What kind of air is in the accumulator. General principles of operation. Main types and features

To create a smooth and constant flow of water in private water supply systems, use hydroaccumulators, pressure or expansion tanks. These instruments smooth out pressure jumps during operation (on / off) pumping equipment or analysis of the resource by consumers.

The reservoir of such a tank is divided into two compartments by a powerful and elastic membrane. In one compartment (bottom), water enters through the filter connection. The other part of the total tank capacity (upper) is filled with air. The work begins with the pump on. The increase in pressure in the network provokes the injection of liquid into the lower compartment, while the membrane begins to stretch. When the pressure falls, it squeezes the water back. This is how the destructive shocks of water in the pressure pipes and knots are smoothed out.

Video review - The principle of the hydraulic accumulator

A special relay unit automatically turns off the pump when the pressure tank is full. And for a while the energy of the membrane does not give the pressure to decrease. When the accumulator is empty - the pump starts again. Such an arrangement relieves the machine shaking the water from short-term and frequent starts / cuts. This reduces the wear rate of its parts. In order for everything to work properly, the pressure tank must be of the capacity to match the amount of water required. Normally, the tank must contain from a quarter to half of the capacity, which pipes are able to pass per minute.

Correctly selected volume of the device provides a frequency of its operation from five to fifteen times within an hour. In this mode of operation, it is extremely necessary to use a reliable and elastic membrane that will withstand large loads.

Since the accumulators work in domestic water supply systems, the material from which they are made must be non-toxic, with a permit for use in contact with clean drinking water.

The water that enters the hydroaccumulators for water supply mainly comes from underground wells or wells. Hence, its oxygen saturation, which during the operation of the system is released, accumulating in the membrane. For this purpose, most modern devices of this type on the upper part of the housing are located safety valve, bleeding if necessary air. As a rule, hydraulic accumulators are used on cold water lines, therefore temperature regime, in which they are used, is more sparing.

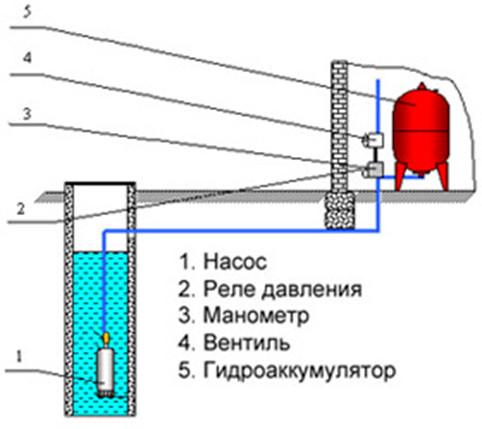

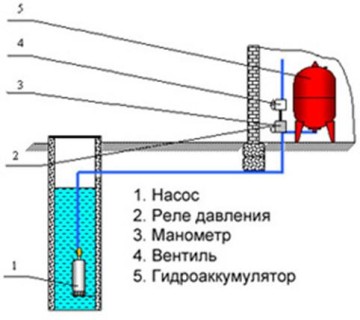

It is advisable to install such a pressure element before the water circuit begins to branch out. The best place is immediately after the entrance of the water supply pipe to the housing. Also does not hurt and installation check valve.. Especially if there is none in the pump. In addition, the installation of a pressure gauge is recommended to monitor the pressure created.

Installation of equipment in the water supply system

Hydroaccumulators can be vertical and horizontal. Choose from them the one that will fit into the space more compactly. The mounting position is selected as high as possible. So the whole scheme is easier to function. The fact is that by raising the unit to a height, for example 5 m, we get a water column that "helps" the working membrane with an additional pressure of ½ atmosphere.

Such devices as hydroaccumulators for water supply are auxiliary devices of cold and hot water supply systems. They provide the water pressure necessary for the operation of the main line. The operation of such systems reduces the number of pump inclusions and reduces the likelihood of hydraulic shocks. Also in them there is some water supply, which will prove to be important during a power outage.

How to choose the right one?

Choosing hydroaccumulators for water supply is necessary, given the amount of water that the system uses. According to their configuration, they are divided into two types:

- vertical, the main advantage - take up less space;

- horizontal, it is more convenient than hydroaccumulators of the first type, since they have fasteners for installing an external pump.

Also important in the choice of accumulator is the question of its volume. A tank with a small volume will make the pump inclusions more frequent. Still such small volume devices are prone to frequent pressure spikes inside the system. A large tank will store enough water.

Particularly, one should take into account the moment when the pump is frequently turned on. Because of frequent inclusions, it overheats, which, accordingly, significantly reduces the life of the work.

However, here you can pay attention to the choice of the pump itself. Submersible pumps have a limit of 20-30 starts per hour, but external ones are not so fastidious to frequent starts, so they work fine with small tanks.

The subjective factor responsible for the correct choice of the dimensions of the accumulator is an approximate calculation of how many times the pump will turn on for an hour. Or, how many people at the same time will use the water in a room using the water supply system. To date, there is a patented methodology for calculating the volume of the accumulator, which was developed by Italian engineers. It is intended directly for private houses with sewage, the presence of bathrooms and other equipment that consumes a sufficient amount of water.

To make the system autonomous water supply could work, drill a little well (as an option - dig a well) and lower the pump there. It must necessarily contain a device that provides constant pressure and storage of water reserves.

This may be, for example, water tower. But - this is a very complex and expensive construction, which, moreover, takes place on the site. An alternative is a membrane hydraulic accumulator.

By and large, the water tower is the simplest kind of hydraulic accumulator, providing a level of pressure depending on the height of the rise of the liquid.

By and large, the water tower is the simplest kind of hydraulic accumulator, providing a level of pressure depending on the height of the rise of the liquid.

It performs three major functions, without which the operation of the water supply system is impossible.

- Maintains constant pressure in system.

- It is a storehouse of water.

- Protects the system against water hammers, playing the role of a buffer between the lines and the lifting pump.

There is also a fourth function, in the implementation of which the supplier is more interested than the consumer. This reduces the pump's running time and the number of its inclusions, which not only increases the time of its trouble-free operation, but also saves electricity.

For a privateer who owns his own water source, it is no less important than the first three.

For all its apparent simplicity, the water tower is a very complex and material-intensive structure, subtracting part of the useful area of the suburban area. Therefore, in systems individual water supply Compact membrane devices are more often used.

The device of a membrane hydroaccumulator

The pressure in it is created not by lifting the liquid to a certain height, but by using its incompressibility properties. For this purpose, a rubber pear is placed in a metal tank, something like a large syringe.

It is filled with water, and air is pumped into the tank or nitrogen. The elastic membrane of butyl rubber perceives this pressure and transfers it to the liquid inside it.

Since water is an incompressible substance, the pressure created by air or nitrogen in the accumulator is transferred to the entire system. If you connect it to a pump with a high working pressure, then the elastic membrane inside the tank will compensate it, preventing a hydrodynamic impact.

The amount of water pumped into the accumulator can be considerable. Therefore, when the water supply stops, it begins to play the role of a supply tank. The pressure in the system in this case gradually decreases.

Types of membrane accumulators

The main difference lies in the location of the branch pipe, connecting this device with the entire system. Therefore, they can be of only two types:

- Vertical;

- Horizontal.

The vertical branch pipe is usually fed from below. This type of device has a unique advantage over horizontal models - it can provide a larger volume of single consumption. This is due to the fact that top part The elastic membrane, when drained by gravity, falls below the axis of the horizontal branch pipe and blocks it.

Horizontal hydraulic accumulators produce, for example, russian company Unipump. The 50-liter model is the smallest size for a small water supply system a country house - costs from 7 thousand rubles.

Horizontal hydraulic accumulators produce, for example, russian company Unipump. The 50-liter model is the smallest size for a small water supply system a country house - costs from 7 thousand rubles.

Vertical from the company "Gileks" (also russian manufacturer) of the same volume is much cheaper - from 3.5 thousand rubles. The price is affected by the material of manufacture (the expensive Unipump is made of stainless steel), as well as the material of the flange for connecting the trunk - it can be both plastic and metal.

Please note that the expansion tanks for the cold water system are usually painted blue, and connected to the mains with hot water - Red. The membranes in them can be either replaceable or non-removable.

How to choose

The main criterion of choice is volume. Formulas for its calculation are available, but they are all complex, and the results of calculations are approximate, since they are based on the average water flow taken almost from the ceiling.

You can try to do already ready calculations, and go from the opposite - assuming that the amount of water consumed is equal to the amount of sewage. In the book of V.М. Masyutin "Modern Manor House" he is defined for a family of four in the amounts indicated in the table.

Now for calculations it is necessary to find a compromise between the desired water supply and the number of pump inclusions during the day.

This will help the table, which shows a single water flow, after which the pump starts.

For example, take a one-story "hacienda" in which four people live, and they use water for washing, washing dishes and washing. The water supply is provided by submersible pump "Aquarius 0,5-16 U".

Pressure in the water supply system is standard - 1.3 bar, the pressure switch is set to start the pump with a head of 1.5 and turn off at a pressure of 2.5 bar. If you choose a storage capacity of 100 liters - half the daily water consumption rate, then let's assume a one-time consumption of 26.3 liters.

After exhausting this limit, the pump is turned on. Considering that almost 30 liters are not always consumed at one time, and the productivity of this pump is almost two tons of water per hour (1.8 m 3), the pumping device will be switched on no more than three or four times a day.

The larger tank volume, equal to two hundred liters - the full daily consumption rate, will allow to spend almost 53 liters at a time, not including the pump, which seems excessive if there is no need to water the kitchen garden and barely enough if there is such a need.

In the example of calculation, there is a special parameter - the pressure in the system, on which the choice of the pump model depends directly and indirectly - the volume of the accumulator.

Determine how it should be very simple: every 10 meters of water column - this is one atmosphere or bar. In the water supply system of a single-storeyed building there is enough pressure of 1 bar, and in a two-storey building it must be at least one and a half bar, otherwise on the second floor the water will hardly ooze out of the tap.

Given that the pump pressure should be higher than in the system, the hydraulic accumulator is injected 0.2-0.5 bar less. And the more floors in the building, the greater the volume of the accumulator required that the pump is not in a permanent stop-start mode.

How to connect

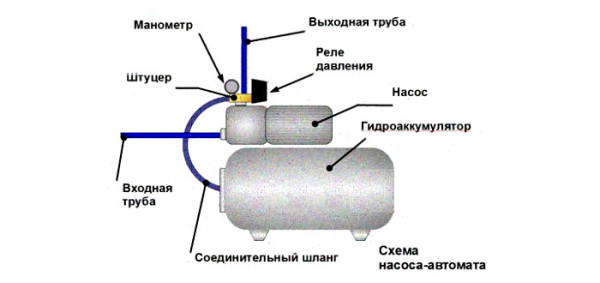

To connect this device, a minimal set of plumbing tools and consumables - a wrench and a sealing tape FUM - is sufficient. But without one detail, it will not be possible, under no circumstances. It is called a "5-outlet choke". These conclusions are needed to connect:

- Accumulator;

- Pump flow;

- Manometer.

- Pressure switch (pump start);

- The inlet pipe branch of the water main.

Accumulator maintenance

This device is constantly under pressure and experiencing dynamic loads. Therefore, it is always necessary to monitor it, approximately the same as for the condition of the tires of the car - before each trip.

Visual inspections for a leak are alternated with pressure measurements in the chamber. To do this, at the end opposite the inlet branch pipe, a cover is removed, beneath which there is a slide valve. Through it, air or nitrogen is pumped. The pressure is measured by a car manometer.

A clear sign of a malfunction of the device is a constant decrease in the number of injected atmospheres. Most likely, the integrity of the rubber diaphragm is broken, and the air goes into the system.

How to replace the battery membrane:

Conclusion

The hydraulic accumulator is a very simple device, but its serviceability and correct selection of the model directly affects the efficiency of the local water supply system and the comfort of living in the house.

Accumulator is a metal sealed container, inside which is an elastic membrane. This device is necessary to maintain constant pressure in the water pipe and protect the water pump from premature failure due to frequent operation. If you want to buy a storage battery and install it own hands in a private house, it is necessary to understand its technical characteristics and the principle of operation.

Accumulator functions

A hydraulic accumulator, also called a membrane tank or a hydraulic tank, performs a number of functions:

- Maintains pressure in the water supply system at a stable level.

- Saves the pump from rapid wear due to frequent use. In the tank there is a certain amount of water, so the pump does not work for every tap opening, but only when the water is completely consumed. Each pump provides a standard indicator of the number of inclusions per hour. Using a hydraulic tank allows increasing the number of unclaimed pump connections, and this affects its service, increasing the operational period.

- Protects water supply system from the probabilistic hydrostorm that occurs when the pump is connected, which is capable of damaging the pipeline.

- Allows you to create a certain amount of water in the system. Thanks to this, you will always have water, even during periods of power outages, and this is often a phenomenon in our world. This function is especially useful for owners of country houses.

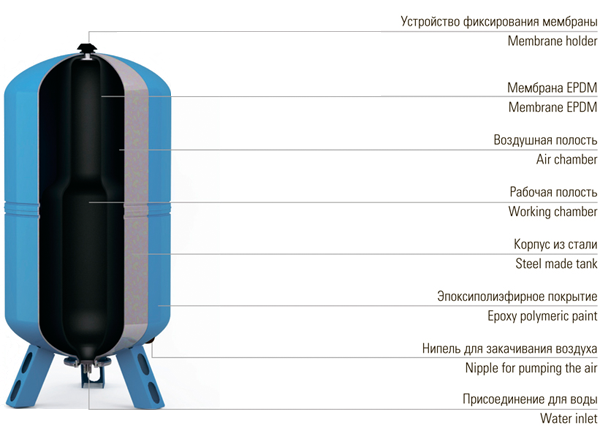

What the hydraulic accumulator consists of

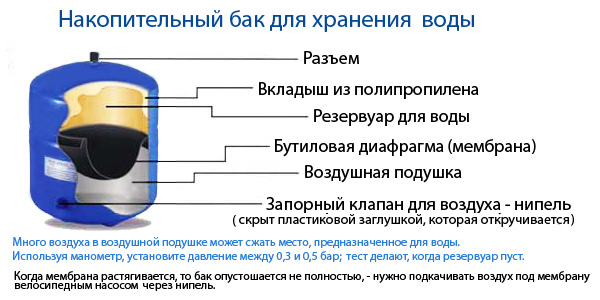

It should be noted that the capacity of the tank is tight and divided into two chambers using a special membrane, the first is for water, and the second is for air.

Accumulator unit

As for the air chamber, it has a pneumatic valve that regulates the pressure. The connecting branch pipe, with a thread, allows filling the hydraulic accumulator with water.

The connecting pipeline is selected in such a way that it corresponds in diameter to the discharge nozzle, since this directly affects the occurrence hydraulic losses in the water supply system.

See the video: Why in the water supply system a hydroaccumulator

The accumulator, designed for a volume of water greater than 100 liters, provides for the presence of a valve that ventilates the air that has accumulated in the water. For a tank with a smaller volume, without such a valve, there are devices in the water pipe that allow bleeding air. It can be either a tee or a tap that covers the central water main.

In general, the accumulator must be so mounted that it can be easily disassembled for repair or maintenance work, without draining all the water from the system.

How does the accumulator work?

Principles of work are as follows:

- Water is pumped through the pump to the diaphragm of the tank, thanks to the pressure created;

- Once the pressure has reached the desired level, the pump turns off, which means that the water stops flowing;

- After the next intake of water, the pressure gradually decreases, so the pump is automatically connected, starting to supply water to the membrane.

Scheme of operation of the accumulator

It is established that the maximum performance of the tank depends directly on its total volume. There is the possibility of regulating the operation of the pressure switch.

During operation, air dissolved in an aqueous medium accumulates in the membrane of the device. This reduces the effectiveness of work a membrane tank. To correct the situation, it is necessary to conduct preventive work, during which bleed air.

The scheme of connection of the accumulator directly depends on its purpose. The battery charger does not look like an ordinary water tank, so its installation requires special knowledge and skills. The installation should be carried out by an experienced technician, since the entire water supply system depends on it directly.

For urban residents, the hydraulic accumulator for water supply systems (water accumulator or hydraulic tank) concept is completely unfamiliar. Buying, for example, a dacha or vacation home in an area without a central water pipe, the owners are stunned by a multitude of complex abbreviations, technical requirements, concepts. Such as: an autonomous water supply system, borehole pump with a frequency converter, setting the minimum and maximum pressure, the maximum number of inclusions of the deep pump. And all this only for the water to flow from the tap. In this article, we describe the role of this device in pumping systems.

The most common type of hydraulic tank

Note! Not to be confused with the expansion tank for the heating system, these two devices are similar in shape and design. Most of the expansion tank is red, and the accumulator is blue, but not always. Check with the sales manager, when purchasing, what function the required appliance should perform.

This structural element has two main purposes:

- Ensuring uninterrupted and even operation pumping station;

- Ensuring the reliability and integrity of the DHW system (hot water supply).

The role of the accumulator in the work of the pumping station

In the absence of a central water supply, owners of private houses, to supply water to the house, drill a well or erect a well equipped with a deep pump. With its help water is fed into the room, fills the water accumulator, it is necessarily filtered and branched to the places of consumption.

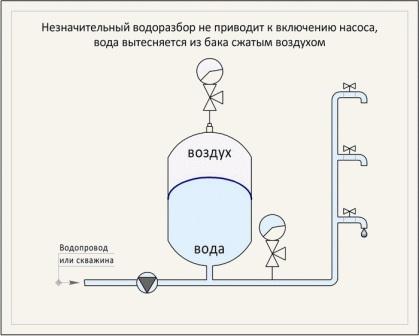

Let us consider in more detail the operation of this scheme. With the rapid opening and closing of the water faucet, for example, you rinse your hands, a small amount of water is consumed and it is at this moment that the accumulator starts working. The pump was not turned on, the pressure was created by the pressure of the water battery membrane, since it contains a certain amount of water. Numerous sources state that emergency water supply is the main function that the accumulator for water supply systems performs. This information is incorrect. The unit capacity of 100 liters can accommodate no more than 35 liters of water.

The primary purpose of installing this unit is to save an expensive deep pump from overheating and malfunctioning starts. In the absence of this device, the pump, in the case described above, will start and immediately turn off without gaining maximum power. At this point, a hydraulic shock is created in the circuit, that is, a sharp pressure drop. The unit with a combination of these factors will quickly fail. Conclusion - the accumulator in water supply systems serves for uniform distribution of pressure in the circuit and long-term operation of pumping equipment.

Accumulator in the DHW system

There are three main types of hot water supply using a hydraulic tank:

- Installation of an indirect heating boiler;

- Installation of a double-circuit solid fuel boiler, with the function of supplying hot water;

- Scheme with a single-circuit boiler in conjunction with an indirect heating boiler.

In either variant, the water accumulator plays a role expansion tank, as the water increases in volume when heated, and this device compensates for the amount of water. In spite of the fact that both the boiler and the solid fuel boiler have a safety valve in the form of a check valve, with continuous operation, the through valve quickly fails, this entails damaging the boiler or leaking in the water circuit.

Note! The appearance and shape of the hydraulic accumulator tank for cold water supply are very similar to the accumulator for hot water. Their difference in the temperature resistance of the built-in membrane. When buying carefully read specifications device. Not experienced managers often offer the sample you do not need.

Accumulator Classification

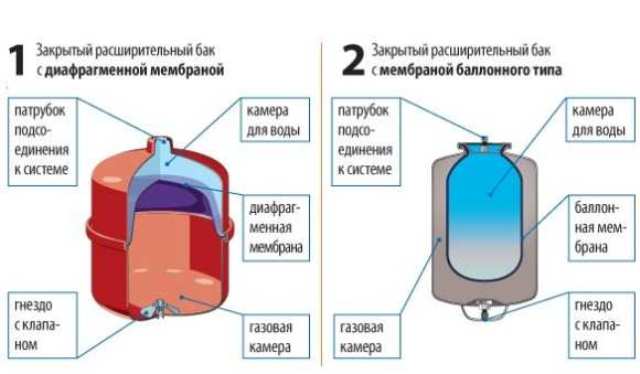

The accumulator, as a concept, has many applications. It is used in all types of mechanical engineering, in heavy industry. In this article we will consider the tankers used only in domestic water supply. The most popular in this industry are pneumatic type units. They are divided into two types:

- Membrane disposable. Samples in which the membrane is enclosed in a retaining ring in the center of the tank;

- Water batteries with the ability to replace the membrane.

Each of these species has a different form of execution:

- Vertical;

- Horizontal.

Related article:

In the article we will consider how to solve the problem of insufficient pressure of water, which complicates the adoption of water procedures and the operation of auxiliary household appliances, how to choose the right pump, and what to look for.

Principles of operation, arrangement and preferential sides of the tank in water supply systems

What does the tank consist of?

- The body of the device is usually made of ordinary steel. There are samples of stainless steel. They are more durable, but are less common, due to the high cost;

- Rubber membrane. It is made of elastic material, which ensures long-term operation;

- The working pressure is controlled via a slide valve, using a conventional machine pump and a manometer;

- In the case the filter is installed coarse cleaning, in addition to a separate filter mounted in the circuit.

Also in the group of battery equipment is a pressure switch - this is an automatic sensor for starting and stopping the pump unit.

The advantages of pneumatic equipment are:

- Simplicity of design;

- Ability to replace the membrane;

- Easy connection to the pump station;

- Compact size;

- Light weight;

- Affordable price

Briefly describe the operation of the water battery

When water is consumed at any point of water intake, the pressure switch turns on the pump set. Water, getting into the tank, stretches the membrane. Further, when the valve is closed, the pump continues to operate. The membrane, stretching, increases the working pressure of the unit. When the pressure rises to the maximum value, the pressure switch disconnects the pumping unit.

In the standard scheme, where water enters, for example, from a well or not deep well the capacity of a conventional pump is enough to supply water even to the second or third floor. In this case, the system does not cause any difficulties and the hydro-instrument is installed indoors.

What will be required to assemble the entire accumulator group

In the group of the tank, in addition to the pressure switch, a manometer is included.

For convenience of connection of all components, a five-branch choke is used.

When assembling the entire group it is recommended to use cranes of "American". For unobstructed removal and replacement of any device in the event of a breakdown. That is, on the tap to the battery, on the pipe leading to the pump and on the wiring to consumers. If you assemble a group without "American women", with a minor breakdown or replacement of the membrane, for example, you have to drain the water from the entire system.

When landlords do not have the opportunity to connect to the central water supply, they need to equip it themselves.

It is important to correctly calculate the system, and also to select all necessary equipment. And one of the important components of the water supply system is a hydraulic accumulator for water supply systems. Naturally, you need to understand what it is and why it is needed.

Accumulator

What is a hydro accumulator

The hydraulic accumulator for water supply is a metal tank with an air chamber located inside it. This tank is connected to the water supply system. In fact, this is a reserve capacity designed to accumulate a small water reserve, and to equalize the pressure in the system

Accumulator unit

Principle of operation of the accumulator:

- in one compartment water is pumped;

- into another chamber, compressed air is injected;

- due to this, the water in the system is under a constant pressure of 2-2.5 atmosphere;

- when the volume of liquid in the tank falls below the set value - the relay turns on the pump, and after the set, switches off.

In fact, there is nothing difficult in his work.

Hydraulic tank functions

Each element in the water supply system has its own specific functions. Naturally, they also have a tank. So, what is the need for a hydroaccumulator in the domestic water supply system:

- reserve water in the system is, of course, not the main task of these devices, since they rarely have a large volume. But, all the same, the tank can save a small amount of water, which can be very useful when the electricity is cut off;

- equalize the pressure in the water supply system - thanks to its design, the hydraulic tanks can provide a constant pressure in the water supply. Moreover, even when several points are simultaneously turned on, for example, a tap in the kitchen and in the bathroom;

- protects water from water hammer - submersible pump, delivers water with high pressure, and the hydraulic accumulator, leads it to the optimum for water equipment, so all equipment is protected from hydraulic shocks.

In addition, the hydraulic tanks protect the submersible pump from overheating. The fact is that the pump operates on this principle:

- as soon as the pressure in the water supply system falls, it turns on;

- and when it is typed - turns off.

But there is a big minus - for example, an ordinary tap, consumes no more than 0.5 m3 / h. And the pump gives out 4 m3 / hour, so when the tap is open, the pump will have to turn on and off after every second. And this is fraught with the fact that it will quickly fail.

It is quite another matter when there is a storage tank for water in the system - the pump will be switched on only in order to replenish its volume, and not every time the crane is opened. Accordingly, such inclusions will be much less.

Types of devices

These accumulation tanks differ on several grounds. One of them is capacity. The most popular devices are 50 and 100 liters in volume. Also, the tank is different in configuration. There are two types:

- vertical;

- horizontal.

They do not have any special differences, because the scheme of the device and the principle of operation of the accumulator in the water supply system will be the same in both cases. Only the structural arrangement of the elements of the tank changes.

Therefore, to choose between a horizontal and vertical device, you need to proceed from the convenience of its installation and further operation. For example, for small rooms often take vertical aggregates - they are conveniently located in the corners.

The main difference is that vertical devices, with a volume of more than 50 liters, have special valve to discharge excess air from the tank. Horizontal, usually they are not equipped, so when installing the tank, you need to make an additional tap. It will allow you to completely lower the contents of the tank.

However, the main difference internal device. There are such types:

- membrane;

- balloon.

Membrane and cylinder accumulators

The cylinder tank consists of a metal tank and a rubber or rubber pear located inside it. In this pear water is collected from the system, and air is pumped into the space between the pear and the inner walls of the tank under pressure.

Pros of this design:

- water only contacts the surface of the pear - there is no contact with the metal;

- if necessary, the pear can be changed on its own - thus, the balloon structure is easily repaired.

The hydraulic accumulator is membrane, it is arranged differently, there is no additional capacity in it. Instead, the tank consists of two separate chambers, separated by a special rubber partition. In one part water is supplied from the water supply system, and compressed air is pumped into the other.

Disadvantages of this design:

- water comes in contact with the metal walls of the accumulator - and this leads to unavoidable corrosion;

- replace the membrane is more difficult than the pear.

Thus, the balloon type of devices is the best choice for use. They are more practical and easier to repair. Moreover, when the water is in the pear, it does not come into contact with the main tank, which means that the probability of corrosion is minimized.

Selection of the tank

Determining which accumulator is best purchased, usually pay attention to two criteria:

- its location;

- volume of the tank.

The design does not play a principal role, therefore it is selected proceeding from the dimensions of the room and the convenience of operation. After all, the tank must be positioned in such a way as to be free to approach.

When choosing a container, it must be taken into account that only half of the tank is filled with water. In general, you can adhere to such rules:

- when there are no more than three points of consumption in the house, a battery with any capacity will work;

- if the consumers are under 5, at a pump power within 3 m3 / h, then a tank with a capacity of 50 l;

- if more consumers, then you need to take a battery for 100 liters.

Naturally, there are other factors that affect the choice of the device. You can read about them in the article "".

Mounting the hydraulic accumulator

This process needs to be approached as seriously as possible, because how the hydraulic accumulator works determines the quality of the entire water pipe. At installation, it is necessary to adhere to such rules:

- the tank must be securely fixed to the floor;

- connection to the water pipe is done through flexible tubes;

- before switching on, it is necessary to check the pressure in the tank - it should be in the range from 1 to 1.5 atmospheres;

- it is important to understand that the lower the air pressure, the more water can enter the tank, and the less often the pump will turn on. However, the total water pressure will also be lower;

- now you need to use the instruction and adjust the pressure switch - it is responsible for turning the pump on and off;

- after that, you can type water in the device and check its operation.

Wiring diagram of the hydraulic tank

At the first start-up, it is necessary to collect water under low pressure. The fact is that the walls of the rubber pear could stick together and the great pressure of water can damage them.

Basic Faults

Although the device of the accumulator does not differ in complexity, sometimes it can involve malfunctions.

The most common failures are:

- the pump frequently turns on - this can be caused by several reasons. For example, the tightness of the tank is broken, the membrane is damaged, or the pressure switch is incorrectly set. Also, such a problem can be caused by the lack of air in the battery;

- the pressure in the water supply system has dropped - there is no air in the accumulator, or the pump is to blame;

- the tank is leaking - this indicates damage to the membrane or rubber bottle.

More details about the problems and how to repair them can be found in the article "". In general, to repair and adjust the hydraulic tank, it is better to use the help of specialists. Moreover, it is relevant when the device is new and still under warranty.