Repair and installation of hydraulics. Repair of hydraulic systems, as well as their components

Our company offers every customer a qualitative diagnosis and repair of hydraulics of special equipment. Works of any complexity are realized. We work with professional and specific equipment. The company "Hydrotema" is located in Moscow, and the production base in Ivanteyevka, so it is available to every major industrial enterprise. In the process of using high-quality and original spare parts, combined with a variety of metal alloys. The parts are selected in accordance with the manufacturer and the specific features of the specific machinery.

Technology of repair work

Repair is carried out in the following sequence:

- it determines what is the cause of the breakdown, so it is carefully considered, and if necessary, all the details of the equipment are diagnosed;

- the hydraulic cylinders from special equipment are being disassembled, which will provide an opportunity for repair or replacement of rods and sleeves;

- all available seals, pistons, axle boxes, eyelets, bushings, etc .;

- machining of all parts is carried out;

- after carrying out work, crimping is carried out, and further - testing, determining the operability of special equipment.

Nuances of work

The hydraulics of tractors, excavators or other types of equipment is rather complicated, so trusting such repairs follows the exclusively proven organizations that have long functioned on the market and offer high-quality services with the use of suitable tools.

Special equipment is intended for carrying out the most complicated works in the field of construction, road works or in different directions of industry. It is formed with the use of strong, highly reliable and resistant to various factors of materials. However, if improperly used or overloaded, serious damage can be expected. To prevent them, it is recommended to carry out scheduled maintenance at regular intervals in order to avoid possible failure of different parts of the equipment.

Our company offers repair and maintenance of special equipment.

If the hydraulics of a tractor or any other type of special machinery is out of order, please contact our organization immediately, since we offer an excellent result repair work, reasonable prices and warranty.

How is the hydraulic excavator repair carried out?

One of the most popular and necessary types of equipment for construction and other complex works is an excavator. It is produced by many large industrial organizations. Their service life is significant, but only if the operation takes place under acceptable conditions and at optimum loads. Also, planned maintenance is routinely carried out, which is recognized to prevent possible violations and breakdowns of equipment.

Repair of hydraulic cylinders of excavators is carried out only after diagnostics and defects. They consist in the following actions:

- in the joints of the hydraulic cylinders of the boom, bucket or handle, the backlashes are measured;

- calculates the hydraulics of the main parts of the machine;

- the condition of the hydraulic cylinders during the operation of the equipment is monitored;

- it is checked whether the working fluid flows.

Thus, hydraulic cylinders in different types of special machinery are the most important and essential elements that guarantee the possibility to use the equipment for the intended purpose. If they fail, repair is required, which must be carried out exclusively by experienced and qualified specialists working in our company.

We provide warranty for work performed up to 6 months.

Theme number 4: Repair of hydraulic systems, as well as their components.

To make a report:

1.Main non-serviceability and cause of occurrence.

2.Repont, elimination of malfunctions and basic adjustments.

3. Create an instruction card for restoration (node, details)

REPAIR MAIN TROUBLESHOOTING OF THE HYDRAULIC SYSTEM

Gear pump. Wear of the walls and bottom of the body wells, the ends of the gears and the surfaces of the trunnions, the bores of the bushings under the pin, the chamfering of the edges of the pump cover under the sealing gland, the wear of the cover plane.

Distributor. Cracks of the body and lid, wear of the spools, wear of the cone surface of the bypass valve, the edges of its nest, the gap between the axle and the upper cover lever is more than permissible, wear of the chrome cover of the lever, spools and holes for the spools in the body, thread failure in the holes of the casing.

Cylinder. Wear of the shell walls, surfaces of pistons and rods. Worn holes in the front cover, connecting holes in the covers and stem plugs. Wear and damage to the sealing rubber rings, wear or tear of the stem thread.

Hydraulic power steering of tractors MTZ-50, MTZ-50L, MTZ-52, MTZ-52L, MTZ-80, MTZ-80L, MTZ-82 and MTZ-82L. Wear of the working surface of the abutment, wear and damage to the rail, wear holes for the finger rail, cylinder liner, piston rod, wear of the necks and bend of the rotational shaft, wear of the housing holes under the slide valve and spools.

Locking device and breaking sleeve. Damage to valves, wear and damage threaded connections, defects of crosses and springs.

Tanks and filters. Cracks welded joints and holes in the walls of tanks, breach of tightness, wear of valves, damage to the filter parts.

Hoses. Infringement of tightness of an encapsulation and ruptures of hoses, damages of rubber layers.

REPAIR OF HYDRAULIC SYSTEM AGGREGATES

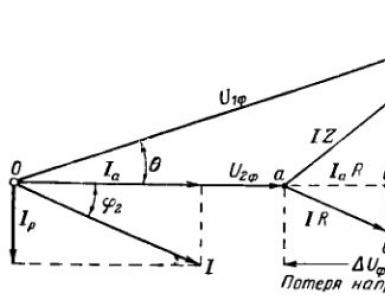

Gear pump dismantled and repaired if it has a volumetric efficiency of less than 0.6 (after replacement of the seals). To properly monitor this indicator, it is necessary to distinguish the designations of hydraulic pumps. In the markings NSh-10D, NSh-32 (NSh-32E) and NSh-46U, the figure corresponds to the theoretical performance of the new pump in cubic centimeters per gear revolution. The letters D, E, U after the numbers indicate the model of the pump. The direction of rotation of the drive gear is shown on the pump nameplate with the letter L (left) or P (right).

Dimensions of the body of the hydraulic pump, mm

|

Pump brand |

Marking |

||||||||

Dimensions for enclosures, reduced by compression.

When disassembling the pumps, the bolts are removed, the pump is removed from the pump and the parts are taken out manually. The puller is used only when removing the lower pair of bushings from the socket. Bushings, covers and sealing rings of pumps NSh-32 and NSh-46 are interchangeable, but if the pump is collected again from these parts, then the depersonalization of bushes and gears is not allowed.

Received the first time in repair pumps are repaired by the method of shifting the gears with concentric bushings. This method allows repairing the pump at a lower cost, since the restoration of the pump body is reduced to one operation - boring the wells to an increased size (Table 30, Fig. 37). The pump is assembled with eccentric bushings, the displacement value of the pinion axis should be equal to half the difference in the sizes of the gear teeth and body wells.

http://mehanik-ua.ru/images/image014_5_95dd9d736467e2f7e3f8162c7227bf6d.jpg "realsize =" 600x282 "width =" 100% "align =" left "\u003e on the pressure gauge of the stand to 6.0-7.0 MPa. oil through the connection for connecting the hydraulic battery should not exceed 6 cm3 for 10 minutes.After completion of the test, open the throttle and turn off the electric motor of the stand;

b) to test the tightness of the slide, the handle of the FGP is set to the position

"Off" (Figure 61, b).Then the electric motor of the stand is turned on and the pressure is set by the throttle on the manometer of the stand to 6.0-7.0 MPa. At the same time, the amount of oil leakage

through the connection for the hydraulic accumulator must not exceed

50 cm3 for 10 minutes.

Overlapping the choke of the stand, set the pressure on the pressure gauge of the stand to 10.0 MPa and check the tightness of the FGP for 1 min.

At this pressure, as well as during other tests, oil leakage at the connection points is not allowed.

At the end of the test, open the throttle and turn off the motor of the stand;

c) to test the tightness and the pressure of the safety valve, the handle of the FGP is set to the "on" position (Figure 61, at).The plug is moved from the drain plug to the hydraulic battery connection. Include the electric motor of the stand and with the help of the throttle increase the pressure before the trip

valve, which is determined by the flow of oil from the drainage nozzle. The operation of the valve must be clear. Leaking oil before the valve operates indicates that it is leaking.

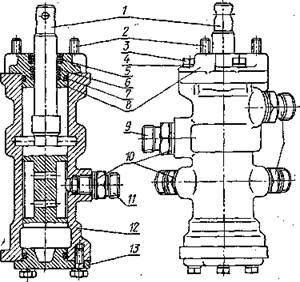

Switchgear:

1-tap; 2-stud; 3-bolt; 4-spring washer, 5-wiper-fit cuff; 6 and 7-seal the ring, 8-top cover, 9 and 11-piece; 10 - a lining; 12- housing; 13- lower cover.

1-tap; 2-stud; 3-bolt; 4-spring washer, 5-wiper-fit cuff; 6 and 7-seal the ring, 8-top cover, 9 and 11-piece; 10 - a lining; 12- housing; 13- lower cover.

The valve activation pressure is checked both with the FGV handwheel turned off and with the handwheel wrapped. It should be 0.8-2.0 MPa above the charging pressure of the hydraulic accumulator.

The work of the FGP and hydraulic accumulator is checked according to the scheme.

Before the test, turning the handwheel clockwise clockwise, set it to the extreme position and, rotating the needle of the device, overlap the drain hole. The handle of the FGP is set to the "on" position. The electric motor of the stand is turned on and, overlapping the choke of the stand, the gauges of the stand and the flowmeter are observed. The pressure gauge of the stand will show pressure only when charging the hydraulic accumulator. Pressure gauge of the flowmeter - pressure athydraulic accumulator (back pressure).

To check the operation of the automatic controller, rotate the MSW handwheel counterclockwise. from one extreme position to another. In this case, the pressure of the back-up, determined by the manometer of the flow-meter, should vary from 0.8 MPa to 2.8 | MPa irregular. The number of jumps should be 3-4, given the jump in the initial charge of the hydraulic accumulator. The test is repeated 2-3 times, discharging the hydraulic accumulator by screwing the throttle-gauge needle and releasing the oil.

Hydraulic accumulator of tractors MTZ-50, MTZ-50L, MTZ-52, MTZ-52L. The hydraulic battery is tested on the KI-4200 stand, having screwed the choke-flow meter onto its choke for verification and connecting it to the discharge line of the stand. At a pressure of 6.0 MPa, oil leakage along the split planes, as well as from the hole closed by the stopper, should not be for 3 minutes.

Smoothness of work is checked with gradual discharge of the accumulator, which is under pressure of 4,0-6,0 MPa. The pressure in the range from 3.1 to 0.8 MPa should fall smoothly, without jumps.

Switchgear. After flushing the parts in diesel fuel, the bottom cover 13 inserting into its annular bore a rubber sealing ring 7.

Fig. 37. Hydraulic pump housing.

Repair of hydraulic systems, as well as their components. - 4.5 out of 5 based on 2 votes

Special equipment is a complex and multifaceted tool, which sooner or later starts to suffer from small problems or serious breakages. This work does not tolerate downtime and financial losses, so we offer you timely diagnostics and professional repair services.

Repair of hydraulic equipment in our country

Hydraulic systems are one of the most complicated working units of special purpose machines. The replacement of filters and waste oil in time in such systems is extremely important, because otherwise the fluids will become unusable, gradually worn out the mechanisms of hydraulics. As a result, complex and expensive repairs may be required.

Professional and operative repair of special machinery hydraulics in Moscow will avoid possible problems. The specialists of our company have rich experience and sufficient knowledge to ensure the long and productive operation of any technical means, which you use in your work:

- truck cranes;

- excavators;

- loaders;

- manipulators;

- concrete mixers;

- concrete pumps,

as well as other special equipment, which combines the availability of hydraulic systems. We are not important manufacturer: we work with all major brands. One of our undeniable advantages is the availability of our own repair center, where your machinery and equipment will remain intact and safe for the time of repair.

Do not wait for wear and tear hydraulic system and, as a result, its failure. Buying a new node or serious repairs will cost more than early diagnostics and prevention, especially in a crisis. Entrust your hydraulic motors and hydraulic cylinders to us. Even if they already need repairs, we'll put your equipment in order in a matter of days.

How we are working

Before proceeding directly to repair, each of our clients receives professional advice, during which the approximate terms of work, approximate cost and the possibility of discounts are stipulated. Further:

- 1. The first step will be diagnostics performed at the exit to the client's territory or the delivery of equipment for repairs to our service center.

- 2. Partial defects are carried out, that is, this time the exact repair cost and its duration are determined.

- 3. It is self-repair hydraulics special equipment.

- 4. The repaired product is handed over to the customer or installation will be made.

Pros of cooperation with us

Repair of hydraulic excavators and other construction machines is very in demand. Therefore, among the LLC and other firms that offer such services, there is good competition. We aspire to stand out against the background of the majority not by advertising, but by the quality of our repair and individual approach to each client.

Ordering repair hydraulics excavators in our country, you are turning to the experts in your business. We have:

- a modern repair base and all necessary diagnostic equipment;

- a friendly team of qualified specialists;

- great opportunities to repair and restore a variety of types of equipment;

- democratic price policy;

- guarantee the quality of their work.

Contact us on time, and instead of a complex repair that takes time and money, you will get an accurate diagnosis and inexpensive replacement of consumables with minor preventive measures. If you do this regularly, by the time when the special equipment will require a real overhaul, it will be much cheaper.

We carry out maintenance and quality repair of most of the working units used in construction and related works. Pleasing the next customer with the quality of their work, we are striving to establish lasting and effective cooperation. If you need repair of hydraulic equipment or you want to make sure of its protection from breakdowns, call us! We will not fail.

Are available:

- Hydraulic pump Hidromatic A11VO95LG10S / 10L price 315000 rub. (used in good condition)

- Hydraulic pump Hidromatic A11VO60LRDS / 10L price 283500 rub. (used in good condition)

- Hydraulic pump Hidromatic A10VS060DFR / 52L price 157500 rub.

- Hydraulic pump Cat 258-3261 price 18900 rub.

- Hydraulic shock absorber SAİP 260713/110811 at 15 Bar. price 9450 rub.