The main measures to reduce losses in electrical networks. Methods for reducing energy losses in ep

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Hosted on http://www.allbest.ru/

Introduction

1. The main part

1.1 General

1.2 Energy savings in transformers

1.3 Electricity saving in lines

1.4. Energy saving in tires

1.5 Electricity saving in three-phase networks with a voltage of up to 1000 V with an asymmetrical load

1.6 Energy saving due to application of increased voltages

1.7 Reduction or elimination of additional devices in SES that consume a significant amount of electricity

1.8 Amendments to the tariff system of payment for electricity by consumers, powered by power systems

1.9 The influence of the quality of electricity on its overruns

1.10 Impact of the Electric Balance of an Industrial Enterprise on Electricity Savings

Conclusion

List of used literature

INTRODUCTION

The problems of saving electrical energy at all stages of its life cycle are among the central problems facing the energy sector. A comprehensive solution to these problems is associated with the transition to new information resource-saving and environmentally safe technologies for the production, transmission and consumption of electrical energy. It is necessary to minimize the losses of electric energy in electric networks during its transmission.

At present, considerable experience has been gained in modeling and optimizing the functioning of energy systems, i.e. experience in solving problems of planning and management of modes of transmission of electrical energy. The results of optimization of the structure and parameters of electric networks revealed significant reserves of saving non-productive losses of electric energy to 15-20% of the total volume of transmitted electricity. However, some models and optimization methods developed up to the present time are deterministic and do not take into account the actual conditions of functioning of electric networks and the electricity market. The optimal solutions obtained by these methods correspond only to specific boundary conditions and are, as a rule, on the boundary of the admissible region. Naturally, such "optimal" solutions prove to be unacceptable in practice. From a formal point of view, the problem of taking into account the actual conditions for the functioning of electric power systems is that in mathematical programming models, to which planning and control tasks are reduced, some parameters of the objective function and constraints are random variables. In electric power systems, the main external disturbing factors are random processes of electric energy consumption, and the main internal disturbing factors are failures of the elements of the process equipment.

It is known that almost 100% of all electric networks and electric consumers in the world work on alternating current.

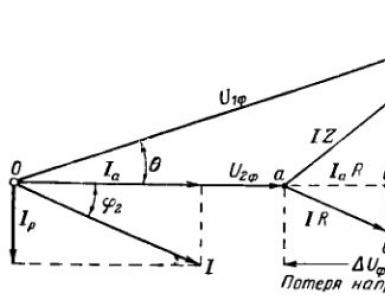

Electric power in the world is becoming more expensive, and its consumption by civilization is continuously increasing. Therefore, the current problem of world energy is the saving of electricity from an alternating current. Virtually all receivers have inductances. As is well known, inductance creates a phase shift between current and voltage in the AC circuit. In many respects, it is because of this phase shift that there is a huge overrun of electricity in electrical networks (the so-called "cosine phi" problem is well known to electric power industry). This inherently acute problem of the overrun of electricity in circuits with inductances is of global nature in the world electric power industry.

1. MAIN PART

1.1 General

About 70% of the electricity produced by Russia's power plants is spent in industrial enterprises. From this we can conclude how important the issues of saving electricity in industrial installations. Reducing the consumption of electricity through its rational use will expand the production of the country's products, will make it possible to use electricity more widely in the everyday life of people. Saving power in industrial plants can be obtained by reducing the consumption of it by receivers (electric motors, electric ovens, electric lamps, etc.) and reducing energy losses in various elements of the power supply system (transformers, reactors, lines, etc.)

When electricity is transferred from power sources to receivers, 10-15% of electricity released from the buses of power plants is lost; The rest (85-90% of electricity) is spent by receivers. Therefore, the task of saving electricity at industrial enterprises should be solved by technologists and power engineers through the rational use of it.

Saving only 1% of electricity in each enterprise can, in aggregate, free up huge capacities in power systems. Below are the methods and ways of saving electricity in the elements of the power supply system.

electric energy saving transformer

1.2 Saving epower in transformers

At the industrial enterprise, power transformers are installed on the main lowering, on the shop floor and at special substations. Electricity transformers, welding, etc. Electricity losses in transformers are inevitable, but their size should be brought to the possible minimum by choosing the correct power and number of power transformers, as well as the rational mode of their operation. In addition, one should strive to reduce power losses by eliminating the idling of transformers at low loads. This event is of particular importance in the operation of shop floor transformers of enterprises operating in one or two shifts, as well as on weekends.

Usually at the enterprises in their spare time or on weekends repair work is being done, equipment testing, etc. Electricity is also required for the production of such works, but in much less quantity than on working days. Inclusion of all shop transformers causes large non-rational losses due to losses of idling of transformers. To eliminate such losses, it is recommended to design new power supply schemes by providing redundant links (jumpers) on the low-voltage side of the shop transformers. In this case, it is advisable to feed installations for repair work, night, security and emergency lighting throughout the enterprise, etc., including the work of only 1, 2 transformers at different points of the network.

In the conditions of operating industrial enterprises, in the absence of a projected scheme of such power supply, it is possible, by means of an insignificant network reconstruction, to provide an expedient operating mode for power transformers. The limitation of idling is of great importance also for such installations as welding and electric furnaces.

It should be noted that the operation of transformers in idling or close to it causes a change in losses not only in the transformer itself, but also in the entire power system because of the low power factor when the transformer is idling

1.3 Eelectricity congestion in lines

The loss of electricity in the lines depends on the value of the resistances and the current passed through the lines. The resistance of operating lines can be considered practically constant. Hence it follows that in order to reduce power losses, one way is possible - a reduction of the current flowing through them. To reduce the current value, for example, you can use a significant number of redundant lines. In the presence of parallel lines, it is desirable, for reasons of energy saving, to keep them switched on in parallel. When designing the power supply system of an enterprise, it is necessary to choose an option in which there are no reactors, or an option with minimal losses in the reactors. From this point of view, the options under consideration must necessarily be compared in terms of technical and economic indicators. For example, the power supply system of an enterprise with a voltage of 6 kV with reactors should be compared with a power supply system for a voltage of 20 kV without reactors.

1.4. Energy saving in tires

When feeding powerful power receivers (electric ovens, etc.), as a rule, multi-pole busbars are used. If the tire arrangement is used, as shown in Fig. 14.1 a, then the power losses in such a busbar trunk will be much larger than in the case shown in Fig. 14.1 b. This is because with the arrangement of the tires shown in 14.1 a the "proximity effect" is strongly affected, "at which the inductive resistance of the tires sharply increases and the reactive component of the current increases, which ultimately leads to an increase in the total current and, accordingly, the loss of power and energy.

With the arrangement of the tires shown in Fig. 1 b, the interaction of magnetic fields is such that their actions are mutually destroyed and the increase in the reactive current is negligible. The losses in power and electricity in this case are almost halved compared to the location in Fig. 1 a.

A B C A B C A B C A B C

Fig. 1 W ichovka strips of tires and busbars.

a) Incorrect, with increased power losses;

b) correct.

Energy saving in three-phase networks up to 1000 V with unbalanced load.

With an uneven distribution of loads across the phases of a three-phase system, the energy loss is greater than with a symmetrical load. Uniformity of phase loading should be ensured first of all due to the correct distribution of single-phase and two-phase loads in phases. The second measure to reduce asymmetry in networks with voltages up to 1000 V is the installation of neutralizers on the ground leads of the lead sheath of the cable. The economic feasibility of the second measure is determined by the ratio between the costs of installing neutralizers and the cost of energy saved as a result of eliminating the asymmetry of the load.

Measures for equalizing the phase load are advisable to be carried out in transformers loaded with more than 30% of the rated power, the load non-uniformity can be neglected, since the load losses slightly exceed the idling losses.

1.5 Energy saving due toexcessive stresses

Installation of step-down transformers with higher voltages of 110, 32, 10 and 6 kV near the receivers of the power plant and shortening the length of the workshop networks with a voltage of 0.69-0.23 kV provide significant energy savings. However, the higher the voltage of the supply networks, the more expensive the electrical equipment (cable and air lines, switches, etc.). The voltage 35 kV recommended in due time for deep input was not widely used in industrial power supply systems, as it proved too high for most industrial enterprises. The operation of industrial power supply systems has shown that it is advisable to limit the power (the principle of substation reac- tion) of 1000 kVA transformers with a secondary voltage of 4000 V and 1800-2500 kVA with a secondary voltage of 35 kV,

With such insignificant currents for supplying shop floor substations, it would be advisable to use air lines with steel wires, since cables with copper conductors at 35 kV have a minimum permissible cross-section of 370 mm 2 with a throughput of 11800 kVA, and cables with aluminum conductors 350 mm 2 with a capacity of 8000 kVA.

However, the laying on the territory of industrial enterprises of overhead lines 35 kV with P-shaped and AP-shaped supports is practically excluded. The industry does not manufacture cables with steel conductors with a voltage of 35 kV. These circumstances mainly caused the voltage of 35 kV not to be widely used for distribution internal networks. To implement deep commissioning at industrial enterprises, it is rational to apply voltage not 35 kV, but 20 or 18 kV (10.5 = 18 kV).

The voltage of 20 kV, as shown by the practice of the operation of power supply systems in Russia and abroad, makes it possible to construct lines with simple, cheap candle-like supports (similar to the 6 and 10 kV line supports) of small dimensions, which is important in an industrial enterprise whose territory, as a rule, is filled with various facilities and communications.

In this case, for the supply of transformers with a capacity of 1800 kVA, a current equal to

The minimum cross-sections of an aluminum wire of 16-25 mm 2, selected according to the conditions of mechanical strength and economic feasibility, will be close to the smallest cross-sections by the permissible current density. The cost of switching devices for 230 kV is much lower than for 35 kV.

Application of 20 kV voltage for networks of industrial enterprises allows to fulfill the decision of the governing bodies on the reduction of electric power consumption for losses in electric networks of industrial enterprises.

The application of 66 V voltage in the shop networks also significantly reduces energy losses and consumption of color metal. The experience of operating 660-volt shop networks in a number of industries has proven the indisputable advantages of this voltage.

However, in Russia, for distribution networks that are the most extended, in general, voltages of 6 and 10, less than 35 kV, are used.

Voltage 6 kV from the point of view of energy saving is not promising, but occupies a significant place in power supply systems (SES) of all categories. Analysis of 6 kV networks is conducted in order to show the possibilities of saving electricity in distribution networks when switching to 10 kV.

The modern rapid growth of electrical loads often leads to a technical limit to the use of existing SES. To improve the quality of voltage apply voltage regulation in power transformers, and to provide power to new consumers, construct parallel lines. However, these measures do not solve the problem of providing industrial enterprises and cities with electricity of the required quantity and quality.

The use of a voltage of 20 kV in these distributions in these cases makes it possible not only to significantly reduce the loss of electric power in the lines, but also to substantially reduce the number of transformations due to the enlargement of the transformer substations. In 1975, it was instructed to switch distribution networks from 6 kV to 10 kV. This decision, although it is correct, is not enough, since it requires considerable expenses for the reconstruction of networks, by the time of completion of which, in connection with the constant growth of the loads, a further increase in voltage may be required.

According to the analysis of the transfer of electrical networks from a voltage of 6 kV to 20 kV, many research works have been carried out. The calculations carried out in the study of the power supply systems of Mosoblenergo obtained in MPEI made it possible to conclude that when the 6 kV voltage is replaced by 20 kV, the energy saving will be 19.35 million rubles.

For the period of depreciation (about 25 years), taking into account the dynamics of load growth, the total savings due to the reduction will be approximately 2 billion rubles.

For the reconstruction of SES, design organizations often make unpromising decisions.

For example, in the USSR, the main objections of electricity supplying organizations and departments producing and consuming electricity were as follows: transformers, cables and equipment for 20 kV (current and voltage transformers, disconnectors, insulators, reactors, fuses, etc.) were not produced in the USSR. These objections can be answered as follows:

Transformers with a voltage of 220/110/35 kV produced by the Ministry of Electrical Engineering can be switched from star to delta in a few hours and receive transformers with a voltage of 220-110 / 20 kV.

There were no difficulties in producing 20 kV cables. Cables for the voltage of 20 kV we have produced, but their price was overstated.

Measuring voltage transformers of 20 kV in the USSR were produced serially.

Measuring current transformers of 20 kV in the USSR were also produced serially. Only current transformers for small currents (50/5, 100/5, etc.) were not produced for these voltages, however their production on the basis of the produced ones would not cause any special difficulties.

In the manufacture of complete switchgear, the disconnectors are not required. For other cases, the cost for the 20 kV voltage and the process of its production will not change at all in comparison with the 10 kV disconnectors, since the insulator height varies little and the porcelain mass increases by only 2%.

Insulators with a voltage of 20 kV can be produced in any required quantity, while the number of insulators produced at a voltage of 6 kV will be reduced.

The release of switches for 20 kV and 400-2000 A currents was actually required. Switches for currents above 2000 A in the USSR were not serially manufactured. For a short period of time (2-3 years) it was possible to use switches for currents less than 2000 A, produced serially in socialist countries, for example in Bulgaria. The use of 20 kV circuit breakers led to a sharp decrease in the number of circuit breakers in SES. At the same time, they provided much higher throughput. Schemes of power supply have become simpler and more reliable. Costs of non-ferrous metal decreased.

Reactors for a voltage of 20 kV might not be required if we investigate the installation of two 6-10 kV reactors connected in series by our industry.

The position with fuses is similar to the position with switches, but it is much easier to solve. Rise in fuses is no more than 1%.

1.6 Reduction or elimination of additional devices in SES, which consume significantamount of electricity

At present, when balancing a three-phase system, balancing devices (SS) are used. In this between the shop transformer and the receivers in the SS, not less than 10% of electric power is lost additionally and installation (we will simplify) of one more power device equal to the power of the supply transformer is required. To exclude SU it is possible with replacement of a feeding transformer with the scheme of connection of star-star windings by the transformer with the circuit of connection of windings star-zigzag. In this case, the losses and cost of the transformer will increase by 2-3%. But due to the elimination of SU, losses of electric energy are reduced by 5-8% and there is no need to produce balancing equipment.

A similar situation occurs when installing additional filter compensating devices (PKU) with non-sinusoidal shape of the current and voltage curve. By installing rectifiers on the 12-24 phase diagram, it is possible to significantly reduce the non-sinusoidality and dispense with PKU.

1.7 Making changes in the tariff system of payment for the electric power of the consumerfrom power systems

Not only is the step of the standard nominal capacity of the transformers, but the tariff policy being implemented contributes to overstating the installed capacity of the transformers. Currently, the consumer is fined tenfold for overspending (even short-term), and when it is underutilized, a penalty is imposed on the full amount of unused electricity.

On the basis of the above research work, it can be argued that both the fines and the reduced scale of the rated power of the transformers lead to a low coefficient of transformer capacity utilization.

1.8 Impact of qualityelectricity at its overrun

Any deterioration in the quality of electricity entails its overrun. This situation is also true for those cases when this deterioration lies within the limits of the norm and corresponds to GOST. In case of recalculations related to the design and operation of SES, the losses occurring in devices used to maintain the voltage at an acceptable level are not taken into account. For example, for transformers with on-load tap-changers, these are losses in control devices.

Based on a large number of studies conducted in MPEI, it can be argued that the installation of control devices of any type (with the exception of technological) is due to the choice of an unreasonable nominal voltage for SES. Therefore, when designing and operating the SES, it is advisable not to use regulating devices (symmetric, filter-compensating, etc.), as they lead to additional investments, load plants and ministries of the electrical industry with unnecessary orders, increase the consumption of ferrous and non-ferrous metals, most importantly, cause large losses of electricity.

Recently, attention is also paid to the quality indicator, such as the deviation of the voltage frequency from the nominal values, which also leads to power losses. Production costs due to low-quality electricity are not evaluated and are not taken into account, which is still necessary to do. For this purpose, it is advisable to develop devices that in each manufacture would enable us to compare the quantity and quality of the enterprise's products, as a function of the quality of electricity.

The current sanctions aimed at improving the quality of electricity are, as a rule, unilateral, for example, penalizing consumers for overspending or underutilization of the declared electricity, while the power supply systems do not bear any material responsibility for the poor quality of the supplied electricity.

1.9 Influence of electric balance of industrial enterprisei save on electricity

In order to save electricity, it is necessary first of all to know for what purposes and in what quantity it is spent. The definition of electricity consumption items is the main task of drawing up the electric balance of industrial enterprises.

Annual drawing up of an electric balance allows to observe results of actions on rationalization of an electrohouseholdy of the industrial enterprise. For example, analyzing the change in the total and specific electricity consumption for the production of compressed air, we can conclude that the measures taken in compressor plants are rational in order to reduce electricity consumption.

The electric balance of an industrial enterprise should consist of a revenue and expenditure part (active and reactive capacity). The incoming part includes the electricity received from the power grid or from networks of other consumers, as well as the enterprises produced by the electric plants (generators of industrial TPPs and HPPs, SC and capacitors).

Electricity everywhere is becoming more expensive, and its consumption in the world is continuously increasing. More than 80% of the electric power is consumed in the world by an alternating current. Therefore, an urgent problem of world energy is to reduce power consumption and increase the efficiency of all AC electric receivers. Transformers and AC asynchronous electric machines are the most massive inductive electric receivers. They are used everywhere from household electrical appliances, computers, city electricity to the traction railway electric drive and electric drive rolling mills. All of them consume excessive electricity. Asynchronous electric machines are the most common in the world due to the simplicity of construction and good adjusting properties.

Virtually all existing AC receivers have inductances and waste unnecessary electricity from the network for its electromagnetic recharging at reactive time intervals, and then again give this stored energy to the grid by exchanging inductive currents with the AC mains twice per period.

Electricity savings in them can be ensured by eliminating these reactive intervals of return of reactive current to the grid and the useless consumption of the stored electromagnetic energy of inductances - by breaking the circuit in the reactive time intervals and using this stored energy for the benefit of this load itself

In three-phase inductive loads with a secondary circuit, it is possible to save energy by forcibly circulating reactive currents through the phases by interrupting the phase currents in the electronic time switches (in case of a mismatch in the signs of phase currents and inductance voltages).

The maximum mode of energy saving in inductive loads is achieved by a high-speed rupture of the inductor current at the moment of its maximum - twice during the AC period. The electric power is recovered thanks to the useful use of self-inductance counter-emfs when phase inductive windings with current are broken.

The physical essence of this "discontinuous" method of radical energy saving in inductive electrical receivers is the emergence and useful use of the phenomenon of electromagnetic self-induction for the useful use of electromagnetic energy inductances in the load itself.

An original multi-winding transformer with a commutator in the primary winding, circulation of reactive currents and a circuit of electric power recuperation between the primary and secondary windings at "reactive" time intervals is proposed. The energy saving is 80-100%

A method is proposed for circulating reactive currents in a multiphase AEM in the "reactive" intervals and the method of electric energy recuperation using the original self-oscillator circuit of a multi-winding asynchronous valve machine. Energy saving - 80-100%.

An original multi-winding asynchronous valve machine with a commutator in the primary winding, circulation of reactive currents and a circuit for the recuperation of electric power between the primary and secondary windings at "reactive" time intervals is proposed. The energy saving is 80-100%.

CONCLUSION

The problem of energy saving is becoming more urgent in the world and therefore the methods of saving it proposed in the report are of great practical and scientific importance. Existing multiple AC consumers that contain inductors (transformers, asynchronous electric machines), while uneconomical consume consumed electricity, because it is useless to exchange reactive currents and reactive energy inductances with the mains. This useless reactive energy exchange of the network and inductive electric receivers by reactive currents twice a period, in order to save electricity, can be completely eliminated by different methods. Including the method of capacitor compensation of reactive power, resonant methods of tuning the receivers to a single input power factor and a method using compensating capacitors and electronic (s) switches connected in series in the power supply circuit in series with the inductive winding (s).

As a result of switching off the inductive load from the AC network to the data of the "reactive" time intervals, the useless overflow of the reactive currents is eliminated. The previously stored reactive energy of the inductance is stored for a long time inside the multiphase electric receivers due to the phenomenon of circular circulation of it along the phases of the inductive load, which leads to significant energy savings.

This method of cyclic disconnection of the inductive load from the network to the "reactive" intervals will allow us to achieve energy savings of up to 20-30%.

Radical energy savings by inductive electric consumers (up to 100%) can be achieved with a high-speed commutation of the current consumption twice per period at the moments of its maximum.

The effectiveness of this "discontinuous" method of saving electric power consists in the useful use of the phenomenon of electromagnetic self-induction that arises when the current in the inductor is broken. For its realization, inductive electric loads (consumers) must have closed secondary electric and electromagnetic circuits. In asynchronous electric machines, the secondary electric and electromagnetic circuits are its stator magnetic circuit and rotor, in the transformers - their magnetic cores and secondary windings.

LIST OF USED LITERATURE

1. Arseniev G.V. Power plants. - Moscow: Higher School, 1991.

2. General electrical engineering. Ed. V.S. Pantyushin. - Moscow: Higher School, 1970.

3. Fedorov AA, Kameneva V.V. Basics of power supply to industrial enterprises. - Moscow: Energoatomizdat. 1984.

4. Konovalova LL, Rozhkova L.D. Power supply of industrial enterprises and installations. - Moscow: Energoatomizdat, 1989.

5. Lipkin B.Yu. Power supply of industrial enterprises. - Moscow: Higher School, 1990.

6. Lipkin B.Yu., Knyazevsky B.A. Power supply of industrial enterprises. - Moscow: Higher School, 1986.

7. Rozhkova L.D., Kazulin V.S. Electrical equipment of stations and substations. - Moscow: Energoatomizdat, 1987.

Hosted on Allbest.ru

...Similar documents

Classification of losses in the power supply system of an industrial enterprise. Influence of the power factor of the network on power losses. Ways to reduce losses in the power supply system of industrial enterprises due to compensation of reactive power.

thesis, added 08/06/2017

Determining the currents in the elements of the network and the voltages at its nodes. Calculation of power losses in transformers and power lines with a uniformly distributed load. Reduced and calculated loads of consumers. Measures to reduce power losses.

presentation, added on 10/20/2013

Improvement of the quality of electric energy due to reduction of asymmetry in traction substations of alternating current of traction power supply system with the help of transformer consoles. The law of variation of the coefficient of stress in the reverse sequence.

test work, added on 03/12/2017

The influence of the deviation of the quality of electrical energy from the established norms. Parameters of quality of electric energy. Analysis of the quality of electrical energy in the power supply system of cities with a million population. Development of measures to increase it.

thesis, added on 01/21/2017

Measures to reduce the volume of energy resources in the enterprise. Annual electricity consumption. Annual power losses in transformers and cables and total annual consumption taking into account losses. The basic schemes of power supply.

course work, added 08/06/2015

Characteristics of electricity supply sources and electricity consumers. Determination of design loads for the enterprise and workshops. Calculation of short circuit currents. Determination of energy losses in the elements of power supply systems. Select the light source.

graduate work, added 29.07.2012

The concept of a power supply system as a set of devices for the production, transmission and distribution of electricity. The task of power supply to industrial enterprises. Description of the scheme of power supply. Criteria for choosing electric motors and transformers.

term paper, added on 05/02/2013

The role of power supply in the technological process. Assessment of electricity consumers, their impact on the quality of electricity. Power supply of the shops of the enterprise. Calculation of the electric lighting system. Calculation of the power of the transformer and selection of the substation.

thesis, added on 24/09/2012

Energy-efficient light sources. The mechanism of operation of energy-saving lamps and incandescent lamps. Advantages of using electronic ballasts. Ways to save electricity in enterprises. Energy saving in heating.

essay, added on

Features of the formation of the power supply system for industrial enterprises. Characteristics of electricity consumers. Methods for calculating electrical loads. Calculation of the electrical power load up to 1000V. Power loss in transformers.

The power losses in the networks are determined in order to reduce them. The process of loss reduction is the optimization of the electric network mode. They are optimized during operation and when designing the network. In the operating environment, measures to reduce losses are called organizational (they are not related to additional capital investments), and in the design - mainly technical activities that require additional capital investment.

Organizational measures to reduce losses in electrical networks

1. Establishment of accounting for generation and consumption of electricity.

where: Wh is the counter.

ΔE = Wh 1 - Wh 2

Thus, it is necessary to organize the account of the flow of energy and its control.

The matter is that the networks have an isolation stock:

from an electric current to 220 kV - by 15%,

from a 330 kV power source - by 10%,

from 500 kV and above - 5%.

This is especially important in networks of 0.4; 10; 35; 110; 220kV, as these networks are very branched.

Thus, correct regulation of the voltage in the networks is necessary to account for energy losses. It is necessary to strive to maintain the maximum possible with increasing voltage by 1% in networks up to 110 kV of power loss and by 2%. In 220 kV networks it is always necessary to maintain the maximum possible voltage. In networks of 330 kV and higher, the voltage should be regulated taking into account the losses to the crown.

Δ P = ΔP to + ΔP n

3. Optimization of regimes of transformers in substations. Usually there are 2 or more transformers in the substation.

This measure is reduced to obtaining power at which it is preferable to disconnect one transformer. Thanks to this save on idling, but slightly increase the load loss. Since the transmitting power is less than the rated power, the increase in losses is insignificant.

4. Development of reasonable standards of consumption for production of a unit of production.

5. Fast and reliable network repair.

6. Determination of the optimal places for the opening of the electrical network,

Electric networks of 6-10 kV (city) and 35-110 kV networks are often closed, but operate in the normally open mode. They on their sites have a different cross-section of wires and are heterogeneous.

In a closed heterogeneous network, the equalizing power flows and the natural flow distribution deviates from the economic one corresponding to the minimum of losses. Under these conditions, according to the criterion of minimum losses, the places where the network is opened are often found.

Technical measures to reduce losses to reduce losses in electrical networks

1. Compensation of reactive power to reduce energy losses. This improves the stress regime.

Probably everyone who has a house in the village, lives in a private sector in the city or builds a house, will eventually face the problem of electricity network instability. This is manifested in sudden voltage surges, problems of protecting electrical appliances during thunderstorms, long periods of highly overestimated or underestimated voltage in the electrical network.

Many of these problems are related to the peculiarities of the air electric lines, others, with the non-fulfillment of the elementary rules for laying the lines and their maintenance. Unfortunately, in our country the slogan is becoming more and more implemented: "Salvation of drowning people is the work of the drowning themselves". Therefore, let's try to consider these problems and ways to solve them in more detail.

Where do losses in electrical networks come from?

Om is to blame for everything.

For those who are familiar with Ohm's law, it is not difficult to recall that U = I * R. This means that the voltage drop in the wires of the power line is proportional to its resistance and current through it. The more this fall, the less voltage in the sockets at home. Therefore, the resistance of the power line must be reduced. And its resistance is made up of the resistance of the forward and reverse wire - phase and zero from the transformer of the substation to your house.

Incomprehensible reactive power.

The second source of loss is reactive power or more precisely reactive load. If the load is purely active, for example, it is incandescent lamps, electric heaters, electric stoves, then electricity is consumed almost completely (efficiency greater than 90%, cos tends to 1). But this is an ideal case, usually the load is capacitive or inductive. Really cosine phi the consumer is variable in time and has a value of 0.3 to 0.8, unless special measures are applied.

From the statistics it is known that due to uncompensated reactive power, the consumer loses up to 30% of electric power. In order to eliminate such types of losses, reactive power compensators. Such devices are commercially available. And they come from a "single-socket" version, to devices installed on the substation transformer.

Werewolves in sweatshirts.

The third source of losses is the banal theft of electricity. It would seem that this should be done by law enforcement agencies, but they do not have energy audit departments. Therefore, the third source of losses should also be dealt with by the consumer, since according to the law, he must have a house-keeping or general economic counter and for the theft of the black sheep pays the entire herd.

Estimation of losses in a line on a concrete example.

The active resistance of the line is R = (ρ * L) / S, where ρ is the resistivity of the wire material, L is its length, and S is the cross section. For copper, the resistivity is 0.017, and for aluminum 0.028 ohm * mm2 / m. Copper has almost half the losses, but it is much heavier and more expensive than aluminum, so aluminum cables are usually chosen for air lines.

Thus, the resistance of one meter of aluminum wire, cross-section of 16 square millimeters, will be (0.028 x 1) /16-0.0018 Ohm. Let's see what will be the losses in the line length of 500 m, with a load power of 5 kW. Since the current flows through two wires, the line length is doubled, i.e. 1000 m.

Current strength at 5 kW is: 5000/220 = 22.7 A. Voltage drop in the line U = 1000х0.0018х22.7 = 41 V. Voltage on the load 220-41 = 179 V. This is already less than the allowable 15% reduction in voltage. At a maximum current of 63 A, which is calculated this wire (14 kW), i.e. when its load will include the nearest neighbors, U = 1000х0.0018х63 = 113 В! That is why in my holiday home in the evenings the light bulb does not shine!

Ways to combat losses.

The first is the simplest way to deal with losses.

The first method is based on lowering the resistance of the neutral wire. As you know, the current flows through two wires: zero and phase. If the increase in the section of the phase conductor is quite expensive (the cost of copper or aluminum plus dismantling and installation work), then the resistance of the zero wire can be reduced quite simply and very cheaply.

This method was used from the moment of laying the first power lines, but nowadays because of "pofigism" or ignorance is often not used. It consists in re-grounding the zero wire on each pole of the power line or (and) on each load. In this case, parallel to the resistance of the neutral wire, earth resistance is connected between the zero of the transformer of the substation and the zero of the consumer.

If the grounding is done correctly, i.e. its resistance is less than 8 ohms for a single-phase network, and less than 4 ohms for a three-phase network, it is possible to substantially reduce (up to 50%) losses in the line.

The second is the simplest way to deal with losses.

The second simplest method is also based on lower resistance. Only in this case it is necessary to check both wires - zero and phase. During the operation of overhead lines, due to wire breaks, local resistance increases-twisting, splices, etc., are formed. In the process of work in these places there is a local warm-up and further degradation of the wire, which threatens to rupture.

Such places are visible at night because of sparking and glow. It is necessary to periodically check the electrical line and replace especially bad parts of it or the entire line.

For repair it is best to apply self-supporting aluminum insulated CIP cables. They are called self-supporting; Do not require a steel cable for suspension and do not tear under the weight of snow and ice. Such cables are durable (the service life is more than 25 years), there are special accessories for easy and convenient fixing them to poles and buildings.

The third way to combat losses.

It is clear that the third way is replacement of the old "air" with a new one.

SIP-2A, SIP-3, SIP-4 cables are available for sale. The cross-section of the cable is chosen not less than 16 square millimeters, it can pass current up to 63 A, which corresponds to a power of 14 kW for single-phase network and 42 kW for three-phase. The cable has a two-layer insulation and is covered with a special plastic, which protects the insulation of wires from solar radiation. Approximate prices for CIP can be found here: http://www.eti.su/price/cable/over/over_399.html. Two-wire SIP cable costs from 23 rubles. per running meter.

The fourth way to fight losses.

This method is based on the use of special voltage regulators at the entrance to the house or other object. Such stabilizers can be of single-phase or three-phase type. They increase the cos and provide stabilization of the output voltage within + - 5%, with a change in the input voltage + - 30%. Their power range can be from hundreds of watts to hundreds of kW.

Here are some websites dedicated to stabilizers: http://www.enstab.ru, http://www.generatorplus.ru, http://www.stabilizators.ru/, http://www.aes.ru. For example, the single-phase stabilizer "Leader", rated at 5 kW, listed at http://www.gcstolica.ru/electrotech/stabilizer/x1/, costs 18500 rubles. Note, however, that due to phase distortions and losses in the power line, the voltage at the input of the stabilizer may fall below 150 V. In this case, the built-in protection works and you have nothing to do but to reduce your electricity needs.

The fifth way to compensate for energy losses.

This is the way use of reactive power compensation devices. If the load is inductive, for example, various electric motors, then these are capacitors, if capacitive, then these are special inductors. You can see the implementation examples here: http://www.emgerson.ru/produkciya/krm, http://www.nucon.ru/dictionary/kompensator-reaktivnoi-moshnosti.php, http://www.sdsauto.com/ kompensator_moschnosti.html, http://www.vniir.ru/production/cat/cat/abs-vniir-ukrm.pdf, etc.

The sixth way is to fight against the theft of electricity.

From the experience of work, the most effective solution is to take the electricity meter out of the building and install it on the power transmission column in a special sealed box. In the same box an introductory machine with a fire RCD and surge arresters are installed.

The seventh way to fight losses.

This method of reducing losses by using a three-phase connection. With this connection, the currents in each phase are reduced, and therefore the losses in the line and you can evenly distribute the load. This is one of the simplest and most effective ways. As they say: "Classics of the genre."

Conclusions.

If you want to reduce power losses, then first audit your power grids. If you are not able to do it yourself, now many organizations are ready to help you for your money. I hope that the advice given above will help to understand where to start and what to strive for. All in your power. I wish you success!

When designing and operating various types of electric drives, it is necessary to take into account the consumption and losses of electric power, the effect of EPS on the network and other electrical receivers. Evaluation of these properties is carried out with the help of so-called energy indicators: efficiency, power factor, power and energy losses.

The loss of power and energy in the EA is made up of losses in the electric motor, the mechanical transmission, the converter, the control system, but the main losses are in the electric motor, which is the main focus.

In order to reduce energy losses during the period of start-up or braking, the engines are selected for working machines in such a way that the reduced moment of inertia of the drive at the same speed is the smallest. This is realized due to the use of small engines with a lower J (motors with an increased ratio of the length of the anchor to its diameter, with a hollow or disk armature). It is advisable to use two half-power engines. Calculations show; that ΣJ of two half-power engines is less than the moment of inertia of one engine at full power. For example, two engines of the 4AN200 type with a power of 45 kW each have a total moment of inertia 2 * 1.38 = 2.76 kg * m 2. The 4AN250 engine with a power of 90 kW at the same speed has j = 3.53 kg * m 2, i.е. almost 30% more.

Another way to reduce ES losses is to regulate the ideal idle speed, which is well realized in the stepwise start-up of EP (for AD - speed control by means of the frequency of the supply current or the number of pole pairs, for the DPT - speed regulation by voltage).

With the step-by-step start-up, the loss of electrical energy is reduced by a factor of 2.

Due to a change in the transient process w 0, energy losses in the rotor AD are reduced. Reducing energy losses in the rotor will also cause a reduction in losses in the stator and complete losses in the BP. The given moment of inertia of the EP depends not only on the moment of inertia of the engine or working machine, but also on the transfer of the relationship between them. To reduce the energy loss during start-up, the gear ratio -i should be selected based on obtaining the minimum reduced moment of inertia of the EP and verified by economic calculation.

Efficiency

In the general case, when the EP operates with different speeds and loads on the shaft

where A is the gender, A is the useful and consumed energy,

ΔА - energy loss in the EP,

P sex i is the useful mechanical power of the EP at the i-th section of the cycle,

ΔР - power losses in the EA at the i-th part of the cycle,

n is the number of EP work areas.

Such efficiency is called a cyclic or a weighted average.

If the EP operates in a constant mode with a constant power

The efficiency of the EP as an electromechanical system is determined by the product of the transducer, control device, electric motor, and mechanical transmission, η e = η η * η yy * η ed * η mp.

The most significant value is the efficiency of the engine, which increases with increasing power and speed (Figure 2).

- Печать!}

From the power plant, electricity with a voltage of 110-750 kV is transmitted via power lines (power lines) to the main or district downsizing substations, where the voltage is reduced to 6-35 kV. From the switchgears, this voltage is transmitted over the air or cable transmission lines to the transformer substations located in close proximity to the consumers of electrical energy.

At the substation, the voltage value is reduced to 380 V and by air or cable lines goes directly to the consumer of electricity in the house.

Note.

The lines have a fourth (zero) wire 0, which allows to obtain a phase voltage of 220 V, as well as to protect electrical installations.

This scheme allows you to transfer electricity to the consumer with the least loss. Therefore, on the way from the power plant to consumers, electricity is transformed from one voltage to another. A simplified example of the transformation for a small section of the grid is shown in the figure.

Fig. An example of the transformation of electricity during transmission to the consumer

Why use high voltage in the transmission of electricity?

The answer is simple - to reduce the loss of heating wires during transmission over long distances. Losses depend on the magnitude of the passing current and the diameter of the conductor, and not on the applied voltage.

Suppose that from a power plant to a city located 100 km from it, it is necessary to transfer electricity along a line of 30 MW. Due to the fact that the line wires have electrical resistance, the current heats up. This heat is dissipated and can not be used. The energy spent on heating is a loss.

It is impossible to reduce losses to zero. But to limit them is necessary. Therefore, allowable losses are normalized, that is, when calculating the line wires and choosing its voltage, it is assumed that the losses do not exceed, for example, 10% of the useful power transmitted along the line.

In our example, this is 0.1x30 MW = 3 MW.

Example.

If you do not use the transformation, that is, transmit electricity at 220 V, then to reduce the losses to a given value, the cross-section of the wires would have to be increased to about 10 m 2. The diameter of such a "wire" exceeds 3 m, and the mass in the span is hundreds of tons.

Applying the transformation, i.e., increasing the voltage in the line, and then, reducing it near the location of the consumers, use another way to reduce losses: reduce the current in the line.

Rule.

The transmission losses are proportional to the square of the current.

Indeed, when the voltage is doubled, the current is halved, and the losses are reduced by a factor of four. If the voltage is increased by a factor of 100, the loss will be reduced by 100 2, i.e., 10,000 times.

As an illustration of the efficiency of voltage increase, I will say that 1000 MW per 1000 km is transferred through the 500 kV transmission line of a three-phase alternating current.

Voltage variations

The passage of an electric current through the wires is accompanied by losses and a drop in the part of the voltage on the line, so the consumers' voltage is somewhat less than at the beginning of the line at the substation. To provide acceptable voltage levels along the entire line, the substation must maintain a voltage higher than the nominal value, i.e., not 380/220 V, but 400/230 V.

Note.

In electrical networks of rural areas, consumers, according to the current regulations, allow voltage deviations of 7.5% of the nominal value. This means that a voltage of 350-410 V is allowed on a three-phase electrical receiver, and a 200-240 V single-phase voltage.

However, there are cases when the voltage value is beyond the permissible limits. When the voltage is lowered:

♦ Significantly decreases the intensity of electric lighting from incandescent lamps;

♦ the performance of electric heaters decreases;

♦ the stability of the operation of televisions and other electronic devices with power from the network is disrupted.

Increasing the voltage leads to premature failure of electric lamps and heating devices. Electric motors are less sensitive to voltage deviations.