Vibrating pump forester repair. Dehumidification of flooded premises. Interesting video about pumps "Brook"

Pumps "Rucheyok" are very similar to the model "Kid," both in terms of use and characteristics. Both were developed in the USSR 40 years ago, for the needs of summer residents. But until now they are in high demand. The design of the pump is well thought out, the capacity is sufficient to meet the needs of a small family and watering the plot to 12 hundred parts. The pump rarely breaks, the service life is 8 years.

Technical characteristics of the pump "Rucheyok"

Energy consumption does not exceed 300 W, which is comparable to an aquarium pump filter of 500 liters. If you need it, you can run it from the battery. At a depth of 40 m, a capacity of 40 liters per hour, but with a surface fence (not more than 1.5 m) - 1500 liters per hour. The operating mode is 12 hours a day, the pump is transferring normally. This is due to the design features, excess heat is removed with the help of pumped water.

The scope of the pump is extensive - pumping water from wells, wells, ponds, basins, reservoirs and natural reservoirs.

Pump unit

When installing the "brook" fastenings are optional, in most cases it is enough to hang vertically on the rope. But you can not strictly hang the pump by the wire. During operation, vibration occurs, which will lead to damage to the wire. The body is made of metal and is well protected from damage, but for additional cushioning from above put rubber ring on. All parts of the device are easily replaceable.

Principle of operation

The magnetic field created by the electromagnetic voltage leads to a change in pressure and due to the oscillation of the diaphragm, the water is raised. Continuous non-stop operation is possible due to the absence of intrusive parts.

The magnetic field created by the electromagnetic voltage leads to a change in pressure and due to the oscillation of the diaphragm, the water is raised. Continuous non-stop operation is possible due to the absence of intrusive parts.

Application possibilities

The scope of the "Brook" is purely domestic. For industrial use, it takes power, the same applies to farms. If you have a large water flow, it is better to purchase a powerful pumping station. A pool of 100 cubes "Rucheyok" will fill in a week. Its main convenience in the possibility of using in shallow boreholes. Where a powerful pump empties it very quickly and turns off, the "streamlet" will work and pump up to 6 liters per minute. It is often possible to observe the increased capacity of the well by 30% after using the device.

Scope of application:

- Delivery of water from wells, wells.

- Delivery of water for irrigation system.

- Pumping water from reservoirs, pools.

- Filling the heating system.

"Rucheyok" is used for cleaning wells, thanks to vibration and suction of liquid this happens quickly.

Drainage water drainage

The pump was designed to pump out drinking water. But the situation is different and "Stream" was used as a drainage. There are special protective attachments for working in dirty water. When using the device for other purposes, its service life is significantly reduced. And getting into the mechanism of small stones and sand, guaranteed to disable it. Do not use for viscous liquids.

The designers laid enough power to calmly pump out melt water of medium pollution. But before such work, install an additional protective filter, it resembles a glass.

Modifications of protective housings there is a large number, but the most common is a rubber boot that is worn on a warm pump.

Design Features

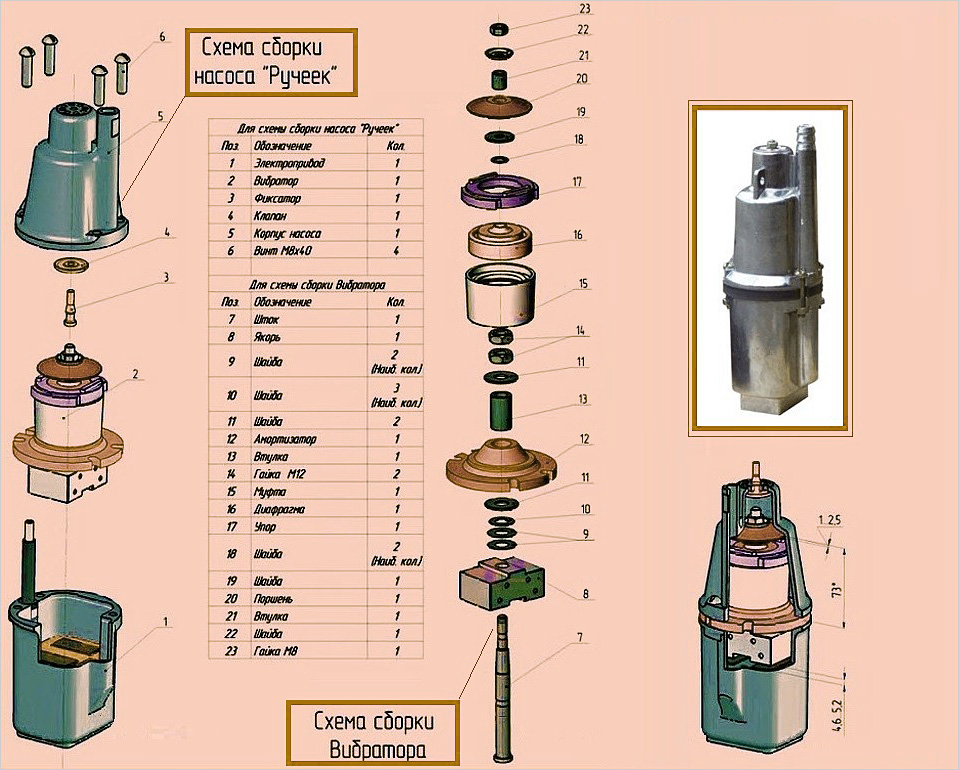

The design of the pump is very simple and consists of the following elements:

A constituent parts only two:

- Vibrator or mechanical. It includes a rod, an anchor and a shock absorber. The anchor is made of electrical steel and is filled with a steel rod. After the anchor is put on the shock absorber and fixed with nuts M12. Further, an aluminum clutch is located on which a rubber diaphragm is mounted, which is needed to separate the electrical and internal parts of the pump. On the upper part there is a rubber check valve, which protects the suction part of the pump from water ingress, with increasing pressure.

- Electrical. It contains an electromagnet, which is made of a U-shaped wire, and coils with copper wire with a diameter of 0.6 to 0.7 mm.

The core together with the coils are placed in an aluminum casing and fastened with epoxy resin. Pouring acts as a reliable means of fixing parts, and also effectively removes heat.

Connection sequence "Brook"

At the very beginning, a check valve is attached to the branch pipe. This will relieve you of the need to control the fullness of the well. The pipe will prevent water from draining when the pump is turned off. A cup-shaped filter is attached to the suction nozzle. This will protect the working chamber from flooding.

At the very beginning, a check valve is attached to the branch pipe. This will relieve you of the need to control the fullness of the well. The pipe will prevent water from draining when the pump is turned off. A cup-shaped filter is attached to the suction nozzle. This will protect the working chamber from flooding.

Pressure hose is attached to a reverse type valve. By the hose, the water enters the outlet tap. The second end of the hose is attached to the accumulator. For more secure fixation, attach them to the adapter.

The electrical cable and the pressure hose are fixed together with polymer clips or screeds. Using a wire will damage the hose. A polymer rope is attached to the hole in the upper part of the case, on which the pump will hang in the borehole.

After everything is collected, he slowly and accurately descends into the well. The entire weight of the device is held by a rope. Do not use the hose for lowering.

Features of repair

Because of the low cost of "Brook" many neglect the repair, and immediately buy a new device. Repair is simple, but the cost is low. So do not throw the broken pump, but hand it in the repair and buy a new one. So you will have 2 devices, which will ensure you an uninterrupted supply of water. If you have free time, then you can make repairs yourself, the design is very simple.

Disassembling the pump

The first thing you need to do is remove the bolts. They are rusty and sit tightly in the hull. If it did not turn out to unscrew the screwdriver, you need to cut off the head with a bulgarian. Use a small diameter disc to avoid damaging the motor accidentally. Do not forget to fix the pump in a vice.

Replacing the membrane

A common cause of pump failures is the release of their membrane construction as a result of foreign matter entry. On sale there are special repair kits. If you do not have spare valves and membranes at hand, they will be replaced by rubber caps from medications. This artisanal solution copes well with its task.

A common cause of pump failures is the release of their membrane construction as a result of foreign matter entry. On sale there are special repair kits. If you do not have spare valves and membranes at hand, they will be replaced by rubber caps from medications. This artisanal solution copes well with its task.

Replacement of winding

Without special engineering knowledge is indispensable, the best option - to pay for repair specialist.

Repair of the electromagnet surface

This damage is easily eliminated by an auto-sealer. With the help of the Bulgarian, apply a shallow groove, and then apply glue.

Price of the pump "Brook"

The price of the pump depends not only on the technical characteristics, but also on the producer's country:

- Power 225 W, able to lift water from 60 m - 2500 r.

- Power 280 W, able to lift water from 40 m-1600 r.

It is better to buy a more powerful model, the difference in price is not very large, but the characteristics of the winnings are obvious.

Pros and Cons of "Brook"

Pros:

- The reliability of the design is proven over the years.

- Simplicity, which allows to carry out uncomplicated repairs yourself.

- Unwillingness to working conditions.

- There is no need for additional fasteners.

- Low price.

Minuses:

- Low power.

- The thermostat operates with a delay.

- Deliver washing machine in one place, and the shower in another, does not work out.

When using a pump with a well, it is necessary to use cushioning, which will not allow the walls of the hull and borehole to touch. If this is not done, the pump is guaranteed to fail. "Brook" works on vibration and without damping it beats about the well.

Although it has been more than 40 years, but so far the design has not undergone significant changes, and the quality has remained high. This pump by the ratio of technical characteristics, prices and service life, there are no equal until now.

Most consumers, even from Soviet times, know such brands of submersible pumps for the well, like Rucheyek, Malysh and Aquarius.

The presented vibrating-type pumps of Rucheyk, Malysh and Aquarius brands for extraction of water from the well have excellent specifications.

Submersible pump type Brook, Toddler or Aquarius has been known for more than forty years due to its high quality and maximum usability.

1 Scope of application of pumps for a vibration well

Specifications vibrating pump Brook, Toddler and Aquarius to extract water from the well allow it to be used to solve most household tasks - such as pumping a flooded cellar or draining a ditch or a swimming pool.

It should be noted that the technical characteristics of the vibration pump Rucheyk, Malysh and Aquarius allow them to easily and without interruption to extract and subsequent water supply in the country or in a private house.

The possibilities of a vibrating pump A streamlet, baby or Aquarius is somewhat limited, because at the same time all tenants will not be able to wash, take shower and wash dishes - this simply does not have enough power of devices that are considered to be "summer cottages".

This is due to the fact that the downhole vibratory borehole pump A stream, a kid, or Aquarius can produce no more than seven liters of water per minute.

However, if you use a vibratory submersible borehole pump Baby, Creek or Aquarius is more local, then its automation can provide the consumer with sufficient water intake.

Characteristics of the water intake of pumps Brook, Toddler or Aquarius directly depend on the depth of the water resource used.

The higher this value, the better the submersible vibratory well pump will collect and pump water. It is also worth noting that repairing the water pump with your own hands can in most cases be made quite easily.

Like repair, the installation of the pump by one's own hands is also not very complicated. It is strongly discouraged to connect a pump with a lower fence at the same time to several sources of consumption - the unit's automation may not be able to withstand, and urgent repairs will be necessary.

1.1 Provision of water supply to the site

Pumping vibratory submersible unit with a lower water intake, installed on the dacha or vegetable garden with their own hands, can be actively used for water supply.

The fact is that the connection diagram of the unit, to ensure the irrigation of the site is extremely simple. Vibrating submersible pump with a lower fence is equipped with an outlet by a special crane, which serves to connect to the hose system.

1.2 Application in slow-filling sources

The presented vibrating pump is actively used for the creation of wells or wells. The fact is that after intensive operation of a well or well, it is not always possible to predict how soon the water level will recover.

It happens that a vibrating pump can pump water much faster than it can replenish. Typically, standard aggregates are automatically shut off when the water in the source is running out and the entire system needs to be restarted.

However, using the Trickle pump, you do not have to worry about such consequences, even when fetching from sources with a low and slow recovery level.

This is due to the fact that the intensity of the fence in the presented unit is significantly reduced, and the work is more stable. In addition, the repair of such a device can always be made independently and without much difficulty.

1.3 Rehabilitation of the affected well

With intermittent use, many wells are gradually washed away. This leads to a decrease in the water level. Vibration pump will help to repair such a well.

In order to carry out repairs of this kind, it is necessary to carefully lower the unit to a close distance to the filter and start it.

Due to the work of the vibrating mechanism, the solid layers gradually disappear from the filter, which subsequently leads to the correct operation of the well.

The pump can help in the event that as a result of spring floods the cellar in the country house or the inspection pit in the garage will be flooded. In most cases, drainage water is fairly clean, so there is practically no difficulty with pumping.

1.4 Filling the new heating system

Sometimes, when building private houses, the heating system is built earlier than the house is connected to the centralized highway.

In such cases pipes need to be filled with something. A hose connected to the pump is withdrawn from the reservoir with water. The second challenge is connected to drain cock radiator batteries. The crane opens and starts the unit. Thus, the system is being filled.

2 Principle of operation and technical characteristics of the device

The presented pump consists of several basic parts. It:

- Electromagnet;

- U-shaped core;

- Vibrator;

- Housing.

Knowing how the unit works, you can easily repair it yourself.The core, equipped with coils, is mounted in the housing, and is subsequently filled with an epoxy compound.

This allows the coils and core inside the case to be fixed with a high degree of strength. The vibrator is presented in the form of an anchor, in which the rod is pressed.

The stem is equipped with a rubber spring, which performs a damping function. The end of the rod is equipped with a rubber piston. Between the body of the device and the valve there is a gap equal to 0,6-0,8 mm.

Due to its presence, the liquid can flow freely even if there is no pressure. When the unit is connected to the mains, the armature is pulled to the magnet.

In the process of magnet reversal of the poles during each half-period of the shock absorber, they initiate a reverse throw of the armature. This leads to the fact that the piston of the device is able to vibrate at a frequency of 100 times per second.

During operation, the valve is able to significantly limit the injection of water and delay its exit through the suction holes. Depending on the particular modification of the unit, it may have slightly different characteristics, so you can get acquainted with them using the example of averaged data:

- Power consumption: 220 to 300 W;

- Power supply: 220 V (household network with alternating current);

- Maximum head: 40-60 m;

- Productivity: 430 l / h at a depth of 40 m;

- Hose diameter: 18-22 mm;

- Current frequency; 50 Hz;

- The length of the power cable: 10-40 m;

- Unit weight: 4-5 kg.

2.1 Types of pumps

The presented units are manufactured with orientation to several types of execution:

- Baby, Baby K and Brook - are equipped with suction holes located from the bottom;

- Kid M - differ in the upper location of the suction holes;

- Kid 3 and Aquarius - is actively used in three-inch wells with a casing of 80 mm in diameter.

Those modifications that differ in the lower location of the suction holes, it is recommended to buy in a complete set with a thermal relay.

Units equipped with a lower fence are capable of pumping water even from the smallest reservoirs. All units are additionally equipped with a cable made with the use of capron.

Thanks to him, you can repair the device and fix it. The cable made of capron is not electrically conductive, therefore at installation or damage of insulation of a power cable the unit can be pulled out, using a cable.

2.2 Faults and repairs

Repair of the unit may be required in the event that a depressurization occurs. The point is that when conducting water from a well or a well, care must be taken to ensure that the body of the device does not come into contact with the walls.

Otherwise, the vibrating unit receives a whole series of strong impacts. In a minute there will be about a hundred. The body of the unit is not able to withstand such a level of load, and as a result of this, the casting peels off from the surface of the magnet that is inside.

The same can happen if the device is launched "on dry", without water in the system. In order to make repairs, you need to get the whole electrical part out of the case, and then a magnet. Through the entire area of the magnet, make small incisions and then carefully lubricate the sealant.

In the event that the drainage water is pumped, care must be taken to ensure that small pebbles or large sand do not get inside.

Otherwise it will be necessary to replace the failed cleaning filter. To delay this moment, you need to apply an additional filter.

It is pulled on the suction pipe in preheated form. In addition, when small stones and sand fall, there is rapid wear and deletion of the rubber valve.

If a foreign object enters the valve, then, during operation of the unit, it can break into small parts. In this case, the repair is quite easy. The valve can be temporarily replaced with a stopper from a medical bottle.

2.3 Pump connection sequence

First, an attachment is made to the pump connection check valve. Subsequently, this device can relieve the user of the well from constant monitoring of the state of filling the working well.

The installed device effectively prevents unauthorized drainage of water, which can occur after the unit is turned off.

A pressure hose is attached to the reverse-type valve. At the same time, the water from the well comes up the hose to the outlet valve through the hose.

The second free end of the hose is attached to the accumulator. It is possible to make an attachment to the inside of the adapter.

With its help it is possible to arrange the withdrawal of the main from the well. The connection of the electrical power cable with the pressure hose is made with the participation of polymer ties or clips.

The use of wire in this situation is extremely contraindicated - it can squeeze the hose and damage it, which will lead to water supply disruption.

In the holes of the brackets, which are in the upper part of the case, the polymer rope is inserted into the unit, on which the device will subsequently hang in the well.

The whole structure slowly and accurately falls into the borehole. The pump is only supported by the use of a rope. It is not recommended to lower, using a bundle of cable and hose.

Before the rope can be lowered into the borehole, the rope can be connected to the main bunch with the already used screeds. After the unit is submerged in the well and the ligaments are disconnected, a test run is made.

2.4 Nuances of using the pump Brook (video)

If you take at random a dozen suburban areas, at least one of them will have a water pump Brook. This relatively small device has been successfully used for decades for the entire territory of Russia, near, and in some places far abroad. With proper treatment, this indefatigable toiler will be beneficial in the home and on the site for many years.

Pump "Brook" - one of the most popular pumps of vibration type. The central part of the construction of this unit is the membrane. When the pump is turned on, it is attracted and repelled by the electromagnetic coil built into the pump. Vibrational movements of the membrane create a pressure difference in the pump body, which allows you to move the water to a sufficiently high altitude.

"Brook" is a submersible pump, i.e. to work it must be lowered on the cable in the water. The device is relatively small, weighing only 4 kg. The performance of the standard model is usually estimated at 450 l / h. Technically the pump is designed for pumping clean water, so the product warranty does not apply to breakdowns caused by work in difficult conditions.

The "Brook" pump has compact dimensions, low weight and capacity, which is able to provide one or two points of water intake simultaneously

A special rubber ring is mounted across the rugged metal pump casing. It protects casing wells from impacts during the immersion or excavation of the device. To hang the pump, you can use a kapron cord or a sufficiently strong twine, since the weight of the unit is small. Of course, it is necessary to fix the cable securely on the string so that it does not fall into the borehole.

Modern models of the pump "Brook" are equipped with a special sensor. It detects the temperature of the device, and turns off the device when it reaches critical values. Most often, such situations arise if, for some reason, the pump is outside the water column. Protection from the so-called "dry running" prevents equipment breakdown and prolongs its useful life.

Image Gallery

The water temperature that such a pump can pump must not exceed 35 degrees. To work with seawater "The brook is not intended. The pump capacity of the "Brook" is 150-270 W, so its operation will not greatly increase the total cost of electricity. The maximum immersion depth of the pump is 40-60 m. It should be remembered that the deeper the pump is suspended, the lower its productivity.

If the pump is submerged only one meter or less, it can pump water at a speed of 1500 l / h. But usually with the help of "Brook" from the well or well it is possible to get about 7 l / min. This is a very modest figure. Residents of the house will have to include water withdrawal points in turn: first wash the dishes, then take a shower, then turn on the washing machine. For all the needs at once productivity "Brook" may not be enough.

Connection and operating instructions

Before installing the pump "Brook" in the well or borehole, a number of preparatory measures should be performed. To begin with, determine exactly at what depth the pump will be suspended. It should be stocked with a cord or rope of suitable length and provide a place for fixing the cable during operation of the pump.

Each pump "Brook" is completed with a technical passport. Before starting the installation of the device, the manufacturer's recommendations should be carefully studied and applied

The cord should be strong enough to withstand the load, five times the weight of suspended equipment. In the case of "Brook" it is about twenty kilograms. Do not neglect this moment, because a pump that has fallen into the well can become a real disaster. And from the well to get the broken equipment - not the greatest pleasure.

It is not recommended to suspend the vibration technique on a metal cable, since such structures do not fit well with the vibrational effect that arises during the operation of the unit. To partially extinguish vibration, the pump is attached to a cord on a suspension bracket of strong and elastic rubber, which also needs to be stocked in advance.

To suspend the pump "Brook" should use a strong kapron cord, withstands five times the load. If the length of the complete cord is not enough, you need to buy a new one, the extension of the cord is unacceptable

Another necessary element is a hose, through which water will flow upward. Its length should correspond to the depth of immersion of the pump, and the diameter of the hose should approach the nozzle of the pump. However, there are adapters that allow you to fix a hose of a larger or smaller diameter on the branch pipe. The end of the hose on the spigot or on the adapter should be fixed with a clamp, unless other ways of fastening are provided.

If the use of a hose is for some reason undesirable or inconvenient, you can use a flexible water pipe from plastic. It must also be securely fastened to the spigot with a clamp. If all materials are prepared and the nuances are taken into account, you can start installing the pump. For this, you need to perform a number of simple steps:

- Unpack the pump "Brook", straighten the electrical cable.

- Attach a nylon cord with a rubber adapter to its eyelet.

- Attach a hose or water supply pipe to the pump outlet.

- Put a special protective filter on the water intake hole.

- Carefully and smoothly lower the pump into the well or borehole.

- Secure the nylon cord.

- Connect the pump to the power supply.

- Press the power button and check the operation of the device.

When buying a pump "Brook" should immediately specify the length of the cable, which is completed with the product. The standard model can be equipped with a cable length of 10, 15, 25 or 40 m, this affects the cost of the device. If the length of the wire is not enough, the problem can be solved in one of two ways.

The length of the pump cable "Brook" can be 10, 15, 25 or 40 meters. It is best to immediately purchase a device with a cable of sufficient length

The first is to completely replace the pump cable with a new wire of suitable length. To perform this operation, the pump must be disassembled, and then reassembled. Sometimes it is easier to increase the cable, i.e. just attach a sufficiently long piece to the already existing wire.

The connection point of the cables should be carefully insulated and protected with a special shrink sleeve. A complete replacement of the cable is more reliable, since a part of the wire immersed in water remains intact. But building up the cable is a less time-consuming procedure. After the pump is lowered into the water, inspect the system and make sure that the load falls on the kapron cord, not the cable or hose.

If you decide to increase electrical cable pump "Brook", you should use a special shrink sleeve to protect the junction

Both the cable and the hose should hang freely, remaining in an unstrung state. However, excessive sagging of the cable should not be tolerated, as it may become entangled in the process of lowering-lifting the pump, and this will create additional problems. Proper Use pump allows you to extend the period of its operation and trouble-free operation. The manufacturer indicates the time of continuous operation of the pump no more than 12 hours.

This diagram clearly shows the order of installation of the pump type "Brook", depending on the model, which can be with the lower or with the upper water intake

After this, the appliance should be switched off to cool down. Manufacturers also recommend that they take small breaks every two hours of operation. Such a gentle mode of operation will positively affect the resource of the device. When suspending the device, remember that it should be located approximately 0.5-1 meter from the sandy bottom, otherwise it can simply be tightened into sand or a layer of silt.

Advantages and disadvantages

The popularity of the submersible pump "Brook" is explained simply: at a relatively low price, this device has a fairly high quality. But this is not his only dignity. "Brook" is extremely simple in operation. It needs to be customized in any way, just press the power button and it will start working.

This diagram shows the components of the pump "Brook". In the event of a breakdown, the device is not difficult to disassemble and repair

The simple design of the pump ensures its exceptional maintainability. In the event of a breakdown, the pump is not difficult to disassemble, repair or replace the damaged nodes, and then reassemble. All components necessary for repair are usually available for free sale. The next "plus" of this pump is a wide range of tasks that can be solved with its help.

"Brook" swings not only clean water, but also some contaminated liquids, although this also shortens its service life. The disadvantages of the pump "Brook" can be attributed to the nature of his work. Continuous vibration effects can adversely affect the state of the filter well. Vibrations destroy the layer of sand, which increases the speed of filling the well and can completely disable the structure.

Deep well, extracting water from fissured limestone, vibration is not terrible, but "Brook" is not designed to digest water from such a large depth. Thus, pumps of this type are not suitable for permanent operation in wells on sand. However, to draw water from the well, such equipment can become a real find.

"Brook" for all occasions

Relatively shallow well with low production rate or a well with similar characteristics is best equipped with a pump "Brook" or other budget model. More powerful and expensive equipment is simply not necessary. It will empty the well too quickly, the danger of a "dry run" in this situation is very high.

In the product data sheet it is said that the pump is designed only for digestion of clean water. However, during the decades of the model's existence, the owners of private houses and suburban areas have found this device the most diverse application. For example, this model is widely used in the pumping of filter wells.

This table shows the main characteristics of the pump "Brook", thanks to which this unit is able to cope with the solution of many economic problems

After the completion of drilling of such structures, the water remains heavily soiled with particles of silt, sand, etc. To obtain a potable, clean water, this mixture must be performed. Practice has shown that the "Brook" is doing a very good job of this task. The peculiarity of the pump device of the Brook consists in the fact that there are no rotating parts in it. Therefore, it is not too quickly clogged when working in contaminated water.

Periodically, the pump is removed, disassembled, washed, perform necessary repairs, and then again collected and allowed into the case. Of course, with this treatment, the rate of wear substantially increases. It is not surprising that in the process of pumping a well, the pump can completely fail.

To clean one well, depending on the situation, two or even three or four such units may be needed. But for money it goes much cheaper than buying special equipment with increased resistance to wear. Inexperienced site owners sometimes believe that a well can be pumped through a pump that will supply water to the house water supply. This is absolutely wrong decision.

Owners of wells and wells periodically have to clear their structures. In these cases, a pump of this type is indispensable. It will effectively cope with pumping contaminated water from a well or well. If the pump is at hand, all work will be done much faster. If the well is silted or sealed, the vibrations arising from the operation of the Brook are transformed from an enemy into a friend.

This looks like the pump "Brook" in disassembled form. Durable steel case protects the device from external influences and frequent breakdowns

Qualitative and expensive submersible pumps are usually designed for a long time with clean water. Pumping abundantly contaminated with sand water is better with the help of "Brook" or other budgetary equipment. If, after pumping a well, some "Brook" managed to "survive", it will certainly find further application.

Vibrating action allows you to quickly and efficiently destroy the sludge plug, clean the holes of the borehole filter and pump out dirt on the surface. As a result, the well production rate will increase significantly. It is recommended to use the model with the upper water intake for cleaning the silted wells.

Image Gallery

![]()

The "Brook" in the shed will be a real find if the main pump in the well or well is broken for some reason. It will become an acceptable temporary replacement, allowing in a few hours to restore the water supply in the house. While repairing the main pump, you will not have to purchase or rent new equipment.

Underflooding the drainage waters of the basement, the observation pit in the garage or other such deepening - the situation is unpleasant. And to take out unnecessary liquid with a bucket, it will take a lot of time and effort. Since drainage water usually does not contain a lot of contaminants, the pump "Brook" is ideal for pumping them.

Of course, it works slowly, but it is stable. Expect from the drainage water of perfect purity, of course, is not necessary. To improve the pump, it is recommended to use a special additional filter, which will protect the structure from contamination. The filter is in the form of a cap and is designed for the upper part of the pump. To wear it, it is recommended to warm this element first. Then the filter will be installed much faster and easier.

If the house has a swimming pool or another large tank of water, the "Brook" pump can be used to pump water out of such containers. In this case, it makes sense to use the "Brook-1M" model. Unlike other models, it is equipped with a lower water intake, which allows to remove water from the reservoir completely.

Use pumps such as "Brook" and when installing heating systems, namely - for crimping, when it is required to fill the system with water. Water can be taken from a well or brought in a separate barrel. On the intake port of the pump put the hose and lower it into the water. The second hose, which is put on the pump inlet pipe, is connected to the open drain cock of the heating system.

The pressure in the system is monitored using a manometer. After crimping, eliminate the identified malfunctions. In general, it can be said that pumps like "Brook" can be used to solve almost any task of pumping liquid or pumping it to the destination. The main requirement is that the water should not be too dirty.

Models and Analogues

Three models of such a pump can be found on the market: "Rucheyk" (produced by OAO "Livgidromash", Russia), "Rucheyk-1" and "Rucheyk-1M" (produced by Technopribor, Belarus). By design, they are very similar, but there are some differences. So, the model "Brook-1" is equipped with an upper water intake system, which allows you to get the most pure drinking water.

But the "Brook-1M" hole for water intake is located below. With the help of this model, it is more convenient to pump out water from tanks, which need to be completely emptied. Since in the models "Brook" and "Brook-1" water is taken from above, the structure itself serves as a reliable protection against overheating.

Water entering the pump housing simultaneously cools the engine. During testing it was confirmed that devices of this type can withstand the "dry running" regime for seven hours. In this case, the windings of the electric motor do not burn. Not all pumps, even more expensive and productive, boast such a level of stability. If the pump is operated for a long time without water, many other models simply burn out the motor.

The Omnigena-Dorota pump is a worthy analogue of the Brook, developed and produced in Poland. High quality and good performance

Among a similar "Brook" pumping technology it is impossible not to recall the pump "Kid". He is very close to the "Brook" and the technical characteristics, and the quality of performance, and maintainability. This equipment is produced by the Bavlensky plant "Electromotor", and also by the AEK "Dynamo" (Moscow). Some indicators for "Baby" is slightly better, but the price is slightly higher than that of "Brook".

Among the lesser known analogs, it is worth mentioning UNIPUMP BAVLENEC - a Russian brand, which is produced in China. The study of the technical characteristics of the unit shows that it differs little from the more famous "Brook". The price characteristics of these pumps also almost coincide. The price of the same pump can vary depending on the length of the cable.

An interesting alternative could be Omnigena-Dorota, a submersible vibrating pump manufactured in Poland. The principle of its operation and the device is not much different from the pump "Brook". Is that the aluminum case is a little shorter, and the weight of the pump is slightly smaller. The power of the model is 300 W, and it can be immersed for 50 m. Reviews about the quality of the Polish pump are quite satisfactory.

Interesting video about pumps "Brook"

Visual information about the use of the pump "Brook" is contained in the following video:

Here you can see a practical example of the pump of this brand:

The pump "Brook" is an indefatigable toiler and faithful helper for all owners of dachas and private plots. Of course, its performance is not too great, and it is not designed to solve global cleaning tasks. But where it is necessary to pump water or to clean the well, "Brook" can be the best option.

In order to obtain small and stable volumes of water in countryside (a private house, dacha), many owners use a water pump Brook. Basically it is used as a pump for a well, but it can be used in wells or open reservoirs.

Due to the simplicity of design and low cost, the Brooks pumps have become very popular and have been successfully used for more than forty years.

1 Pump characteristics

Technical characteristics and basic parameters of the vibrating pump The brook is described by several points:

- submersible pump with upper or lower water intake;

- working depth up to 40 m;

- the capacity is about 450 liters per hour;

- power supply from the household 220 V;

- power consumption 270 W;

- weight - 4 kg.

Such characteristics of the pump Brook not very impressive, but to meet the needs for water in a small farm - it is quite acceptable.

1.1 Principle of operation

Vibratory submersible pump The trickle has a diaphragm, the vibration of which creates a pressure difference inside the casing. The flow of water is formed by the intake valve, which alternately is in the closed or open position.

Such a vibro pump does not require constant maintenance, since the diaphragm is driven by an electrical coil, which creates an electromagnetic field. The absence of rotating parts, bearings, complex kinematic schemes does not allow critical wear of parts, so breakages practically do not occur.

1.2 Description of models

Despite the simplicity of the design, the water pumps of the Brook are of several modifications:

- B-10, B-15, B-25, B-40;

- H-10, H-15, H-25, H-40.

The difference in the models lies in the location of the working valve for the upper (B) or lower (H) water intake. The figure after the index indicates the technical characteristics that allow the device to operate at different depths from 10 to 40 meters. Any submersible pump works normally, provided that its housing is completely in the water.

Since some wells have limited water filling with intensive pumping, all devices are equipped with a protective relay that turns off the pump in the event of drainage of the source. This avoids overheating when working in a dry environment.

2 Scope of application

Technical characteristics, which the deep electric pump of the Creek possesses, allow its use in several directions. As a rule - only in one of the below listed items, due to the fact that the performance of such a device is designed exclusively for small volumes of pumped water.

2.1 Water in the house

Customer feedback indicates that it will not be possible to meet all the needs of household water consumption without an additional installed storage tank. With direct feed, one pump is able to pump not more than seven liters of water per minute, and this is not enough for a system in which several consumers are included.

To get water in full consumption, you need to install accumulation tank (which is periodically filled) or use a more efficient pump.

2.2 Watering

Provide garden and garden plots with water, using irrigation system built on the Brook base, it is quite possible, because its technical characteristics allow it to be done. In this case, the volume of pumped water is not large, and the device works only a few hours.

2.3 Emergency use

Many diligent owners set up an alternative device for water supply in parallel with the main one. For several reasons:

- to secure in case of breakdown of the main equipment;

- with a decrease in water consumption;

- to save electricity;

- when the source is depleted.

If the main pump fails, it takes several days to dismantle, repair and reinstall it. During this period, a pre-installed emergency pump will operate, which will ensure the supply of water in the minimum amount necessary. In the case of reduced consumption, the backup device comes back to the rescue. If there is no need for large volumes of water, it is logical to use a low-power alternative device.

With a full load of pumping water with a powerful pump, high energy costs are inevitable. In any economy, there are peaks of maximum and minimum consumption, so it is rational to use two devices with different power consumption. With this approach, significant savings in the form of fees for electricity and the lack of frequent repairs of major equipment.

Each well (well) has its own resource by volume and filling. With intensive pumping out of water, a situation may arise with complete drainage of the source, and this is not acceptable for the operation of submersible pumps. If the water level is restored slowly, a device with a small amount of water intake should be used, which will allow the source to recover much faster.

2.4. Cleaning (restoration) of wells

With irregular pumping of water from the well, there is a high probability of its washing out. In this case, the level of clean water becomes very low, and its accumulation is too slow, which does not allow the use of a powerful submersible pump.

Increase the water potential of the well with the help of Brook.

2.5. Dehumidification of flooded premises

Under adverse weather conditions (frequent rains) or during floods (during spring melting of snow), groundwaters can fill the cellars, cellars, inspection pits. To remove water manually using buckets is a tedious, time consuming and time consuming task.

With such a disaster, it's easy to cope, installed in a flooded space, the Trickle pump. Usually ground water, in a stagnant state, is of sufficient purity for safe pumping with a submersible pump.

2.6 Filling of heating systems

When the construction of a private house is completed, there are situations when everything is ready, except for centralized connection to heating or water supply networks. In the cold season this is a problem, as the heating system is not filled with water. Start heating system you can use Brook. To do this, it is necessary to deliver the capacity of the required volume with water to the yard and then pump it directly into the heating system.

2.7 Breakage and repair

The main reason for the failure of the device is the depressurization of the enclosure. If the installation is unsuccessful, in contact with the walls of the well (well), the operating pump receives shocks during vibration.

This leads to a gradual leakage and the closure of the electrically conductive elements. In addition to damage associated with physical impact, it may cause a malfunction from excessive heat. Overheating of the pump is possible when working on a dry and faulty thermal relay.

Stopping the pump is also due to the ingress of large solid particles inside. Small stones or coarse sand destroy the intake valve, since it is made of rubber. To prevent such a breakdown, knowledgeable people recommend placing the device in a strainer in the form of a glass that covers the entire body of the device. You can also use a filter-attachment in the form of a hood, which is worn on the intake (intake) part of the pump.

Independently to restore tightness of the case, it is possible applying glue sealant, which is designed for fastening of glasses in modern cars. The valve destroyed by solids is easily replaced by a rubber stopper from a medical bottle.

2.8 Some peculiarities of using the Trickle pump (video)

Pumps "Brook" and similar in purpose and technical characteristics "Baby" were developed in the old Soviet times, about 40 years ago, for the needs of summer residents and are still in good demand.

Pump quality, not expensive, enough power for the needs of a small family and delivery of water for irrigation in the area of 6-12 acres.

Breakages are rare, repairs are simple, spare parts are available and cheap. Average service life 5-8 years.

Submersible vibrating pumps for delivery of water from a well with a width of more than 100 mm and a depth of up to 40 meters. Some modifications have been developed for wells with a depth of 60 m.

The weight of the pump without wires and hose is about 4 kg, the intake of the device "Rucheyk" is upper, which prevents dirt and sand from entering the water intake.

Technical characteristics of the pump "Brook"

Power consumption is only 220 - 300 watts, which is comparable to the pump-filter of the aquarium for 300-500 liters, or with the work of the average computer. If necessary, it can easily be powered even from a battery or generator. Powered by household electricity, 220 volts.

The power at the depth of the well up to 40 meters is about 40 liters per hour, with a surface water intake (depth less than 1.5 meters) to 1.5 cubic meters per hour.

The possibility of long-term work is envisaged and widely practiced, up to 12 hours. The design features and the upper water intake ensure efficient heat removal from the working electrical part.

In accordance with the instruction, it is desirable to disconnect the device every 2 hours for about 15 minutes.

This practice will extend the life of the engine. In practice, very few people do so. Most have a spare pump.

The device can be used universally and equally effectively for pumping water from wells and wells, as well as natural reservoirs and reservoirs, pools and ponds.

Fastening of the pump in most cases is not required. The device is suspended vertically using a cable.

The hermetic metal case is strong. To protect against contact with the walls of the well, an additional rubber ring is added to it as a shock absorber.

All nodes of the device are replaceable.

Principle of operation of the vibrating pump

Electromagnetic voltage creates a magnetic field, causing a change in pressure inside the device. Fluctuations in the diaphragm provide a rise in water under pressure.

Vibratory submersible pump - operating principle

Absence of rubbing, rotating parts, ensure a long and trouble-free operation.

Capabilities

Features of the water pump The trickle is limited to the sphere of household use.In industrial needs, it is not used because of low power and insufficient water.

In farms, more powerful devices with storage tanks are used.

If the water consumption of the family is significant, it is better to purchase a serious pumping station. Because the pool for 100 cubes "Brook" will pump up about a week.

The convenience of using the "brook" is that it can be used in wells with low power. Where a more powerful pump will empty the well and go to idle operation or turn off, if the thermal protection is triggered, the "trickle" will continue to pump the well at a rate of 5-7 liters per minute.

Quite often, as a result of the use of the "brook", the capacity of the well increases by 30-50%.

Application area

- Delivery of drinking water from the well;

- Delivery of water for irrigation;

- Filling of heating systems;

- Pumping water from pools and reservoirs.

The pump "Brook" is used for cleaning silted boreholes. Due to vibration during water intake and effective suction of liquids, there is a fairly fast cleaning of wells.

Use for pumping drainage water

The pump is designed for pumping clean water for drinking needs. However, the situation at the dacha is all sorts and therefore there are data on the use of "Brook" as a drainage device.

Special devices are also available to protect the pump when operating in polluted waters.

Use "Brook" as a drainage device

It is important to understand that misuse of machinery always leads to a shortened service life.

Getting into the mechanism of sand and small stones is guaranteed to lead to a malfunction of the pump. Its use in viscous liquids is excluded.

Surprisingly, the capacity and reliability of the device "Brook" is quite enough even for pumping drainage, meltwater and flooding of average pollution. The only thing to worry about is the purchase of an additional safety filter, into which the pump is plunged, both into a glass.

There are various modifications of protective covers, the most common are synthetic rubber covers that need to be pulled on a preheated pump.

Features of repair

At low cost, repair is often neglected, simply by purchasing a new one. But this is not entirely correct.

The device in most cases is excellently repaired and the cost is low.

Therefore, a logical decision will be to purchase a new pump, giving the old one for repair. You will have two working devices, which guarantees uninterrupted supply of water in case one of the devices fails.

Since the device of the device is simple, you can repair the trickle pump yourself, replacing a pair of gaskets or clear important parts of the device from sand and dirt.

Difficulty disassembling

The first difficulties arise when trying to disassemble the device. The fixing bolts on the body are covered with a dense layer of rust until it is completely impossible to untwist them with a screwdriver.

Do not attempt to unscrew the rusty bolts. It is recommended to cut the head of the fasteners gently with a bulgarian.

Internal device of the pump - motor

To avoid damage to the motor during this procedure, use a small diameter disc, and always fix the pump in a vice. At its fastening it is convenient to use dense rubber linings or a shock-absorbing rubber band.

Worn membrane

Rubber elements of the pump can fail due to wear or foreign objects. There are special repair kits that should be used in such cases, replacing the failed valves and membranes as needed.

Alternative use of rubber caps from medical vesicles. Rubber pharmacy caps successfully replace the failed valve of this pump. Tested by practice.

Winding Repair

Winding the electromagnet can cause a malfunction of the device. If you do not have an engineering specialty, it is better to give the device for repair to restore the winding.

Damage to the filling of an electromagnet

Such malfunctions are eliminated by auto-sealing.

Such malfunctions are eliminated by auto-sealing.

Instructions for pouring is extremely simple.

On the surface of the electromagnet, a shallow groove is cut using a grinder for better fixing.

Then glue is applied to the product.

Interesting about. Pristenny drainage, with a blind area and a variety of options for placing a storm shower.

About the technical characteristics of the pump baby read in the article.

And here everything is about a submersible pump for a well with automation, installation and tying automation.

Advantages and disadvantages

As for the advantages and so everything is clear, they are obvious. Reliable pump, thoughtful and simple design, the ability to work in wells, Soviet unpretentiousness to working conditions, no need for fastening, general reliability. The undoubted advantage is the low price.

Now about the shortcomings.

Insufficient water supply. Using a water pump "trickle", it is impossible to build a full-fledged water supply system. The power of the device is not enough. The water tank installed in the attic will fill slowly. Therefore, many users use a storage water tank - a cistern, located near the well.

Arrange a shower in one place and install a washing machine at the other end of the house will not work. Possible outage of equipment.

The pump thermostat does not always work quickly.

Destruction of the wells and breakdown of the motor, abrasion of the shell.

Many know the healing effect of pumps "Brook" on the wells. But not everyone understands the rules of safety.

The immersion of the vibrating pump into the well without damping, which does not allow contact with the walls of the borehole with the housing, is guaranteed to lead to the failure of the device and, in some cases, to the destruction of the well.

Vibration pump is called, because it sucks in water with the help of strong vibration. And without a shock absorber, it will be hit in the wall of the well with considerable force. Of course, this will lead to destruction.

In general, it is intended for people with an engineering mind and knowledge of technology.