Heating closed with a pump. Which heating system is best for the home: closed or open

When designing the heat supply of a private house today, the closed heating system is mainly chosen due to its numerous advantages, which we will consider below. Open-type heating systems are already becoming archaic, although they can still be used to heat small rooms.

Features of open heating systems

Device and operation

The open heating system got its name because of its leakage - it freely communicates with the air through an open expansion tank. It is a box of stainless steel, where excess water is merged when it heats up and, accordingly, expands. When cooling, water decreases in volume and returns from the tank to the pipeline.

Open heating systems differ natural circulation coolant: water moves in pipes without the use of pumps, so these systems do not depend on electricity. To achieve this, several rules are observed in the design and installation:

- The heating boiler is placed at the lowest point, for example, in the basement.

- Expansion tank is installed at the top, for example, in the attic of the house.

- Pipes all the way from the top to the bottom should have a slope so that the water runs down them without delay.

The water heats up in the boiler, expands and naturally rises up the riser to the upper point, from where it is diverted down the radiators and, cooled down, returns to the cauldron. If during installation the pipe in any place was raised too high, the angle of inclination is not maintained, then an air bubble forms in this place, which stops the water flow and subsequent batteries remain cold. The velocity of the coolant is small, so it is necessary to put large diameter pipes, especially at the feeder stand - 40-50 mm in diameter.

Advantages and disadvantages

- Ease of operation.

- Independence from the presence of electricity.

- Noiseless operation due to lack of pump.

- Low cost of equipment and components.

- From the open expansion tank air enters the system, which leads to the appearance of air congestion, intense corrosion of metal parts, cavitation.

- The tank must be insulated to prevent the water from freezing.

- It is necessary to monitor the water level in the tank.

- It is impossible to use antifreeze instead of water - it evaporates from the expansion tank.

- Due to the lack of a pump, the total length of the pipeline is limited, so open heating systems are suitable for heating only small rooms.

- Due to the weak circulation of the coolant, it is necessary to heat it to a higher temperature, and this is unnecessary waste, especially since the volume of the heat carrier is greater than in closed heat systems.

- Also extra costs for the pipeline due to the larger diameter of the pipes and the need to take them to the attic to the expansion tank.

- Pipes are all visible, usually they can not be closed with finishing panels.

Features of closed heating systems

Specificity of the arrangement and performance characteristics

Heating systems closed type hermetic: the expansion tank in them is a closed container, which is divided inside by a membrane of heat-resistant rubber into two compartments. In one compartment excesses of heated water merge, in the other there is air (or nitrogen) under pressure, which squeezes water back when it cools.

Important: the volume a membrane tank choose from the calculation of 10% of the total volume of the coolant in the system.

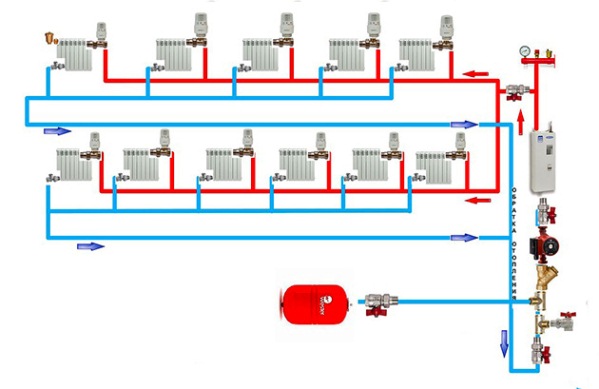

Closed heating systems of a private house are systems with an artificial forced circulation coolant. The circulation pump can be integrated in the boiler or installed separately - usually on a return, where the water is cooler. Due to forced circulation, the installation of the entire heat system is much easier: you do not have to withstand the slope of the pipes, you can use pipes of smaller diameter, the expansion diaphragm tank can be put in any place for easy maintenance. On the other hand, because of the pump, the heating system becomes dependent on electricity. To compensate for this dependence, it is necessary to provide backup power sources: UPS, gasoline generator, etc.

Advantages and disadvantages

- Simple installation.

- Evaporation of the coolant is eliminated, so antifreeze can be used.

- The absence of air in the system eliminates oxygen corrosion, and air congestion.

- Lower pipeline costs. Pipes can be laid so that they are hidden under the finish.

- You can connect additional heating circuits, for example, warm floors (with a separate pump).

- Due to the higher velocity of the coolant, the system has better heat transfer and is faster heated when switched on.

- Equipment for a closed system is more expensive than for an open system.

- Dependence on electricity supply.

- High requirements for tightness of joints, especially when using antifreeze.

Filling with closed heating system

The correct filling of the closed type heating system takes place in several stages. The hose is connected at one end with a filling tap, and the other with a water pipe, or with a pump that will pump the prepared water from a suitable container. First, water is fed until the pressure reaches 0.5 bar. At this stage, you should check all joints for leaks. Then the pressure is raised to 2 bar and air is removed from the heat system: the radiators are opened with Mayevsky cranes and other air vents. The pressure decreases and additional feeding is necessary. When the equipment is filled with water, all the valves close and again check for leaks at the joints. After that, the coolant is lowered to a pressure of 1.5 bar - this is the optimal value for cold water. When heated, the pressure rises.

Open or closed heating system can be mounted independently. But it is important not to be mistaken in calculations when choosing the appropriate pipe diameter, the volume of the expansion tank, the boiler's capacity and other characteristics of the heat system. Such errors can be too expensive. Therefore, it is better to contact the professionals of a specialized company to calculate and install the heating system.

Video: single-pipe and two-pipe heating systems

The creation by unknown inventors of a water heating system is without a doubt a brilliant solution that uses a change in the physical properties of water when heated. The water heated in the boiler moves upwards and creates a certain head (pressure). Under its action, the water moves by gravity through the pipes of the circuit, gives heat to the radiators and returns to the boiler by "return". The first operating heating system was, of course, open. After the emergence of new technologies, materials and equipment were created closed circuits heating, but still there are disputes, which heating system is closed or open is better for heating the dwellings.

There are only two options: closed or open system heating the house. Did anyone wonder why the first created systems were only open? And they were open for one simple reason - the boilers that heated the water were solid fuel. When circulation stops, the water in the boiler boils, the explosion of the boiler prevents the safety valve, but it is quickly impossible to extinguish it. Therefore, closed heating systems with forced circulation began to be used for electric and gas boilers, which can be switched off automatically at any desired time.

There are only two options: closed or open system heating the house. Did anyone wonder why the first created systems were only open? And they were open for one simple reason - the boilers that heated the water were solid fuel. When circulation stops, the water in the boiler boils, the explosion of the boiler prevents the safety valve, but it is quickly impossible to extinguish it. Therefore, closed heating systems with forced circulation began to be used for electric and gas boilers, which can be switched off automatically at any desired time.

Open heating system

The open heating system is currently considered obsolete and is used in small private houses and country cottages. In this case, it is necessary to install an expansion tank in an open heating system at the highest point of the upper collector, to ensure circulation under the influence of gravity.

The open heating system is currently considered obsolete and is used in small private houses and country cottages. In this case, it is necessary to install an expansion tank in an open heating system at the highest point of the upper collector, to ensure circulation under the influence of gravity.

The modern open circuit of the heating system from a closed system has borrowed the most important unit - the circulation pump. It is usually used when the system is started to reduce its inertia. Then, during operation, the pump shuts down and the bypass opens. Know where to put the pump in the heating system is necessary for its reliable and long-term operation. The pump is put in the point with the lowest temperature of the coolant, usually in the "return" around the boiler.

The modern open circuit of the heating system from a closed system has borrowed the most important unit - the circulation pump. It is usually used when the system is started to reduce its inertia. Then, during operation, the pump shuts down and the bypass opens. Know where to put the pump in the heating system is necessary for its reliable and long-term operation. The pump is put in the point with the lowest temperature of the coolant, usually in the "return" around the boiler.

The system is called "open" because the atmospheric air is constantly in contact with water in an open expansion tank.

The open system is simple, reliable, and its cost is minimal. There is an erroneous opinion that its installation costs more, because for such systems pipes with a larger diameter are required. If we take into account the cost of a circulating pump, an expansion membrane tank and the cost of electricity for a closed heating system, the installation will obviously not be cheaper. In some cases, there is no alternative to using an open heating system. For example, in the absence of electricity.

The open system is simple, reliable, and its cost is minimal. There is an erroneous opinion that its installation costs more, because for such systems pipes with a larger diameter are required. If we take into account the cost of a circulating pump, an expansion membrane tank and the cost of electricity for a closed heating system, the installation will obviously not be cheaper. In some cases, there is no alternative to using an open heating system. For example, in the absence of electricity.

The main advantages of open heating systems:

Of course, a simple and reliable open heating system is usually a two-pipe system, it does not lack the disadvantages:

Closed heating system

If a closed-type heating system is chosen, the circuit of which can be any one-pipe or two-pipe, with heated floors or without, its main feature is the absence of contact of the coolant with air, i.e., it is completely hermetic. The movement of the coolant in the circuit provides, and the thermal expansion of the liquid is compensated in the hermetic membrane expansion tank. The use of forced circulation facilitates installation, because you do not need to withstand the slope of the pipes, which can be of smaller diameter. The presence of a pump makes the system volatile.

If a closed-type heating system is chosen, the circuit of which can be any one-pipe or two-pipe, with heated floors or without, its main feature is the absence of contact of the coolant with air, i.e., it is completely hermetic. The movement of the coolant in the circuit provides, and the thermal expansion of the liquid is compensated in the hermetic membrane expansion tank. The use of forced circulation facilitates installation, because you do not need to withstand the slope of the pipes, which can be of smaller diameter. The presence of a pump makes the system volatile.

With the increase in the number of private houses and the complexity of heating circuits, a closed-type heating system is mainly used, which may include several circulating pumps, collector beam distribution and automated electronic temperature control of different rooms. In the closed circuit, the installation scheme of the expansion tank in the heating system differs from its placement in an open system. The most optimal option, the placement of the membrane tank in the "return" near the boiler.

With the increase in the number of private houses and the complexity of heating circuits, a closed-type heating system is mainly used, which may include several circulating pumps, collector beam distribution and automated electronic temperature control of different rooms. In the closed circuit, the installation scheme of the expansion tank in the heating system differs from its placement in an open system. The most optimal option, the placement of the membrane tank in the "return" near the boiler.

A popular closed heating system has both advantages and disadvantages:

Commissioning of a closed heating system

After completing the installation, the system must be filled with water and tested. The initial filling of the closed-type heating system is carried out according to certain rules. In the design of the heating circuit, drain cocks located at the lowest point of the system and taps for filling the system with water should be provided.

After completing the installation, the system must be filled with water and tested. The initial filling of the closed-type heating system is carried out according to certain rules. In the design of the heating circuit, drain cocks located at the lowest point of the system and taps for filling the system with water should be provided.

The sequence of actions for filling the circuit with a coolant is as follows:

If there are leaks during the filling process, the process of filling the system should be stopped and the problems that have arisen eliminated. After eliminating the shortcomings of the work can continue.

If, after carrying out all the above operations, the system does not work well, some batteries get warmed up badly, the circulation is broken, this indicates the presence of air in the system. In such cases, the heating system is purged, which consists in careful removal of air. The Maevsky crane opens and not only air is removed, but also some water. It is desirable to provide high blood pressure, in the heating system having opened the make-up from the water supply. Usually the repetition of the procedure results in the complete removal of air bubbles from the circuit.

If, after carrying out all the above operations, the system does not work well, some batteries get warmed up badly, the circulation is broken, this indicates the presence of air in the system. In such cases, the heating system is purged, which consists in careful removal of air. The Maevsky crane opens and not only air is removed, but also some water. It is desirable to provide high blood pressure, in the heating system having opened the make-up from the water supply. Usually the repetition of the procedure results in the complete removal of air bubbles from the circuit.

Why makeup in a closed system

For efficient operation of a closed heating system, it is necessary that the working pressure is constantly maintained in it. Despite the fact that the system is hermetic, there are imperceptible at first glance and insignificant leaks. Water from the system is lost when air is removed through the Maevsky crane, seeps through the oil seals, through various contour joints. These losses are summarized and after a while have an impact on the operability of the system. To compensate for these losses, it is necessary to replenish the closed heating system from the water main.

For efficient operation of a closed heating system, it is necessary that the working pressure is constantly maintained in it. Despite the fact that the system is hermetic, there are imperceptible at first glance and insignificant leaks. Water from the system is lost when air is removed through the Maevsky crane, seeps through the oil seals, through various contour joints. These losses are summarized and after a while have an impact on the operability of the system. To compensate for these losses, it is necessary to replenish the closed heating system from the water main.

Manual or automatic replenishment

For simple and small heating systems, a tap with mechanical control. It is installed at the point of least pressure that is in front of circulation pump. At this point, a pressure gauge is installed to monitor the make-up process.

For simple and small heating systems, a tap with mechanical control. It is installed at the point of least pressure that is in front of circulation pump. At this point, a pressure gauge is installed to monitor the make-up process.

To prevent the coolant from entering the water main, a shut-off valve is used.

In complex and branched systems, the heating system is automatically recharged. The price of the make-up valve depends on the brand of the manufacturer. Sometimes automatic make-up valves are part of the boiler equipment. If make-up is carried out from a water pipe, in which the pressure is usually 3 to 4 bars, then everything happens quite simply. The factory setting of the valve is 1.5 bar.

In complex and branched systems, the heating system is automatically recharged. The price of the make-up valve depends on the brand of the manufacturer. Sometimes automatic make-up valves are part of the boiler equipment. If make-up is carried out from a water pipe, in which the pressure is usually 3 to 4 bars, then everything happens quite simply. The factory setting of the valve is 1.5 bar.

If the pressure in the heating system falls below 1.5 bar, the valve will open and open until the set pressure is reached. If the automatic make-up will use a coolant from other sources, then a pump is needed that will be switched on by a signal from the valve and the coolant is supplied under a certain pressure to the heating system.

If the pressure in the heating system falls below 1.5 bar, the valve will open and open until the set pressure is reached. If the automatic make-up will use a coolant from other sources, then a pump is needed that will be switched on by a signal from the valve and the coolant is supplied under a certain pressure to the heating system.

Automatic temperature control

How to automate and choose the optimal mode in the premises of the house, especially with frequent absence in the apartment or in a private country house. Very simple, you need to buy a controller for the heating system - a device that allows you to program and monitor the temperature in the house. Before buying a controller for heating, you need to make sure that the boiler has an appropriate control unit. The best option is consulting specialists.

How to automate and choose the optimal mode in the premises of the house, especially with frequent absence in the apartment or in a private country house. Very simple, you need to buy a controller for the heating system - a device that allows you to program and monitor the temperature in the house. Before buying a controller for heating, you need to make sure that the boiler has an appropriate control unit. The best option is consulting specialists.

One of the most optimal options automation is obtained when using. On the comb are installed special valves, which are controlled by the control unit of the multichannel controller. The same control unit gives a signal to turn on the boiler.

One of the most optimal options automation is obtained when using. On the comb are installed special valves, which are controlled by the control unit of the multichannel controller. The same control unit gives a signal to turn on the boiler.

Each room is equipped with a separate thermostat, which is set to a certain temperature. The multichannel controller of the radiant heating system, processes the data from the thermostats and when the temperature is lowered in some room it turns on the boiler and opens the valve of this room on the comb. In any case, the boiler will work until the temperature reaches the programmed value in all rooms.

Each room is equipped with a separate thermostat, which is set to a certain temperature. The multichannel controller of the radiant heating system, processes the data from the thermostats and when the temperature is lowered in some room it turns on the boiler and opens the valve of this room on the comb. In any case, the boiler will work until the temperature reaches the programmed value in all rooms.

It is impossible to say unambiguously which heating system is better - open or closed. The use of a particular system depends on many factors, for example, the size and number of storeys of the house, its location, the availability of financial resources and the region. Only a reasonable approach will allow you to choose a home heating system that will provide comfort and coziness in the house with the best costs for installation and operation.

It is impossible to say unambiguously which heating system is better - open or closed. The use of a particular system depends on many factors, for example, the size and number of storeys of the house, its location, the availability of financial resources and the region. Only a reasonable approach will allow you to choose a home heating system that will provide comfort and coziness in the house with the best costs for installation and operation.

1.

2.

3.

Open heating system Today it enjoys a steady demand, but at the same time it has a number of shortcomings that negatively affect the efficiency of such a design (read: ""). The most important drawback is the contact with the atmosphere: the air in the system contributes to the rapid deterioration of the pipeline and worsens the performance of the system. It was to avoid this process that the scheme of the closed-type heating system, which is not affected by the atmosphere, was developed.

The principle of closed heating

What does the closed-circuit heating scheme look like? Basic constructive feature, which determines the name of such a system - its tightness. The closed-type heating system, the scheme of which includes elements, some of which is used in other types of heating, looks like this:- boiler;

- air valve;

- thermostat;

- heating devices;

- expansion tank;

- balancing valve;

- ball valve;

- pump and filter;

- manometer;

- safety valve.

The closed-type heating system is protected from air ingress, but it is impossible to eliminate this process. For example, when the liquid is poured into the system, some amount of air will still be able to seep into the pipeline. The air that enters the pipes will accumulate at the top of the system and form air plugs that will degrade the system and increase the risk of malfunctions.

To lower the air entering the system, it is possible to use the Mayevsky crane or float valves, which work automatically. If air is dissolved in water, then it can be removed with the help of separators, which are installed directly in the pipeline.

To save heat, the closed-type heating system uses a thermostat that automatically switches the pump on and off when the room temperature changes.

Choice of boiler for closed heating system

Closed system heating in a private house is able to work with any type of fuel: you can use gas appliances, and electricity, and solid fuel. The choice of a suitable boiler should primarily be affected by the results of calculations of the required heat output. You can assign the calculations to a specialist, but you can do it yourself - but in this case the result will be approximate.

There are different types of heating boilers: one-circuit, two-circuit or with a boiler. AT country houses often double-circuit boilersBecause their effectiveness in small areas is quite sufficient. The boiler equipped with a boiler is a little more convenient: there is always hot water in it, and it does not need to be filled constantly.

Choice of expansion tank for closed heating

The coolant in the heating systems of private houses is usually ordinary water. When heated, water has the property of expanding, thereby increasing the pressure in the system. If the pressure in the sealed system exceeds the critical point, a pipeline breakthrough may occur. How to make a closed heating system that will not damage the pipes?To solve this problem, expansion tanks have been created, which allow eliminating excess fluids, thereby preventing pressure build-up.

The expansion tank consists of two parts: a metal body and an elastic diaphragm, which is located inside and divides the body into two halves. The "rear" part of the tank is filled with air or gas, and the expanded part gets into the lower part of the liquid. When the temperature rises, the water continues to increase in volume, affecting the membrane, which begins to contract.

In the event that the pressure in the system is still critically high, there are safety valves (read also: ""). When the liquid cools, the diaphragm begins to expand, filling the closed-type heating system with water by pushing it out of the tank.

Expansion tank usually installed near the boiler.

Membranes in tanks can be of two types:

- Fixed. Such a membrane is fixed around the perimeter of the expander and ensures stable operation, but in case of damage it will be necessary to change the entire tank.

- Replaceable. Membranes of this type are usually produced in the form of bulk rubber products that are filled with water. Replaceable membranes are installed on the flange of the tank, and in the event of a rupture, the replacement can be made independently.

The heating system is an important element of the house, and its calculation must be carried out in accordance with all the rules. The question is, which is better: a closed heating system by one's own hands or built by professionals remains open, but it is not the most important.

It is very important to choose the right elements of the system, which will ensure maximum efficiency and economy, will be reliable and quality. Closed heating system, the scheme of which is depicted in the photo, can be an excellent choice, ensuring the fulfillment of all requirements.

If everything was done correctly, the closed heating system will heat the building for many years, creating a cozy and comfortable environment.

The widely spread open heating system has a number of serious shortcomings. One of them is direct contact with the atmosphere. As a result, a coolant flows through the pipes, in which there is air. Air bubbles can gradually cause corrosion of the metallic elements of the heating system, and also cause "noise" of the coolant. All this can be avoided by doing the entire private heating system of a private house.

How does closed water heating work?

The main feature of such systems (and what does not have an open circuit) is complete isolation from the influence of the environment. In a closed heating system, which you can do with your own hands, includes the following elements:

- boiler;

- automatic air valve;

- thermostatic valve;

- radiators of heating;

- expansion tank;

- balancing valve;

- ball valve;

- pump and filter;

- manometer;

- safety valve.

How does it work water heating closed type? If the coolant temperature rises, excess liquid is squeezed out into the expansion tank. When the temperature falls, the liquid returns to the system, i. E. supported by constant pressure in a rather narrow range.

For effective circulation of the coolant, a pump is used (the open system can have a natural circulation). The truth here, too, has its disadvantage - in the absence of electricity supply, a closed system can not function normally (the absence of electricity for a country private house is a very pressing problem). But the advantages of using a "pump" are more than compensate for shortcomings - and for the apartment and for a private house it is possible to install additional heating systems. In particular, you can make a warm floor.

The circulation pump is installed on reverse pipe ("Return") in front of the heating boiler. An expansion tank is immediately installed here. Such an arrangement of these important elements allows one to be uncritical of the diameter of the pipes used in the installation and the compliance with the slope, which must necessarily have an open water heating system.

As a result, the installation of such a heating system is less time consuming, materials (for example, it is not necessary to insulate the pipeline, since the expansion tank is installed next to the boiler). However, it is not necessary to "abuse" such advantages. This is especially true of the slope (it is better to do it anyway) - if it is observed, the system in the event of a power outage is at the very least, but it will still work, i.e. The defrosting does not threaten it.

In the video below you can see a detailed example of the organization of closed type heating using solid fuel and electric boilers.

The closed heating system is insulated from air penetration. However, its operation does not ensure 100% airtightness: air can fill the pipes, for example, when refilling in the coolant system. In this case, it will accumulate at the top points. To get rid of it it is possible by means of the crane of the Majewski or float collectors working on the "automatic machine". The air already dissolved in water is removed with the help of special separators installed directly in the pipeline.

Good results in terms of saving heat gives the use of a thermostat. It includes the main electricity consumer (pump) only when the room temperature falls below a set limit.

How to choose a boiler for closed heating

The scheme closed heat supply The private house provides for the use of any type of fuel. This can be gas (the most efficient and profitable option), electricity, diesel or solid fuel.

Pay attention to the power of the boiler. The approximate value for the insulated room, which has ceilings up to 3 meters high, is 1 kW per 10 "squares" of the area of the private house.

The figure, voiced above - is very, very approximate. It all depends on many factors: the material that they are building the building, the quality of the insulation, the presence (absence) of a heated attic or attic. The efficiency of heating is affected by the number of windows and the way in which their installation was performed. Therefore, competent heat calculation is required, which can be done by a qualified engineer.

The heating boiler can be single-circuit, double-circuit or with a boiler. As practice shows, in the main country houses have a small area and, therefore, a small need for hot water. From this point of view the best choice there will be a two-circuit boiler (its installation is simple), capable of heating for 30 minutes to + 30 ° C about 10 liters of water. The boiler with the storage boiler is more comfortable - it constantly "has" already ready several tens of liters hot water - Constant filling is not required.

Expansion tank for closed type heating

Most often in the heating system of a private house the role of the coolant is played by water. As the temperature rises, its volume increases, the pressure increases. If the scheme of closed heat supply is used, the pressure can overcome a certain critical value and then the elements of the heating system will be destroyed.

To avoid such a development of events, the installation of a private house heating system implies the use of an expansion tank.

Features of the construction of a closed type tank

Any tank of this type has two main parts: a body made of metal and an elastic membrane inside.

The scheme of its operation is quite simple: air is pumped into the upper half of the tank (in expensive modifications - inert gas), the lower part is filled with water from the pipeline.

When the coolant is heated, the pressure rises, the membrane "bends", sealing the air or inert gas. To prevent dangerous situations, there are safety valves. When the pipeline with water cools, the pressure of air on the membrane becomes stronger than the pressure of the coolant, and it fills the heating system. The expansion tank is installed next to the heating boiler. Membranes are of 2 types.

- Fixed - tightly fixed around the perimeter of the expander. Such devices can be found in the heating tanks of a private house or a small enterprise.

These membranes will last a long time if you follow the operating instructions. In the case of a rupture, you can not change such a membrane - you will have to change the entire tank;

- Replaceable - they are made in the form of rubber pears, balls, which must be filled with water. Installation of such a membrane is performed on the flange of the tank. If there is a gap, then you can replace the damaged membrane with a new one yourself, without involving specialists.

When planning the heating scheme, it is important to calculate first the capacity of the heating boiler, take into account the number of radiators and the length of the pipeline.

Careful planning and calculation of the water heating system, and the installation carried out in accordance with the received data, will help you achieve efficient, economical and efficient heating.

The system of water heating, in which a membrane expansion tank is used and the heat carrier does not in any way contact with atmospheric air, is considered closed and operates under pressure. This scheme is the most common at the moment, as it has many advantages. In this article, we will analyze what is the closed system of heating a private house, its pros and cons, and also the features of service.

What is a closed heating system?

An important feature of such a system is the absence of contact with outside air and the presence of a slight excess pressure. As a rule, the circuit operates with an artificial stimulation of the circulation of the coolant by means of a pump. This makes it possible not to worry about observing large slopes of the mains, and also to take smaller diameters of pipes and to lay them in the most convenient way.

As a rule, a gravitational heating system with natural circulation of the coolant is made with an open expansion tank installed at the highest point. A closed system is traditionally supplied with a circulation pump, which increases the efficiency of its operation and reduces the material consumption.

Due to their features, closed systems have a lot of advantages:

- the heat carrier, which is under pressure, heats up more quickly;

- the likelihood of the pipeline network and radiators being inflated is very low;

- the coolant is not saturated with oxygen and does not evaporate into the atmosphere, which is very important when filling the system with antifreeze;

- installation of the expansion tank in a closed heating system is carried out on the return pipeline near the boiler, which is very convenient in terms of maintenance;

- there is no need to use pipelines of large diameters and to lay them in plain view, in this respect a closed system with forced circulation - the best choice for a private house.

A significant drawback is only one - dependence on the reliability of electricity supply, a closed heating system without a pump, powered by electricity, will not work. Fortunately, the circulation units for individual systems have a small power consumption, and therefore at the time of power outages will be able to function from an uninterruptible power supply unit for a long time.

Some experts say that a closed system with natural circulation will help solve the problem of power failure. Recall that in this case the movement of the coolant is due to the difference in the density and mass of hot and chilled water. The first, heating in the boiler, as the lighter is forced out upwards by the cooled coolant, which has a large mass, coming from the radiators.

Despite the fact that the pressure in the closed heating system (1.5-2 bar) does not hinder the gravitational movement of hot and cold water streams, the efficiency of its operation is highly doubtful. The fact is that the difference in convective forces is still not great, and here it is still necessary to overcome the resistance of the membrane of the tank, which expands with the expansion of water. In order not to contact these slippery moments, it is better to always put the pump on a closed system. If there is a need to mount a gravity circuit, then it must be done openly.

Scheme of closed heating system

In private housing construction, two types of schemes are traditionally used:

- single-tube;

- two-pipe.

One-pipe, more commonly known as "Leningrad", works satisfactorily in one- and two-story houses of a small area, when no more than 5 radiators are installed on each floor. The implementation of the circuit requires accurate calculation of the pipe diameters and the number of battery sections, since the coolant significantly cools after passing each subsequent radiator. In order to meet these requirements, single-pipe circuit closed-type heating systems with an upper wiring, as shown in the figure below:

Note. Regardless of the type of scheme chosen, a closed system must contain a security group, sometimes it comes with a boiler. The group consists of a manometer for pressure monitoring, an air vent and a safety valve for emergency water discharge. The unit is installed on the supply pipe leaving the boiler, without any shut-off valves.

The two-pipe system of the closed system is easier to calculate and install, is famous for its good performance. After all the coolant to all radiators is delivered with the same temperature, and when the associated scheme is implemented, the same distance also passes. Example two-pipe system shown in the picture:

Some additions have a closed heating system with a solid fuel boiler. To avoid condensation in the furnace of the heat generator, the circuit is supplemented by a mixing unit with three-way valve and a bypass line. The valve forces the water to circulate through the bypass until it warms up to the set temperature, and only then starts the coolant from the pipeline into the boiler.

How to fill the system with a coolant?

When the make-up connection is connected to the water supply network by means of a ball valve, it is quite simple to fill the closed-type heating system with a coolant. For this case, it makes sense to attract an assistant, especially if the house has several floors. One man controls the tap, and the second manages to release air from the batteries. The crane opens about a third, so that the pressure is not strong.

The person in the boiler room monitors the pressure gauge, the make-up of the closed heating system closes when the pressure reaches 2 bar. Now the assistant using the Mayevsky cranes bleeds air from the radiators, after which the pressure drops. The goal is to reach the design pressure by removing all the air from the pipelines by gradually replacing it with tap water.

It is more difficult to pump the coolant into a closed system, when there is no make-up from the water supply, or it is necessary to fill the non-freezing liquid. To do this, you need a special manual or electric pump and a container for the coolant, from which it will be pumped into the system. Beforehand, you need to open all the air valves on the radiators, and then fill the pipes through the drain connection, connecting to it a pump with a non-return valve.

As the liquid is pumped in, it is necessary to close the Mayevsky cranes, from which the coolant will flow. After pumping the system to 1.5 bar, it is necessary to perform air removal, after which the pressure is brought to the working one. At the end, a test run of the boiler and pressure adjustment are performed, and, if necessary, air bleeding.

Why does the pressure in the closed heating system drop?

The reason for the drop in pressure, there is one - the lack of leakage, that is, leakage. The question is to find it. A characteristic sign of leakage is a puddle in a certain place or a brown stain when the water has time to dry. During the search, the following nodes and elements should be examined:

- pipe joints and fittings: it happens that in the latter there are cracks;

- automatic air deaerators: a defective element with a stuck float will let in water;

- shut-off and control valves, safety valve;

- expansion tank: a crack in the membrane will cause a pressure drop, the appearance of air in the system and frequent boiler shutdown.

To eliminate leaks, you can not do without partial or complete emptying of pipelines. At the end of the work, it is necessary to fill the system with water, create the necessary pressure and follow the manometer for several days.

Conclusion

Closed heating system has a lot of advantages, hence its popularity. If the installation and commissioning is performed correctly, then for a long time it does not require intervention in its work. Most of the problems that arise can be safely eliminated by yourself, as well as maintenance of the system. It is advisable to annually check the operability of elements such as air vent, valve and expansion tank.