Is it necessary to insulate the coaxial pipe. How to insulate coaxial chimneys. Installation of external structure

To install heat generators in the house, working on gas, it is necessary to have certain knowledge and observe all technical conditions. Fulfillment of these requirements will allow the entire heating system of the premises to work stably. Also created a system of chimneys, which will easily remove the gases generated by the combustion of fuel.

In addition, it is necessary to ensure regular supply of fresh air of the required volume, so that it is not consumed from the premises. All these requirements are met by a coaxial chimney for gas boiler.

What is a coaxial chimney for a gas boiler

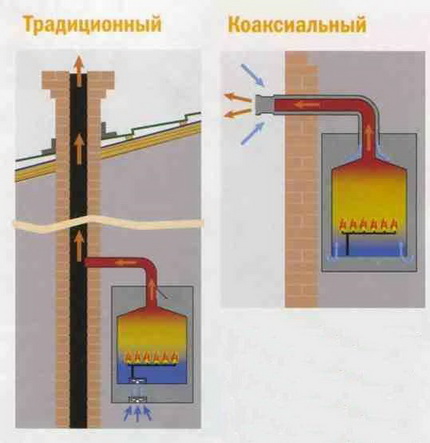

The coaxial system of the chimney consists of two pipes of different diameters inserted into each other, with a gap between the walls. This design is great for a gas boiler.

This is the structure of the chimney does not allow air to be expended from the room. Cold air, necessary for combustion of fuel in a closed chamber, comes from the street through the outer pipe. The release of combustion products occurs with the help of inner tube.

Positive aspects of coaxial chimney

Compared to conventional chimneys, coaxial has the following advantages:

Installation requirements

Installing a coaxial chimney is carried out according to and the rules specified in the instructions and technical documentation.

Necessary requirements:

- Supply pressure natural gas should not exceed 0.03 kgf / (0.003 MPa).

- The gas pipeline is installed directly into the room with the heat unit.

- It is allowed to make flue gas out through the outer walls of the house (for boilers with a power of up to 30 kW).

Mounting the coaxial chimney

You can feel the benefits of using a coaxial tube only if you have made a quality and correct installation. If the installation is performed unprofessionally, without observing the necessary technologies, the safety and environmental friendliness of such an assembly will be a big question.

Coaxial chimney: installation and advantages

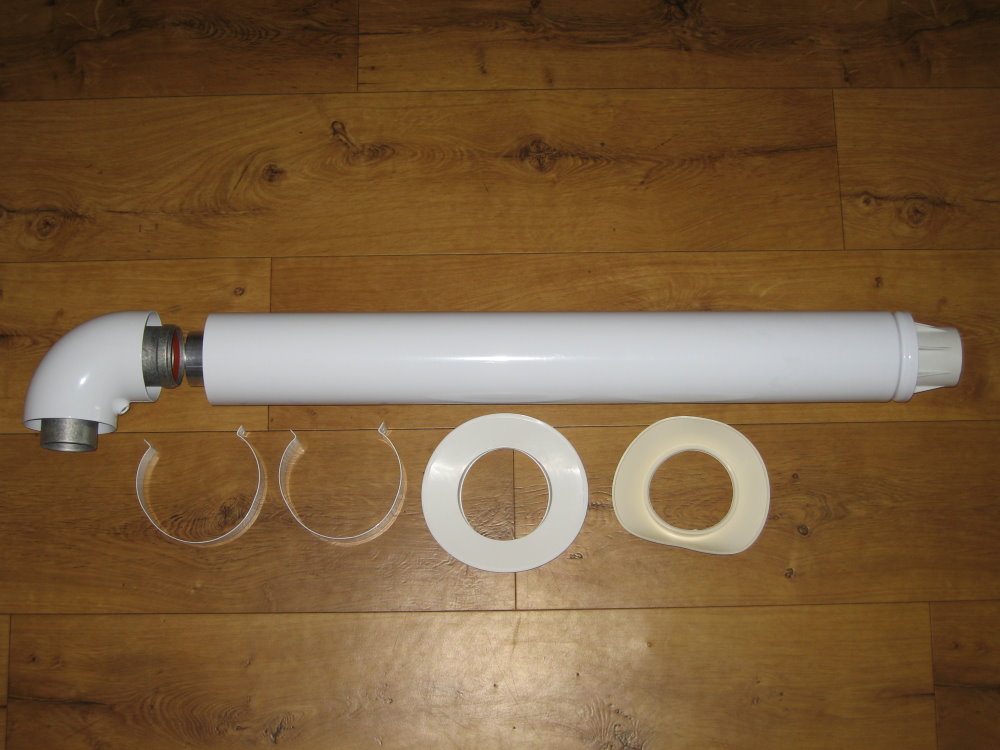

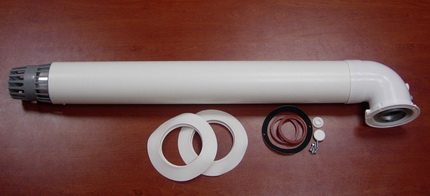

Installation begins with the fact that they make sure that all the chimney has everything necessary parts, and also prepare necessary tools and materials for work.

To install a coaxial chimney, you will need:

- Coaxial tube (one or more).

- Pipe for smoke removal.

- Flange.

- Connecting clamp.

- Adapter for connection.

- Two overlays on the walls.

- Tip on the pipe.

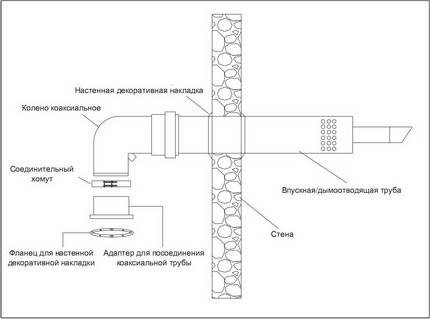

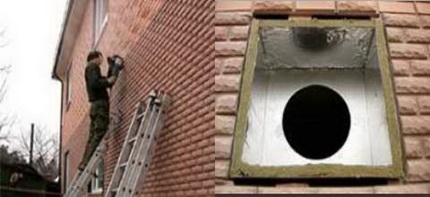

Installation follows start by choosing a place. Gas boiler and coaxial chimney must be installed simultaneously. Ideally, the location of the pipe is 1.5 meters above the boiler. If required, you can extend the pipe, but not more than three meters high. Then remove all unnecessary. After that, drill a hole 11 - 12.5 cm in diameter.

Further, with the help of the clamp, the pipe is connected to the throat of the boiler and clamped on both sides with bolts. Then they construct the configuration of such a configuration that is required, connecting details with yokes. If the pipe leaves the room, do it slightly with a slope so that the condensate runs down.

After installing the chimney for the boiler, the hole in the wall should be covered with special decorative pads using liquid nails or building glue. These pads can have a variety of shapes and are made from different materials. The street opening is covered with foam so that cold air does not get into the boiler room and does not create condensation or drafts.

At the end of installation, the chimney for the gas boiler should check on the quality of fastening, on the angle of inclination and other moments.

For inspection and cleaning, the boiler is turned off and waited until the pipe has cooled down, and only then proceed to work.

Do I need to insulate coaxial pipes

If there is severe frost in the street, some sections of the coaxial chimney can freeze, which reduces its effectiveness. To insulate pipes it is necessary that they are separate, and this is not suitable for coaxial chimneys.

The only solution is reduce the size of the structure. If condensate freezes on the chimney head, the inner tube is shortened.

Safety precautions

Installation of the coaxial pipe must be carried out in compliance with safety measures and with the use of personal protective equipment.

Pipes can have sharp edges, and in order not to injure them, special dense tissue gloves should be worn on their hands. You can put on the palm of special pads made of synthetic material. You can not isolate aluminum tapes, gypsum dressings and other similar materials, but only refractory silicone.

For installation and installation, use only those materials that have undergone a state inspection. Nothing can be changed in their configuration and design. Installed pipes must meet the necessary standards. Otherwise, because of the discrepancy in size, there is a possibility of leakage of exhaust gas, as a result of which you can get poisoned carbon dioxide.

The chimney should not be installed in a place where people often walk, because in the winter the condensate drains into an icicle and can fall on the head.

Thus, a coaxial chimney for a gas boiler has certain advantages before the usual chimney. If it is properly installed in compliance with all the necessary requirements, then it will work long and efficiently.

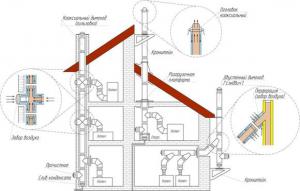

The word "co-axial" means finding one object in another. Coaxial chimney is a design for a gas boiler, which allows the pipes to enter each other. It is a two-circuit structure of pipes of different diameters, which are located one in the other. Inside, they are connected by jumpers that do not allow contact. Installed in heat generators with combustion chambers closed type. Such devices include gas boilers, radiators, convectors, etc.

In gas boilers it performs two functions: it serves as the outlet of combustion products to the outside and ensures the supply of clean air, necessary for combustion of gas in the chamber. In boilers with a closed combustion chamber, the length of the pipe, as a rule, is not more than two meters. Often it is paved through the wall into the street. In rare cases, there is a construction, derived through the ceiling and the roof.

Coaxial chimney is a design of two pipes of smaller and larger diameter that enter one another

This is important to know! A coaxial chimney is provided for a horizontal arrangement.

If the location of the supposed output is near the window, it is recommended to do it slightly above the roof. In this case, the vertical part of the installation is also required.

In the standard version, the coaxial type installation consists of the following parts:

- straight pipes;

- cleaning;

- tee;

- condensate collector;

- the knee (with a 90-degree turn angle);

- upper tip.

From the straight pipes the chimney itself is formed, the knee is used to connect the vertical and horizontal parts of it, as well as to connect the horizontal part and the gas boiler.

A set with a horizontal directivity consists of:

- a set of straight pipes;

- lateral tip;

- the knee (with a 90-degree turn angle).

Modern industry produces chimneys of coaxial type for gas boilers of the following range:

- from acid-proof stainless steel;

- stainless steel;

- from the zinced steel.

Chimneys can be manufactured in different combinations, when the inner and outer pipes are made from different types of steel.

Chimney accessories should be standard to avoid gas leakage through slots

About advantages

The main advantage of coaxial chimneys is that the air needed for combustion is received from the outside, and not from inside the premises, such as an oven. For this reason, rooms with a conventional oven need constant airing. A coaxial type chimney operates on a different principle. The combustion product enters the inner tube, while the external one serves to inflow fresh air.

Thanks to this design, several problems are solved that are found in traditional heaters:

- The air coming from outside comes into the room hot, as it heats up from the inner tube, through which passes the hot air saturated with combustion products. Due to this, the heat losses, and the efficiency of the heating system, respectively, increases.

- Due to high efficiency, complete combustion of natural gas occurs. Therefore, the particles of unburnt fuel do not enter the atmosphere, do not pollute it, which makes the boiler environmentally friendly.

- It is also important that by giving heat to the outer tube, the inner tube is cooled. This reduces the risk of ignition in the areas of contact between the pipe and flammable surfaces, interior details (wallpaper, plating, etc.).

- The whole process, including the intake of air and the removal of combustion products, takes place in the combustion chamber, which is a closed space. This creates a certain comfort for people, as it eliminates the need to equip the ventilation of the room in case of smoke and carbon monoxide.

- Presented in the widest range, which provides the possibility of their selection for different in power systems.

- Small sizes of coaxial chimneys allow to save space.

The advantages include the ease of installation. A heating system of this type is easy and simple to use and maintain.

Installation of coaxial chimneys

With the advantages of coaxial chimneys one can not but agree, but only if the correct and qualitative installation is made. If installation work are performed unprofessionally, without compliance with technology, its environmental friendliness and security can be a big question.

This is important to know! Before starting the installation, it is necessary to check the presence of the chimney parts in the kit, and also necessary tools and materials.

For assembly you will need:

- coaxial tube or several pipes;

- smoke exhaust pipe;

- adapter for connection;

- flange on the lining;

- two pads on the walls;

- clamp connecting;

- tip on the pipe.

The chimney is connected to the boiler and taken out of the premises. In the presence of foreign interfering objects they are removed before the removal of the pipe. In addition, it is recommended to free the space around it from highly flammable objects and substances.

The layout of the coaxial chimney must be carefully thought out and meet the installation rules

The installation of the coaxial chimney begins with the selection of the place, including the boiler itself. A gas boiler with a coaxial chimney is recommended to be installed simultaneously. The best option is to place it 1-1.5 meters above the boiler. If necessary, the chimney is lengthened, but so that the knees are not more than two, with a total height of up to 3 meters. Further, as already noted, all unnecessary is removed. Then drill a hole of the required diameter, which can be from 11 to 12.5 cm.

So it looks like a coaxial pipe and a boiler in the room

Further, the pipe is connected to the throat of the boiler by means of a clamp, which is clamped on both sides with bolts. Then, the configuration of the desired configuration is assembled. All parts are connected with clamps. At the chimney, leaving the room, there should be a slight slope for the spontaneous removal of moisture (condensate).

After installation in the right places put on decorative lining, performing an aesthetic function. Lining can be of different shapes, as well as different materials. They are fastened with liquid nails or with the usual construction adhesive. It is recommended to seal the holes with foam, so that there are no gaps that let cool air in and accumulate moisture.

Upon completion of work, it is necessary to check the quality of fastening of the entire structure and connecting elements, pay attention to the slope of the pipe for removing smoke and other parts. For maintenance - preventive inspection, cleaning and other actions, the boiler must be switched off, wait for the pipe to cool down, and then carry out the work.

How to insulate coaxial chimneys

What should I do if the chimney freezes? As practice has shown, insulation only helps with the installation of separate pipes, so this option is almost not used in coaxial pipes. The only solution to this problem is to reduce the size of the structure. When the head gets frozen due to the condensate from the pipe with combustion products entering the air intake pipe, the inner tube is shortened relative to the external one.

Safety precautions

When installing the chimney requires compliance with safety regulations, personal protective equipment should be used. Since sharp edges of pipes can cut hands, workers should be in special dense gloves made of cloth or with synthetic material overlays on the palms. To strengthen the nodes it is forbidden to use aluminum tapes, plaster bandages and other similar materials. Insulation must be carried out with refractory silicone.

It is recommended to use materials that have passed state verification. Changes to their configuration and design can not be made. Pipes must comply with current standards, otherwise there is a risk of leakage of exhaust gas and carbon dioxide poisoning due to a mismatch in size. Do not install chimneys over a place where people walk and drive cars, since water can drip from its end and icicles are formed.

When carrying out all work on the installation of the chimney, it is necessary to strictly observe the safety

For violation of the instruction and failure to comply with technological requirements during installation, which led to a breakdown or an accident, the responsibility is borne by the person who performs the installation work or carries out direct supervision. For the qualitative installation of the chimney, it is necessary to invite proven professionals with access to such work.

Gas fired boilers there are atmospheric (there is a chimney with natural draft) and turbine (there is a coaxial tube and forced ventilation). In either case, the boiler can stop its work, because under certain conditions it has a freezing temperature gas pipe. Learn how to prevent icing, and what you need to do to prevent such a situation.

Gas boiler with coaxial pipe

Causes of freezing

The cylinder is the most acceptable form of the pipe.

A severe frost and wind, high humidity, falling snow from the roof, improper installation of the pipe and its location in the zone of wind pressure - all this can lead to the fact that the pipe of the gas boiler freezes, and your mini-boiler room ceases to function.

The main rule when connecting the boiler - do not ignore the recommendations of the manufacturer. Everything is important here: the permissible length of the pipe, its slope and location. The fan not only releases the chamber from the combustion products, it creates the rarefaction necessary to suck in a new portion of air for combustion. Coaxial kits can differ both in the material of manufacture and constructively.

Causes of condensation

When the chimney is insulated, combustible materials should not be used.

Condensation arises from the presence of water vapor in the smoke, and its temperature is below the "dew point" temperature (the limiting temperature of the air over the saturation with moisture, above its vapor condenses in the form of droplets).

As the water drops freeze, an ice crust forms, blocking the access of the air necessary to maintain combustion. As a result, the boiler ceases to function. If the gas boiler is installed on the upper floors apartment building, get a terminal (in order to get rid of the ice build-up) is not possible.

How to eliminate icing

The problem can be partially solved by removing the plug (at the top of the boiler). In this case, the flue gases will leave, as before, outside, and the air required for combustion will flow into the system from the room.

When the ice melts, the plug has to be put in its original place, the boiler will not be able to work continuously in this mode. Otherwise, the impurities that are contained in the air (kitchen soot, dust particles) will lead to a breakdown of the unit. If icing does not happen often (1-2 times a year), use this method is permissible. If freezing occurs regularly, you need to purchase a set of "anti-ice".

Varieties of boilers with a chimney

Coaxial gas pipe can freeze under adverse weather conditions due to installation errors.

The role of the chimney is the removal of combustion products. But on how it is designed, depends fuel consumption, and hence, the economy of the boiler. The height of the pipe and the diameter of its section, the material from which the chimney is made and its location - all this has a direct effect on the efficiency of the heating system.

Reducing the efficiency from 95% to 60%, wet walls, carbon monoxide in the room, over-consumption of gas - all this may be due to improper selection and installation of the chimney. When designing, take into account the boiler's power, type of burner, barrel height and temperature of waste gases.

The chimney can be steel, asbestos or brick. Brick well accumulates heat, but it is destroyed after 3 years of operation. Asbestos does not corrode, has insignificant thermal conductivity, serves a long time, but it is not stable due to the physicochemical properties of the material. Steel chimney - the most the best option.

Advantages of stainless steel pipe:

- Inside the pipe is perfectly smooth (brick rough).

- Inner surface brick chimney absorbs the substances formed during the combustion of gas, and the resulting acids destroy the walls of the chimney. AT steel pipes this does not happen.

- It is easier to heat steel pipes than brick ones (you can also buy a pipe with a ready thermal insulation layer).

- The process of purification and removal of condensate is easier to perform in steel pipes. Condensate in the metal chimney is eliminated after 2 minutes, in brick - after 40 minutes. Continuous contact with water destroys the chimney.

- It is better to install a complex pipe system out of metal, since in this case it is possible to use a connecting mounting material.

In the event that in the already constructed house there is no pipe for flue gas discharge (it was not stipulated by the project), it is possible to build a chimney made of stainless steel.

Options for insulation

Warming metal pipe with minimal time and effort. Thermal insulation is placed inside between two pipes.

The main purpose of the chimney insulation - inside should not appear condensate, formed due to the temperature difference inside and outside. In addition, the insulation of the pipe will also protect the roof near the chimney.

Work can be done with the help of such materials: cinder blocks, bricks, mineral wool or slag solution.

Plastering

- Prepared from lime, cement and slag, the solution is applied by a layer of 3 cm onto the reinforced mesh of the chimney.

- When the mixture is a little dry, mineral cotton wool is placed on top of it.

- Again, apply the solution and lay the glass cassette.

- After complete drying of the previous layer, the surface of the pipe is primed and dyed.

Thermal insulation with mineral wool

A warmed chimney reduces the heat loss of the entire heating system.

- The outer surface of the pipe is cleaned.

- Make a lath of profiles. Using a perforator and a screwdriver, drill holes, fix the guides with dowels.

- Then the vertical racks are fastened, securely connecting them to the guides. The distance between them is equal to the thickness of the insulation.

- Mineral cotton wool is densely laid in the crate.

- Using a construction stapler, a polyethylene film is attached from above, the joints are closed with adhesive tape.

- The final stage of work: facing with corrugated board.

For the heat-insulating layer of the asbestos tube, a galvanized casing is mounted. The distance between it and the pipe should be at least 6-8 cm. After laying the insulation (fibrous material, glass wool), the remaining gaps are filled with cement mortar. You can even do without a casing, but in this case it is impossible to use mineral wool as a thermal insulator, and the heat insulation consumption will be twice as much.

Builders also apply metal structure, which can be called a "pipe in a pipe". Free space inside is filled with mineral wool.

The coaxial pipe of the gas boiler will not be covered with ice if it is installed in accordance with the manufacturer's requirements. If the natural gas pipe of a natural gas boiler freezes, it is necessary to insulate the walls of the chimney. This will increase the efficiency of the gas boiler, which means it will make your home warmer and more comfortable.

Video: a set of coaxial pipes to protect against icing.

An autonomous heating system, if it does not work on electricity, can not do without the combustion products of the device. If earlier it could only be a traditional chimney, now there are other options, more effective and practical. Installing a coaxial chimney provides many advantages, in addition, it can be produced in an already constructed building. What is so good about the coaxial type chimney? We'll figure out.

In technology, the concept of "co-axial" means the presence of two objects located so that one is inside the other. Thus, the coaxial type chimney is a two-circuit structure made of pipes of different diameters. Inside the larger element, there is a smaller part. The distance between them is strictly the same throughout the length of the structure, including all the bends and knees.

For this purpose, special bridges are placed between the pipes. In a section such a system looks like a pair of concentric rings. The duct for removing smoke is an internal, smaller diameter pipe. Through the gap between the two parts inside the heater from the street, the oxygen required to maintain combustion is supplied. Thus, the gases inside the system move in opposite directions.

Image Gallery

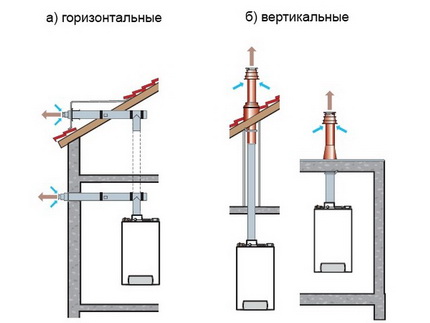

Features of the construction of a coaxial type chimney enable it to perform functions immediately. The device ensures uninterrupted air intake, which is necessary to maintain the combustion process. In addition, it successfully removes combustion products from the boiler. The length of the structure usually does not exceed two meters. The most commonly installed systems are oriented horizontally, but there are also vertical variations.

A coaxial chimney is called a "pipe in a pipe" system. By the internal element of the boiler, combustion products are diverted, external air is supplied

The coaxial type chimney is a system of modules, which makes it possible to produce chimneys of various configurations taking into account the architectural features of the building. All elements included in the system are standardized, which greatly simplifies their installation.

A coaxial type chimney can be oriented horizontally or vertically. In practice, mixed structures with vertical and horizontal sections are more common

A standard set consists of several modules:

- Straight pipes. From the straight pipe segments the chimney itself is formed.

- Tee. It is installed in the system only if two or more boilers are used.

- Connecting elements. These are the bends at 90 ° and 45 °, couplings.

- Device for condensate discharge. Such a set is necessarily provided for each vertically oriented section. It is equipped with a water seal, which prevents the pressure of the gas-air mixture in the chimney from decreasing.

- Elements with a revision hole. It is designed to inspect and clean the system.

- Output and input nozzles. Supplied complete with heads, used for the withdrawal of combustion products and the intake of clean air. The outlet nozzle is always mounted at a distance from the air intake so that it does not mix with the exhaust gases.

- Adapter. It is used to connect the system to the boiler.

- Fittings for fasteners. These include brackets, clamps and flanges.

- Seals. Devices required to ensure tightness of the passage of the pipe through the wall or roof.

- Decorative overlays.Flanges closing the chimney passage through the building structure.

For the manufacture of parts for coaxial chimneys use galvanized or stainless steel. It is resistant to high temperatures, strong and light. Some models are made of aluminum alloys or heat-resistant plastic. For seams, seals made of heat-resistant polymers capable of withstanding temperatures of the order of 230-250 ° are used.

Chimneys of coaxial type are standardized modules, from which the construction of the desired size and configuration is easily assembled

Types of chimneys of coaxial type

There are several types of construction "pipe in the pipe." Let's consider each of them in detail.

External and internal systems

All coaxial chimneys, depending on their location, are divided into external and internal chimneys. The first are located on the outside of the building and are fixed directly on the facade. Given that such structures somewhat spoil the appearance of the building, they are trying to place on the inner sides of the building. A distinctive feature of the outer type chimney is the ease of maintenance and installation.

Internal structures are mounted in specially laid mines that pass inside the building and are separated from the living quarters. In some cases, traditional chimneys can be used as such mines. It is important that their device and dimensions fully comply with modern fire safety requirements. Internal systems are quite difficult to maintain and install.

Non-insulated and insulated devices

In cold weather, especially in severe frosts, the channel supplying air to the system may freeze. In this case, the amount of oxygen entering the combustion chamber decreases sharply, which leads to a deterioration in the operation of the heater. In some cases, and to stop it. Therefore, where low temperatures last for a fairly long period of time, and where severe frosts are frequent in winter, it is recommended to install insulated systems.

Insulated coaxial chimneys are distinguished by the presence of another pipe. Between it and the external part, a layer of a non-combustible heat insulator is laid, which prevents the structure from freezing

The coaxial chimney of insulated type differs from the standard one by the presence of another pipe. The system looks like three nested parts. Free space between the two end elements is insulated. To this end, it is filled with any suitable insulation. This reliably protects the air duct from icing and freezing.

Horizontal or vertical output

Initially, coaxial chimneys were designed as horizontally oriented systems, but in practice this arrangement is not always possible. Most chimneys of this type are mixed structures. They can be present as vertically oriented, and horizontal areas. This is due to the location of the heater in the building. In some cases, it is possible to use vertical chimneys, but only for boilers without forced draft.

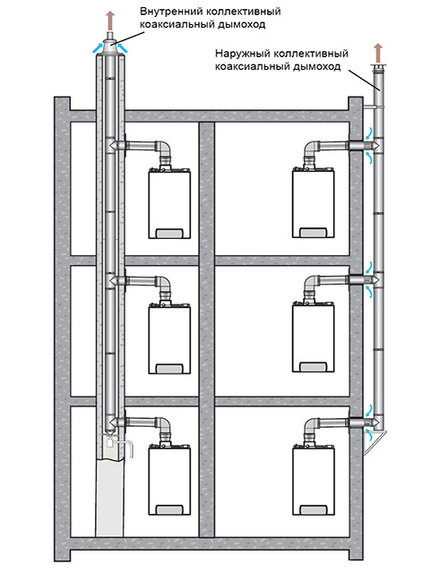

Collective and individual designs

Individual coaxial chimneys are used to service one heater. These are simple systems without branchings, which can have a different configuration. To work with several boilers, a collective chimney is installed. This is a mine system with several branches. In this case, each of the branches goes to one of the heat generators. Such a design can only be vertical.

Collective chimney coaxial type is characterized by the presence of several heat generators connected to one shaft. Can be both external and internal

Why choose coaxial systems

The design features of the coaxial type chimney enable it to work on a principle different from the traditional smoke extraction system. To ensure combustion in the furnace of the boiler must be supplied oxygen, and the products of combustion are diverted. Boilers equipped with separate chimneys take the air from the room in which they are installed. This is quite dangerous for a person and requires constant airing of the room.

The exhaust gases are discharged through the natural draft. Instruments with coaxial chimneys work differently. Such chimneys are a combined system of air supply and smoke removal. The thrust required to operate the device is created naturally or with the help of a fan, which allows the use of small in length construction.

A good plus of coaxial chimneys is the ease of installation and the ability to remove combustion products by the nearest way, for example, through a wall

Thus, a complete isolation of the removal of combustion products and oxygen supply makes it possible to completely exclude their effect on the air composition in the room where the boiler is installed. "Burnout" of oxygen does not occur, as a result of which there is no need for airing the room. The amount of air in the combustion chamber is optimal, which increases the percentage of fuel combustion and, as a result, the boiler operates more efficiently and environmentally.

Hot smoke from the heating device is diverted through the inner pipe. It passes inside the other, through which cold air moves. Thus, there is no thermal effect on the walls and ceilings, inside which a chimney is laid. This significantly increases its fire safety, which is very important for buildings made of wood and other fairly easily inflammable materials.

The figure shows schematically the main difference between coaxial chimneys and traditional ones. The first takes the air in the street, the second - in the room, which is dangerous for those who are in it

The coaxial system increases the efficiency of the heating device. This is due to the fact that the air supplied to the furnace, passing through the internal cavity of the structure, heats up from the pipe, which removes hot smoke. Another significant advantage of chimneys of this type is their compactness and relatively small size, especially in comparison with traditional separate chimneys.

It would be a mistake to think that the system has no shortcomings. They are. First of all, this is a fairly high cost of such a design. On average, it is 40% more expensive than traditional. Another is due to the construction of a coaxial type chimney. Pipes with hot smoke and cold air come in contact, which inevitably leads to the formation of condensation, especially in cold weather. Thus, the system needs a special drain for condensate and additional insulation, which further increases its cost.

How to choose device dimensions

In the technical documentation, which is attached to the chimney, its diameter must be indicated. The designation is two digits, written through a fraction. The first one shows the diameter of the inner tube, the second - the outer one. Find the right size is easy enough. It should be indicated in the boiler's passport, which will be connected to such a chimney.

The dimensions of the coaxial type chimney are selected in strict accordance with the type of boiler and the dimensions of its boiler outlet. All necessary information must be in the technical documentation of the heater

The determining factor in this case is not only the diameter of the system, but also its length. The latter is defined as the sum of the lengths of all sections of the chimney. It has limitations fixed in the installation instruction, and is measured in equivalent meters. In addition, all these nuances are indicated in the selection table, which should be attached to the technical documentation of the heating equipment.

Installation of a chimney in the light of normative acts

A smoke-exhausted coaxial-type system can be installed in a private or multi-apartment building. The latter is also quite common, especially in connection with the widespread installation of individual heating systems in the apartments. Until 2012, the design and installation of coaxial-type smoke detectors in multi-family and private homes was regulated by one SNIP and did not differ.

In 2012 the set of rules of the joint venture 60.13330.2012 was adopted, which is an updated version of SNiP 41-01-2003. The document divided the conditions for installing a coaxial chimney in an individual and multi-apartment building. In the latter case, it is forbidden to install individual chimneys in apartments, as it was permitted before, and the installation of a collective chimney is required.

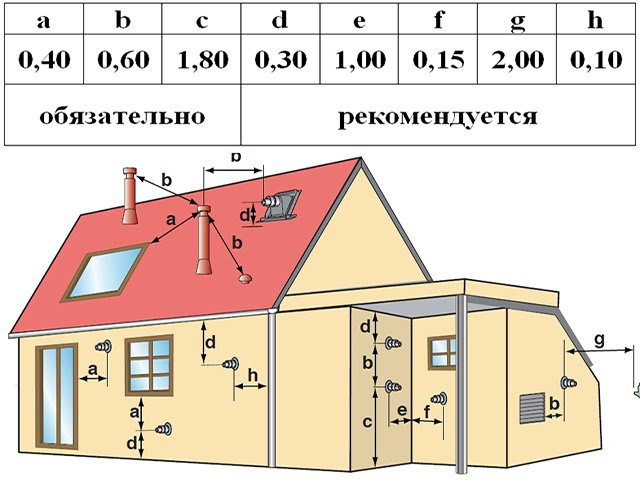

Therefore, you need to be very careful and know that if the designers propose to equip an individual exhaust gas discharge from a heat generator located in one of the apartments in an apartment building, this is contrary to the current regulations. The distance from the roof ridge to the section of the smoke channel must not be less than 1.5 m. A similar value for a private house is from 0.5 m.

The outlets of coaxial chimneys should be located at a sufficient distance from the windows, otherwise the smoke will enter the room

There were no special acts concerning individual buildings, therefore it is considered that their arrangement should not contradict the requirements applied when installing chimneys in apartment buildings. Based on the new edition of the SNiPa, private houses can be installed coaxial systems any type. In multi-unit - only vertical.

Important nuance. If the chimneys were installed in the building before 2012, contrary to the current version, they can be left unchanged if they do not cause inconvenience to the neighbors.

Some installation features

For each boiler, the direction of the duct, diverting the combustion products, is determined individually. Horizontal systems can only be used for devices with forced ventilation.

Errors in calculations and installation can lead to freezing of the system and freezing of condensate at the outlet. In such conditions, the boiler will not be able to work

But even in this case maximum length such a site should not be more than 3 m. It happens that the manufacturer establishes other standards for its boilers, therefore, you should familiarize yourself with the technical documentation of the device.

Constructions vertical type for private houses are used only in the event that there are reasons preventing the outlet of the chimney duct through the wall. It can be a window close to the outlet pipe, a narrow street on which the building stands, and so on. In some cases, if it is very necessary, an inclined installation is allowed.

Variants of the passage of a coaxial chimney through building structures and the distance between the chimney and the elements of the house are given on the basis of many years of operation

The system is connected to the heating device using a tee, elbow or pipe. In this case, the diameters of the discharge channel and the outlet of the boiler must be the same. During the installation, all subsequent parts are fixed in the previous ones so that no obstacles form which could disrupt the movement of the combustion products. The number and type of elements for assembly directly depend on the location of the outlet branch pipe.

If it is on the side, horizontal system, if from above - vertical. The latter option is easier to install. In the process of equipping a coaxial chimney, it is mandatory to use transition nodes with rigid fastening of the joints of two elements using clamps. Some "craftsmen" prefer to use self-made variants.

The figure shows the arrangement of the passage of the horizontal coaxial chimney through the wall

It can be made with own-made adapters, tape rewinders or sealant seals. Such things are unacceptable in use, because they are extremely unreliable. The system collected with the help of such elements is considered unsafe in operation. In addition, during installation, the following rules are observed:

- The outlet of the horizontal chimney must be inclined 3 ° downwards. At entering into common site chimney horizontal section slope is carried out in the opposite direction, that is, is reduced to the boiler. This is necessary for unimpeded drainage of condensate.

- There must not be more than two folds along the entire length of the chimney.

- Inspection hatches, adapters and a device for the discharge of condensate should be easily accessible for periodic inspection.

- The chimney can not be brought out below ground level. The distance from the output of the coaxial chimney to the adjacent building must be more than 8 m. If a deflector is installed on the pipe, this distance is reduced to 2 m for a blind wall and 5 m for a wall with window openings.

- If the horizontal chimney is installed in a place where winds predominate, the direction of which is opposite to the direction of smoke extraction, a tamper barrier must be installed at the outlet of the pipe. The distance between it and the outlet should be not less than 0.4 m.

- On coaxial chimneys, towering above the ground level less than 1.8 m, it is necessary to install a deflector grate. It will work as a protection against hot smoke.

All elements of the structure must fit tightly to each other. Each subsequent detail must enter the interior of the previous one by a distance equal to not less than half the diameter of the channel section. To obscure the construction around an obstacle, a knee specially designed for this purpose is used. The angle of their inclination can be different. If the system is removed through the roof, all fire safety requirements must be met.

Arrangement of the passage of a coaxial chimney through a roof or through a wall must be carried out with strict observance of all fire safety requirements

To this end, special insulating pipes and non-flammable insulating materials are used. Between the pipe and the overlap must be an air gap. To avoid contact between the smoke channel and fragments of the roofing cake, a protective cover is used. The exit of the structure through the roof is carefully sealed. Sections of joints are covered with a special apron.

Coaxial chimney installation technology

The process of installing the external and internal coaxial chimney has differences. Let's consider both variants.

Installing the internal system

First of all, we check the correspondence between the diameters of the boiler outlet and the chimney. Then we proceed to prepare a hole in the wall, through which the smoke channel will go out into the street. Its diameter should exactly match the dimensions of the coaxial tube. After completing the hole, you can proceed with the installation of the structure. It starts with the outlet pipe of the boiler, to which the corresponding element of the chimney is attached.

The resulting connection is fixed with a yoke and fixed on both sides with bolts. Next, the entire structure is successively collected. Each element is inserted into place and fixed with special clamps to give the system additional reliability. Decorative cover plates are installed over the fasteners, so an attractive design looks.

The chimney is led out through the wall to the street. If necessary, a deflector or additional wind protection is installed on the outlet pipe. The section of the passage in the wall is closed. At the same time, fire safety requirements are observed. A special protective cover is put on the pipe. The bayonet joints are sealed and covered with an apron.

Outer chimney of coaxial type of vertical orientation. Such systems are quite simple to install

Installation of external structure

Before its beginning determine the location of the exit of the coaxial chimney and mark its location on the wall of the building. Then a hole is made in the wall with a diameter corresponding to the section of the smoke channel. Further all internal works. Begin with a pipe joint with heating device. For this, a single-loop elbow and a two-circuit tee are used.

The latter is needed to fix the structure in an upright position. The resulting design is fixed to the wall surface with special brackets. Further all the work is carried out in the same way as described above. The section of the chimney outlet is closed and the pipe is assembled to the required height. The design is fixed to the wall with clamps. For connection of double-circuit pipes, transition nodes are used.