Coaxial chimney vertical arrangement. Important requirements for installation. Constructive composition of the coaxial smoke removal system.

When equipping the heating equipment, which operates on gas, it makes sense to equip coaxial chimney, the installation of which will not cause difficulties.

The rules and regulations for the installation of any heating equipment, including solid fuel, require the mandatory installation of a suitable chimney.

Its main purpose is to provide the necessary oxygen supply while simultaneously withdrawing all combustion products.

Only the chimney can provide the required combustion of the coolant used in the boiler.

If almost any type of chimney can be used for a solid fuel boiler, then the universal coaxial chimney will be the optimal solution for a boiler that operates on gas.

At present, more and more often such heating equipment is used, in which a combustion chamber is provided closed type.

This type of boiler can be installed in almost any home, including wood.

For such boilers, the developed norms and requirements allow not to equip classical exhaust systems, which, as a rule, take up a lot of space.

In this case, it is allowed to install a coaxial chimney, which has a simpler and more compact design.

There are certain requirements that must be met if a coaxial chimney is to be installed for gas boiler heating.

The classical coaxial chimney has a rather specific design. Any such chimney consists of individual pipes, placed one in the other, which have a different diameter.

In the internal space, these pipes do not touch each other by installing special jumpers along its entire length.

These jumpers provide not only the rigidity of the entire structure, but also give the whole system a certain strength. Pipes that have different diameters perform certain functions.

The pipe, which has a smaller diameter, is responsible for removing all combustion products from the boiler.

The pipe, the diameter of which is larger, in turn ensures the inflow of the necessary volume of oxygen into the combustion chamber.

Thus, coaxial type pipes allow simultaneous flow of air and smoke from the chamber.

In this case, the air in the house does not mix with the air masses inside the boiler.

It should be noted that special pipe Co-axial type for all its positive characteristics is not suitable for all heating devices.

For example, in a solid fuel boiler, as a rule, the combustion chamber is not of a closed type, which means that this pipe is not suitable in this case.

This type of exhaust systems for combustion products is suitable for those boilers that have a closed combustion chamber.

The greatest advantage of this device is its simplicity in installation and subsequent operation.

In addition, when installing it, there is no need to carry out work on the roof, since the pipe can be removed near the window directly into the wall.

The installation of the coaxial pipe allows completely eliminating the contact of air in the house and the combustion products from the boiler.

Also, that air, which is taken from the street, enters the chamber in an already heated form, which allows to raise the overall efficiency significantly.

Coaxial pipe for a gas boiler is the best solution for any home, except it, it can be arranged in a wooden structure.

Requirements for installation

Installation in the house, including in the wooden, heating equipment, which is equipped with a closed-type combustion chamber, requires a mandatory device of an autonomous heating system.

It has some differences from the system that is designed for a solid fuel boiler, which is installed in most cases only in a private house.

Existing requirements allow to install a gas boiler of this type, including in multi-unit buildings.

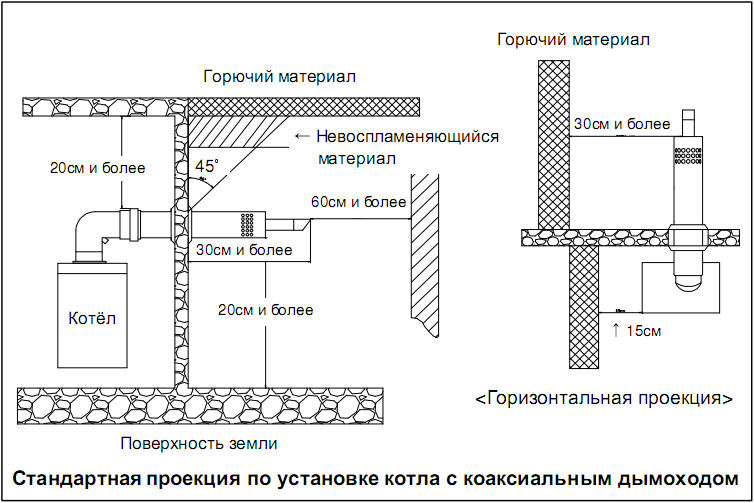

Under the coaxial chimney for the gas boiler, certain standards and safety requirements have been developed, which are mandatory for everyone.

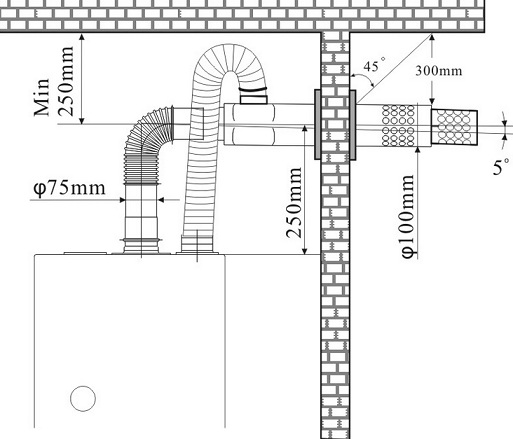

Thus, the maximum permissible length of a discharge pipe of such a system should be on average up to three meters. The main pipe must be taken out to the street only in a horizontal position.

In turn, the length of the pipe section, which should be in a horizontal position, should not exceed more than one meter.

In the event that forced draft is provided by the additional installation of fans, there is no need to install a vertical section of the coaxial tube.

The outlet for a coaxial type pipe should be located at a distance of at least one and a half meters from the boiler.

If it is necessary to make a longer pipe, only a standard factory extension cord should be used.

The distance of the outer part of the coaxial pipe from the base of the wall is chosen at an arbitrary value.

It is also necessary to make a small slope of the horizontally running part of the pipe in order to ensure that the condensate does not accumulate in the internal space of the chimney.

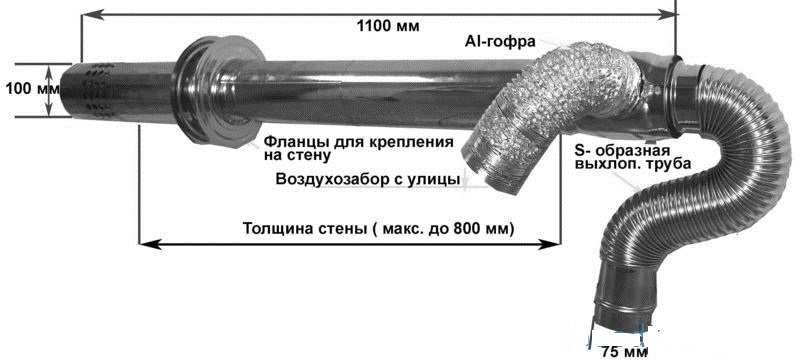

The diameter of the outlet in the wall under the chimney coaxial type should be slightly larger than the diameter of the pipe itself.

For more information on how to equip a coaxial type chimney in a house or apartment, see the video below.

Chimney installation

In order to independently mount a coaxial chimney in a house under a gas boiler, you do not need to have any special knowledge.

The main advantage that a coaxial chimney possesses is the maximum simplicity in installation, unlike a chimney for a solid fuel boiler.

All that is required for its arrangement is to strictly follow the recommendations of the relevant instruction and to adhere to the current rules and safety standards as precisely as possible.

As a rule, a coaxial type chimney is installed simultaneously with the boiler, however this is not a matter of principle. To begin with it is necessary to establish by all rules the heating equipment.

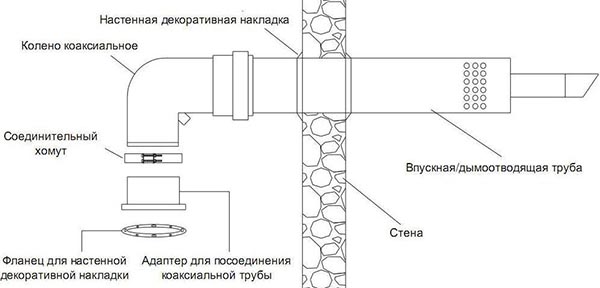

A special extension piece must be firmly connected to the boiler outlet. Fastening is carried out by means of special clamps.

The outlet for the chimney coaxial type, which is located in the wall, must necessarily impose a non-combustible heater.

After that, the horizontal section of the pipe is connected to the vertical section. When installing a chimney of this type, all connections must be made as tightly and tightly as possible.

On the outside of the coaxial type chimney, it is not necessary to wear additional protection elements in the form of umbrellas or deflectors.

For more information on how to install such a chimney, see the video below.

Coaxial pipe has a specific design, and its installation should be done extremely accurately.

Do not allow the formation of defects and any damage, since internal depressurization may occur, resulting in the boiler failing.

The length of both horizontal and vertical pipe sections of a given type is selected from technical conditions, while it is recommended to take its minimum value.

The distance from the boiler is very important. The optimal value is from one and a half to two meters.

As practice shows, if all the requirements for installation are met, the premises will be maintained with the most optimal conditions for living.

In any case, before starting the installation work, it is recommended that you familiarize yourself with the relevant requirements and operating rules for heating equipment.

The installation of the coaxial chimney is done with the slope of the outgoing pipe. If it is made in the direction of the street, the condensate formed on the walls will flow out by gravity to the outside.

It should be noted that in this case the system will be able to work fully only in the absence of negative temperatures on the street, since at the end of the pipe icicles can sometimes be formed.

They will hinder the operation of the boiler, and reduce the value of its efficiency. Specialists recommend making the necessary slope of the pipe directly towards the boiler.

In this case, it is necessary to install an additional device, which is called the condensate collector.

There is no need to conduct additional insulation of the tube coaxial type.

If you install the coaxial chimney correctly and in accordance with the generally accepted technology, there will be no problems with the operation of the heating equipment.

Comfort and comfort in the house creates warmth. And in our time there are many ways to heat the house. In multi-storey buildings, heating is central, but owners of private houses prefer various boilers that directly need a smoke channel. On it, the smoke will go to the street, and not into the living room. On the mezhu standard pipes come more advanced and compact.

Coaxial chimney is the newest system, which has an increased level of security. It is designed for many gas boilers. Especially popular is the coaxial chimney baxi. Let's take a closer look at what a coaxial smoke removal system is, with its device, installation standards.

What is a coaxial chimney?

This question is asked by many owners of heating boilers. Coaxial chimney is a structure that is assembled on the principle of "pipe in a pipe" and is used in heaters, such as: gas boilers, convectors, radiators with buried combustion chambers. The uniqueness of such chimneys is that this structure is assembled from several parts, which are inserted into each other and kept due to the fact that there are specialized jumpers inside this device. They do not allow contact and slip away details.

The advantage of these chimney channels is that the cold air streams that are needed for traction penetrate the outer tube from the street, and not from the room. Also chimney channels of a coaxial type are solved at once by several most important questions in heating:

- increased safety during operation of the chimney due to the intake of cold air through the outer pipe, which cools the internal;

- carries out the supply of oxygen, which is simply necessary for burning and burning out;

- increases the efficiency of heating appliances due to warming cold air flows on the heated exhaust pipe;

- good efficiency increases the degree of ecological compatibility of heat generators and improves the afterburning of gas fuel;

- the entire working process is carried out outside the room, which increases the comfort in it when heating with a gas boiler;

Read also about our portal.

- they reduce the consumption of combustible material and increase the efficiency of the heating system as a whole due to a full-fledged combustion;

- at low weight and affordable price they have high refractoriness and high quality steel. Especially these qualities are known coaxial chimney for the gas boiler baxi;

- they have a special drain for condensate;

- the risk of ignition is reduced to zero, because due to constant circulation, the air temperature in the chimney drops to a safe temperature.

The equipment with such a chimney is ecological, as they do not allow the remnants of unburned particles to fly out into the air and enter the atmosphere.

Advice! They are great for homes, as they provide comfort and security to owners even wooden houses due to their device.

For the current situation in the field of heating, the actual issue is the arrangement of the chosen type of equipment. An important item is the chimney for a gas boiler in a private house or apartment. Today, there are a number of products suitable for this purpose, so it is important not to make a mistake in the choice. To do this, it is necessary to take into account specific conditions and comply with the established requirements.

Types of coaxial chimneys

They are divided into two types: insulated and insulated. The first of them is most adapted to winter conditions and is successfully applied throughout the territory of Russia.

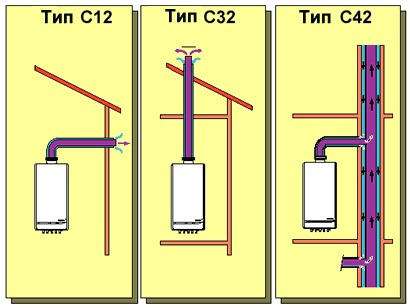

They are divided into three types of installation:

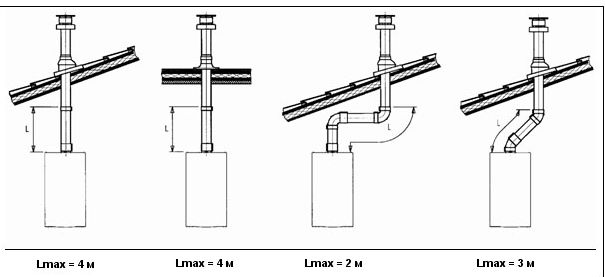

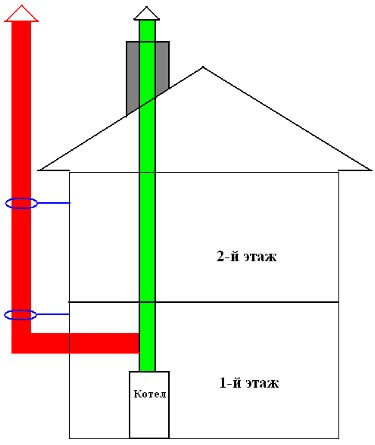

- vertical coaxial chimney. Can be used if there is no possibility to lead the chimney through the wall;

- horizontal coaxial chimney. It is installed during installation forced ventilation boiler. Maximum length the horizontal section is limited. It should be no more than three meters, but still manufacturers put their limitations. Before engaging in structural design, it is necessary to study the characteristics of the device being installed;

- inclined coaxial chimney. The rarest version of the installation and apply only when the other two options can not be used.

For each boiler, the direction of the chimney is individual.

Installation requirements

Coaxial chimney, the installation requirements for which are specified in the passport for each device, are individual, but there are also common ones. Among them:

- to installation work should be carefully prepared. First you need to choose the right section. It is necessary to carefully examine the passport for the boiler and the instructions from the manufacturer, in which information about the required length of the chimney must be indicated;

Advice! If it is not specified, then you should focus on the generally accepted framework. In the best options, the length of the chimney duct should be at least five meters.

- to ensure that the draft in the chimney was better, it should be installed slightly above the ridge;

- they must be installed very carefully and carefully fastened. If the chimney duct is improperly installed, there may be a leak or the supply of smoke into the heated room;

- outflow channel at correct installation The chimney must be larger than the diameter of the outlet from the boiler;

Advice! Before installation, it is necessary to verify the data with the technical passport on the flue gas duct in the field - diameter. This will help to avoid mistakes.

- the appliance for the heating should be installed one and a half meters lower than the outlet of the smoke outlet, while the pipe inlet must have an angle of at least three degrees. This arrangement ensures unimpeded condensate drain.

- The entrance of the chimney must be located at a height of not less than a meter and a half from the floor. This will protect it from contamination.

Advice! If installing a false chimney system, do not make it longer than three meters. This will allow the smoke to flow unhindered.

Required Fasteners

The list of elements required for assembling the coaxial smoke channel of the elements will depend on where the smoke outlet will be installed: from the side or from above. For the first case, a horizontal assembly of the structure will be required, in the second variant the outlet of the chimney channel will be much easier. To bring the tap into the vertical position, brackets of various modifications and clamps will be needed to secure the joints.

Important! It is strictly forbidden to use sealant and self-made adapters for fastening, as this is unsafe and can lead to incorrect functioning of the system.

With the correct selection of elements, the installation does not take much time, and the system will serve for a long time.

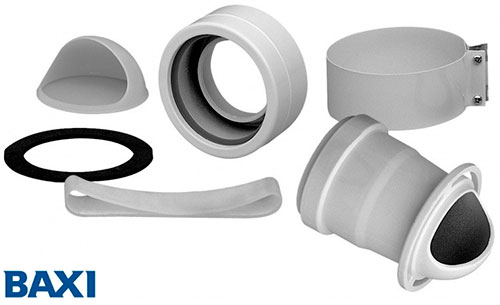

Features of Baxi chimneys for boilers

Baxi is one of the most famous companies for the production of heating systems. It produces chimneys made of high quality polypropylene.

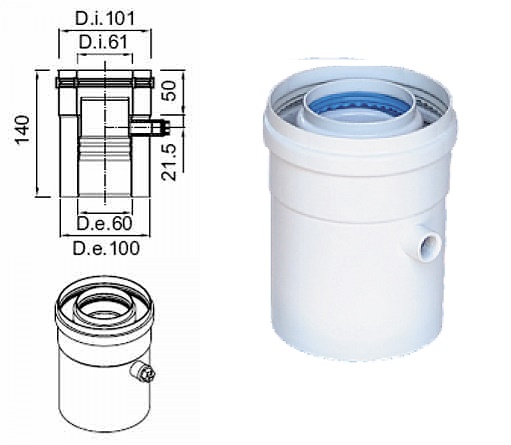

Coaxial chimney for the gas boiler Baxi has such characteristics as: reliability and ease. They are manufactured by the manufacturer in diameters of two types: 100/60 millimeters and 125/80, while the size of the ledge of the chimney is 350 millimeters. This type is suitable not only for southern, but also for northern regions of Russia. They prevent the appearance of internal ice at low temperature conditions. Baxi chimneys have an elongated head and a protection design that allows them to work without interruptions at fifty degrees Celsius frost.

Video: tips for installing a coaxial chimney

Coaxial chimneys are a new step in creating modern heating systems for private houses. They are environmentally friendly, safe and comfortable, and also easy to install. When choosing, it should be taken into account that some of them are not designed for operation at low temperatures, so the inhabitants of the northern regions should pay attention to the Baxi heating system. Providing a home with heat with the advent of such a system will become easier.

A modern autonomous heating system consists of many elements. Its composition can vary depending on the type of coolant or on the method of heating it. When the heating medium is heated in piping systems or in heat exchangers by open fire, heating furnaces operating on different types fuel. Regardless of the combustion material, the boiler must provide a flue gas discharge system, or a chimney. Such a construction can also be built in different ways. So if there is a gas heating system good choices there will be a coaxial chimney for the gas boiler.

What is a coaxial chimney?

The very concept of "coaxial" involves placing one cylinder inside another cylinder. Thus, the coaxial chimney system for gas boilers is one pipe in the other. In this way, the system will have two circuits created from a pipe of larger and smaller diameters. To ensure that the distance between the large and small pipes remains the same throughout their length, they are fixed by bridges, which prevent the walls of the pipelines from coming into contact.

Assignment of coaxial chimney system

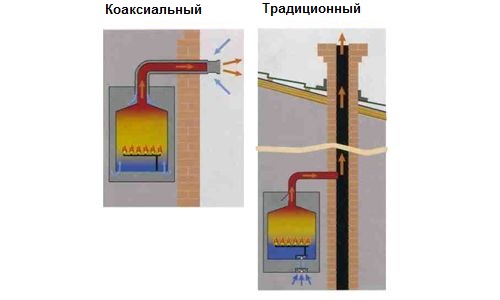

The main area of use of coaxial chimneys are heating systems with gas heating boilers equipped with closed fireboxes for fuel combustion. It can be represented by a gas boiler, a convector or a radiator. Two circuits of the coaxial chimney perform different functions:

- The first circuit is responsible for diverting the products of gas combustion from the boiler furnace.

- The second circuit is responsible for the inflow of fresh air into the combustion chamber, which is necessary for effective combustion.

In order to ensure effective traction and uniform combustion of gas - boilers with closed combustion chambers must be equipped with coaxial chimney systems not exceeding 2 meters in length. Otherwise, during the pipe, vortices are formed, which will prevent the free release of combustion products and the intake of fresh air.

Placement of coaxial chimney systems

A small length of coaxial chimney stoves for gas boilers dictates and the location of their placement. The most common method of installation is the direct passage through the wall to the street. More rarely, during installation, the passage of coaxial chimney systems through overlapping or through the roof is observed. The most efficient coaxial flue duct works if it has a strictly horizontal arrangement. In the event that the gas heating boiler is located in an inconvenient place for such an output - it is possible to remove the coaxial chimney pipe and through the roof, using vertical sections of the structure.

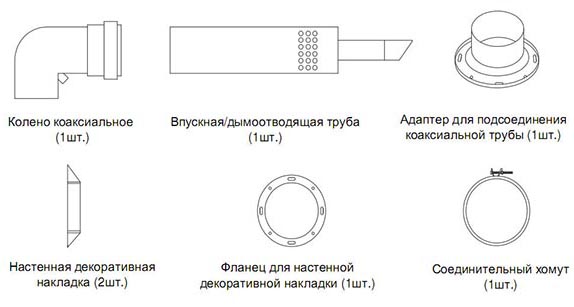

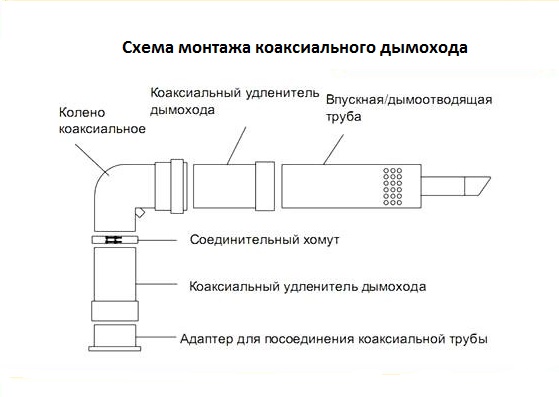

Composition of the coaxial chimney

The standard design of the coaxial chimney for gas boilers consists of the following main parts:

• Straight pipes - they form the channel of the chimney system

• Connectors (tee or swivel section), designed to connect the straight sections and connect the chimney directly to the gas boiler. • Cleaning site, designed for regular maintenance,

• A place to collect water condensate - the products of gas combustion carry water vapor, which can accumulate on the walls as it cools down. To prevent its entry into the combustion chamber, such a section is formed.

• Upper outside chimney - designed to protect the internal contours of the chimney flue system from the influence of weather conditions: snow or rain, as well as for wind protection. Material for the production of coaxial chimneys Industrial production of coaxial chimney elements for gas heating boilers is made of many materials:

• Pipes made of stainless steel. This is perhaps the most long-lived material, but such equipment has an increased price.

• Pipes made of galvanized steel - these devices are sold cheaper, but they are more susceptible to corrosion.

• In addition, different sections of the chimney, as well as the outer and inner pipelines, can be made from the most different materials, up to high-strength polymers.

What does the installation of the coaxial chimney provide?

The most important advantage of placing the coaxial chimney for a gas heating boiler is the fact that the fresh air intake for the constant maintenance of combustion in the furnace takes place outside the room. In this case, you will not experience discomfort due to burning out oxygen in the room, do not run into excessive dryness of the air. Using coaxial chimneys will avoid frequent airing. This is especially important in cold weather, because when you air through the windows you cool the air in the rooms, and for back heating you need an increased flow of coolants and energy.

In addition, the air entering the contour of the coaxial chimney when heated from the street to the combustion chamber is heated, which facilitates the combustion reaction and increases the efficiency of your gas boiler. With a constant influx of fresh air, heated to room temperature - the gas in the furnace of your boiler is completely burned, greatly increasing the efficiency of the entire heating system.

It is worth noting that the complete combustion of fuel improves the ecological compatibility of the heating system - you do not pollute the surrounding air with unburnt elements.

Also, the combustion products, when passing through the emission circuit, give away some of their heat to fresh air coming from outside. This reduces the risk of fires inside the pipe in areas with the accumulation of unburned particles. The coaxial tube has an external surface temperature significantly lower than the classical chimney, which reduces the fire-fighting requirements for its installation. Thus, coaxial pipes (with appropriate insulation, of course) can be carried through wooden walls or floors, which is impossible for a conventional steel chimney. A gas heating system with a coaxial chimney creates a completely closed fuel combustion circuit in which the oxygen for constant combustion is taken from the outdoor air and the combustion products are also disposed there. This creates a comfortable atmosphere in the room where the gas heating boiler is located. This is important, since gas water heating boilers are often located in habitable rooms, for example, in kitchens.

A wide range of

Selection of a coaxial chimney is possible for almost any gas heating system, regardless of its capacity: there are pipes of various diameters, made of a wide variety of materials. Installation of such a system is relatively simple and can be easily accomplished even by an unprepared specialist.

Mounting the coaxial chimney

Please note that improper construction or installation of a coaxial chimney system can negate all of its advantages. For correct installation follow the step by step instructions:

- Make sure you have all necessary materials and tools. To do this, you need a set of coaxial pipes and connecting elements, wall lining to form seals and a street lug.

- Before proceeding with the installation, make a marking, calculate the path of the chimney, remove excess objects, make a hole in the wall of the appropriate diameter. When designing the unit, make sure that there are no flammable objects near the pipe.

- The best choice is the simultaneous installation of a gas heating boiler and the corresponding coaxial chimney.

- The outlet of the chimney should be located about a meter and a half above the level of the combustion chamber of the gas. To achieve an optimal location, the chimney system can be lengthened, but mounting more than two knees in it will lead to vortices with a sharp decrease in its efficiency.

- The coaxial pipe is connected to the outlet pipe of the combustion chamber of the gas boiler with a clamp. It is fixed by means of two bolts.

- After that we assemble the chimney system in accordance with the projected configuration.

- Chimney knees are also fixed by means of clamps.

- At the outlet section of the chimney, we form a small downward slope, so that the condensing moisture is removed by gravity from the system.

- On the upper outer part of the coaxial chimney can be put on a protective flywheel.

We heat the coaxial chimney

At low negative temperatures on the street, some sections of the coaxial chimney can completely freeze, which adversely affects its effective operation. In order to avoid negative moments - such areas must be insulated. It would seem that this is a reasonable solution, but the very construction of the "pipe in the pipe" negates any warming. " Instead, the best way is to reduce the section of the chimney system. In the event that there is frost on the chimney head - try to make a shorter inner pipe of the system. In this case, condensation can be avoided. In extreme cases it is practicable to install two separate steel pipes, one of which takes the air, and the other takes the products of combustion.

Coaxial chimney for gas boiler video

In order to create comfortable conditions in the room, it is necessary to prepare for heating period. In our time, there are many options for equipping heating equipment. For multi-storey buildings, the centralized type of heating is mainly used. While in private houses installation of various boilers is most often performed. When installing a device that heats the room, burning fuel, an additional device is required that works to divert the flue gases. Previously, the installation of a pipe, which served as a discharge device, was made. But to date there are more and more new designs that significantly improve the operation of the heating system. Often the owners of private structures establish coaxial chimney , which is characterized by efficiency and practicality, compared to a conventional chimney.

The essence of this device is that one object is inserted into another, hence the name "coaxial" resembles. Generally, the design consists of a pair of pipes of different sizes that are inserted one into the other. Therefore, the coaxial chimney is a two-circuit structure. In the middle of this device special jumpers are provided, which do not allow the elements to touch each other. This device is installed complete with boilers, the combustion chamber of which is made in closed version. The devices with this construction include gas boilers.

The essence of this device is that one object is inserted into another, hence the name "coaxial" resembles. Generally, the design consists of a pair of pipes of different sizes that are inserted one into the other. Therefore, the coaxial chimney is a two-circuit structure. In the middle of this device special jumpers are provided, which do not allow the elements to touch each other. This device is installed complete with boilers, the combustion chamber of which is made in closed version. The devices with this construction include gas boilers.

Each of the circuits of this chimney has its own task:

For boilers with a closed firebox, chimneys with a length not more than 2 meters. This is important, because with a larger amount of smoke draft will be bad, and, therefore, the fuel will not be fully burned. This is due to the formation of peculiar vortices that interfere with the exit of combustion products and the inlet of air flows from outside.

Advantages and disadvantages

As for the advantages of this type of construction, they can include the following:

- Quite a high level of EFFICIENCY, since air intake occurs in a well-warmed state.

- Small size, because with a conventional chimney installation requires the presence of two pipes, but here one is obtained.

- No need for accommodation additional system ventilation.

- Eco-friendliness in use.

- Staying in the boiler room is absolutely not harmful to human health, since the heating system takes oxygen for itself not from the room, but through chimney channels from the street.

- Cost-effectiveness in spending money.

- To heat a room like a sauna, fuel is consumed much more economically.

- Due to the constant arrival of cold air near the walls, there is no way to go into a state of overheating.

But there is also some flaw . At a large negative temperature, a pipe of a smaller diameter may freeze, because the flue gases along the way give up their heat to the inner pipe and at the exit already have a fairly low temperature. That is why the formation of condensate accumulations in the pipe is a normal phenomenon. When the temperature drops to -15 ° C, the pipe may be subject to severe freezing, which leads to a large number of undesirable consequences.

But there is also some flaw . At a large negative temperature, a pipe of a smaller diameter may freeze, because the flue gases along the way give up their heat to the inner pipe and at the exit already have a fairly low temperature. That is why the formation of condensate accumulations in the pipe is a normal phenomenon. When the temperature drops to -15 ° C, the pipe may be subject to severe freezing, which leads to a large number of undesirable consequences.

It is believed that chimneys of this type are absolutely not suitable for the harsh climate of Russian cities. At the very beginning, this system was developed for the southern countries. But many experts come to a common opinion that the freezing of the pipe is the result of the illiterate design of this system. But regardless of the reasons, the final consequences are the same - the galvanized chamber, as well as the burners quickly become unusable. Repair of this equipment is quite expensive.

Most often, these malfunctions occur in those types of chimneys that perform in terms of parameters that can significantly improve the efficiency. To this end, the pipe diameter is usually made as small as possible, which practically brings the temperature values of the flue gases to the dew point.

For southern countries, these indicators do not affect anything, but in Russia, at the first major drop in temperature, the freezing of the pipe leads to a complete installation of the heating system. Manufacturers can only breed with their hands, since testing of this system is not carried out under similar conditions.

Summarizing after all of the above, we can say that the resistance to negative temperatures depends entirely on the diameter of the coaxial chimney. It should also be noted that this system is adversely affected by significant voltage drops, as well as a complete power outage.

Selection of a chimney for a bath

For the arrangement of heating the bath does not exist an individually designed  chimney system. Select it depending on the type of boiler, fuel and structural parameters of the room. The design of coaxial chimney systems for different furnaces is almost identical. Coaxial pipe for chimneys is usually applied made of plastic and aluminum. The quality of both options is quite high. When purchasing this chimney system it is necessary to pay attention to the presence of all jumpers, which are necessary to prevent contact of pipes.

chimney system. Select it depending on the type of boiler, fuel and structural parameters of the room. The design of coaxial chimney systems for different furnaces is almost identical. Coaxial pipe for chimneys is usually applied made of plastic and aluminum. The quality of both options is quite high. When purchasing this chimney system it is necessary to pay attention to the presence of all jumpers, which are necessary to prevent contact of pipes.

All recommendations for proper design can be found in the Russian SNiP 2.04.08-87 "Safety rules in the gas economy." Not having special skills and education in these rules is very difficult to understand. For simplicity, you can purchase a fully finished system, which includes all the necessary certificates. By its design, coaxial chimneys are in horizontal and vertical execution.

Manufacturers

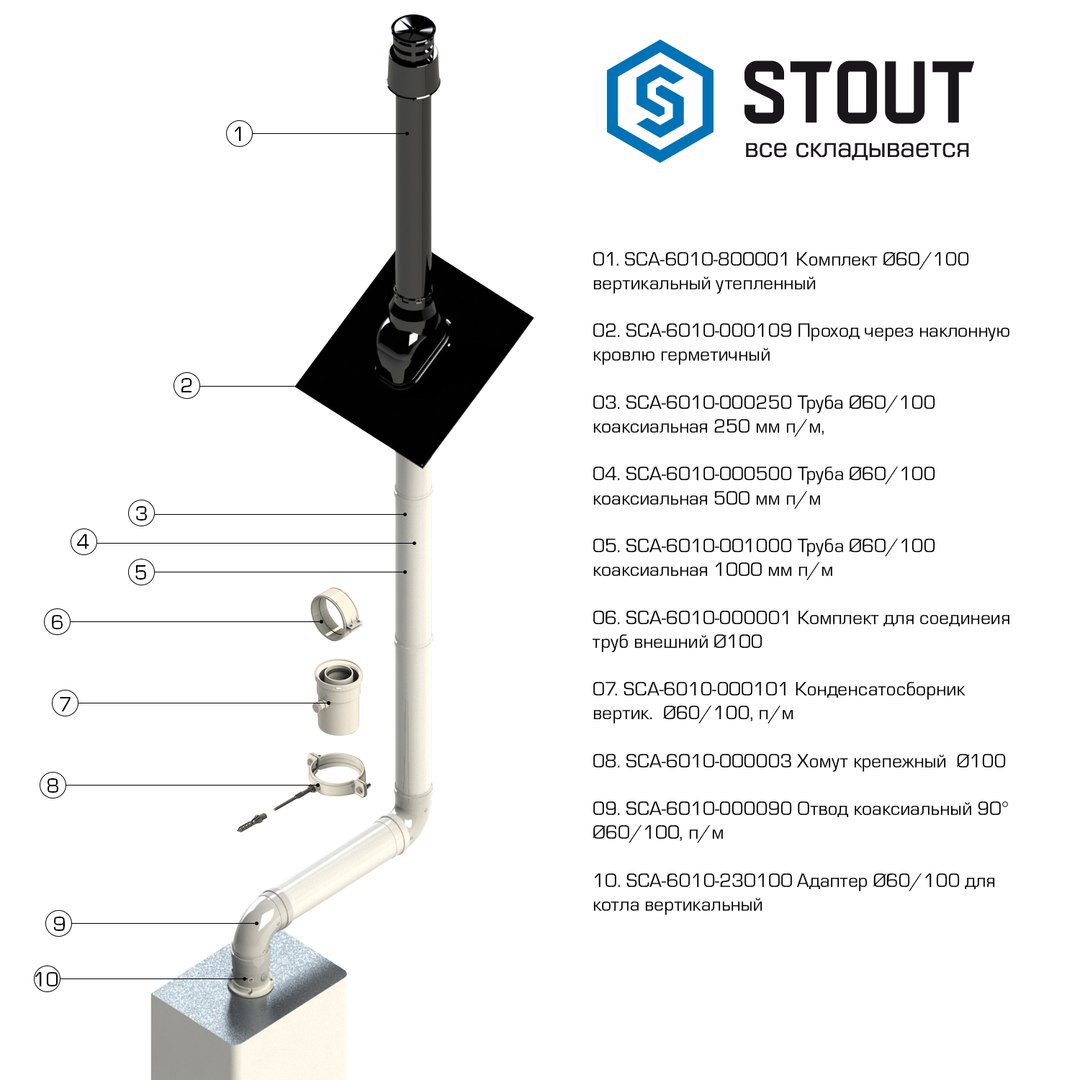

A universal option for most popular gas boilers will be a coaxial chimney from the brand STOUT . All the components of the whole system are ideally suited to each other, easy to install and maintain, adapted for operation in our country.

The variety of elements allows to create absolutely any smoke removal system. The manufacturer gives a two-year warranty on all products. Technological process production is carried out at the same factories in Italy, where a similar but more expensive product is produced. STOUT is the choice of those who do not overpay for the loudly untwisted brand name, but are accustomed to choose only high quality.

Coaxial chimneys of firm «Baxi» They are produced for boilers that run on gaseous fuels. Their construction consists of stainless steel of the highest quality.

Coaxial chimneys of firm «Baxi» They are produced for boilers that run on gaseous fuels. Their construction consists of stainless steel of the highest quality.

Firm Immergas produces horizontal coaxial chimneys. It is possible to use a coaxial chimney for gas boilers, as well as working on liquid fuels.

Chimney systems of the company Buderus are made horizontal. For their production, galvanized and stainless steel is used.

Chimney systems of the company Buderus are made horizontal. For their production, galvanized and stainless steel is used.

Coaxial chimney for gas boilers Hermann is manufactured in certain sizes: diameter inner tube - 6 cm, the diameter of the outer tube - 10 cm. The production of these systems occurs in both horizontal and vertical versions.

Coaxial chimney, which is produced by the company «Vaillant»,  is performed with some features in the design, allowing it to be used in conjunction with boilers from other companies.

is performed with some features in the design, allowing it to be used in conjunction with boilers from other companies.

Korean manufacturers of the company «Navien» Chimneys that are used together with floor or wall boilers, with a power not exceeding 75 kW, are used.

Coaxial chimneys of a popular firm Viessmann are produced in several versions with diameters: 6/10 cm, 8 / 12,5 cm, 10/15 cm. The designs can be both vertical and horizontal.

Firm Protherm produces horizontal and vertical coaxial chimneys in sizes 6/10 cm and 8 / 12.5 cm.

Chimney design of the company Daewoo is designed so that the installation can be performed on both the left and right sides of the boiler.

Chimney design of the company Daewoo is designed so that the installation can be performed on both the left and right sides of the boiler.

Production of horizontal and vertical chimneys Ariston comes from enamelled steel.

Requirements for installation

The installation of a coaxial chimney has its own rules. They should be described in the instructions that are attached to the equipment. The gas service and the Ministry of Emergency Situations can make some adjustments and additions.

When installing a coaxial chimney, certain rules must always be taken into account:

The design of this pipe is designed in such a way that there can not simply be a return thrust. Before the furnace is installed special valve, which does not allow blowing of flue gases inside the room.

Passage of a coaxial chimney through a wooden wall

In SNIP and fire safety regulations, there are no recommendations for horizontal chimneys. There are some general rules. In accordance with these rules, the passage of a pipe through a wooden wall must be carried out with some cuts. To a greater extent this condition is not implemented in order to protect the structure from fire, but to eliminate incidents, in the form of fines and injunctions, with fire services.

Passage of a coaxial chimney through a wall made of non-combustible materials

The preparation of the hole necessary for the discharge of the chimney is quite easy. Aperture of the required diameter is cut out, the slope of which will be directed to the ground. The size of this hole should not be much different from the size of the chimney itself. A special connection extension must be inserted into this hole, which fulfills the requirement of the connection to the wall.

Protect the chimney from icing can only be done by installing additional elements. You can buy a special nozzle, which will prevent the condensate from freezing. This element will also help in case of incorrect design and subsequent installation without the necessary bias. The nozzle does its job, keeping the temperature inside the pipe at a certain level.

The distance from the pipe that feeds the gas to the chimney must be within 60 cm.

Installing a coaxial chimney

It is important to know that failure to comply with the rules of construction and installation of a coaxial chimney can nullify all the advantages of this device.

Installation Instructions:

In the family of devices for the removal of combustion products, the coaxial chimney stands apart. This modern design much more efficient and safer than a conventional chimney. Such a system is ideal for boilers with a closed combustion chamber. Installation of it is also relatively simple, but before starting work, you should carefully study the installation rates of the coaxial chimney.

To make a coaxial chimney, it is necessary to take two pipes of different diameters and insert a narrow tube inside a wide one. It is also necessary to connect the inner side of the wide pipe and the outer side of the narrow tube with special bridges in such a way that the central axes of both tubes coincide. Well, the coaxial chimney is ready.

In practice, such a design, of course, is easier and more reliable to buy than to do. The cost of a coaxial chimney will be higher than the price of an ordinary stainless steel pipe, but the costs will be repaid in full.

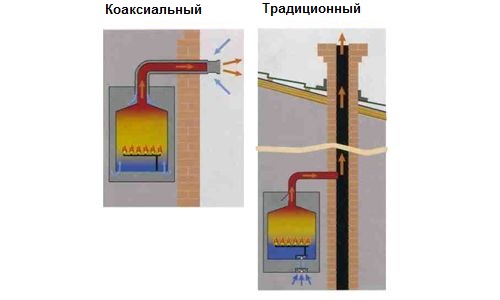

A double pipe is required for the simultaneous execution of two functions. On the inner narrow pipe, combustion products are taken from the furnace of the boiler. And through the gap between the inner and outer tube, air enters the combustion chamber; oxygen required for fuel combustion.

This solution has a number of advantages. An alternative to a coaxial chimney is a traditional chimney in combination with forced air injection into the combustion chamber. In this case, air is usually taken from the room in which the boiler is installed. Coaxial same chimney allows you to take air from the street and feed it directly to the furnace.

The diagram shows general principle work coaxial chimney, as well as its device compared to the traditional chimney

What happens in such a chimney during the operation of the boiler? Hot combustion products move along the inner pipe outward, and in the opposite direction there is a parallel flow of fresh cold air. As a result, a completely natural heat exchange takes place: hot gases give off heat to the neighboring cold stream.

Air enters the combustion chamber already in the warmed state, which increases the overall efficiency of the boiler, because you do not need to spend precious kilojoules on heating air masses. In this case, the temperature of the outer surface of the coaxial chimney is significantly lower than when using a standard chimney. This circumstance makes the design safer.

Another advantage of the coaxial chimney is the simpler installation of the boiler, because you do not have to install a forced ventilation system. In addition, these designs have different requirements than traditional chimneys. As a result, the combustion products removal system takes up less space.

On the outside of the building, the coaxial chimney pipe looks much laconic and takes up less space than with the external installation of a traditional chimney

Coaxial chimneys are universal, they can be installed with gas boilers, and with devices operating on liquid or solid fuels. On sale there are chimneys with different diameters, which allows you to choose suitable pipes for a particular boiler.

Installation of a traditional chimney in an already constructed building is a rather complicated task. If the installation of the chimney was not provided for in the design, it is necessary to cover the roof and the roof or take the chimney out.

A bulky structure can create problems both inside the building and outside. But coaxial structures easier and more compact. The conclusion of such a chimney on the outer wall looks laconic, it does not spoil the appearance of the house.

Features of installation of coaxial chimneys

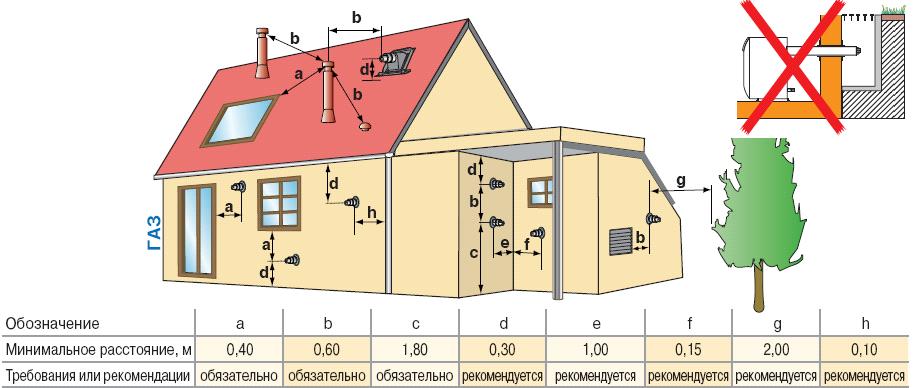

Chimneys of this type can be installed horizontally or vertically. Preferably the first option, which is considered to be simpler and takes up less space. A number of requirements must be met:

- the distance from the pipe to the ground level on the outside of the house must be at least 2 m;

- the pipe must be at least half a meter horizontally away from windows, doors, vents, etc .;

- the same distance to these objects should be maintained and vertically;

- if over ventilation duct a window is located, the distance to its lower edge must be at least one meter;

- free space in front of coaxial tube must be at least one and a half meters, i.е. next there should be no walls, fences, poles and other similar obstacles;

- if there is no special device for collecting condensate, then the coaxial chimney pipe should be placed under a slope to the ground;

- the size of such slope can vary within 3-12 degrees;

- it is not allowed to remove the chimney channel not into the street, but into another room or structure: an entrance, a cellar, a tunnel, an arch, etc .;

- a distance of at least 20 cm should be maintained between the elements of the chimney and gas pipes, if they pass by.

Separately, we should consider the situation where the outlet of the coaxial chimney pipe is located under a balcony or some kind of canopy. This is a perfectly permissible situation, but the following point must be taken into account.

You need to mentally draw a circle in a plane perpendicular to the wall. The center of the circle will be the junction of the canopy and the wall, and the radius is the length of the canopy or balcony. The chimney pipe must extend beyond this conventional boundary. It turns out that the closer to the canopy is the hole for the chimney, the longer it should be outside part pipes.

This diagram demonstrates the basic requirements for placing a coaxial chimney in relation to various objects located next to it (+)

It is believed that the length of the coaxial chimney using a horizontal installation scheme can not be longer than three meters. it general rule, from which there are exceptions. For example, some models of Ferroli chimneys can have a length of four or five meters.

A set of materials for installing a coaxial chimney depends on the type of its location, but in general the list of elements may look like this:

- the chimney pipe itself;

- adapter for connecting the boiler with a chimney structure;

- knee, tee, etc .;

- crimp clamps for reliable connection of elements.

Typically, the delivery kit of the coaxial chimney includes all the elements necessary for its installation. To conduct a pipe through a wall, ceiling or roof, it is necessary to use fireproof gaskets. They will prevent overheating and ignition of materials surrounding the chimney.

This diagram shows some elements of a coaxial chimney. If the pipe needs to be enlarged, additional details of industrial production should be ordered (+)

Here is one of the options: a hole is made in the wall and a sleeve is inserted into it from the asbestos-cement pipe. Then the space between the surface of the coaxial tube and the sleeve is filled with an asbestos cord. All elements of the coaxial chimney must be manufactured in industrial conditions and meet the established standards.

It is not recommended to use homemade structures even for the adapter. Some amateur craftsmen try to increase the length of the pipes using a sealing tape and sealant. But this option does not withstand any criticism from the point of view of security.

Basic installation requirements

Installation type - horizontal or vertical - depends on the features of the room in which the boiler will be placed. In the space between the boiler and the wall into which the coaxial chimney will be drawn, there should be no foreign objects, this is an important safety requirement.

In this case, the outlet of the chimney pipe from the wall and the branch pipe of the boiler to which it is connected must separate at least 1.5 m vertically. The pipe should also have a slight slope - about 3 degrees, to ensure the outflow of condensed moisture on the surface of communications.

The space between the boiler and the wall into which the coaxial chimney is drawn should not be obstructed by any foreign objects

The next important parameter is the diameter of the pipe and the branch pipe of the boiler. In size, they must coincide. In no case is it allowed to install a pipe, the diameter of which is narrower than the dimensions of the branch pipe of the heating device.

Before starting the installation, you should carefully review the technical data sheet of the boiler to ensure that the dimensions of the branch pipe and chimney are in accordance with the established norms. The boiler connection can be located on the top or side. It is believed that the upper position of the branch pipe simplifies installation.

The dimensions of the boiler connection for the chimney, adapter and coaxial pipe must correspond to each other. Use of a smaller diameter pipe is not permissible

For the connection of the flue pipe, an adapter in the form of a tee, a knee or a piece of a conventional pipe is usually used. At the same time, there should not be any obstacles inside the adapter to move the gas and air masses.

If the length of the coaxial tube is to be increased, care must be taken to ensure the tightness of the joint. To do this, use crimp clamps. Similarly, connect the adapters, bends and other elements of the chimney.

The individual elements of the coaxial chimney are inserted into each other in such a way that they do not create obstacles for the movement of air and combustion products. The joints are tightly fixed with clamps

During installation of the coaxial chimney, its lower elements are inserted into the upper and rigidly fixed with clamps. This method of connection allows you to provide good traction. Individual elements must fit into each other to a depth of at least half the diameter of the structure in accordance with the requirements for coaxial chimneys.

For reliability, the outlet of the pipe from the external wall is blown with a mounting foam. On top, special decorative grilles are installed to make the installation site look attractive. The grid can be glued with a suitable adhesive composition, for example, with liquid nails.

The problem of correct bias

Concerning the slope of the coaxial chimney pipe, the question may arise: where exactly should it be directed? Some experts say that the condensate should drain towards the boiler. According to other masters, the slope should be done in the opposite direction, so that moisture flows down the pipe to the ground. In both cases, the reason arguments are given.

Quite logical is the option, in which droplets of condensate move as far as possible from the boiler. The firebox is protected from unnecessary moisture, which remains outside the house and naturally dissolves in the environment. It looks like this until the temperature of the ambient air drops below zero.

The icing of the coaxial chimney is a natural but dangerous phenomenon. Ice deposits prevent the removal of combustion products and entry into the furnace of fresh air

In the event of frost on a coaxial pipe installed with a slope to the ground, condensation droplets freeze to form an ice crust. The icing can be observed both on the outside of the chimney and in the space between the two pipes of the coaxial structure.

This happens because the temperature of the outer contour of the chimney of this type is low, it is not enough to melt the ice quickly. As a result, ice deposits create obstacles for the normal flow of air into the furnace, as well as for efficient removal of combustion products.

And this reduces the efficiency of the device. Long operation of the boiler with an iced coaxial flue can even lead to substantial equipment breakdowns. It turns out that in warm regions where even in winter there is hardly any frost, a coaxial chimney can be installed with a slope to the ground.

In all other cases it is recommended to make the slope of the pipe towards the boiler, which usually corresponds to the recommendations of the manufacturers of these structures. What to do with the condensate, which will drain to the heater during such an installation?

Everything is simple, you need to install and use a special container to collect condensate. Such a condensate collector is a small device, which copes with its tasks quite satisfactorily. Partly the problem of freezing the chimney can be solved with the help of its insulation, but this measure does not give one hundred percent guarantees.

This scheme demonstrates the construction of a special element - a condensate collector. It catches droplets of moisture, flowing along a coaxial pipe to the boiler, and protects the equipment from corrosion

Some craftsmen believe that it is possible to prevent condensate freezing in a coaxial chimney with a slope to the ground if you shorten the inner tube, however, experts do not recommend changing the structure on its own.

On the issue of icing coaxial chimney also there is another interesting opinion: the larger the diameter of the pipe, the lower the probability of freezing condensate. While craftsmen broke their spears, discussing optimal gradient coaxial chimney, the manufacturers took care of creating a special kit.

To prevent the coaxial chimney from becoming overcast, it is recommended to use a special model with an anti-icing head. The intake of air into such a pipe is carried out through the holes on its underside

This design is resistant to icing and is designed for operation in the severe Russian winter. This device is equipped with an extension nozzle for the gas escaping (ie internal) pipe. A narrow protective spiral is installed inside the nozzle. In this case, the air intake holes along the edge of the outer tube are located at the bottom.

Horizontal or vertical?

To fulfill all the requirements for horizontal installation of a coaxial chimney is not always possible. It is possible to encounter difficulties if the room where the boiler is installed is very small. The outside of the building may be problematic. For example, if there are windows that are close to each other.

![]()

If necessary, the coaxial chimney can be withdrawn vertically through an inclined or flat roof using appropriate weather attachments. The length of such a chimney depends on the power of the boiler connected to it (+)

It also happens that the distance to neighboring buildings is too small to ensure a normal draft of the coaxial chimney. If you meet all the conditions for horizontal installation of the structure is not possible, you should give preference to the vertical installation, i.e. pull the pipe through the roof.

With vertical installation of the coaxial chimney, as with the installation of a traditional pipe, brackets are used. They allow to keep the structure in the correct position and at a distance from the walls.

When removing a coaxial chimney through a roofing cake special attention give attention to fire safety. Here you should use insulating pipes, and also recommended the use of insulation, resistant to fire.

Also use protective covers to isolate the chimney from contact with other objects and materials. Between the coaxial pipe and the overlap area, a small air gap should be left, but the roof at the outlet of the pipe is sealed very carefully. The joint of the pipe and the roof is covered with a dense protective cover.

Need good ventilation

It may seem that heating device with a closed combustion chamber and the presence of a coaxial chimney relieves the owners of the house of the need to provide the boiler room with normal ventilation. Indeed, the air enters the furnace from the outside, and the combustion products are removed through a reliable airtight channel.

However, the need to ventilate the room in which the boiler is installed is still necessary. To begin with, normal air exchange will maintain the optimum humidity level in the room, which prevents the development of corrosion processes and protects the equipment body from destruction.

And it should also be taken into account that any system can eventually fail. If there is good ventilation in the boiler room, in the event of a breakdown, a small amount of carbon monoxide will be removed from the room by natural means. As a result, the risk of accidental carbon monoxide poisoning becomes significantly lower.

Useful video on coaxial chimneys

The device of the coaxial chimney, its operation principle and mounting features are presented in the following video:

Here is a detailed description of the configuration of the coaxial chimney of industrial production:

Overview of the coaxial kit with protection against icing:

Coaxial chimney is a convenient and simple to install device, which can significantly improve the life in the house. But for such a chimney to function effectively, it is important to comply with the norms and requirements when installing it.