A brick chimney in a private house. Chimney made of stainless steel. Material for the chimney pipe - which is better

The usual pipes for the chimney, made of brick or non-galvanized metal, having a black tint, gradually give way to other types. This is due to the emergence of new materials and technologies for manufacturing smoke exhausting structures that have a specific purpose and their own distinctive features.

Material as a key selection criterion

Furnace heating has always been in demand, since it is impossible to find an adequate substitute for living fire. In order to avoid problems with the efficiency of heating devices, it is necessary to properly approach the arrangement of chimneys. When deciding which of the available options is best, it is necessary to analyze them in accordance with key criteria.

Along with the dimensions, one of the most significant criteria is the material used by the manufacturer for the manufacture of pipes. Knowing its characteristics and recommended directions of use, it will be possible to correctly make a decision and purchase a reliable chimney.

Asbestos cement

Asbestos is an inexpensive feedstock, thanks to its vast deposits. The simple production cycle for the production of asbestos-cement pipes and simple installation without additional insulation supplement the chain of merits. It becomes clear why they have long been popular in various construction sectors, although they were originally used for land improvement.

Over the years of using asbestos cement pipes as chimneys, their weaknesses have been revealed along with worthy corrosion resistance. Among the main shortcomings are the following factors:

- pollution of the surrounding atmosphere by harmful emissions;

- the ability to burst, sometimes with an explosion when the temperature reaches more than 300 degrees. For this reason, asbestos-cement pipes are placed in the upper segments near the roof, where the smoke is already slightly cooled;

- the possibility of igniting soot, which accumulates in considerable quantities on the rough surfaces inside the chimney, which is dangerous by its explosion;

- susceptibility to destructive effects of condensate;

- a sophisticated technology for periodic cleaning of the chimney.

Stainless steel

Thermal resistance of pipes (withstand heating to 500 degrees), for the production of which stainless steel is used, has determined their relevance. There are a number of advantages that such chimneys possess:

- no deformation due to high corrosion resistance;

- reliability due to non-adherence to negative impacts of aggressive substances;

- practically no soot on perfectly smooth internal planes;

- affordable price;

- light weight;

- fire resistance;

- durability;

- environmental Safety;

- nice external decor.

Installation of ceramic chimney

Steel modern chimney pipes, do not cause problems during installation. They can be installed from the outside with the help of special brackets or inside, as the building under construction, and already ready building. In case of external placement, it is necessary to carry out measures for the insulation of the chimney. You can close the pipe with a special casing.

Cink Steel

Steel after treatment with liquid zinc receives additional positive qualities, which explains the same popularity of chimneys made of galvanized steel in comparison with stainless steel.

Having acquired a pipe made of galvanized steel, the consumer will receive a fire-safe flue. Rapid heating of its walls provides good draft. Heating device can work on any kind of fuel, which will not affect the high quality of the chimney functioning.

It involves simple installation, as well as good resistance to the destructive effects of condensation and corrosion. Soot accumulates in minimum quantities, because the internal walls are absolutely smooth.

Concrete

Concrete pipes are selected as a chimney for some characteristics. They are durable and cheap. When pouring, no seams are formed. If you plan to make a pipe on your own, then you need a sliding formwork and high-quality concrete. It will require portland cement grade M400 and sand in a proportion of 1: 3. To correct the heavy weight of a pipe with monolithic walls, the introduction of expanded clay into the composition of concrete.

Brick

Aesthetic, not subject to ignition, a brick chimney is known for a long time, therefore all its advantages and serious shortcomings have been studied.

The main disadvantage is the roughness of the walls, which contributes to the rapid accumulation of soot and soot, significantly worsening cravings.

The next disadvantage is the heavy weight. It is also difficult to repair brick chimneys, which are also gradually destroyed by condensation.

Cast iron

Pipes made of cast iron are made welded. The main advantage is an affordable price, corrosion resistance. Cast iron well withstands high temperatures. The cylindrical shape of the pipes creates the most favorable conditions for the movement of smoke. The walls are fairly smooth, so care for such a chimney is not difficult. Among the shortcomings are heavy weight and high heat capacity. To improve traction, the inner planes are covered with special compositions that increase their smoothness. From the inside, a brick box or pipes are often painted with heat-resistant paint.

Modern solutions

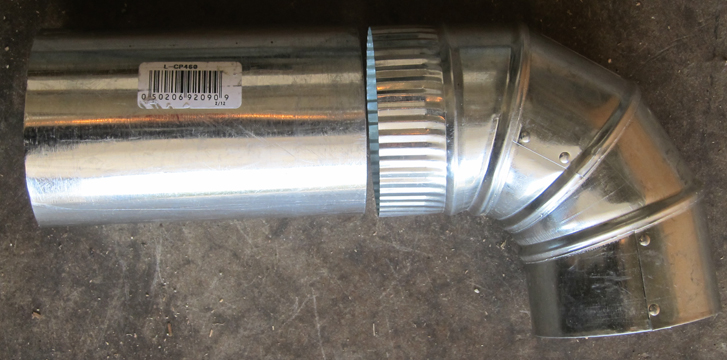

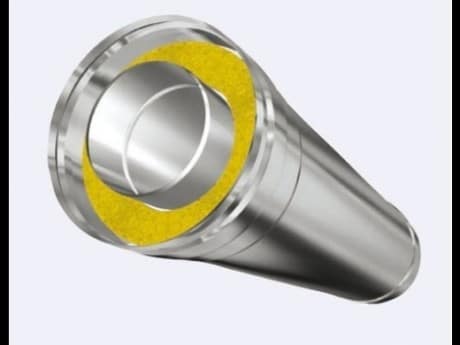

Improved pipes are a three-layer "sandwich". In fact, these are pipes inserted into each other with heat insulation in the gap. Such a system allows external planes not to heat up, providing safe operation. For the same reason, condensate is formed in minimum quantities. Corrugated varieties of such pipes are used as additional elements when it is required to make turns.

Ceramic pipes are the most durable. They are not afraid of corrosion, high degree of heating, condensation. Absolutely smooth walls allow the care to be made rare and simple, since the products of combustion are practically not retained on them. The disadvantage is the fragility of the material, the high price and weight.

The novelty of the construction industry is vermiculite pipes - light, non absorbent, not accumulating soot, excellent heat transfer, resistant to mechanical stress.

Solving the actual problem, which of the manifold pipes is better for equipping the chimney, it should be understood that its durability largely depends not only on the material, but also on the competent operation.

Video: Revision of modular chimney

Secrets of treating joint pain from our regular reader.

Hello!

My name is Gennady Alexeevich. I'm a stove man with more than 20 years experience. I am engaged both in repair and construction of Russian furnaces and fireplaces. The work is always performed very accurately and carefully, which negatively affects the condition of the joints. With age, the pain began more and more, right up to the point where I could no longer work. After a lot of both drug and folk ways treatment, I realized how serious my disease is, since there was no positive effect. Until I came across one tool, which I want to tell you about.

This is a unique mixture of the rarest and most powerful natural medicinal substances. This tool has proved its effectiveness not only to patients, but also to science, which recognized its effective drug. The pains in joints and back go for 10-15 days, as studies have shown. The main thing is to follow the instructions in the methodology clearly. Order the product in its original packaging, with a guarantee of quality can be on

The primary function of the chimney is the withdrawal of combustion products from the furnace outside, but one should not underestimate its role in the combustion of fuel and the formation of thrust. Experts say that with the right choice of material for the chimney pipe and a competent installation, the heat transfer of the furnace or boiler can be increased to 10-15%. However, for either a solid fuel boiler and a stove, you need a chimney not only of different heights and diameters, but also of the material. If you previously chose only between brick and galvanized metal, then today the range of suitable options is much wider. We understand what materials for the chimney, more precisely the chimney pipes, there are, for what conditions they are intended, and which chimney to choose depending on the type.

What to consider when choosing a material for the chimney?

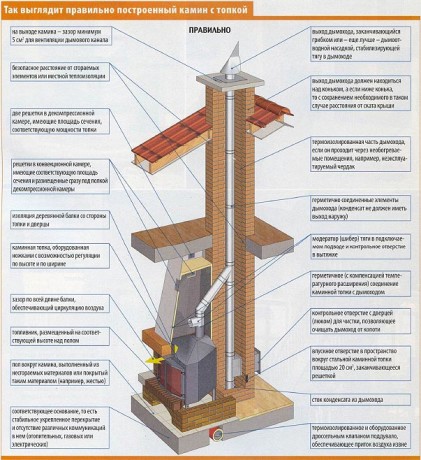

Chimney is a complex a construction consisting of vertical pipe, umbrella for rain protection, inspection window for maintenance, condensate collection tray and other elements. Vertical tube It is considered the main part of the chimney, and safety and efficiency of functioning depend on it.

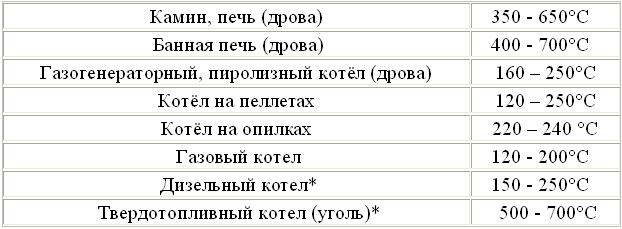

To properly choose the material of the chimney, it is necessary to clearly understand, what fuel will be used: natural gas, diesel fuel, coal, wood, peat or sawdust. Each of them differs with different combustion temperature, temperature and composition of waste gases. Therefore, when selecting materials for a chimney, take into account such parameters:

From all this it follows that:

- for woodburning stoves, solid fuel boilers, sauna stoves and fireplaces it is necessary to choose a material that can withstand an operating temperature of about 700 ° C and a short-term increase to 1000 ° C. These are brick and, more rarely, ceramic chimneys;

- for gas boilers a chimney is required that can withstand a temperature of 200 ° C with a brief increase to 400 ° C. Usually metal pipes are used for this purpose;

- for boilers at liquid fuel and sawdust it is necessary to have such material for a chimney pipe that would withstand the temperature to 250 0 С with an increase to 400 0 С, and if it is a question of diesel fuel, then it is resistant to aggressive environment of waste gases.

Now we will understand the properties of the most popular materials that are used to equip the chimney pipe.

№1. Brick chimney pipe

Brick for the arrangement of chimneys have been used for a long time, and it has already become traditional material. Today it can not be called universal, which, however, does not reduce its popularity. A brick chimney is built inside the walls of the building, those parts of it that pass through unheated rooms or outside the building, carefully so that the flue gases inside do not cool. For the arrangement of such a chimney suitable brands are not lower than M150, for its masonry use.

The main advantages of brick pipes for the chimney refers to their durability and excellent heat resistance (ceramic bricks withstand temperatures of up to 800 0 C), and outwardly they look great, and for fire safety they practically have no equal. A brick chimney fits for stoves and fireplaces on firewood, and when working with boilers on liquid fuels, gas, pellets and solid fuel pyrolysis boilers is rapidly destroyed. The thing is that similar boilers are designed in such a way that the exhaust gases have a low temperature. They quickly condense and settle on the walls of the pipe, due to which the latter are constantly moisturized. Considering the fact that aggressive chemicals, including sulfuric acid, are contained in the waste gases, the brick is rapidly destroyed. The results of such an effect are manifested by wet spots on the outer surface of the pipe.

True, there is always a way out of the situation. To connect a modern boiler with gas or liquid fuel to the brick chimney pipe, brick channel embedded steel or ceramic pipe, which have somewhat different performance characteristics.

Since the surface of the brick is rough, it is well settled with soot, which gradually leads to a reduction in thrust. Cleaning and repair of a brick pipe is not an easy task. In addition, a large design weight will necessarily require availability. On the other hand, it is difficult to find a worthy analogue for furnishing a chimney of a stove or a fireplace.

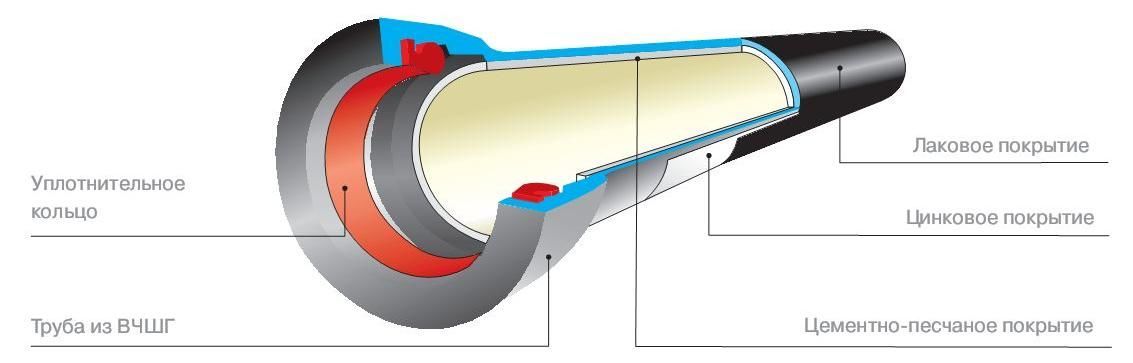

№2. Chimney made of steel pipe

For gas and solid fuel boilers pipes are best suited from steel, but it must be stainless, heat-resistant and acid-resistant, since the sulfur particles, which are practically in every kind of fuel in one or another quantity, when combined with moisture and coal particles form an aggressive medium. Stainless steel is capable to withstand temperatures up to 500 0 С, for the arrangement of chimneys, pipes with a wall thickness of 0.6 mm are used, but for steel 1 mm thick it is better to use. Steel pipes represent a whole system of straight sections and various shaped elements, including adapters, bends, tees, etc. Such a system can be mounted independently or be built into an existing brick channel.

The main advantages of steel pipes:

- simplicity and high speed of installation, because the weight of the structure is small, the need for a foundation is missing, and from the finished elements not even the biggest professional without problems will collect the entire system;

- repair work is easy;

- on smooth walls do not accumulate soot particles, their surface is simply cleaned, so you can talk about the consistently high aerodynamic characteristics for the passage of waste gases;

- high corrosion resistance;

- the possibility of creating complex structures;

- high tightness, due to which it is possible to create a forced draft.

Among the minuses called high cost, especially when compared to a brick or ceramic analog, but if the simplicity and speed of the arrangement is important, low weight and resistance to aggressive environments, then the choice is better to stop it on a steel chimney. The disadvantages sometimes include low heat resistance, but for modern boilers with a system of slow combustion greater heat resistance and unnecessary.

Depending on the characteristics of the room, boiler and climate, one of the following types of steel chimneys:

It should be noted that sometimes for the construction of the chimney use thick pipes of low-alloy steel - this option is usually found in bath ovens. Also, folk craftsmen sometimes use cast iron for the same purposes sewer pipes.

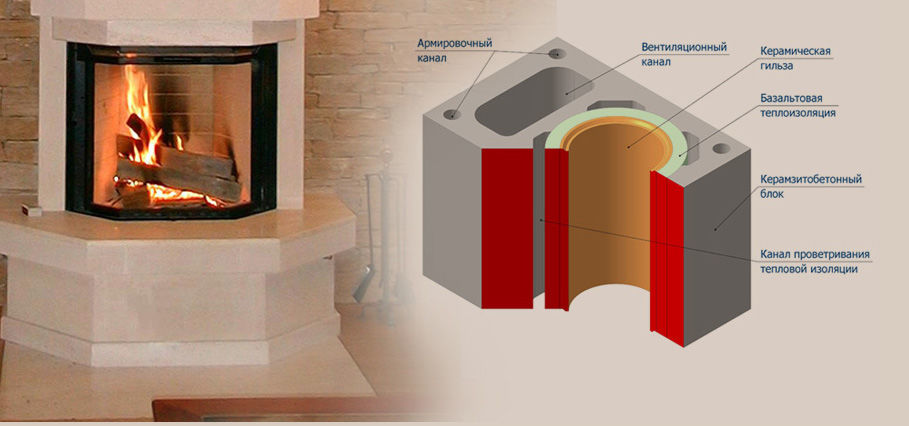

No. 3. Ceramic pipe for chimney

Ceramic pipes for a chimney are considered the most universal, and among them main advantages:

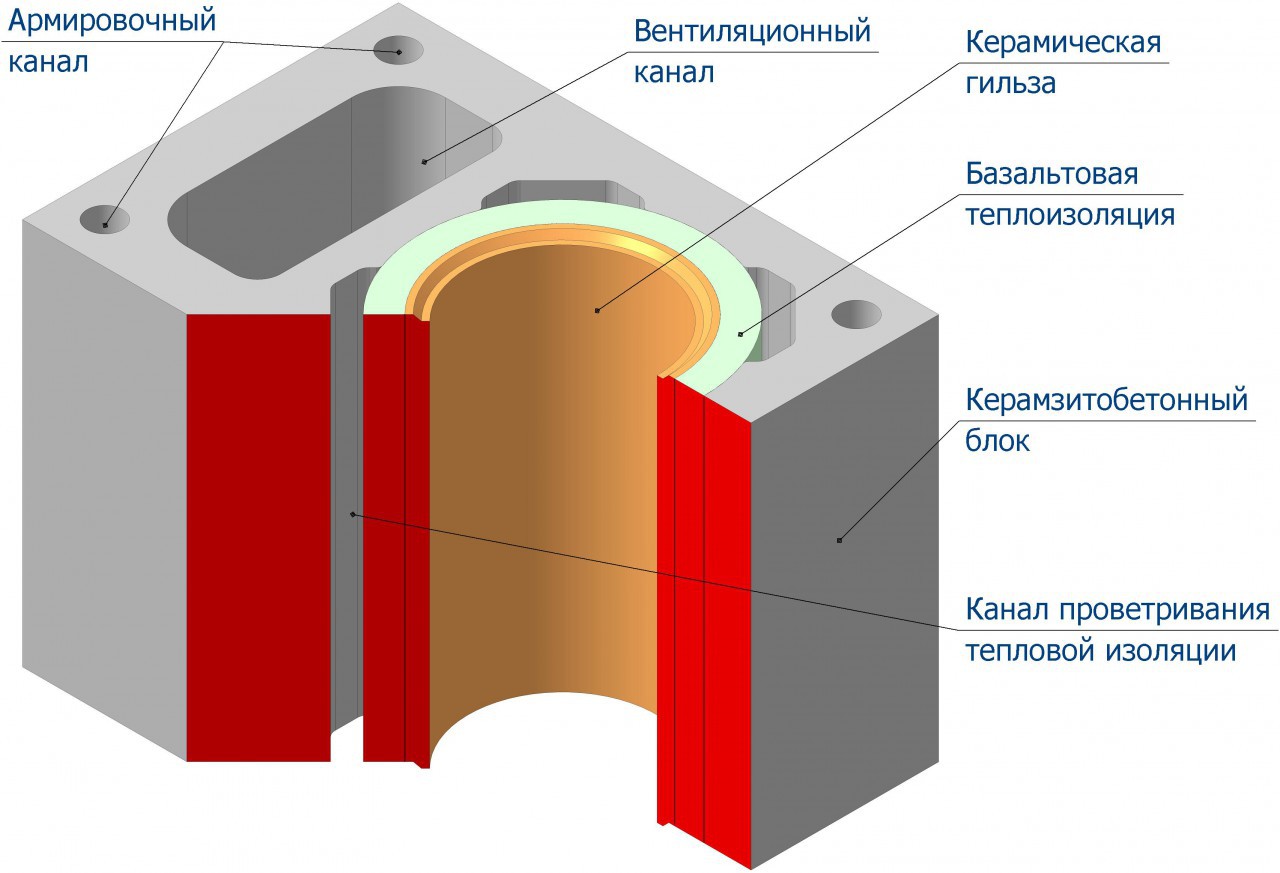

Installation of a ceramic chimney requires the installation of a separate channel. The shell is made up of special ones with voids. A layer of mineral wool insulation is placed around the pipe to protect the adjacent structures from excessive heat and to reduce the formation of condensate. Both the pipe and the thermal insulation are able to absorb water, so they need to ensure the normal. It is created due to the presence of vertical air channels between the heater and concrete blocks. By the way, in the concrete blocks there are also channels for placing reinforcement in them. It is imperative to reinforce the part of the chimney that goes out into the street.

To expand the scope of use of ceramic chimneys, they are produced in steel casing, as well as in the form elements rectangular section . The first do not require the arrangement of a foundation and the creation of special channels, the latter can be used for the reconstruction of brick chimneys.

№4. Chimney from asbestos-cement pipe

A couple of decades ago, asbestos-cement pipes were widely used to equip chimneys. Actually, initially they were not intended for such purposes, as is easily verified by studying their performance. From the advantages of the material, only its low price, and here shortcomings much bigger:

Use an asbestos-cement pipe for a chimney can only be done with the confidence that the installation will be done correctly, and also if the chimney is cleaned regularly, but it is better to pay attention to other options.

№5. Vermiculite pipes for chimney

Not so long ago, vermiculite chimneys were on sale. These are stainless steel pipes, covered with a layer of mineral vermiculite 5 cm thick. This mineral has a low thermal conductivity, therefore, in fact, it is a natural heat insulator. Moreover, vermiculite is absolutely inert to aggressive combustion products.

Among the others advantages vermiculite pipes high durability, relative ease in installation, no need for chimney insulation. Main flaw is the ability to accumulate soot, so it is often necessary to clean the chimney.

Other options

At the moment there are other ways to equip the chimney:

Finally, we note that before choosing a material for the chimney, you must choose a boiler or determine the design of the furnace. In addition, it is necessary to take into account the design features of the building, and it is best to think about all the nuances of its future heating even before the construction of the house. Calculations of the chimney channel for your safety is better to entrust to the specialist.

Furnace equipment has a stable popularity in our country. Classics, as is known, do not come out of fashion, for this reason thousands of people rush to install a fireplace or stove in their house, thus creating an unshakable home. Heat is a symbol of comfort, therefore the issue of heating is given special attention. But the installation of the equipment itself presupposes the installation of a chimney. In this case, a quite reasonable question may arise as to which pipe to use for the chimney. Many do not betray the moment of choosing a great value, because, in their opinion, it is possible to use any pipe made of incombustible material, but not everything is so simple.

Asbestos-cement pipes

Asked which pipe to choose for the chimney, many recall that on the roofs of most Soviet houses could be seen pipes of asbestos and cement. Their popularity at the time was explained by the following advantages:

- There are huge reserves of asbestos in the country, so their cost is quite attractive. There are several plants that manufacture such products, so there is no need for expensive transportation from foreign countries.

- The very manufacture of pipes for a chimney is not difficult. No advanced equipment is required. (See also: )

- No additional insulation is required when using.

The dignity seems to explain the demand for such pipes, but there are certain features that do not allow the chimney from the asbestos-cement pipe to be used at high temperatures. First of all, the internal walls of the pipe do not have a high degree of smoothness, so the soot immediately accumulates on the walls during operation.

Soot, or rather a large number of it, without difficulty will cause inflammation. The flame will raise the temperature in the chimney to an undesirable high mark, so an explosion will occur.

The shells that emerge from the condensate become the haven of a huge amount of soot. Thus, the thrust is reduced and, as a consequence, the fuel in the furnace burns not to the end. The operation of the boiler will be significantly disturbed, therefore the condensate becomes more concentrated.

Pipes made of stainless steel

There are several types of stainless steel pipes, consider them:

- Single-walled pipes assume no insulation. They are installed from inside the duct of the chimney. There are no restrictions on the type of fuel. These products perfectly update the dilapidated chimney, moreover, their installation can not be called difficult in technology and time-consuming.

- Double-walled pipes are insulated, hence the name. Such a flexible chimney pipe can also be installed outdoors. In this case, the service life can be called large due to fire resistance and wear resistance of the structure. (See also: )

There are several types of lining that are used for stainless steel pipes:

- Zinc-plated makes chimneys and chimneys are even more durable and resistant to impacts from outside.

- Also used is galvanized steel with special polymer spraying.

Special attention should be paid to the flue pipes for chimneys, which are also made of stainless steel. They are two-circuit modules. For their manufacture, standard double-walled pipes with different cross-section are used. Thanks to the stainless steel, the resulting product has a colossal level of thermal insulation between the pipes. The layer of such thermal insulation can be 40 mm on average.

For example, consider a sandwich pipe volcano. Many believe that the installation of this design not only guarantees a productive and safe work chimney, but also produced without any difficulties and unforeseen circumstances. The sandwich tube for the volcano is composed of several elements that fit tightly together. With a visual inspection, the whole device reminds everyone of the famous sandwich - a sandwich, hence the corresponding name. Three-layer construction, despite the apparent complexity, can be collected by one person. In each set there is an instruction in which you can learn about all the steps step-by-step. The price for such products is not high, despite the fact that the service life is quite large. Design features in tandem with the advantages of stainless steel guarantee a lasting and fruitful service without any force majeure. But, of course, whatever the pipe, it must be cleaned with soot.

Pipes made of stainless steel are very popular due to many positive features:

- They have a long service life due to the reliability of their own design. Anticorrosive protection, available in stainless steel, does not allow condensate with aggressive composition to affect the surface of the pipe. (See also: )

- The light weight greatly simplifies the installation process of such a pipe. Not so long ago, pipes made of bricks or ceramics were popular, but they are quite heavy, so the installation alone was not possible.

- Stainless steel systems do not require a special foundation, as they do not have to be installed in the house itself. Special brackets, which can be purchased at any construction store, allow you to easily fix the pipe outside the house. Answer the question about how to fix the chimney pipe to consultants in construction shops, and a lot of Internet resources.

- The installation itself can be performed by one person, with the minimum amount of time spent. Among other things, it is possible to install such a tub not only in the process of construction, but also with the finished construction.

- Smooth internal walls do not allow soot to settle in a large amount on the walls. Cleaning such pipes is required much less often.

- Aesthetic appearance has a positive effect on general view structure. The pipe looks restrained and cute in any house in view of the universal color and shape

Pipes made of galvanized steel

Zinc plating does not equal the popularity of stainless steel, although it has more pluses. Not many know exactly how galvanized steel is produced, but there is nothing complicated in the technology itself. Steel sheets fall into liquid zinc. Thus, a conventional steel sheet is endowed positive properties zinc. The pipes for the chimney from galvanizing have the following advantages:

- This material has a high degree of refractoriness. Work of galvanizing is absolutely fireproof.

- The design quickly warms up, so the thrust in such pipes is different in quality and productivity.

- It does not matter which fuel will be used in this boiler. Regardless of the fuel, the chimney with such a pipe will work fully and durably.

- When installing, no serious effort or large space is required. The installation itself is within the power of one person, so there is no need to call the masters.

- Galvanized pipes can also be double-walled. At the moment there are several manufacturers of such products, both in Russia and abroad.

- The effect of aggressive condensate is minimized, as the internal walls successfully resist corrosion. In this case, if we compare products made of stainless steel with analogs only from galvanized steel, then the first ones benefit from corrosion resistance.

- Inside, the pipe also has smoothness, so soot accumulation is minimal. But, of course, this aspect depends on the type of fuel.

Cleaning chimneys

Despite all the above characteristics, it is worth noting that the pipe and the iron pipe for the chimney, and brick, and even stainless steel, should be cleaned from soot at least once a year. This is necessary for the furnace to function properly and properly. In the event that the clearance in the chimney due to soot is reduced or even lost - the soot will heat up until ignition. For this reason, regular cleaning is necessary.

Many are sure that the chimney sweeps have not existed for a long time, but this is not so. This profession exists in our time, moreover, it is quite in demand. Furnace equipment is popular and relevant, so the demand for chimney sweep services does not stop. These craftsmen quickly and fully clean the chimney, moreover, they inspect the entire furnace and pipe for the presence of characteristic damages that can lead to a fire.

Of course, the chimney sweep services are quite expensive, so a reasonable question may arise as to whether it is possible to purge yourself. We will answer unequivocally - yes. For this, it will be necessary to familiarize yourself with all the subtleties of this procedure and acquire the necessary adaptations. They can be bought at specialized stores.

Use of materials is allowed only if there is an indexed link to the page with the material.

The fireplace in the room is fashionable and beautiful, and yet it gives warmth and an incredible sense of comfort. But it's important not to forget about the safety of equipment operation. It depends not so much on the particular model of the fireplace as on the properly selected and mounted chimney. It is the chimney for the fireplace that is responsible for evacuation of products of combustion dangerous to human life.

There are many options for arranging a chimney chimney. Widely distributed as budget solutions, as well as exclusive flue systems, made to order and organically fit into the most refined interior. But, regardless of the material of production and aesthetic appeal, in the first place, the chimney must meet the basic safety requirements, so it is worth taking seriously and stocking up with the necessary baggage of knowledge to choose and arrange it.

Purpose and operating principle of the chimney

In its essence, the fireplace is just a box in which the combustion of fuel takes place. A hotbed with live fire in a dwelling is extremely dangerous, if not properly arranged. For safety of operation of all fireplace system the chimney answers.

What is a chimney? This is a vertical sealed pipe, the bottom of which is built into the fireplace, and the top rises above the roof of the house. The chimney channel passes through the interfloor and the attic. Its main task is to remove smoke and combustion products from the house and throw them into the atmosphere.

In addition, the chimney provides the necessary conditions for a bright and even flame burning, creating a natural draft.

Helpful information! Thrust is a natural current of air, thanks to which simultaneously the process of burning of fuel and emission of harmful substances outwards occurs. The only safe and permissible flow direction is from the house through the chimney, i.e. out. If there is a reverse thrust (air current in the opposite direction), smoke is generated in the room, which can trigger a fire.

Requirements for accommodation

The chimney of the fireplace works according to the laws of physics, therefore, in its arrangement it is important to strictly adhere to building standards (SNiP) developed for this design.

Primary requirements:

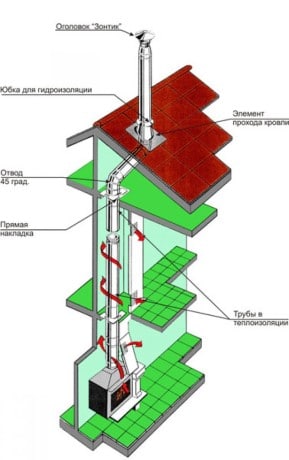

- A non-insulated pipe can not pass through the ceiling, so an insulated flue in a heated room for 0.6 m before crossing with the ceiling is insulated with sandwich panels.

- The chimney for the fireplace must be at least 5 m in height.

- The minimum height of the chimney, its cross-section and thrust force is determined with the help of precise calculations, and not "by eye". In a properly designed chimney: the higher the pipe section, the stronger the thrust.

- The pipe joint is arranged above or below the ceiling and makes it visually open for routine inspections.

- Throughout the length of the chimney pipe is securely attached to the vertical surface by clamps. The same type of fastening is provided for the angle bends.

- According to the norms of fire safety, all wooden sections and elements of the chimney must be protected with flame retardants and insulated with non-combustible materials.

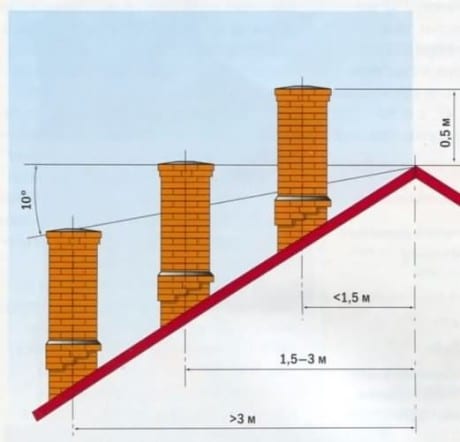

Construction standards stipulate the compliance of the ratio of the height of the roof ridge to the height of the pipe. So, with a flat roof, the height of the external section of the chimney must be at least 1 m. For pitched roofs, other rules work. If the fireplace duct is located at a distance of 1.5-3 m from the ridge, the chimney should be not lower than the ridge. If the distance from the pipe to the roof ridge is less than 1.5 m, the chimney must rise no less than half a meter above the ridge. If the fireplace chimney is located at a large distance (more than 3 m) from the ridge, then its height should be no more than a straight line visually drawn from the top of the roof to the horizon at an angle of 10 °.

Schematic diagram of height calculation chimneys for a gable roof

Helpful information! Each fireplace is designed for a smoke pipe of a certain design and configuration, so when selecting and calculating the chimney it is important to focus on a particular (selected) type of fireplace system.

Types of fireplace chimneys

Depending on the constructive features and the installation method, the following types of structures are distinguished:

Built-in

They are vertically oriented channels for unobstructed removal of smoke. Such a construction is mounted at the construction stage with the construction of a capital wall. Recognized as the most economical and effective.

Pave directly in the wall

Suspended

Arrange in the already erected house. The chimney flue is attached to the bearing elements of the roof base and the ceiling slabs with the help of brackets withstanding a considerable weight of the structure and cable-stayed stretches.

This is important to know! Suspended models "hover" above the fireplace, creating a significant load on the ceiling of the upper floor. To reduce the overall weight of the structure, experts recommend the use of metal chimneys, which are lighter compared to other species.

The suspended construction looks very unusual, as if it "floats" in the air

With support on the fireplace

Chimneys resting on the fireplace, occupy an intermediate position between built-in and suspended. Such designs significantly increase the overall weight of the product, which necessitates the creation of a separate foundation.

Chimney with support on the fireplace increases the load on the foundation

Important! To effectively remove combustion products from a particular fuel type, it is necessary to choose a chimney of the appropriate design with suitable characteristics.

From what it is better to make a chimney

The chimney should be insensitive to high temperatures, corrosive substances released during the combustion of fuel, and water condensate, which is formed as a result of sudden temperature changes. Therefore, to equip the chimney use the most resistant to different types of Impact building materials such as brick, steel, ceramics and glass.

Brick is a tribute to traditions

A brick chimney is a vertical channel made of bricks. This design is the most budgetary, but it requires a significant expenditure of effort and time for the arrangement.

Previously, a brick chimney was the only option for a chimney pipe for a fireplace or a stove, but over time its design was changed. Now inside the chimney inserts a special steel liner, which significantly increases the reliability and efficiency of the entire output system.

Today, pure brick chimneys are practically not used. Under the layer of brickwork, as a rule, a steel liner is found

Helpful information! A brick chimney is most effective for fireplaces working on solid fuels (wood or coal, firewood). For high-quality masonry use only burnt full-bodied clay brick.

Steel - solid and practical

Steel chimney is a round tube made of galvanized or stainless steel, having an outer contour and an interlayer of insulation. The main advantages of a smoke exhaust pipe made of steel are its low weight, high heat resistance and easy installation.

Which chimney is better for a fireplace - galvanized or stainless, the owner of the house should decide. Galvanized models are more affordable, but less resistant to corrosion. The expensive chimney from stainless steel will last longer, which means that in the future it is economically more profitable.

The walls of the steel chimney are slightly susceptible to the deposition of soot and soot, so cleaning such a pipe can be carried out less often than a brick analog. The only drawback of the chimney from steel can be called its small self-supporting ability, but at the same time it is this quality that makes it possible to install such a structure in an already finished house simply by letting the pipe on the outside of the building.

Steel chimney with insulation from polyurethane foam

Pottery - reliable and durable

Ceramic chimneys for fireplaces are distinguished by high reliability and long service life. In fact, it is a round ceramic pipe, covered with a thick layer of insulation and additionally protected by an outer layer of foam concrete.

This design has many advantages:

- good heat capacity;

- resistance to high temperatures;

- high performance indicators;

- resistance to condensation.

The only drawback is the high cost, but it fully pays off for a long service life of the product.

consists of 3 layers: 1 - inner ceramic pipe, 2 - thermal insulation, 3 - lightweight concrete blocks / chimney brick

Installation of such a design requires certain knowledge and experience, so it is more expedient to entrust such responsible work to professionals.

Note! Correctly mounted ceramic chimney has a service life of about 30 years, which is very high.

Glass - exquisitely and unusually

The chimney of glass looks exotic in any interior. In this case, glass has good indicators of thermal stability, insensitivity to corrosion and condensation, sufficient strength and durability.

The cost of glass structures is very high, and installation work can only carry out professional masters. The main advantage of a glass chimney can be called an incredible aesthetic appeal.

tempered glass chimney of tempered glass

Helpful information! For the arrangement of a fireplace chimney no wood, clay, galvanized sheet, silicate and hollow bricks are used. Asbestos-cement pipes are considered to be a controversial material, according to building codes, they are used only when the temperature of the removed smoke does not exceed 300 ° C. But for a fireplace this indicator is too low.

Features of installation work

Installation of a chimney for a fireplace can be made independently, but it is better to address for the help to experts. Only an accurate design calculation and carefully conducted installation work can ensure proper safety of operation of the entire fireplace system.

Two ways to equip the chimney

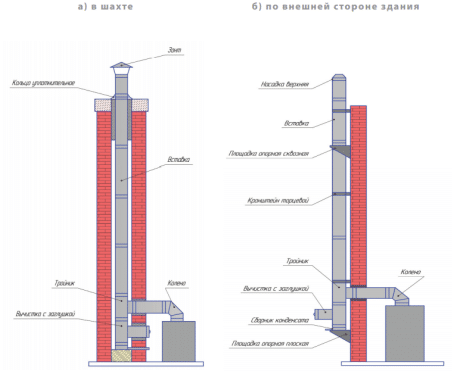

The chimney can be arranged in two ways: in the mine or along the external wall of the building. Each option has its strengths and weaknesses, but if we talk in general, then external chimney use in the case of installing a fireplace system in an existing building, and a mine - lay in the project and build in parallel with the erection of the house.

Installation of the chimney is carried out from the bottom upwards, that is from heating element (fireplace) to the outlet outer pipe. Each element of the smoke channel is inserted into the previous one, which allows to protect the heater from possible penetration of the condensate.

The order of mounting the structure

Pipe joints are reliably fixed with special clamps, and the design itself is mounted on brackets directly to the structure. The horizontal elements of the chimney must not exceed 1 meter in length and should not touch the existing internal communications.

Summarizing, it can be said that the chimney is a complex structure, which is selected individually for each type of fireplace, taking into account its operational characteristics, fuel type, location in the dwelling, etc. Minor errors in the design or installation phase can lead to serious consequences (smoke, fire, equipment failure), so it is better to entrust the work to specialists.