Inflow of ventilation into the house wall valves. Designation and installation of a non-return valve for ventilation

The ventilation system is designed to supply the room with clean air and remove the spent, saturated with smells and dust.

But what if the ventilation shaft on the contrary becomes a source of extraneous "flavors", or when there is a strong wind, frosty air blows out of the street into it? We'll figure out why the reverse thrust can occur, how to deal with it and how to make a check valve for ventilation with your own hands.

A non-return valve is needed to prevent ventilation from overturning the draft. Why this can happen:

- There is insufficient supply air (no air supply ventilation, or it is clogged, does not function).

- Invalid location exhaust pipe on the roof (in the zone of the wind shadow).

- If the apartment has several exhaust openings, and in one of them for some reason the thrust is amplified (for example, the time of switching off one fan coincided with the intensive work of another).

- A similar situation happens in houses with stove heating. AT chimney, during combustion, the thrust is increased, and in the channel with natural ventilation the reverse current is obtained.

- The role of a powerful hood can also play a ladder in a two-story cottage.

- In multi-storey houses, intensive forced extraction in one apartment, can disrupt the flow of flows in other apartments.

- Reverse traction can lead not only to the penetration of foreign odors, but also to poisoning by gas, entering the house of frost, in those periods when ventilation is turned off.

Check the presence of the correct thrust by using a candle flame, or a sheet of paper. You need to open the window, and bring the sheet to the vent. If the flow is "correct", the paper does not fall, but remains hanging on the wall.

Design

The design of any check valve for natural ventilation - the shutter, which opens the flow only one way. When changing the direction of travel, the shutter on the contrary closes and stops the reverse stroke.

For ventilation systems, disc-shaped structures are used. They can be of several models.

Types of check valves for ventilation

The axis of rotation of the shutter of the check valve is:- Horizontal.

- Vertical.

Material of execution:

- Metal.

- Plastic.

Metal today are less likely to be acquired. Although they are more hardy, but can be covered with droplets of condensate, rust, and clap when working.

Plastic models are lighter, noiseless.

Based on where the ventilating valve is applied, it happens:

- Heated.

- Without heating.

Simple valves are installed indoors. If the device is in contact with a warm, then with cold air, it is equipped with heating to avoid the formation of ice.

The structure of the valve can be:

- Single-leaf.

- Membrane.

- Bivalve ("Butterfly").

- "Jalousie".

Ventilation Valve Membranes

Single leaf Is a flap fixed to the horizontal axis, which opens and closes the passage, rotating by a stream of air.

Membrane the option is very sensitive. Here we use a thin flexible damper, which deviates, even from a small, natural draft.

"Butterfly" has an axis in the center of the circular hole and two shutters that return to their original position, thanks to the springs. It is used in powerful forced installations.

"Jalousie" - a set of blades on several axes, arranged horizontally. Other model names are the flap check valve for ventilation or gravity.

By the shape of the section of the ventilation duct or hole, you can choose:

- Rectangular.

- Round devices.

Different can be the size of the product.

During the closing of the leaflets, cotton occurs. Improved models are supplemented with a sealant, which extinguishes noise from the device.

For systems with forced draft, it is important to select the device with the appropriate capacity. And where it applies natural circulation air, many valves will not work, because a weak thrust may not be enough to open it!

Ventilation is very important not only for an apartment, but also for a private home. devices and the principle of installation.

Ventilation is very important not only for an apartment, but also for a private home. devices and the principle of installation.

Instructions for the manufacture of air recuperator with their own hands, see.

Qualitative ventilation in the garage extends the life of the car. In this topic are the schemes of the device of the ventilation system in the garage with their own hands.

Non-return valve for manual ventilation

Often, to take up the reproduction of this element of ventilation, the owner forces not only the desire to save, but also that it is difficult to find an industrial model with which natural traction can cope.

The self-made variant is very sensitive, even to the slightest movement of air. And everything is done very simply.

To manufacture a membrane valve for ventilation, you will need:

- Flexible plastic or film.

- Lovsan Scotch tape.

- Stationery knife and ruler.

Manufacture of the ventilation valve in steps

Requirements for film:

- The size should be slightly larger than the vent hole.

- The thickness depends on the size of the cells - the more, the thicker. And on the strength of the flow - it must suffice to bend the curtain.

- The film with a rough surface will not do.

- Do not use crumpled material for the membrane.

Step Instruction:

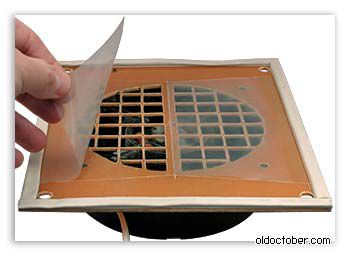

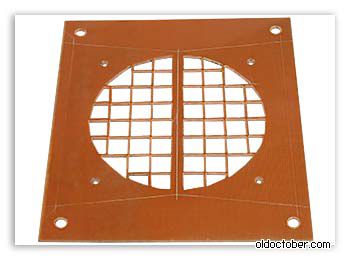

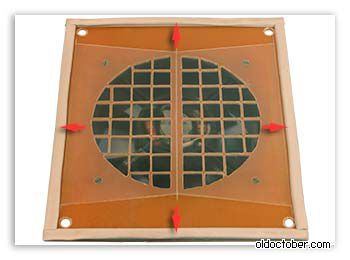

- On the grid is done marking - the location of the future halves of the membrane.

- With the help of an adhesive tape, a piece of a film of large dimensions (not yet cut) is attached to the grate. Scotch tape should not be tightened when attaching.

- Knife cut out the contours of the leaflets (right and left, like shutters on the windows).

- The design must be leakproof. This means that in closed type The membrane should completely cover the apertures of the grate, do not have defects and irregularities. And the fastening points of the leaflets are glued very carefully.

For greater comfort, you can provide a homemade valve with a filter made of mesh or nylon. It will prevent insects from entering the house.

Cost of finished structures

The most affordable are galvanized butterfly valves for round ducts.The price for a valve for ventilation of this type (depending on the size) is from 200 to 900 rubles. The cross section can be from 10 cm or more.

Rectangular ducts are less common, and therefore a valve to pick up to it is more difficult and expensive. For example, the frame of petal blinds measuring 30 by 15 cm can cost about 2 - 3,5 thousand rubles.

Conclusion

It can be said that the check valve is not the most necessary part in the ventilation system. Often it works so well that it does not remind of itself.

But if there are failures, wind blowing, penetration of foreign smells into the house, etc. - the installation of the valve for ventilation will solve all the problems at once. Instead of buying expensive models, or clapping butterflies, it's worth trying to make the simplest valve yourself.

When designing a ventilation system, it is important to choose the material of the air ducts. can be plastic and metal, and someone uses and sewer pipes. We'll figure out which option is better.

When designing a ventilation system, it is important to choose the material of the air ducts. can be plastic and metal, and someone uses and sewer pipes. We'll figure out which option is better.

Video on the topic

In multi-storey houses, there is sometimes a problem of the appearance of unpleasant odors from the channels of natural ventilation. They appear when the ventilation system is malfunctioning, when exhaust air It is not thrown out, but comes back from one room to another. One way to solve the problem is a non-return valve for natural ventilation installed on the outlet from the ventilation duct. Such a situation occurs not only in houses and apartments, but in all buildings with a gravitational ventilation system.

Ventilation systems for all types of buildings are divided into two groups:

- with natural motivation (gravitational);

- with artificial motivation (mechanical).

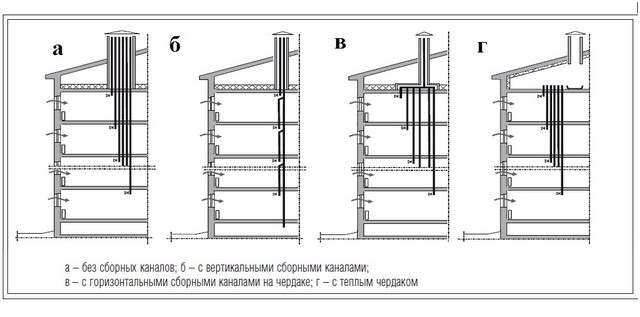

They differ in the mechanism of bringing the air into motion. Natural systems consist of constructive elements:

- external windows, doors and other openings in enclosing structures;

- ventilation shafts (channels).

For the organization of a mechanical system, fans, a duct system and other components are used. It is more convenient to configure and allows you to monitor the parameters of air exchange, but significantly more expensive than natural. In most apartments and houses, gravity ventilation is used. It is arranged for vertical ventilation shafts and tie-ins on each floor of the branch to the premises. What types of check valves for natural ventilation exist and how are they used?

Principle of operation and types of check valves

Non-return valve for mechanical systems and natural ventilation refers to a group of air dampers and regulators designed to change and block the movement of air in the supply and exhaust systems. If the device only accepts the positions "open" or "closed", then it is considered two-position. In multiposition products during operation, the air damper assumes several positions (with different throughput). Check valves are used for air movement in only one direction and are two-position devices.

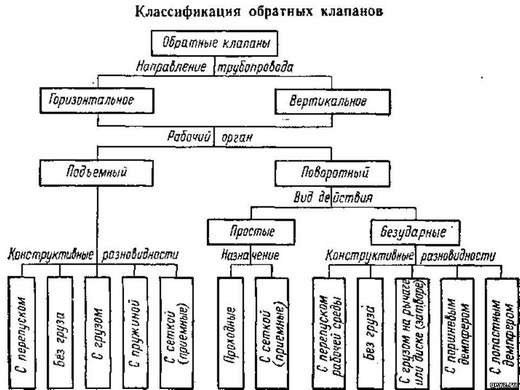

Structurally the check valves are manufactured in the following types:

- petal;

- with a gravitational lattice.

Models with a gravity grating are installed on the end of the branch of the ventilation system. For example, at the outlet from the exhaust network to the street. They are lattices in which the blinds freely rise from the air pressure and fall under the action of gravity. Such check valves are only used when the air moves horizontally.

In the natural ventilation system, this product is not applicable, because of the features of the operation. If you install it at the outlet of the ventilation shaft, the pressure of the flow naturally rising through the air channel rarely reaches a value that can raise the blinds on the grate.

Valves of the second type consist of a body and petals completely overlapping the cross section of the channel when the air flow does not flow to the project side. They are conventionally divided into two groups - one-petalled and two-petalled ("butterfly" type).

In the first type of check valves, the lobe, which blocks the movement of air, is freely fixed to the axis in the cross section of the article. The position of the lobe depends on the angle of the valve and the air pressure. In the deactivated system, they can be in both open and closed positions, and when the air moves in the desired direction, the flow cross-section increases in proportion to the pressure.

Products with two petals are equipped with a spring lock or counterweight. In the absence of air movement, the device completely overlaps. They are used in vertical and horizontal position, unlike single-leaf ones, which can not be installed from top to bottom in the closed position when the system is stopped. All types of valves are produced for both rectangular and circular ducts. The maximum speed of movement in the section of the non-return valve is 12 m / s.

Due to technical and structural features, the two-leaf valves with a spring are not applicable in natural ventilation systems, since the pressure in them is not sufficient for opening. Single-lobe devices are effective as check valves in the natural ventilation system. Let's consider the scheme of application.

Use in natural ventilation

A non-return valve for natural ventilation is used in the system using a single channel to connect a mechanical device (for example, a kitchen hood) and a grill. If there is a reverse thrust from the street in the natural system, the valves are not effective because of the low air speed. The same applies to the problem of unpleasant odors from neighboring kitchens.

Mechanical fans and kitchen hoods can not always be connected to the general ventilation ducts. In some series of high-rise buildings, several branches are connected to one shaft, and when the fan is plunged into it, the head increases so that the air leaves the channel not only to the outside, but also to adjacent rooms. But if the air duct leads from the apartment outside without branches, then such constructions are allowed.

Even if only one ventilation pipe leaves the kitchen, bathroom, or other room, then it can be used for both natural and mechanical extraction by installing a non-return valve. For example, the photo shows a scheme for a kitchen hood.

When using shut-off and control devices, do not forget that they are clogged with dirt, dust and fat deposits. For normal operation, check valves need regular cleaning and inspection.

For the organization of fresh air inflow into the building (both residential and non-residential), nowadays, the inlet ventilation valves (ventilators) are often chosen.

On the location of the most common are wall models - mounted in the outer wall.

Description of construction

Air duct. A pipe through which air flows from the street into the room. The vast majority of models have a plastic duct.

External ventilation grille. Prevents the ingress of rain ducts into the duct. Made of plastic or metal.

Internal housing - head (plastic, usually shipped in disassembled form). Contains a filter, directs airflow into the room. It is made of plastic.

Inside the duct may be insulation or noise insulation. It is necessary to ensure that the wall around the pipe does not freeze, and also to reduce street noise.

As a heater is usually a polyphobe. The parts described above can be purchased separately, and make a self-made airing machine with your own hands, which will cost a little less than buying a finished product.

If the ventilation wall valve is adjustable, the regulator is located in the inner casing (head). Some models (Aereco EHT) are additionally equipped with a hygro-regulation system. It reacts to the humidity inside the room, and opens the valve when a certain value is exceeded.

More complex air-handling units (for example - a line of models Eco Freshness) can additionally be equipped with the following elements:

Fan.

Recuperator (air heater).

Humidity and / or air temperature sensors - to automate the operation of the device.

Remote electronic control panel (by means of which the fan and / or heater are switched on and off).

Purpose of the product

The task of the supply ventilation valve is to provide a person (as well as animals and plants) with enough air for breathing, and to prevent the appearance of mold in the room.

If there is no constant inflow of fresh air into the room (and for one person it takes about 30 cubic meters per hour) - the body does not receive the proper amount of oxygen. In addition, the stuffiness leads to condensation of moisture on the window slopes, frame and window sill, which in time can lead to the development of mold.

Wall air valve it is capable of supplying a sufficient amount of fresh air: under normal conditions (if the pressure difference is 10 Pa) through most models, about 25-30 m³ / h is supplied. Just as much as required health standards for 1 person. If the pressure drop is greater, the amount of incoming air will also increase.

Principle of operation and testing of ventilation ducts

Air from the street comes through the ventilator, because the pressure in the room is lower than on the street. Such conditions (pressure drop) are created due to work exhaust ventilation In the room: a hood or a simple ventilation duct.

An important point to consider: if the exhaust ventilation works poorly, then the ventilator will also give less air (since the difference is less than the norm, or it will not be at all). Therefore, before planning the installation of a fresh air vent valve, make sure that the exhaust ventilation function normally.

To check the operation of the ventilation duct, it is necessary:

Open the window (or window, or balcony, the main thing - that was the influx of fresh air).

Bring a lighted match or a lighter to the grille.

When the exhaust ventilation is working normally, the flame must be "tightened" into the channel. If this does not happen, or if the flame on the contrary deviates from the grille - then there is no traction, and the ventilation in the apartment is broken.

Instead of an open fire, you can check the operation of the ventilation duct and a regular piece of paper (best of all - toilet, because it is thin and light). A small cut must be applied to the ventilation grille. Ideally - the paper should attract: in this case, the exhaust ventilation works perfectly.

The methods of verification mentioned above may prove useless in the summer, in hot weather. The air in the heat is heavier than in the cool weather, and therefore the pressure in the ventilation duct drops. Therefore, even normally operating ventilation may not attract fire (or paper).

On the pros and cons of the application

The use of a wall ventilator is a useful solution for several reasons:

- inside the room the product is invisible (with any method of installation it is easy to cover with curtains), and if it is noticeable, it does not spoil the interior and does not strike the eye;

there is no need to often open and close the window (which means that the hardware does not wear out, calculated on an average of 10,000 movements);

the valve receives less noise than through the open window (thanks to the filter and insulation in the duct);

it is possible to adjust the amount of incoming air (there are no regulators basically only on the cheapest models);

installation near the battery or at the top of the wall avoids sudden temperature fluctuations in winter;

relative cheapness (1 set of the valve and its installation by specialists in the amount will cost about 3-5 thousand rubles).

With regard to the last point: when installing the vent valve near the battery - the air will heat up from it. In the second case (if the valve is mounted at the top of the wall) air will flow into the room from above, and mix with the room (warmer).

More expensive models of inflows can be equipped with recuperators (heaters) and fans. Fans can be either exhaust or supply air. Such installations are more effective, however, they cost at least 8-10 times more than conventional ventilating valves (for example, the quotations for Eko-Freshness, having a fan and heating, start from 15,000 rubles).

There are also disadvantages:

the need to make a hole in the wall (if the inflow after some time will want to be removed - there will be a through hole in the street);

the errors made during installation can lead to the fact that the wall (the section between the hole and the slope) will freeze, or some part of the duct will freeze in winter;

in too cold regions (where the temperature falls for a long time below -10 °) in the winter the inflow can not be used, since the room will be very cold;

models without a fan can average about 30 m ³ / h air (which is normal for 1 person in the room).

Types and Distinctions

All wall inflows differ in several parameters:

How does the ventilator look outside (from the street) and from the inside (from the room)

With manual adjustment of the amount of passing air or without adjustment.

By the presence or absence of an automatic adjustment system.

By the presence or absence of noise insulation duct.

If possible or impossible to install additional accessories.

If possible or impossible to completely shut off the valve.

By the diameter of the duct.

By the amount of air passing through.

Otherwise, the differences are only in the device internal (located in the apartment) housing and the appearance of the elements.

As a special case - there are differences in the form and material of the duct. For all models it is a plastic pipe. Only the SVK V-75 M differs - this airway valve is made of expanded polystyrene and has a rectangular shape. It is located immediately under the windowsill.

The most successful are the following sites:

Under the windowsill, next to the battery.

At a level of 2/3 of the height of the window opening (for an ordinary apartment - at an altitude of about 1.8-2 meters from the floor).

In the first case, the incoming air immediately heats up from the battery. In the second - enters top premises where it mixes with warm air. Both options are good in that this arrangement allows you to hide the wall valve behind the curtains.

The only requirement that should be considered in the second case: from the placement supply air valve in the wall to the window slope should be a minimum of 30 centimeters. Otherwise this site in winter can freeze.

On the device and installation of the valve using the example of KPV 125 (video)

Stages of installation

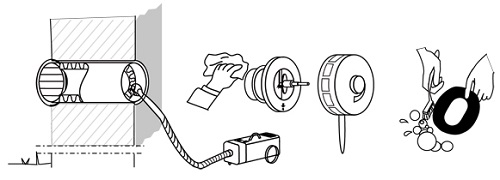

To install the supply valve in the wall (we will consider the installation process for valves with a circular duct, for the installation of the SVK V-75 M - it is possible to read separately):

Marking tools.

Installation of diamond drilling.

Hacksaw (for cutting the air duct as needed).

Glue (if the outer grille is adhered to the duct) or a screwdriver (if bolted).

Unnecessary rags or polyethylene film - to lay the floor at work.

Means of protection of eyes and respiratory organs (from flying dust during drilling).

Installation is performed in the following sequence:

The installation location of the ventilator is chosen, taking into account the rules mentioned above.

A through hole is drilled in the wall. It should have a slight slope (3-4 degrees) in the direction of the street - to prevent moisture from accumulating in the duct.

Drill holes for self-tapping screws (for attaching the inner case).

The air duct is used: the pipe is inserted into the hole and the required length is noted.

Surplus pipe - cut off the mark.

Inside the duct, a noise isolator is installed (if it is included, if not, it is recommended to buy a pipe warmer-the "shell" of the desired diameter) and use it as noise insulation.

The pipe is inserted into the hole.

On the outside, the ventilation grill is fixed to the pipe (for glue or bolts). The blinds should be directed down towards the street, and be horizontal.

The inner case is attached to the wall by self-tapping screws.

The inner case is assembled.

Steps of installation on the example of the valve Domvent (video)

Care and maintenance

For cleaning, it is necessary to dismantle the inner case and remove the filter and noise isolator. This is recommended in the warm season, so that the cold wind does not blow out in the room (or the hole must be sealed).

If the filter and insulator are made of synthetics (and in most models just so) - they can be washed in soapy water. After that, they must dry up without fail.

Pay attention to the purity of the duct inside: you can look inside, while the filter and the heater dry. If there is dust or small debris inside a large layer, you can vacuum it. As an option - you can remove the outer grate and blow the pipe with a vacuum cleaner.

If the temperature in the room in winter starts to drop noticeably (usually at temperatures below -10º and / or in strong winds) - it is recommended to reduce airflow through the valve (if possible adjustment).

That the apartment did not get unpleasant smells from the outside (from the street, from the neighbors), natural system ventilation is often not enough. Non-return valve for ventilation is a device that controls the air flow by increasing or decreasing the opening for its passage. Thanks to the valve, tobacco smoke, smells from neighbors' kitchens, cold air from the street, as well as insects, dust, etc. do not penetrate into the apartment through the hood. The device can be installed in both natural and exhaust system ventilation.

- Section: round or rectangular.

- Diameter: from 100 mm to 1250 mm (round).

- Length: from 7 mm to 72 mm.

- Height Width: from 100 mm to 1000 mm (rectangular).

Kinds

- By material: metal and plastic.

- According to the form: round, square, rectangular.

- By the way of installation: vertical and horizontal.

- By type of construction: butterfly, lattice, petal, supply.

- By the way of management: active, passive.

Let's consider each species in more detail.

Check valves for different types of ventilation

The type of ventilation can be natural and exhaust (forced). For a natural ventilation of the room, only a ventilation shaft is needed. For forced - an exhaust or ventilating device. Both ventilation systems do not guarantee no reverse traction. The guarantee of its absence is a reverse vent valve.

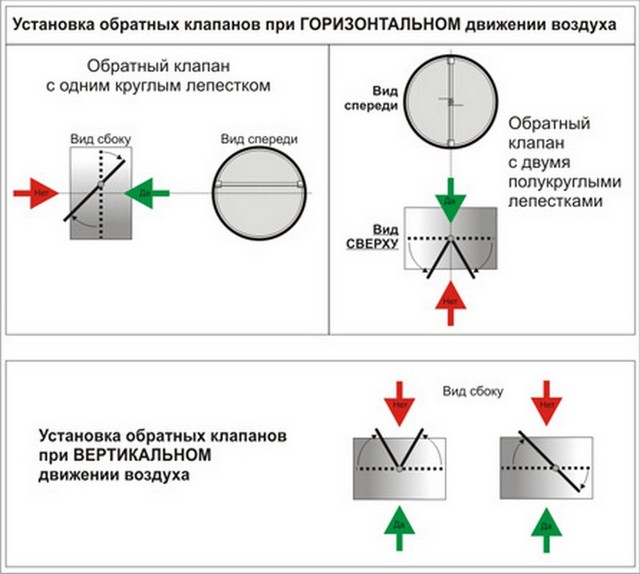

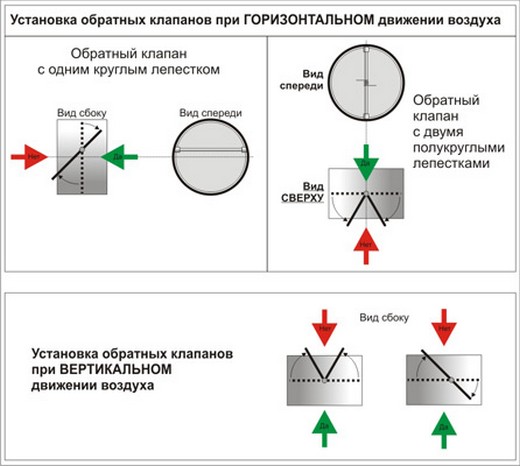

Depending on the features of the air duct there are 2 types of check valves: with a vertical flap and with a horizontal flap. The choice depends on the direction in which the air moves in the shaft.

Installation of non-return valve for ventilation

Installation of check valves is possible on those parts of the duct where the airflow velocity is horizontal at least 6, and vertically at least 4 meters per second.

- We dismantle the hood.

- We insert the valve body into the vent hole, marking on the case where it will be fixed. We drill holes on the extracted valve where they made the marks.

- Next, you need to drill similar holes in the concrete. For this we use a jumper.

- We plug the dowels into the concrete and re-insert the valve, twisting the fastening elements.

- The remaining gaps should be sealed with silicone, otherwise the thrust will not be enough to close the blades of the check valve.

- We finish the work by installing the hood.

There are check valves, for installation of which it is not necessary to remove the venting device. They are mounted in front of them. This overlap protrudes above the surface of the wall, but its housing can serve as an element of the decor of the room.

In the photo - the process of installing a check valve for ventilation in the kitchen

Installation of a non-return valve for ventilation with vertical arrangement axis is performed if the air flow is directed upwards. The horizontal arrangement of the device is possible under the condition of sufficient flow velocity (from 6 meters per second).

Cost of check valves for ventilation

The price of the check valve is determined by the type of section, the size of the device, the material from which it was made, the type of construction, its purpose and brand. About popular manufacturers flexible ducts read the ventilation.

Price range: 300 - 4000 rubles.

Where to buy a non-return valve for ventilation?

Buy a check valve for ventilation can be in the store ventilation systems in your city. You can also order a valve on the Internet. Most companies that implement ventilation systems and their accessories have an online store where you can arrange delivery of goods to your region.

In Moscow:

- Company "Convent"

- Luxair, ZAO Wings-M Partner

- LLC "Armada-Climate" Vent-style

In St. Petersburg

- TBM Market

- Company "ASViK" (online store Mic)

- GK Sfera pro

Video

Reverse ventilation valves - reliable protection of air in the room from unpleasant odors from the outside. In addition, these devices contribute to a qualitative cleaning of the air in the room due to its outflow, when the extractor is activated.

Jun 8 2015 ventsyst

Often ventilation system works ineffectively and part of the air penetrates the ventilation duct back into the apartment. Particularly noticeable is the effect of the reverse draft of ventilation in the kitchens or in the bathrooms of apartments. Reverse valves will help fight off unpleasant odors.

How the non-return valve works

Non-return valves in ventilation are called a group of safety devices to prevent the rotation of air flow in exhaust ventilation systems or simply the return draft of ventilation in the apartments. The valve passes air in the right direction, inhibiting the reverse movement. Check valves are used for exhaust ventilation automatically and this is the main advantage of their use. In ventilation systems of residential and public buildings, non-return valves are used to prevent air from entering the common ventilation duct into separate rooms.

Check valves for exhaust ventilation work in systems with natural and mechanical traction. The valve protects against the penetration of insects, dust into the household ventilation.

If you do not equip the system with a non-return valve, drafts may appear.

Types of check valves for ventilation

The main structural part of any non-return valve for natural ventilation is the shutter. It is he who does not pass air in an undesirable direction.

There are two types of round and rectangular check valves for ventilation:

- with a shutter in the form of a spool;

- with a shutter in the form of a disk or a flap.

The first are used for working with liquid media. The latter are designed specifically for ventilation. There are they with a horizontal axis of rotation or vertical, and also single-leafed and bicuspid.

Non-return valves are produced for ventilation with rectangular and round, with different diameter sections.

The main parameter when choosing a check valve is its throughput.

Check valves for natural ventilation are simple to manufacture, yet very reliable.

They are made of plastic or metal, the material is selected depending on the features of the system. In vertical pipelines, the air flow moves vertically, so the valve is mounted horizontally, which ensures correct operation of the shutter.

The most commonly used are round and rectangular reverse ones with a throughput of 4 to 6 m / s. They work silently and efficiently. They are installed both independently and complete with an exhaust device.

All non-return valves for rectangular or circular ventilation are also divided into:

- Heated. Such check valves for ventilation with electric drive have the advantage: the system does not collect condensate, and the structure will not be covered with icing in severe frosts;

- Without heating. Good only for indoor use.

The presence of an electric drive at the check valve for ventilation requires the participation of an electrician in his connection.

Although the device is cheap, a non-return valve for ventilation can be assembled with your own hands, but more on that later.

Design of check valve for ventilation

The device of the check valve is very simple: the disc-clap is attached to the axis, allowing it to freely swing. To cover the valve during the fan stop, a plumb line is attached. Ventilation valves can be rectangular, circular or square section.

Industrial models differ from check valves for household ventilation with diameter and material, they belong to an explosion-proof category, although the device is the same.

The diameter of a circular or rectangular check valve for industrial ventilation can be from 125 to 1000 mm, they are installed in explosive industries.

Widely used butterfly valve model with two blades.

Butterfly devices are produced more often from metal, the axis for attaching blades is installed in the middle of the section. As soon as the fan stops, the blades cover the section and the return draft of ventilation in the apartment stops. The diameters of the two-leaf valves vary from 100 to 315 mm.

Improved modification of the "butterfly" is equipped with seals, which reduce noise when blades operate.

Very often used for ventilation in the kitchen check valve in the form of blinds or petals (inertial grating). There are several blades in the construction, they are located on horizontal axes.

How to choose a check valve

![]()

Buying a check valve for kitchen ventilation or in the bathroom, you need to take into account the speed of the air, because the shutter must react even to the slightest flow. Poor traction in the system is the main problem in the organization of a natural ventilation system. Therefore, most owners combine the valve with exhaust fan. To cover the structure from the side of the room a beautiful ventilation grille is installed.

But in order for the natural ventilation system to work reliably, it is important to select the check valve correctly. Otherwise, the return draft in ventilation apartment building will continue to poison the existence of residents.

Pay attention to:

- the shape of the section;

- diameter of section;

- valve material;

- the valve arrangement;

- the purpose of the valve;

- firm-manufacturer (affects more on the price than on the quality of the simplest mechanism).

You can purchase an already complete set of fan and check valve. Here it is necessary to pay attention to the power of the fan. For the kitchen is suitable with a factor of 10, and for the bathroom and toilet will be enough 7.

Buying a check valve for household ventilation of a private home, it is important to take into account the climatic conditions. For example, the "butterfly" will quickly cover with icing, rather than a uniaxial construction. In private houses, unlike multi-apartment houses, residents are not annoyed by the return draft in the apartment, but blowing the wind into the ventilation and penetration of rodents into it.

Non-return valve for manual ventilation

Particularly relevant is the installation of the non-return valve of ventilation for the occupants of the last floors of houses, where the problem of tightening "foreign" odors through the air ducts of the general exchange system is common.

We offer an improved model of the non-return valve for ventilation with electric drive and fan.

For the base of the non-return valve for kitchen ventilation a thick plastic or textolite is suitable. A plate of the size of the outlet of the exhaust channel and a thickness of no more than 4 mm will be required. The plate is made of markings: a grid the size of a fan opening, as well as holes for fixing to the wall (at the corners) and for attaching the fan.

The larger the lattice cell, the denser the material for the flaps!

To prevent a "walk" between the base and the fan, a rubber gasket is used.

To prevent not only the return draft in the ventilation apartment of the apartment building, but also the penetration of insects, a small plastic mesh or even a nylon from the tights is attached to the grate of the base. The latter is easily replaced. And that the tenants are not disturbed by the vibration from the fan motor, the installation uses shock absorbers made of rubber.

The valves are made of thick polyethylene (not less than 0.1mm). The film should be perfectly smooth, the smallest waviness will break the tightness of the ventilation, and the return thrust in the apartment of the apartment building will resume. You can fasten the shutters on scotch tape with a tissue base. detailed instructions for the manufacture of valves for the plastic check valve ventilation in the video:

We recommend cutting the leaf in place, from the already pasted piece of film. And, if it is slightly wrinkled during work, it must be changed. Two leaflets are cut with each other only at the very end of the process. You need to cut with a sharp construction blade.

To ensure that there is no gap between the homemade plastic check valve for ventilation and the wall, use a self-adhesive foam tape.

During operation, it is necessary to periodically clean or change the plastic mesh, clogged with dust.

With proper manufacturing, this homemade plastic check valve for ventilation will last for many years. And tenants of an apartment for a long time will get rid of return draft, characteristic for ventilation of apartment houses.