisson - a square or cylindrical shaped structure, usually made of steel. Before installing the caisson around the well, a hole is digged, and a part casing cut off. Then, the caisson is lowered into the prepared cavity, casing through the hole made in his day. At the final stage, the caisson is connected to the wellbore by welding or fixing devices. Despite the apparent inconvenience of this method of arrangement, he has many advantages:

Well construction may include installing a caisson - a square or cylindrical shaped structure, usually made of steel. Before installing the caisson around the well, a hole is digged, and a part casing cut off. Then, the caisson is lowered into the prepared cavity, casing through the hole made in his day. At the final stage, the caisson is connected to the wellbore by welding or fixing devices. Despite the apparent inconvenience of this method of arrangement, he has many advantages:

Complete safety of equipment, groundwater before it will not reach;

The possibility of year-round operation of the well, in winter the water in it will not freeze;

No noise, all sound will be absorbed by the caisson;

Saving of useful space in the house (inside the caisson it is possible to install some equipment, for example, a hydro accumulator).

If you plan to put the equipment in the caisson, you should determine its size in advance.

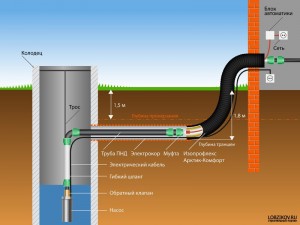

Well construction without caisson

![]() When installing a well without a caisson, for example, for laying a drainage pipe below the freezing level, borehole adapter - a brass device consisting of two parts, one of which is connected directly to the water-lifting pipe, and the other is installed on the casing string. After the pump is lowered into the well, both elements of the adapter are connected to each other - now it is possible to use water in winter. Compared to the caisson, the adapter is worth a penny. But this, as a matter of fact, is limited to the advantages of such an arrangement of the well.

When installing a well without a caisson, for example, for laying a drainage pipe below the freezing level, borehole adapter - a brass device consisting of two parts, one of which is connected directly to the water-lifting pipe, and the other is installed on the casing string. After the pump is lowered into the well, both elements of the adapter are connected to each other - now it is possible to use water in winter. Compared to the caisson, the adapter is worth a penny. But this, as a matter of fact, is limited to the advantages of such an arrangement of the well.

Disadvantages of well construction without caisson:

The complexity of mounting the adapter in the two-pipe design of the well;

The lack of the ability to quickly detect the seepage of groundwater in the well in the event of a breach of the tightness of the joints;

Inconvenience in the maintenance of the pump;

Limiting the choice of options pumping equipment (using an adapter will require a smaller diameter pump than without it).

In addition, if you are going to implement the arrangement artesian well, then the option with the adapter is far from the best. So, if you want to lower the pump to a depth of more than 80 meters, then there will be difficulties with its lifting. And mounting the pump to a depth of over 100 meters will prove to be extremely difficult to solve the problem. Of course, also, that in the absence of a caisson to place equipment for the arrangement of the well will have to either in the house or in the economic building.

Selection and installation of pumping equipment

Needless to say, how important a choice is pumping technology. It is necessary to take into account all the nuances, such as: the diameter of the pipe, which will be fed with water, the expected volume of water consumption, the distance from residential construction to the well, etc.

In order not to be mistaken, when choosing a pump, it is necessary to know for sure the distance between the house and the well, the dynamic and static water levels, the depth of groundwater, the productivity of the well, and others specifications, marked in the passport for the well. You should be aware of all the water points on the site, in the house and the surrounding buildings. All these data are needed in order to choose the pump on their basis necessary power, because it will depend on it the pressure of water in the house.

Knowing all the technical characteristics of your site, you can independently purchase the necessary equipment. But before that, it is still worth consulting with a professional.

Installation of equipment is also better to be entrusted to a specialist, since the installation of a well for water is a very laborious process, which only a person who has a rich experience and is well versed in this matter is able to implement correctly.

Installation downhole pump begins with the installation of a fitting on it, through which the transition from the pump to the water-lifting pipe is carried out. It may also be necessary to install a check valve if it is not integrated in the pump. A non-return valve will not allow water to leave the system back into the well during the period when the pump is off. The valve is mounted on the pump or on the wellhead. In order to "not lose" the pump in the well, in case, for some reason, it breaks off from the water-lifting pipe, a safety wire is used. This cable, with a pump attached to it, clings to a loop located on the inner or outer side of the well head. The borehole head also has two holes - through them the pump power supply cable and the pipe are output.

To draw water from the well with a water level of not more than 7 meters, you can use a pump that is not submersible, but a surface type pump. Such an assembly is not installed inside the well, but on the surface of the earth. And its installation is less labor-intensive than in the case of a submersible pump.

The installation of a hydraulic accumulator, which is a metal tank with a rubber membrane inside, partially filled with air or nitrogen, is one of the key moments in the development of a well. The hydraulic accumulator optimizes the pressure in the water supply system and reduces the load on the pump, thereby increasing its service life. The tank accumulators are on the market in models with a volume of 8 to 1000 liters. For a family consisting of 3-4 people and using water in the kitchen, shower and toilet, 100-liter storage is enough. If you need more water, you need to buy a bigger tank. It should also be remembered that the actual volume of water in the accumulator is 30 to 50% of the nominal capacity of the tank (depending on the model and manufacturer).

If there is a caisson, the hydraulic accumulator can be installed inside it. In addition, the location of the accumulator tank may be a utility room in the house.

Scheme of automation installation

For the normal operation of the automation of water supply from a well with a submersible pump to the water supply system, it is necessary to include a group of devices with control and monitoring functions (automation). These include, for example, the pump control panel, the pressure switch (controls the operation of the pump, turning it on and off), the dry-running sensor (turns off the pump when there is no water at its inlet, thus preventing overheating of the pump motor). To adjust the pressure switch and visual control of the pressure level in the water supply system, it is also necessary to install a pressure gauge.

Pipeline from well to house

To get water from the well into the house, between these two objects it will be necessary to lay a water main. The pipe along which water runs to all places of its consumption in a residential building is laid in a trench dug to a depth of at least one and a half meters - that is, below the freezing level of the ground. Before the place of entry into the house, where the plumbing line is located above the 1.5 meter mark, the pipe is "put on" in a heat-insulating material or wrapped with a heating cable. Selection and installation of a submersible pump with automatics

Today the market of autonomous out-of-town water supply is provided with a wide choice of models of borehole pumps of domestic and foreign manufacturers. For high-grade water supply a country house it is recommended to use high-performance centrifugal pumps. Accordingly, in order to ensure high water consumption, a high-performance artesian well is needed.

The requirements for the design of the pump and the reliability of its components are determined by the purpose and operating conditions - the well pump is placed in water at a great depth in a narrow well space. Installation of submersible pump in the well is one of the most important stages of the arrangement. The estimated operating time of the downhole pump must be at least ten years without lifting to the surface. The complexity of the technical implementation of the uninterrupted operation of the pump under such conditions is obvious: it is necessary to combine high performance with limitations in size due to the small internal diameter of the well.

In addition to ensuring trouble-free operation, the need for high reliability of the pump is explained by the fact that it is difficult and expensive to lift the pump for repair from a great depth (comparable to the price of the pump itself). Professional, competent installation of a submersible pump into the well will ensure a continuous uninterrupted operation of the pump and other water-lifting equipment.

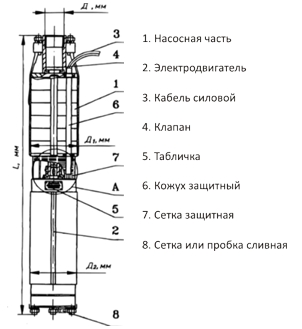

Structurally, modern pumps of different firms are similar - the designers found the optimal solution to the problem of "high performance with small diameter." An electric motor that drives several impellers on a single shaft is located at the bottom of the downhole pump. The performance of the pump can be increased by increasing the number of impellers, while the overall length of the pump increases.

Restriction for work centrifugal pumps can only be the presence in the water of solid particles and mechanical inclusions that destroy the rapidly rotating parts of the pump. For this reason, the installation of a downhole centrifugal pump in a sand hole is not recommended. But since centrifugal pumps are mainly used in boreholes on limestone, where water does not contain solid inclusions, this problem for most owners of country houses is not relevant.

In addition to centrifugal pumps exist, using the vibrational principle of operation for water intake (for example, the pump "Kid"). Such pumps are structurally much simpler and cheaper, and most importantly - do not fear the presence of solid particles in the water.

For this reason, the installation of a water pump vibrating is done only with the arrangement of sand wells. Vibration Pumps strongly inferior to centrifugal in all important parameters - productivity, durability, reliability, maximum working depth of immersion.

In centrifugal pumps, the water intake is located above the engine. This solution provides high pump capacity, but under certain conditions it can lead to overheating of the motor. Manufacturers of centrifugal pumps are looking for a solution to the problem, changing the layout of the pump. The electric motor is located above the intake part, the entire structure is enclosed in a casing so that running water can cool the engine. However, such a solution leads to a reduction in the diameter of the impellers, which in turn reduces the pump's capacity.

Increasing the productivity could be a simple increase in the engine speed, but the frequency of the 50 Hz power network does not allow the engine speed to be increased above 3000 rpm. This technological limitation makes it difficult to choose a submersible pump. Grundfos has solved this problem by equipping its pumps with electronic frequency converters. In such models a synchronous electric motor with permanent magnets in the rotor is used. This technical solution allows to increase the engine speed up to 10700 rpm.

The functioning of the downhole pump is supported by built-in electronics, which reliably protects the pump from dry running, voltage surges, excess operating temperature and provide a smooth start, which avoids the effect of starting currents.

Scheme of installation of automation of water supply from a well with a submersible pump

To ensure the convenience of using the pump at the level of an ordinary city apartment, it is necessary to install additional automatic devices that provide protection from adverse operating conditions, such as dry running, high and low voltage, excess temperature. The choice of such devices is quite wide: from simple pressure switches to very complex devices, the price of which is comparable or even higher than the price of the pump itself.

The choice of automation depends, in particular, on the equipment of the complex in which the pump operates: in water tower, for example, level sensors (galvanic or float) are installed, pressure accumulators in pressure accumulators, which disconnect the pump when a predetermined level or water pressure is reached. Pressure sensors when used in conjunction with the frequency regulator can support constant pressure at each moment of time.

Submersible pump with automation - reliable and efficient solution for organization autonomous water supply. Properly selected automation allows to protect the pump from a variety of unfavorable factors such as: increased or decreased voltage, increased or decreased current, reduced insulation resistance, broken phase sequence, asymmetry of phase currents / voltages (for three-phase motors), increased or decreased power factor cos φ), an increased input harmonic of the input voltage.

Self-selection of the pump by the customer, which exaggerates the requirements for flow and pressure, often leads to a choice of a pump with too much power. In the case of the initial data considered above, this pump can be SP14A-25. As already mentioned, when installing an overestimated power model, complications are possible. Firstly, since with this choice, the nominal supply significantly exceeds the average water demand, the pump will operate in the frequent on / off mode. Manufacturers allow up to 30 pump inclusions per hour, but only for one hour per day, with a total limitation of 60 cycles per day. In any case, frequent inclusions negatively affect the resource of the electric motor and start-up automatics. To avoid this, the installation of a large-capacity membrane tank will be required. Secondly, if the pump capacity is too high, the water pressure at the input to the house will be too high. At the time of starting such a pump, strong hydraulic shocks will inevitably occur. Some fittings may simply not be designed for such pressure (dishwashers and washing machines, mixers), additional installation of pressure reducers will be required to reduce the head.

The pump is not selected correctly: the operating point is shifted to the right. Third, during the filling of the basin, the pump will operate on an "open pipe" without creating any pressure. Under these conditions, a large flow of water at a minimum pressure is observed. The operating point of the pump is displaced on the curve of the characteristic to the right, into an area not corresponding to the working area of the pump. The power on the shaft will be maximum, and if the engine is to run for a long time in this mode, the engine will fail. The use of a pump with an overestimated capacity will result in a general increase in the cost of the entire system, caused by the use of more powerful electrical equipment, materials and fittings with a large allowable working pressure, wells, as well as increased cost of water treatment. If the nominal pump feed exceeds the flow rate of the well, additional "dry run" protection is required. Throttling and tuning of the pump will lead to a surplus of electricity. In other words, while ensuring the possibility of simultaneous use of all water pumping points by installing an overcharge pump, the cost of the water supply system increases. At the same time, real water consumption will be much less. Therefore, although the final choice will always remain for the customer, it is cheaper and more correct to choose a pump taking into account real needs and with the help of specialists. To meet the user's requirements for the water supply system, observing the rules for its installation and operation, it is possible by choosing the optimum pump in the given situation with a sloping operating characteristic. For the water supply system from the above example, the SP 8A-25 pump can be selected (Fig. In the zone of possible feeds (from 4 to 8 m3 / h) in this model, the curve of the dependence of the head on the flow rate has a gentle appearance, that is, at low water flow rates, there will not be too much pressure increase. At the same time, some allowable stock in the calculation of water consumption will eliminate the possibility of a shortage of water. Given all the data, you can pick up a suitable device for pumping water, but nobody can tell how to choose a submersible pump. When choosing a pumping equipment, please ask for a professional consultation with the managers of Gileks. We will help you make the right choice!

The pump is not selected correctly: the operating point is shifted to the right. Third, during the filling of the basin, the pump will operate on an "open pipe" without creating any pressure. Under these conditions, a large flow of water at a minimum pressure is observed. The operating point of the pump is displaced on the curve of the characteristic to the right, into an area not corresponding to the working area of the pump. The power on the shaft will be maximum, and if the engine is to run for a long time in this mode, the engine will fail. The use of a pump with an overestimated capacity will result in a general increase in the cost of the entire system, caused by the use of more powerful electrical equipment, materials and fittings with a large allowable working pressure, wells, as well as increased cost of water treatment. If the nominal pump feed exceeds the flow rate of the well, additional "dry run" protection is required. Throttling and tuning of the pump will lead to a surplus of electricity. In other words, while ensuring the possibility of simultaneous use of all water pumping points by installing an overcharge pump, the cost of the water supply system increases. At the same time, real water consumption will be much less. Therefore, although the final choice will always remain for the customer, it is cheaper and more correct to choose a pump taking into account real needs and with the help of specialists. To meet the user's requirements for the water supply system, observing the rules for its installation and operation, it is possible by choosing the optimum pump in the given situation with a sloping operating characteristic. For the water supply system from the above example, the SP 8A-25 pump can be selected (Fig. In the zone of possible feeds (from 4 to 8 m3 / h) in this model, the curve of the dependence of the head on the flow rate has a gentle appearance, that is, at low water flow rates, there will not be too much pressure increase. At the same time, some allowable stock in the calculation of water consumption will eliminate the possibility of a shortage of water. Given all the data, you can pick up a suitable device for pumping water, but nobody can tell how to choose a submersible pump. When choosing a pumping equipment, please ask for a professional consultation with the managers of Gileks. We will help you make the right choice!

In any case, whichever pump is selected, during installation it is necessary to check its operating point in all possible operating modes. When commissioning, the flow rate to be measured must be measured (determined by the filling rate of any capacity of a known volume - for example, a barrel), the pressure created (as indicated by the pressure gauge on the head) and the current consumed (measured by current clamps). The obtained characteristics are checked against the pump data by catalog. If the operating parameters are exceeded (as a rule, some reserve of power is provided, for example, for the subsequent installation of filters), it is necessary to cover the gate at the outlet of the well, to create additional local resistance sufficient to establish the correct operating point - the middle of the characteristic Q (H). and the selection of the pump must be carried out by trained specialists, the installation company must have a license to install this equipment.

Well pump protection

Even before selecting and purchasing a pump, you need to obtain accurate information about the power supply voltage at the facility. This is especially important when choosing an import pump. All equipment supplied from abroad corresponds, first of all, to the industrial standards of the producing country. Thus, for all German pumps, the permissible voltage deviation in electrical network of the nominal value is from +6 to -10%. Despite all built-in protection, the pump is not designed for operation from a network with voltages below 200 V, all possible drawdowns and voltage surges have a negative impact on the life of the motor. Here it is necessary to provide adjustable voltage protection in the control cabinet, and for three-phase pumps - also from incomplete operating modes. It is not recommended to install powerful single-phase pumps. The starting current of the motor with a power of 2.2 kW can exceed the nominal value by 4.4 times! To stabilize the voltage within the operating range, such a jump requires a stabilizer with a five-fold power reserve (more precisely, the manufacturers will make the choice of stabilizers). Sometimes it is cheaper for a user to provide 380V power supply at the site than the correct operation of a single-phase pump. According to statistics, about 85% of failures occur precisely with the electrical part of the pump. The main reason is the interturn closure of the stator windings due to overheating due to hydraulic overload, or when operating at a reduced or stepped voltage. Both can be avoided by establishing proper current protection. A conventional current-controlled starter is quite capable of this task, however some installers forget to make the adjustment to the required current value. The result of such negligence is easy to calculate: you have to pay for lifting the pump out of the well, repairing it (the price of a new engine), for re-lowering the pump and putting it into operation. The amount may exceed the cost of the new pump.

Even before selecting and purchasing a pump, you need to obtain accurate information about the power supply voltage at the facility. This is especially important when choosing an import pump. All equipment supplied from abroad corresponds, first of all, to the industrial standards of the producing country. Thus, for all German pumps, the permissible voltage deviation in electrical network of the nominal value is from +6 to -10%. Despite all built-in protection, the pump is not designed for operation from a network with voltages below 200 V, all possible drawdowns and voltage surges have a negative impact on the life of the motor. Here it is necessary to provide adjustable voltage protection in the control cabinet, and for three-phase pumps - also from incomplete operating modes. It is not recommended to install powerful single-phase pumps. The starting current of the motor with a power of 2.2 kW can exceed the nominal value by 4.4 times! To stabilize the voltage within the operating range, such a jump requires a stabilizer with a five-fold power reserve (more precisely, the manufacturers will make the choice of stabilizers). Sometimes it is cheaper for a user to provide 380V power supply at the site than the correct operation of a single-phase pump. According to statistics, about 85% of failures occur precisely with the electrical part of the pump. The main reason is the interturn closure of the stator windings due to overheating due to hydraulic overload, or when operating at a reduced or stepped voltage. Both can be avoided by establishing proper current protection. A conventional current-controlled starter is quite capable of this task, however some installers forget to make the adjustment to the required current value. The result of such negligence is easy to calculate: you have to pay for lifting the pump out of the well, repairing it (the price of a new engine), for re-lowering the pump and putting it into operation. The amount may exceed the cost of the new pump.

A modern country cottage can not be imagined without a convenient system of autonomous water supply. If there is a developed infrastructure nearby and it is possible to connect to the centralized water supply, then no questions arise. But what to do in the absence of it?

At the moment, the most popular are two systems of individual water supply: gravity and on the basis of a hydroaccumulator. In the first case, a metal or plastic container of large volume is installed in the attic space, into which water is pumped from the well or well.

This solution has two advantages:

- a large amount of stored water, depending on the capacity of the container, the debit of the water source and the reliability of the ceiling slabs (the weight of the container with water can reach several tons);

- the durability of the system, which is explained by the absence of wear components.

If we compare the number of advantages and disadvantages, then the gravity system can not be called the best choice and its use is limited. The main reasons for this are:

- low water pressure in the gravity system.

It follows from the laws of physics that in order to obtain a pressure of 1 atm. The container with water should be raised to a height of 10 meters. A lower height means less pressure, so it is easy to understand that under real conditions, the pressure rarely reaches even half of this, despite the fact that at least one atmosphere can be considered comfortable (depending on the person's preferences);

- the need to organize the heating of the tank. Otherwise, in winter, freezing of stored water is possible. This is easy to explain: a non-residential attic space is performed without heating, and in a residential (attic) capacity allocation is impractical;

- automation of the entire system is fraught with difficulties due to the lack of standardized automatic elements;

- the container requires periodic cleaning.

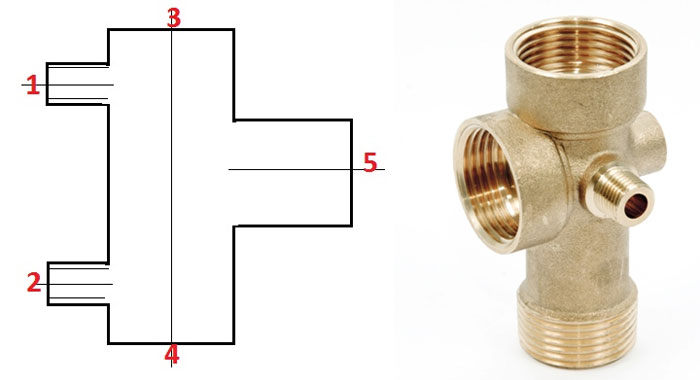

All these shortcomings are devoid of accumulator system. The accumulator is a metal tank, with a special rubber placed inside the "pear". The air is pumped into the gap formed by the walls of the tank and the "pear". When filling the "pear" with water, air is compressed and begins to exert pressure, the strength of which is directly dependent on the amount of water pumped. The pump is controlled by a mechanical pressure switch connected to the accumulator, and check valve does not allow water to flow back through the pump.

All these components are connected via a five-way choke:

1 - to connect a pressure gauge that allows you to estimate the pressure (the amount of water);

2 - a pressure switch is connected here;

3 - a branch in the domestic water supply system;

4 - water supply by a pump from a source;

5 - to connect the tank itself.

As you can see, despite the seeming complexity, in fact the whole design is very simple, and, therefore, reliable. The only thing that you do not need to save is the quality of the "pear". When choosing the volume of the accumulator, it is necessary to take into account the passport data of the pump used: they must correspond to each other, otherwise the pump simply does not have enough power to pump the tank to the desired pressure.

This is a compact product, you can install it even in the bathroom. Although its capacity is often inferior to the volume of the gravity of the gravity systems, however, fully automatic operation makes this distinction invisible. The pressure it creates is sufficient even for the operation of membrane filters drinking water (with the correct setting). The person is required to check the air pressure once a quarter and, if necessary, to pump it up: no cleaning, problems with freezing and excessive load on the floors. The advent of hydroaccumulators allowed a person to approach nature, giving the opportunity to equip a comfortable life away from cities with their centralized water supply systems.

Water supply at home every homeowner is concerned. And not only, of course, water supply, but also the entire communication infrastructure necessary for the normal functioning of an individual home. After all, two or three decades ago, living in a separate house was associated with a certain discomfort. And this discomfort was most determined by the lack of normal water supply.

Was seriously hampered as a total deficit necessary equipment, and a large number of insurmountable complexities of a purely legal nature. At that time all private (and, moreover, a private house) was considered a bourgeois excess and, to put it mildly, was not welcomed. So people had to live in the absence of a normal shower or bathroom, with a toilet behind the house and hand washing. Water - just buckets of a tap in the street or a well in the yard.

ஜ════════════════ஜ۩۞۩ஜ═════════════════ஜ

Our offers:

WAYS OF WATER SUPPLY SYSTEM INSTALLATION

Modern water supply of a dacha or a private house

Modern water supply of a dacha or a private house

Such a scheme is as follows

Heating water supply at home

Such a scheme is as follows

Heating water supply at home

For an apartment house, individual water supply can be carried out in two ways:

- connection to a centralized vodokanal,

- creation of a local system.

The first option is simpler and more reliable, but a significant disadvantage is the lack of such a water supply system near country houses. In a city with a water utility there are no problems, but in settlements such amenities are not available due to the high cost of communicating.

The lucky ones, whose dachas are located near the big city, can enjoy the benefits of civilization and connect to the water canal. But you still have to install a sewage system.

Central water supply

To join a house to a network of street water pipes, the developer needs get a special permit in the relevant organization. Most often, this is a management bureau of a water canal. Further, the conditions are known under which it will be possible to make the connection:

- indicated the place of connection;

- placing the nearest well;

- depth of pipe laying;

- the minimum head in the system.

Also in the specialized office you can get acquainted with the estimate for laying water communications. If the cost for you is too high, you can try to do the work yourself. In general, individual water supply implies the construction of a complex communication system, so it's better to weigh your strengths and capabilities before making a decision.

System accessories

The entire water supply system, when connected to a water canal, consists of three parts:

The entire water supply system, when connected to a water canal, consists of three parts:

- external input,

- pipelines,

- valve.

To lay a water pipe, it is necessary to use Zinc-plated, plastic, steel or cast-iron pipes . Water pipes it is necessary to cover with thermal insulation in order to prevent their freezing and deformation during the winter period.

The system must necessarily provide for certain points:

- the possibility of disconnecting the water pipe (a valve is used to shut off the water supply to the private system);

- the ability of the system, if necessary, to be emptied (complete grinding of water);

- the presence of a slope towards the well.

The second option

- Individual water supply can be carried out according to the second option: through local sources of water intake. If there is no running water in your private home and no one will build it in the near future, you should not despair. Many people, of course, use the antiquated methods with the use of wash-hand basins and similar units. But in our time this is not an option.

The water supply system from the local water intake consists of special facilities:

- wells;

- wells;

- captive chambers of spring water.

It also includes internal and external pipelines, a pump, a water tank or its hydropneumatic equivalent.

Step-by-step connection of the water supply system

Individual water supply commits create a sewage system and water supply. The first step is to install the pump on the water intake. From the electric pump, water must flow into a special storage tank. Further from it it is necessary to lay underground communications.

Individual water supply commits create a sewage system and water supply. The first step is to install the pump on the water intake. From the electric pump, water must flow into a special storage tank. Further from it it is necessary to lay underground communications.

The next step - in the house to the water supply and sewerage it is necessary to connect each point (cranes, washing machine, a dishwasher, a shower cubicle or a bathroom, a toilet, a washbasin).

Sewage communications consist of a pipeline leading to a sump. Further, after filtration and some purification, water enters the drain pit.

Probably, you have already thought about the fact that the municipal water supply sometimes brings a certain inconvenience to our life. For example, you wait for guests, cook, clean. It remains just a couple of hours. You need to wash the dishes, which remained from the preparation of dishes and, in fact, to wash yourself. And then ... turn off the water! Well, how can you not be angry, not angry and not nervous. But individual water supply does not have such shortcomings and will not give you an unpleasant surprise 5 minutes before an important event.

Of course, you can say that individual house water supply will cost you a decent amount. But this is only at first. And then, there are a lot of conveniences from using your own network. But from the communal water main is not always and not always possible. Experts of the company "Savard" qualitatively and quickly ready to arrange for you individual water supply at home. Our engineering organization employs professionals who will make your life truly comfortable!

Independent water supply of the cottage

Usually, independent water supply implies the organization of an independent resource for obtaining water. It can be a well or a well. In any of these cases, a cleaning system is indispensable. Only for the well this will be one system, and for quite another, because the water will come from different layers.

After the source is identified and even equipped, perform (pipes) to the object, without which individual cottage water supply will not be complete and will not be able to function. Pipes are brought to all premises where it is necessary to supply water, as well as to all users of water - household appliances and sanitary.

It is worth individual water supply system differently. This value depends on which source of water was used, what equipment was needed, and what elements were connected. In other words, individual water supply implies individual cost.

In our company, "Savard" accept orders for complex systems, which provide for the pipeline to a large number of water points, and simple, where the system is led to a bathroom, kitchen and washing machine. Any of the orders will be fulfilled on time and qualitatively. Call, if necessary and at any facility in Moscow, the suburbs!

Autonomous water supply in the cottage

Those who have already installed autonomous water supply, can easily tell you about all the benefits that you get with its arrangement. However, according to the individual scheme, it is possible not only the urban boundary, but also at the dacha, which is located in the outback of our region.

To individual water supply in the country was qualitative, it is necessary to take care not only about the organization of the source, but also about the quality internal network:

- interfamilage and external systems

- connection of pipes and meters

- hot water supply

- piping to water users

Managers consultants working for Savard will help you decide what type of water resource you need to equip, and what are the first steps to be taken in this direction. In addition, almost immediately you will know the cost of all the works. If you are interested in Moscow or Moscow region, call us, tell us the details of the object. We orient for the price!

How much does individual hot water supply

Our team builds individual hot water supply for residential and industrial buildings. The price is affected by the type of system and materials from which the water supply will be arranged. You can order from us by phone or through the order form on our website. "Savard" will hold correctly and inexpensively.