Pump stations for the home: how to ensure a stable head of water. Pumps with external ejector. The impact of technical noise on health

Hello,

Pumping stations designed for household use are usually used to lift water from underground sources. They are installed in apartment buildingsconnected to the backbone network. In this case, this equipment can increase the pressure of water, which falls substantially in the evening.

You can find a high-quality pumping station on the site geonasos.ru/nasosnye-stancii/ns-grundfos/ , where the presented time-tested products, characterized by ease of installation and use.

Design features

Pumping stations operated in the home are aggregates consisting of storage tank (accumulator) and centrifugal pump. The tank allows you to create a reserve of water so that the pump does not start every time the faucet is opened. Due to its availability, the service life of the equipment is significantly increased. The main advantage of using a hydraulic accumulator is that it prevents the occurrence of pressure drops in the pipeline.

As a rule, a pumping station for apartment building installed in the basement. It has a large capacity, because it consists of several pumps connected in parallel. The system also includes a large storage tank, internally separated by a membrane. In one half of the tank there is water, in the other - compressed air, which provides optimal fluid pressure.

Easy to set up and operate

Any proprietary pumping station for an apartment building is extremely easy to maintain and connect. The body of the equipment is made of materials that are not afraid of corrosion: brass, stainless steel or reinforced polypropylene. The accumulator is usually made of steel. Manufacturers equip it with a manometer, as well as with sensors for upper and lower pressure. To the power grid, the station is connected by means of a cable, the cross-section of which must correspond to the power of the pump. For safety reasons, the equipment must be grounded.

Household pumping stations are configured for two modes of operation: water withdrawal from the well and increase of liquid pressure coming through the central water supply. When installing the equipment, you just need to configure the mode correctly. You can do it yourself, but it's better to involve qualified specialists with experience in solving the problem.

To solve the problem of water supply, many owners of private houses use pumping stations.

These devices are now available for sale in ready-made form or can be purchased separately. And on forces to each person to execute installation of the pump station in the house. The main thing is to know what elements this machine consists of, how it works, how to start the pump station and where it is better to install it.

What do you need to know in order to choose a pumping station?

In order for the selected station to cope well with its functions, the choice must be made according to its needs. In this regard, you can highlight the following criteria, which should be primarily taken into account by the owner:

- Technical characteristics of the pumping station;

- Features of the well.

Considering specifications, first of all it is necessary to allocate productivity of the unit. The best option is an apparatus capable of providing water pressure from a well that can meet the needs directly in the house, as well as in the surrounding areas.

Based on practical experience, we can say that for a normal residence in the country or an apartment building, designed for 4 people, it is recommended to choose a device medium or low power. In the construction of such units there is a 20-liter hydro accumulator. Such a station is capable of supplying water from the well in the amount of 2-4 cu. meters per hour and a head of 45-55 meters. Installation with such characteristics can fully meet the needs of a family of four.

In the process of consideration of various installations, a number of other important indicators:

- productivity;

- the size;

- water level when the pump is off;

- water level when the pump is running;

- a kind of filter;

- width of pipe.

In any station there is such an obligatory element as accumulator tank. It is worth saying that the installation with a storage tank is an obsolete construction due to the presence of a large number of shortcomings. First of all, the tank has a sufficiently large capacity. In addition, to control the water level and its head, a float is used to ensure that the sensor operates in the event of a drop in the water level. In this case, the sensor gives a signal to switch on the swap.

In any station there is such an obligatory element as accumulator tank. It is worth saying that the installation with a storage tank is an obsolete construction due to the presence of a large number of shortcomings. First of all, the tank has a sufficiently large capacity. In addition, to control the water level and its head, a float is used to ensure that the sensor operates in the event of a drop in the water level. In this case, the sensor gives a signal to switch on the swap.

The main disadvantages we can name the following:

- The water is fed into the system in a natural way, because of which the head pressure at the outlet is insufficient;

- Due to the large size of the unit, it is not always possible to find a suitable place for its installation;

- The process of installing the system is accompanied by certain difficulties;

- It is important for the storage tank to allocate space at the station itself, and this is fraught with additional problems;

- In the event of a water level sensor failure, it overflows the edge of the tank.

The most reliable and practical are the units equipped with a hydraulic accumulator. Their popularity is determined by small dimensions and the absence of complications in the installation. In the design of the system there is a relay that performs the duties of regulating the pressure limit of the ambient air.

Due to the creation of the pressure of water, it is compressed in a hydraulic accumulator. At the moment when the pressure reaches the required limit, the pump automatically turns off, as a result of which water enters the tap from the tank. If the level is lowered, the pump is switched on again and continues to operate until the required water level is again provided.

For the pump, you can choose a place directly in the house or caisson. The latter option is a building in the ground. This design provides it with protection from moisture, groundwater and low temperatures. It must necessarily be built under the freezing line of the soil. However, this option has several disadvantages. First of all, such a building requires a competent arrangement. In addition, in areas where severe climatic conditions are observed, it is difficult to perform caisson insulation, as a result, being exposed to low temperatures, there is a risk of pump failure.

For the pump, you can choose a place directly in the house or caisson. The latter option is a building in the ground. This design provides it with protection from moisture, groundwater and low temperatures. It must necessarily be built under the freezing line of the soil. However, this option has several disadvantages. First of all, such a building requires a competent arrangement. In addition, in areas where severe climatic conditions are observed, it is difficult to perform caisson insulation, as a result, being exposed to low temperatures, there is a risk of pump failure.

The most practical solution is to install a pump in the house. It is best to install it in the basement. However, here it is necessary to mention one important point: one should be prepared for the fact that groundwater can create threat of basement flooding. Therefore, during the spring flood, when the room is filled with water, the station is recommended to be installed on a hill, so that water does not reach it. Choose for the station you need a place that it is removed from the walls, which will prevent unnecessary vibration during operation. When placing the pump in the basement, you must constantly monitor the temperature regime throughout the year to thereby protect the installation from the effects of negative temperatures.

Rules for choosing a place

To find a suitable location for the pumping station, the installation in which must pass in accordance with the technology, you need proceed from the following criteria:

- The distance to which the station will be removed from the well;

- Temperature-humidity regime in the place chosen for installation;

- Availability of free space, so you can easily repair and service the unit;

- Work on the insulation of the room to limit the spread of noise in the direction of living quarters.

To properly install the pump station with your own hands, you need adhere to the following order performance of this work:

An obligatory condition provided by the technology of mounting the pump is its special placement. The legs must be fixed to the base using anchors. As a result, it will be possible to provide increased stability of the structure. To minimize vibration, the pump must be installed on a rubber mat.

Autonomous water supply in a private house is arranged in the absence of centralized communications, or when it is impossible to connect to them. Pleasure is not cheap. However, if you connect the pumping station yourself, you can save money on mounting the equipment a solid amount. For this, it is necessary to select the unit with the optimum characteristics and the installation scheme, and then follow the installation technique.

The pump equipment station performs two functions at once: it supplies water to the water supply system at home and automatically maintains the preset pressure in it. This allows you to build a branched network of water pipes and connect to it household appliances - a shower, a boiler, a dishwasher and a washing machine.

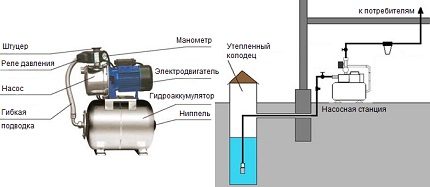

The typical design of the station includes:

- Pump;

- Accumulator;

- Automation unit;

- The inlet screen filter is necessary to prevent particles from getting into the system and possible contaminants;

- Pipelines, hoses and necessary fittings.

To prevent the outflow of fluid from the system when the pump stops or the pressure decreases, a non-return valve is installed in the water intake area. A source of water is also needed. For this, a well or well is arranged. It is possible to use a reservoir (pool) with imported water and open reservoirs, if the characteristics of the unit allow pumping contaminated liquid.

Image Gallery

![]()

If the fence is carried out from a natural pond (pond, river, lake), water is used only for household needs and irrigation. If water is extracted from a well or well, analysis is required. According to the results of the study, water belongs to the drinking or economic category.

Pumping station is a compact and at the same time functional equipment that provides stable water supply to a private house

Types of pumps used

Ready-made pumping stations are installations with a surface pump that draws liquid from a well by means of vacuum. The ejector can be included in the design of the pump itself, or be remote - in this case it is located in the well. However, when assembling and installing the pump station, a submersible or downhole pump can also be used by hand, especially if it is already available.

Most often, they use ready-made pumping stations in which all the main elements are already assembled and tuned. At installation it is enough to connect a feeding and pressure pipeline

Pumps with internal ejector

Installations with an integrated ejector are capable of lifting water only from a shallow depth - up to 8 m. But they provide a powerful head, exceeding 40 m. They are not afraid of air ingress, so filling the system with water before starting work is not necessary - the station first picks up air, and then starts to supply water.

They are characterized by good performance and reliability. The disadvantage is the high noise level, which is why they are installed in the house only if there are auxiliary soundproofed rooms.

When installing a station with a surface ejector pump, it is necessary to take into account not only the depth of the water mirror, but also the horizontal section of the supply pipeline

Pumps with external ejector

Stations with remote ejector equip, if necessary, the intake of liquid from a great depth - 20 ... 50 m. In this case, the ejector is lowered into the well (well), as part of the sampling unit. To it lead two hoses from installation - pressure and vacuum (soaking up).

In the first, the liquid is fed into the ejector and forms a vacuum in the suction chamber, the second - lifts up the water from the well. Such units are characterized by low noise level. They do not consume much electricity, but their efficiency reaches only 30-40%.

Submersible or downhole pump

Stations with a submersible (well) pump practically do not produce noise, water can be taken from any depth and with sufficient removal of the well or well from the building. Not afraid of small leaks in the pipeline and air sucking.

However, submersible pumps are quite expensive. They demand clean water - the installation of a powerful filtration system solves the problem, but in this case it will be necessary to clean it regularly. Repair and maintenance are hindered by the need to lift the unit to the surface.

Not suitable for sources with impurities in the water more than 2 g per 1 m3 - the filters quickly clogged and the pump ceases to function

Accumulator - the device and the principle of operation

The starting current of the pump exceeds the working current by 3-5 times and has a destructive effect on its design. Therefore, the life of the pump depends on the number of inclusions. To reduce them in the system, a diaphragm accumulator must be installed.

In the water supply system of the house, it performs the following functions:

- It protects the pump from wear and increases its service life - thanks to the liquid in the membrane compartment, the number of switchings on the unit is significantly reduced;

- Maintains in the aqueduct constant pressure and protects from pressure drops;

- Eliminates the occurrence of water hammers in the system that are destructive to connected devices and pipeline fittings;

- Provides some water supply in case of power failure.

The device is a sealed vessel, the inner volume of which is divided by an elastic membrane into two containers. One of them is filled with air, and the other is designed for pumping water.

Pressurized air in the hydraulic tank squeezes out water and maintains pressure for a while even in the absence of electricity

The tank works as follows. Water is pumped into the elastic container until the upper pressure threshold is reached. The pump is then switched off. The head in the system is supported by the air layer in the accumulator, the compressed air plays the role of a damper. When the volume of water decreases (consumed by consumers) and the pressure reaches the lower limit, the pump turns on again and fills the tank with water.

Choose the accumulator on the basis of calculations, which take into account the number of residents, the number of water consumption points, the maximum permissible number of inclusions of the pump and its power, the required pressure in the system. Insufficient operating volume of the tank will lead to a permanent pump activation and wear. Capacity with a reserve threatens stagnation of water and a decrease in its quality, a harmful effect on the inner surface of the membrane.

Image Gallery

Control block of pumping station

The standard set of control devices for the pumping station consists of a choke, a pressure switch and a pressure gauge and installed on a pressure pipe. The pressure gauge serves to monitor the current pressure in the system, and the relay is the most important control element of the pumping station. It controls the supply of water to the pressure vessel according to the specified parameters and ensures the automatic operation of the pump, including turning it off.

The main operating elements of the relay are the springs of the minimum and maximum pressure that are triggered when the pressure in the network reaches the set value. At low pressure, the spring is released and the contact closing the pump motor closes. The excess pressure compresses it, and when the maximum threshold is reached, the contact opens. The pump stops and the water supply stops.

The automation unit is a more complex device with more advanced features. In addition to commutation electrical circuits in response to an increase and decrease in pressure, the automation unit protects the system from dry running.

Image Gallery

When selecting a control device for stations pumping water from shallow workings, it is better to give preference to the option with protection against dry running. It will protect the pump from overheating and turn it off if, for any reason (dirt got, the liquid level in the source fell below the intake unit), water ceased to flow into the system.

Sensitive elements of the pressure switch are two springs. The larger is adjusted to the minimum pressure, small - to the difference between the minimum and maximum

Principle of operation of water supply installation

The work of the pumping station occurs in cycles, each of which can be divided into two stages:

- The pump turns on and lifts the water from the source. It fills the system and the tank until the pressure exceeds the upper threshold. After this, the pressure switch disconnects the pump motor and the water supply stops. The pump station goes into sleep mode.

- When consumers are switched on (opening of cranes, use of water-consuming equipment), water comes from the accumulator's capacity. The flow of liquid from the tank is carried out until the pressure drops to the lower threshold. This causes a new pump start and water rise.

The number of cycles per hour must not exceed the maximum number of inclusions allowed for the pump in use.

Benefits of using a pumping station

Device autonomous water supply in his home provides independence and comfort. The pump station offers the following advantages:

- Increases the efficiency of the water supply system.

- Increases the safety of equipment and pipelines.

- Provides some (depending on the capacity of the tank) the water supply and its supply, even when the power supply is cut off.

- Maintains constant pressure and stability of water pressure.

- Increases the durability of appliances and household appliances connected to the water supply system.

- Automatic mode of operation (timely activation and deactivation of the pump unit) reduces equipment wear and energy costs.

- Ability to choose the installation location of the unit.

- Has compact overall dimensions and light weight.

- Easy to mount.

AT countryside, cottage and holiday villages communication networks water supply is often sinful with low pressure and unstable pressure. In this case, the pumping station can be connected to an existing main water pipeline - this will solve the problems with pressure drop and lack of pressure in the water supply.

Where to place the pumping station

When planning the placement of the unit, it should be borne in mind that:

- The location of the pumping station in the immediate vicinity of the water source ensures stable suction and smooth operation of the equipment.

- The installation site must be dry and warm, well ventilated.

- The equipment should not touch the walls.

- It is necessary to provide free access for repair work and preventive examinations.

The installation of a pumping station with a surface pumping unit, especially with an internal ejector, should be carefully thought out, since such a system has a high noise level. There are several mounting options.

In home. The most optimal place for the correct functioning of the station is a heated room. Ideally, if the house has a soundproof boiler room. The last option is the installation of equipment in common rooms (corridor, bathroom, hallway, pantry). But in this case it is located far from the bedrooms and provides sound insulation - for example, make a casing or cabinet.

The best variant of the pumping station device can be considered its installation in a separate room in the house with a borehole drilled directly under the building

In the basement. Quite often a pumping station is equipped in the basement or basement. However, care must be taken to create optimal conditions for the installation of the installation - the room must be sound, heat and waterproof. You can arrange a special box in the subfield, with access to the equipment through the hatch.

A warm and well-equipped cellar with good hydro and sound insulation and ventilation is ideal for installing pumping equipment

In the well. Pumping station is installed on a specially constructed platform in the well. The depth of the installation surface must be such that all equipment is below the freezing level. The well itself is insulated from above. The disadvantage of this scheme is the difficulty in accessing the equipment.

With sufficient width and depth of the well, as well as pump power, the station can be installed in a well on a special bracket or platform

In the caisson. Around the well, a sufficient space is set up for subsequent maintenance of the width, buried below the freezing level of the soil. At the surface of the earth, the caisson is closed and insulated, leaving only a small hatch for maintenance. The device of the pit will allow using a pump with an integrated ejector in the case when the depth of the water mirror from the surface of the earth is 9-11 meters.

In a separate (special) structure or an annex. In this case, there will be no noise in the house. However, just to insulate such a room is not enough, it will also require heating. This leads to additional costs for electricity and heating systems.

When installing a station with a submersible pump, there are no problems with noise insulation. All elements of the system, except for the pump itself, are installed in any heated building of the house.

Pumping installation technology

Having determined the place of installation of the pump equipment station, they begin to install it.

Preparatory work

Prepare a solid base for the pumping unit - concrete brick or wood, the surface under the installation level. You can use a special metal bracket.

As the pump vibrates quite vigorously during operation, there are backlashes in the connections of the pipeline, leaks appear. To reduce vibration, as well as its destructive effect, rubber pads or a rug are placed under the pump supports, and the installation itself is securely fixed - screw the legs with anchor bolts.

The main condition for the uninterrupted operation of the pump equipment station is the unobstructed flow of liquid from the source. The main problem that must be solved with year-round water supply is the protection from freezing. Therefore, a trench is digging under the pipeline - from the foundation to the well or caisson (pit) of the well.

The trench must be straight in plan, preferably without turns and bends, so as not to reduce pressure. To exclude the effect of negative temperatures on the pipes, they are buried below the freezing level of the soil in the area. When forming a trench, it is necessary to take into account a slope of 0.03 towards the intake for draining liquid from the pipeline during the conservation period.

With closely located groundwater, the water pipe is laid above the critical level, but in this case it is insulated and the heating cable is additionally used. Also, serious thermal insulation and heating will be required if the water pipe is lifted above ground level.

If the pipeline passes through the air, or is not deep, then heating and serious insulation

Assembling the water intake unit

The water intake assembly depends on the type of pump used.

- With a standard connection scheme - a station with a surface pump and an integrated ejector - this is connected to polypropylene pipe through a coupling check valve with a strainer.

- Installation with an external ejector. At the suction of the ejector, a check valve with a screen filter is wound, two pipes are connected from above.

- When using a submersible (downhole) pump, the filter coarse cleaning is included in its construction. Therefore, a non-return valve and a pipe are connected to the unit. The pump has a decent weight, so it is suspended on a solid cable.

Lower the unit to the required depth, considering that the minimum distance from it to the bottom of the source is 1 m when using surface pumps and 0.5 m for submersible (well). It should also be borne in mind that the level of the water mirror changes during the year - in the summer it goes down. If the depth of suction is on the edge, then during this period it is possible to lose water supply completely.

Depending on the diameter of the well, the design of the ejector assembly is different. Circulation of water occurs either by two pipes, or by the principle of a pipe in a pipe

Installation of surface elements of the station

In principle, the schemes for installing a pumping station will differ depending on which pumping unit is being used. The basic rule: any additional device is installed through ball valves with an American and check valves. This will remove the devices for replacement or repair without the need to drain all the water from the system.

It should also be possible to drain the water from the system - for this, a branch is formed in the pipeline by installing a tee to which a drain cock is connected. It is desirable to install a coarse filter on the supply line. On the pressure (in the line leading to the consumers) - the filter fine cleaning.

Installation of a surface station-type station is not difficult, since the main elements of the system are already connected to each other. It is a hydraulic accumulator with an electric pump mounted on it and a control unit. In addition to the main fittings, a system is installed in such a system to fill it with water before the first start-up. Similarly to the drainage device, a tee with a connected ball valve and a funnel is inserted into the pipeline.

When assembling the pipeline, all connections should be sealed with flax, FUM tape or sealing paste to prevent air from entering the system

In other cases, the system elements are mounted independently. When installing a surface station, the pipeline (or two pipelines, if an external ejector is used) from the well is connected to the pump.

Next, the hydraulic accumulator and the control unit are installed. For a station with downhole pump it will be all the basic surface elements in the circuit. The most convenient way to do this is to use a 5-outlet choke, which is mounted in a pressure pipe in a convenient location. A pressure switch and a manometer are screwed into it.

A hydraulic accumulator is connected to the side inlet of the union. For the convenience of maintenance, it is connected through a ball valve with an American and arrange a discharge.

Conduct consumers' connection to the pumping station. Most often the first element is the distributing collector of cold water.

Such a system is less sensitive to air entrapment, but all joints must be tight

Launching the station of pumping equipment

The electric motor of the pump has a high power, so it is better to provide the pump equipment station with its own power line, arrange a grounding and install a voltage regulator.

Check the pressure of the air bag of the accumulator. It must be 10% less than the pump start pressure. However, this setting is done in the operating mode. Preliminarily, it is necessary to achieve the following values: for a tank with a capacity of 20-30 liters - 1.4 ... 1.7 bar, a capacity of 50-100 liters - 1.7 ... 1.9 bar.

Before the first start of the installation with a surface pump, the working part of the system is filled with water. To do this, unscrew the plug from the filler hole located at the top of the pump. If there is a filling hopper in the pipeline, it is better to use it. Fill the liquid until completely filled until it begins to pour out. Then the hole (valve) is tightly closed.

When the system is filled with liquid through the filling hole of the pump, it is convenient to use a conventional funnel

Startup sequence:

- The pump is connected to the mains.

- The valve of the fill funnel of the pipeline with the surface pump is slightly opened to remove any remaining air that has entered the system.

- Turn on the unit - within 2-3 minutes from the outlet of the pressure pipe (or open faucet water) should flow water.

- If the liquid does not flow, pump equipment turn off, add water to the system and turn it on again.

After a successful start-up, the equipment should be "run-in" and, if necessary, adjust the settings of the hydraulic unit and the pressure switch.

Operation of the pump equipment station

After the pumping station is put into operation, it is periodically serviced. It is necessary to clean the coarse filter in time. Without this, the plant's capacity is gradually reduced, the water is coming jerks, and a completely clogged filter will lead to a "dry" mode of operation and shutdown of the system. The frequency of purification depends on the content of impurities in the pumped water.

Once a month, or after prolonged downtime, winter conservation or repair work, check the pressure in the air compartment of the accumulator. If necessary, the air is pumped up. When using the station only in the summer, it is necessary to drain all water before the frost.

Video compilation on the topic

The basic rules for connecting a pumping station of surface type:

Maintenance and adjustment of surface-type pumping station:

How to make a pump station based on a submersible pump:

Proper installation of the pumping station provides a private house water supply with parameters that are not inferior to a city apartment - constant pressure and sufficient pressure. For the system to work as efficiently as possible, before choosing and installing the equipment, you should consult a specialist and carry out an estimated calculation.

Many private households face water supply problems. Many houses are built or built in places where there is no centralized water supply. These are holiday villages, cottage towns, small villages and villages.

If the house is in such a place, then the solution of the water supply problem lies entirely with the owner. One of the solutions to this problem will be the installation of a pumping station. It will ensure a stable water pressure in the water pipe, and its supply to all points of water intake.

More recently, the main way to feed water into the house was to use a submerged pump. It was installed in a well or well. He joined the work at a time when a tap was opening in the house. Such a system was notable for its instability in work. Stability was affected by voltage swings, a decrease in the water level in the well or well.

This was the reason for the ubiquitous transition to pumping stations. In the pumping station, a special tank is added to the pump, which plays the role of a hydraulic accumulator. It stores a reserve water reserve, which makes it possible to use water at a time when water can not be taken from a well.

In pump wells, a surface pump is used, which makes it possible to use small diameter boreholes. For a full-fledged supply of an average house, it is sufficient to use a pipe or an inch-diameter hose.

Components

At first glance, the pump station is not a complicated mechanism. It consists of an electric motor, a surface pump, a hydraulic accumulator, an automatic control system.

At first glance, the pump station is not a complicated mechanism. It consists of an electric motor, a surface pump, a hydraulic accumulator, an automatic control system.

Hydraulic accumulators are divided into two types: the first is the tank, and the second battery. In their well-coordinated work, they ensure uninterrupted supply of water to the inhabitants of the house. The pump pumps water from the source, and feeds it to the water supply system of the house.

The hydraulic accumulator helps maintain a constant water pressure in the system, and the automatic control system allows all this to be done automatically.

Using a tank as a bunker, this is an obsolete design. The principle of its operation is based on pumping water from a source, into a tank located on the upper floors, or an attic. Water pumped into the tank, gravity flows to the daughters of water distribution. In the tank there is a float control system for the pump motor.

When the water level drops, a float signal is triggered, including the pump motor. The pump turns on, filling the water level in the tank before turning on the signal of the upper float.

Such a system has good energy efficiency. It does not turn on the engine every time the crane is opened. Suitable for wells with low water flow. The biggest drawback is the possibility of a flood. The tank is located on the top floor or attic, in the event of a leak, it can flood the entire house.

Relay, controls the air pressure in the accumulator. When a certain value is reached, it turns off the pump. Then it turns on when the pressure reaches a certain level. When the water flow is small, the pump is turned on a smaller number of times.

Advantages and disadvantages

The main advantage of the pumping station - in the absence of the need to dig a well, or artesian well. Surface Pump, is capable of pumping a small diameter hose from a depth of up to 8 meters. If the depth of groundwater is below 8 meters, then you can use a pumping station with an ejector. It works on the principle of discharged air. And can get water from 30 meters depth.

The drawbacks include the fact that there are limitations in depth, stations with ejectors are of great value, they are very noisy when working. They should be installed in a separate room. The temperature in the room where the equipment is installed must be above zero degrees. It is necessary to constantly check the operation of the automation.

Criterias of choice

Having decided to install a pumping station in his house, many do not know how to make the right choice. Such mechanisms have a large number of characteristics, and they should be considered with one complex.

Power

When a well has a smaller capacity than a pumping station, then there may be interruptions in the supply of water.

This parameter affects how much water you can get at the same time for all consumers in the house. How far a well can be removed from the house? At what depth is the water-bearing layer located?

Also, when choosing the power, it is necessary to take into account the productivity of the well.

The pump will pump out water faster than it will flow. All these data are indicated in the well data sheet, and the pumping station. The average private house will be able to service a pumping station with a capacity of 1000-1500 watts. It will provide a capacity of 4000-6000 liters / hour.

Storage tank

The storage tank is designed to receive a water reserve, in the event of a power outage, or a drop in the water level in the well. Here, the choice is influenced by the needs of the family in the water for a certain period of time. The tank should, by volume, maximally satisfy your every need. As the material used plastic, steel, cast iron.

In many there are prejudices against plastic. This is the cheapest material, it is considered the most unreliable. In case of a crack, there is a chance to fill the whole house with water.

Steel tanks are reliable, but can be corroded. Cast iron the most reliable, but heavy. Under good circumstances, they will last a long time. The hydroaccumulator comes complete with a pump, usually has a small volume, not exceeding 50 liters.

Protection of the installation

Pumping station - this is a mechanical product, which requires some types of protection. First of all, this is overheating. With prolonged operation, the motor may overheat, which can disable it.

In the second turn, this is protection against dry running. If there is no flow of water, the pump must be switched off. Otherwise, there will be an excessive air pressure in the system, which can lead to a pump failure, and a violation of the sealing of some components. Such protection can greatly affect the cost of the pumping station, but it's worth it.

Control system

Cabinet with automatic control of the pumping station

Two control systems are used - manual and automatic. The difference is that the automatic system pumps the water into the tank when it is empty. In manual mode, this will have to be done independently. Manual, optimally put in the place where they come very rarely. In a normal residential building it is better to put automation.

If there is often a drop in electricity in your area, or the water level falls in the well, you will need to take appropriate measures. For electricity, buy an electric generator, and for water a storage tank.

Installation and operation

Connection diagram of the pump station:

It all starts with a choice pumping unit with the necessary parameters. Further, the necessary pipe structures are installed. When everything is connected, a test run is carried out and, if necessary, control and adjustment of the automation. Further, everything is put into operation.

All these jobs should be trusted by specialists. During operation, it is important to remember the periodic inspection and operation. In particular, on the quality of water, the salt deposits on the pump parts, and the sensors used, can be affected, which can lead to malfunctions.

Not all problems with the water supply caused by a malfunctioning pumping station. Some of the problems can be hidden in the pipes, or in the well. As for the problems of the station itself, it is better to contact specialists. If there is no such possibility, then it should be remembered that the main problems are related to mechanics and sensors.

Price & Manufacturers

There are many different proposals on the market for pumping stations. Economy options start at an average of 6,000 rubles. It is worth noting that for carrying water into the house, this amount should be added to the cost of pipes, hoses, and other necessary parts. The cost, in the first place, affects the capacity of the installation, and the size of the capacity of the accumulator. A significant role in the price can be provided by the manufacturer's brand.

In the Russian market, they prefer manufacturers from Italy and Germany. They are distinguished by their high quality and service. Recently, foreign companies are quietly pushing back domestic producers.

At the final choice, find out about the after-sales service. Pump stations sometimes break down. Therefore, it is better to have the products of the company that will help to fix the malfunction.

Before choosing a pumping station, several necessary conditions must be considered in which the installation will operate. Based on these criteria, equipment is selected that can provide reliable water supply.

The main characteristics of the pumping station are as follows:

- Electric motor power;

- Productivity of the station;

- Maximum storage capacity;

- The height at which the station can raise water.

However, do not forget that the manufacturer indicates the maximum capacity of the pumping station, which in no way will coincide with the required parameters in reality. For example, in the passport for equipment there is a figure - 3 cubic meters of water per hour. This characteristic regulates the maximum volume of pumped water, but when these values are reached, there will already be no head pressure. Or such an indicator as a maximum head of 40 meters, implies that the source of water is at the level of the pumping station, and water consumption is not provided. In such conditions, the pump will give the indicated head, but it will be absolutely useless.

To obtain more accurate data on the dependence of the flow rate on the pressure at the head of the pumping station, use the table and graphic data that are found in the equipment certificate. Usually the manufacturer does not hide the true characteristics of the pump, leaving the choice to the consumer.

TOP 5 pumping stations for cottages

As a rule, the water consumption at the dacha is determined not only by its consumption in the kitchen or the shower, but also by watering the plants. In some cases, the intake of water comes from sources with the possible ingress of a certain amount of impurities in the form of sand or other suspensions, so it is best to preset the installation of an additional filter at the entrance.

1. NeoClima GP 600/20 N (Russia-China) - from 5,600 rubles

Users of this equipment note the convenience and ease of operation of the station, designed to organize water consumption for suburban area, where a small head of water is enough. Quite copes with its "duties", but on the condition that the expenditure is for no more than two consumers. It is usually used to supply water from wells, which is actual when it is impossible to equip the well. The pressure part and the working chamber are made of stainless steel, therefore, there is no risk of corrosion and it is possible to use pumped water for any needs, including recharge washing machine and for cooking. It is necessary to install a non-return valve to prevent a drop in pressure in the network with a reverse current. The pump's power is only 600 Watts. Such a low consumption makes it possible to use the station in summer cottages, where there are norms for the use of electricity or in dachas with low permissible capacity. Of course, there are some minor shortcomings that can be attributed to constructive features models - short network wire and a thin hose between the pump and the tank.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Used to supply water from wells and wells. | |

| Depth of dive | 8 meters | Connection to the suction pipe is made by an incompressible spiral hose or plastic pipe. |

| Maximum head of water | 35 meters | Confident water intake (operating point) is in the range of 20-25 meters. |

| 3 m 3 / h | Under real conditions, the operating point is in the range of 1-1.5 m 3 / h. | |

| Volume of the tank | 20 liters | The pump is switched on quite often, but the safety margin ensures the work of the station for a long time without breakage. |

2. Quattro Elementi Automatico 801 - from 6000 rubles

Household pumping station manufactured in China, is characterized by low cost and long service life. The kit does not include a suction filter and a non-return valve, but they are commercially available from the manufacturer, which indicates an attentive attitude towards the buyers on the part of the company. This station can be considered a "workhorse" for summer residents. Even with intensive operation in limit modes, the equipment can withstand easily, overcomes a five-year period. All buyers who operate the pump station agree in a single opinion that after a little refinement (installation of a filter, a valve and an additional accumulator) is the ideal apparatus.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Surface pump station | Used to supply water from wells and wells, there is an additional function to increase the pressure |

| Depth of dive | 8 meters | If the water mirror is higher, then it is possible to increase the distance from the station to the consumer |

| Maximum head of water | 40 meters | Confident water intake (operating point) is in the range of 25-30 meters. |

| Maximum Performance | 3.2 m 3 / hr | Under real conditions, the operating point is in the range of 1.5-2 m 3 / h. |

| Volume of the tank | 20 liters | In case of frequent power outages, it is recommended to install an additional accumulator of a larger volume. |

3. AL-KO HWF 1000 - from 6200 rubles

The advantages of this pumping station include the availability of the equipment coarse filter, purifying water from sand, leaves and other contaminants, as well as a non-return valve to prevent loss of pressure. There is a system of "dry running", which excludes the operation of the pump in the absence of liquid. Multidirectional opinions exist on the hydroaccumulator, which is made of polypropylene. On the one hand, users by default consider plastic fragile, especially at low temperatures. On the other hand, plastic parts made from modern materials provide all the necessary equipment characteristics.

4. GARDENA 3000/4 - from 9990 rubles

Good materials, easy and noiseless station. But there is a weak point - a plastic tee inside the pump. If the station is not operated in winter and stored at negative temperatures, the water in the tee will tear it apart. The fact is that it is difficult to drain water from it, which spoils the impressions from the operation of the station. The disadvantages include a weak thread on the inlet and outlet hoses connecting hoses. In general, with correct use reliable station. The buyer will have to carefully study the attached documentation, since there is no protection against dry running at the station, and dismantling of the connections for cleaning fine filter can take a long time.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Surface pump station | There is a cleaning filter for supplying clean water to the consumer |

| Depth of dive | 8 meters | It is designed for pumping water from wells and wells. When the filter is clogged, a significant head loss can occur. |

| Maximum head of water | 40 meters | Confident water intake (operating point) is in the range of 20-25 meters, it is enough to supply water to two consumers simultaneously. |

| Maximum Performance | 2.8 m 3 / hour | Under real conditions, the operating point is in the range of 1.5-2 m 3 / h. The water temperature should not be higher than + 35 ° C. |

| Volume of the tank | 24 liters | The material is metal. 24 liters is enough to supply water with a short-term power outage. |

5. DZHILEKS Jambo 60/35 H-24 - from 8500 rubles

Reviews of the owners of this pumping station are reduced to a mark of 4 points. Not only reliability of equipment operation is noted, but also its relatively low price with good characteristics. The main disadvantage of the station can be considered a complicated commissioning of the unit. With improper adjustment, which is described in the passport very sparingly, the station is unstable, and the initial start-up requires you to determine the necessary parameters yourself. The equipment is very sensitive to water hammering, if the cock is closed sharply, it may damage the plastic parts of the pump.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Surface pump station | Currently, in the construction markets, there are all required spare parts and consumables for pumping stations of this type. |

| Depth of dive | 9 meters | This refers to the distance to the water mirror, if you load the hose deeper, you can lose performance accordingly. |

| Maximum head of water | 30 meters | Confident water intake (operating point) is in the range of 18-20 meters. |

| Maximum Performance | 3.3 m 3 / hr | Under real conditions, the operating point is in the range 2-2.5 m 3 / h. The water temperature should not be above +50 ° C. Only pure water pumps, additional filters are required. |

| Volume of the tank | 24 liters | The material is metal. Use the equipment only at positive temperatures. It is not allowed to start operation even at zero values of ambient air. |

Top 5 pumping stations for country houses

If you want to use the pumping station in a country house permanent residence, then you should choose a completely different equipment, which will invariably affect the price offered by the manufacturer.

6. DZHILEKS Vodomet PROF 55/90 The house - from 25000 rubles

Relatively inexpensive product of the Chinese manufacturer. Easy to connect and install. The complete set of the station has everything you need. The filter elements are placed in a flask and replaced without problems. The pump is already equipped check valve and protected from "dry running" automation. The control is simple, the program can save the factory settings, which are sufficient for the initial period of acquaintance with the station. The shortage of equipment is not a very large resource station (3-4 years of intensive operation), apparently, this is due to the use in some nodes of plastic parts.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Surface pump station | The kit includes a bulb with filters. Size of particles to be filtered from 1.5 mm |

| Depth of dive | 30 meters | The station is designed to supply water from wells and according to statistics the depth of the water is less than the specified characteristic. |

| Maximum head of water | 90 meters | Confident water intake (operating point) is in the range of 70-75 meters. |

| Maximum Performance | 3.3 m 3 / hr | Under real conditions, the operating point is in the range 2-2.5 m 3 / h. The water temperature should not be higher than + 35 ° C. There is protection against overheating of the pump |

| Volume of the tank | 24 liters | The material is metal. In addition to the accumulator, the kit includes a control panel and stop valves, necessary for connection. |

7. VMtec Altera Auto 5/5 - from 27,000 rubles

An invariably high German quality, adapted for Russian realities. Those users who operate this device for several years, note its high performance with absolute reliability of all components of the station. If the "dry run" protection is installed in more simple models, the automation that regulates the operation of the pump depending on the water analysis, the privilege of the more expensive models. Virtually all the control of the station is automatic and you can only enjoy the benefits that the equipment provides.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Surface pump station | With the basic characteristics control unit |

| Depth of dive | 30 meters | It pumps only clean water, installed filters allow to "cut off" particles from 2 mm at a sand concentration in water of 50 g / m 3 |

| Maximum head of water | 58 meters | Confident water intake (operating point) is in the range of 42 meters. |

| Maximum Performance | 8 m 3 / hour | Under real conditions, the operating point is in the range 4.5-5 m 3 / h. Minimum water temperature +15 0 С |

| Volume of the tank | - | Works without a hydraulic tank, is an alternative to old systems with an expansion tank |

8. Wilo HMP 603 1 - from 29,000 rubles

The high cost of equipment, according to users, justifies the reliability of the pumping station. In fact, it turns out that its normal work will be provided only by buying protection from "dry running". If the constant pressure at the pump inlet is not ensured, then the automatic system is not able to "understand" the absence of water. In the rest, the station is an example of equipment for a country house. It is reliably protected against pressure surges, and membrane tank compensates for hydraulic shocks, possible when pumping water and several parsing.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Surface pump station | All parts that come into contact with water are made of food grade stainless steel. |

| Depth of dive | 30 meters | It pumps only clean water, it is required to install an inlet filter |

| Maximum head of water | 32 meters | Confident water intake (operating point) is in the range of 25 meters. |

| Maximum Performance | 8.1 m 3 / h | Under real conditions, the operating point is in the range of 6 m 3 / h. Maximum water temperature +40 0 С |

| Volume of the tank | 50 liters | Serves as a good compensation system for possible water hammering. |

9. VMtec Altera Auto 9/4 - from 29800 rubles

A little untwisted brand of a German company in Russia has characteristics that mostly refer to more expensive models. And since our users are suspicious of low prices for premium equipment, this gives food for various rumors. For example, some potential buyers refer to some news that the company buys cheap equipment in China and simply changes the marking. It's no secret that many companies place their production in China, thereby cheapening the final products. And this move was also used in this pumping station. For quite acceptable money, you get high quality, reliable operation of the equipment in the parameters set by the manufacturer and the possibility of automatic pump control.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Surface pump station | Engine Franklin Electric, control unit Presscontrol Time |

| Depth of dive | 30 meters | The station is designed for pumping clean water. To maintain characteristics, the installation of a coarse cleaning filter is required to prevent large particles from entering the equipment, and a fine filter for obtaining high water quality. |

| Maximum head of water | 48 meters | Confident water intake (operating point) is in the range of 38 meters. |

| Maximum Performance | 15 m 3 / h | Under real conditions, the operating point is in the range of 11-13 m 3 / h. There is no requirement for water temperature. |

| Volume of the tank | - | The tank is missing. A station is used to create networks in place of systems with an expansion tank. |

10. Grundfos CMB-SP SET 3-47 (PM 1-22) - starting at 29500 rubles

Self-priming pumping station with an automatic control system that ensures the start-up of the pump during the water cut-off and makes the engine stop when the water flow stops. The automation program provides protection against "dry running" and cyclicity. Owners of the equipment note the extreme simplicity of control of the station, it starts to work in the required modes immediately after installation in the place of operation. The main "complaints" of users refer to the high cost of stations, which, however, is compensated by the absolute reliability of the equipment and its maintainability.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Surface pump station | Low noise level, which is only 22 dB |

| Depth of dive | 8 meters | There is automatic water level control |

| Maximum head of water | 34.9 meters | Confident water intake (operating point) is in the range of 28-30 meters. |

| Maximum Performance | 3 m 3 / h | Under real conditions, the operating point is in the range of 1.5-2 m 3 / h. Permissible water temperature up to + 60 0 С |

| Volume of the tank | - | The tank is missing. |

TOP 5 pumping stations for private houses

To ensure continuous water supply in country houses with a large water consumption and maintaining the quality of supply, pumping stations with improved characteristics are used. Of course, their price range reaches several tens of rubles, but the benefits fully compensate for the money spent.

11. ESPA Aquabox 350 TP 15 4 M - starting at 80,400 rubles

Forget about the uneven supply of water - this is how users comment on entering the market of a new model of a pumping station. Constant pressure, which is provided by the design of the pump and automation, creates really high comfort. In addition to supplying water to the country house, this model is able to provide watering of plants in preset modes, while control over the parameters provides intelligent automation. If there is an emergency shutdown of the pump caused by a lack of water in the borehole, a limiting drop in the liquid or air entering the system, the station will restart after a set period of time. In addition, you can set the time parameters for switching on the station in your absence and rest assured that it will fully fulfill the task assigned to it.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Surface pump station | Vertical installation |

| Depth of dive | 8 meters | |

| Maximum head of water | 42 meters | |

| Maximum Performance | 3,6 m 3 / hour | Under real conditions, the operating point is in the range of 2.5 m 3 / h. Permissible water temperature from +10 0 С to + 35 0 С |

| Volume of the tank | - | The tank is missing. Float automatic water level mechanism |

12. ESPA ACUAPLUS 5M N - from 60,000 rubles

Pumping station, designed to provide several consumers of water at the same time in a country house. Some of the potential users of pumping stations recommend using a simpler solution - to equip a similar installation of cheap equipment. For example, use submersible pump "Baby" and install the German automatics. But, according to the owners, this solution does not hold up to the original performance on a number of mandatory items. First, the ESPA ACUAPLUS 5M N provides uniform pressure regardless of the number of users. Secondly, it reacts sensitively to all changes in the environment. And, third, has several degrees of protection.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Submersible pumping station | A pump is plunged into the well or well, and all automation is in the room. Quiet in operation |

| Depth of dive | 20 meters | Fully controlled by automatics |

| Maximum head of water | 40 meters | Confident water intake (operating point) is in the range of 30-35 meters. |

| Maximum Performance | 3 m 3 / h | |

| Volume of the tank | - | Tank missing |

13. Grundfos CMB 3-46 - from 58000 rubles

Pump station with professional parameters and in excellent performance. It is difficult to find faults in this equipment, which comes with a fully automated water supply system. Stainless steel, used in all parts that come into contact with water and automatic modes that ensure a stable water pressure even with simultaneous analysis of several consumers

| Name of parameters | Values | Note |

|---|---|---|

| A type | Surface pump station | |

| Depth of dive | 15 meters | Fully controlled by automatics |

| Maximum head of water | 35 meters | Confident water intake (operating point) is in the range of 22-25 meters. |

| Maximum Performance | 3 m 3 / h | Under real conditions, the operating point is in the range 1.8-2 m 3 / h. Permissible water temperature up to + 35 0 С |

| Volume of the tank | 60 liters | Stainless steel |

14. Grundfos CMBE 1-75 - from 90,000 rubles

Despite the high cost of equipment, the station has some operational features that directly affect the reliability of some parts. So when you connect to the system reverse osmosis there is a very frequent activation of the pump, approximately 27-30 times per hour and the winding of the electric motor overheats. Therefore, it is better not to use such water purification in a country house. Still, due to frequent starts, the nut on the shaft can spontaneously turn off, which leads to displacement of the impellers. The first sign of such a malfunction will be a decrease in the nominal pressure in the network.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Surface pump station | Supplied with preset values, which allows the equipment to be used immediately after installation in the field of operation. |

| Depth of dive | 15 meters | Fully controlled by automatics |

| Maximum head of water | 44 meters | Confident water intake (operating point) is in the range of 35-38 meters. |

| Maximum Performance | 2 m 3 / h | Under real conditions, the operating point is in the range 1.2-1.5 m 3 / h. Permissible water temperature up to + 35 0 С |

| Volume of the tank | - | Without hydraulic tank |

15. Espa Tecnoplus 25 4M - starting at 75,000 rubles

Pump station with extremely conflicting reviews. Those users who respond about the characteristics of equipment negatively, believe that the reason for all the bad assembly and the attempt of manufacturers to make the model as cheap as possible. So the complaints are caused by the electric motor of the pump with weak protection against water ingress and low-grade bearings. In addition, it is noted that the pump stops in a three-stage mode with a decrease in the frequency of rotation of the pump. Disconnection is accompanied by "sound accompaniment", which causes irritation at each closing of the tap. In the rest the technique is completely reliable, it provides constant pressure in the network, but it is very difficult to drain water from the station during winter storage, a heated room is required.

| Name of parameters | Values | Note |

|---|---|---|

| A type | Surface pump station | Supplied with preset values, which allows the equipment to be used immediately after installation in the field of operation. |

| Depth of dive | 15 meters | Fully controlled by automatics |

| Maximum head of water | 40 meters | Confident water intake (operating point) is in the range of 32-35 meters. |

| Maximum Performance | 7,2 m 3 / h | Under real conditions, the operating point is in the range of 6-6.5 m 3 / h. Permissible water temperature up to + 35 0 С |

| Volume of the tank | - | Without a hydraulic tank, only a small compensator for protection against water hammers |

Editor's Choice

The choice of equipment depends entirely on the system of water consumption and the conditions of its operation. For small houses and watering, inexpensive models are used that provide an initial level of water consumption. To create reliable water supply systems for year-round living in a country house, it is better to purchase automatic stations capable of maintaining a constant head of water in accordance with the established parameters in an automatic mode.

If we take into account the initial price category of equipment, then we recommend the station Quattro Elementi Automatico 801. Good characteristics and reliability of all components, allows you to create a stable water supply system in the suburban area. For a country house or cottage, if you need to use several water points at once, it is best to purchase a pumping station VMtec Altera Auto 9/4 from the middle price segment. This equipment, which has the characteristics of premium stations, is offered at a very modest price.

Well, and from the presented pumping stations of premium class, we recommend ESPA ACUAPLUS 5M N - stable water pressure in the network and almost complete automatic control of the pump parameters.