Connecting the submersible. The scheme of connection of the pressure switch. A detailed story with illustrations

Effective water pumping station depends on the many components of its components, among which the key is the pressure switch. Its task is to automatically turn on and off equipment, as well as control the water supply to the tank according to predetermined parameters. At the moment, it is impossible to say exactly to what extent the pressure range should be limited. This should be dealt with by the consumer himself, determining the optimal indicator and focusing on permissible norms and instructions.

The device and principle of operation of the water relay

In its execution, the relay represents a block of small sizes with springs of maximum and minimum pressure, for adjusting the tension of which nuts are used. To springs the membrane is connected, which, in the event of pressure differences, works in one way or another.

In its execution, the relay represents a block of small sizes with springs of maximum and minimum pressure, for adjusting the tension of which nuts are used. To springs the membrane is connected, which, in the event of pressure differences, works in one way or another.

When the pressure level reaches the minimum value, the spring is weakened, in case of reaching the maximum level, a stronger compression occurs. As a result of the force that is applied to the springs, the relay contacts are opened, which leads to shutting down or switching on pumping equipment.

The use of a device such as a relay in the water system makes it possible support constant pressure and the required head of water. The work of pumping equipment is carried out automatically. If you correctly determine the minimum and maximum pressure levels, you can achieve that this device will be disconnected from time to time. And this allows to extend the service life of the relay.

Using a station with a relay

In the case where the pump station is used in conjunction with a relay, a similar combination of devices will work in the following order:

The main parameters of the relay:

- Lower pressure. At the moment when the relay contacts that enable the pumping equipment are closed, the tank begins to fill with water.

- The upper pressure. When the relay contacts are opened, the pump stops operating.

- Pressure range. It is understood as the difference between the lower and upper values.

- Level of maximum possible shutdown pressure.

When starting the installation of the pump station, it is very important to carefully perform the operation, such as setting the relay. Compliance with all requirements makes it possible to ensure the most efficient operation of the water supply system, and in addition to this reduce the likelihood of breakage for all devices that make up the system.

When starting the installation of the pump station, it is very important to carefully perform the operation, such as setting the relay. Compliance with all requirements makes it possible to ensure the most efficient operation of the water supply system, and in addition to this reduce the likelihood of breakage for all devices that make up the system.

Nuances of customization

According to the scheme, the first thing to do is to determine the pressure maintained in the tank during the first minutes of the pumping station. Most often, the manufacturer chooses as the optimal indicator the level of 15 atmospheres and 2.5 atmospheres for switching on and off, respectively. Perform such a check should only be in the absence of water in the tank and make sure that the pumping station is de-energized. It is advisable at the same time to use an automobile mechanical manometer.

To do this, it should be placed in a steel casing, where higher accuracy can be achieved. Such a verification method is more preferable than the use of electronic or plastic manometers. It should be borne in mind that readings may be distorted under the influence of several factors:

- air temperature in the room;

- battery charge level.

It is necessary to pay attention to that the limit of the scale of the manometer should be minimal. The fact is that if the scale, say, is designed for 50 atmospheres, then using such a device it will be difficult to obtain accurate data when measuring one atmosphere.

Determine the pressure of the tank can only after performing certain actions. First, the cap is opened, which closes the spool. Next, you need to connect a manometer, record the readings, issued by its scale. Subsequently, it is necessary to reconcile the air pressure from time to time. This procedure will provide accurate data provided that the tank does not contain water, the pump is de-energized, and the cranes are in the open state.

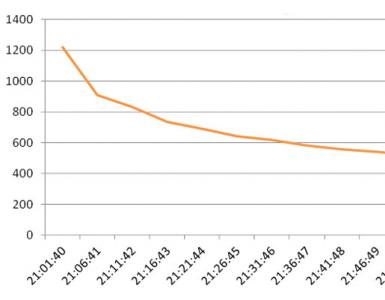

You can also do otherwise. To do this, it is sufficient to control the pump shutdown pressure. If it increases, it can be concluded that the air pressure in the tank begins to fall. And the minimum level of this parameter indicates the presence of a larger space for filling the tank with water. However, the difference in pressure between the states, when the tank is completely filled and does not contain water, is quite significant. Here, consumer preferences come first.

After the preferred mode of operation is set, it is necessary to adjust it by removing excess air or pumping. It should be remembered that the decrease in pressure to the level less than 1 atmosphere and bringing to an extremely high value can lead to negative consequences. If there is too little air, the rubber tank, which contains water inside the tank, will contact the walls and gradually begin to wear off. If the air is too much, it will not be possible to fill the tank with a lot of water, since a large part of the volume of the tank will be filled with air.

If the owner purchased the pump station in assembled form, then the configuration of such models provides a relay with the optimal settings. If it is planned to connect such a station on the basis of various elements in the place where it is planned to use it, then the owner must make corresponding relay setting. This should be done for the reason that the displayed settings take into account the parameters such as tank volume and pump head to the greatest extent.

If the owner purchased the pump station in assembled form, then the configuration of such models provides a relay with the optimal settings. If it is planned to connect such a station on the basis of various elements in the place where it is planned to use it, then the owner must make corresponding relay setting. This should be done for the reason that the displayed settings take into account the parameters such as tank volume and pump head to the greatest extent.

In addition to this, it may sometimes be necessary to make adjustments to the initial settings for the relay. In this case, the owner must follow the following sequence of actions:

Having completed the work on connecting and adjusting the air pressure in the tank, it is necessary to do connection of the pumping station to the household network. After that, the pump starts fill the tank with water. He can stop his work only when he can reach a predetermined maximum pressure. This is about the upper level. All offered for sale such devices initially contain information about the maximum level of this parameter and the maximum possible head for pumping equipment. If they are exceeded, this can lead to irreversible consequences.

To understand that this happened, it is possible by the fact that the pressure no longer increases. If this is the case, the pump is switched off manually. If there are deviations in the value of the limiting pressure from that specified by the instruction, then the owner must perform the necessary adjustment by rotating the small nut accessible by the relay cover.

Similarly, they do the same when necessary determine the lower level. This is done by opening the tap and removing water from the tank. When performing this operation, it is necessary to monitor the readings of the manometer at all times. After a while, the pressure will begin to fall, and when the lower limit is reached, the pump will begin its work.

At this point, you can determine the lower level, the value of which can be confirmed from the data of the manometer. Rotating the big nut, you can change the pressure to the level that is necessary for the effective operation of the system. As a rule, it exceeds by 10% the air pressure in the tank. If you set the parameter a little more, there may be a risk of increasing the wear of the rubber membrane.

In the process of selecting the pump power, it should be taken into account that the optimum value will have a level at which the tank will be filled with water to the extreme. The optimal level of disconnection will be considered a mark for a couple of atmospheres above the threshold of inclusion.

Relay adjustment

The need to configure the relay occurs in situations where it is necessary to set the upper and lower pressure levels in certain values. For example, a problem may arise for establishing the upper one at the level of 3 atmospheres, and the lower one - 1.7 atmospheres. The configuration procedure itself provides the following:

While maintaining high pressure to turn on and low to turn off in the tank will appear sufficient space for pumping it with a large volume of water. This avoids frequent pump starts. In this case, there may be difficulties associated with significant fluctuations in pressure with a full tank or empty. In other situations, when the pressure is maintained in a small range, and the pump often operates to pump water, the tank will maintain the optimum pressure level.

Conclusion

In the process of using the pumping station, it is often necessary to supplement it with additional devices, including the pressure switch. The use of this device is very significant, and it consists in the fact that it is possible to minimize the number of inclusions pumping unit. However, this effect can be achieved only on condition that relay will be properly configured.

The very essence of the procedure for connecting and configuring is reduced to defining optimal values for upper and lower pressure levels. These values allow to optimize the work of the pumping station, which positively affects its uninterrupted operation.

Pumping automation is a unit installed in pumping equipment and designed to ensure its automated operation. In this segment there are: pressure switch, automation unit, start-up protection devices and pump control stations.

Pumping Automation

Pump automation is designed to control the pump and control its operation. The main functions of the pumping automatics are to start the pump and stop its operation. Typically, this is due to the pressure switch, automation unit, start-up protection devices and pump control station. All automation for pumping stations protects the equipment from voltage drops, short circuits, and from continuous uncontrolled operation. Let's consider each automation element for pumping stations.

Pumping automation in the form of a block

Designed to automate the operation of the pump. He reacts to a decrease or increase in pressure in the water supply system and starts the pump when the crane is opened or stops when it closes. The automation unit protects the pump from so-called "dry running", not allowing it to work in the absence of water. In our online store you can find an automatic regulator for flow and pressure Gileks. It is capable of operating at a maximum water temperature of up to 60 ° C and allows a pressure of 10 atm.

Pressure switch

The pressure switch, like the automation unit, is designed to regulate the operation of the pump and its automation. The principle of the device is simple. The relay turns on the pump when the pressure in the system drops (for example, during the use of water by a person) and turns off when the user closes the tap and the pressure rises again to the desired point. The pressure switch also protects the pump from "dry running". These requirements are met by pressure switch DZHILEKS RDM 5.

Start panel (start-up device)

It is designed to start engines in downhole pumps, with a specific start panel selected for each pump model. Such an instrument is responsible for the operation of the pump itself, regulating its activation and deenergizing, albeit only with dry-running sensors.

Pump control station

It serves to automate and control the operation of the pump and protect it from "dry running". Typically, the protection operation time is about 10 seconds. There is a whole model range that can provide reliable control of the pump, it is presented in four modifications: KIV-1 A3 , КИВ-1 Б3 , КИВ-1 В3 and КИВ-1 SQ3.

You can buy pumping automatics right now in our online store "220 volts". At us you always find any household and professional power tools you need, power and construction equipment, and our managers will help you to choose from the widest assortment the most suitable model and the equipment required for it.

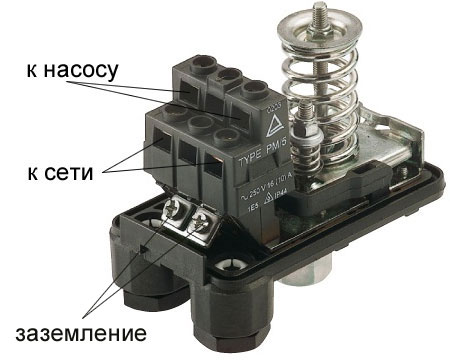

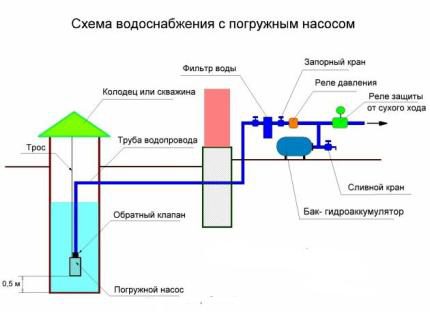

Used to automate the operation of water supply systems and provides control of the turning on and off of the pump (or pumping station). For this purpose, the relay must be connected to the water supply system, to the electricity network and the pump. In this article, we will discuss the simplest example of connecting a relay in a system with a downhole pump and.

Firstly, the relay is connected to the water supply system, then to the pump and the mains.

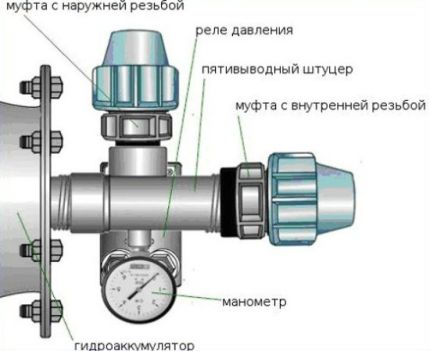

When calculating water supply systems, the water pressure (head) is determined, which must be provided by the accumulator, so the measuring and control devices - pressure gauges and relays - are connected in the immediate vicinity of the accumulator. In the vast majority of cases - directly to the outlet of the accumulator. For this, there are special fittings with five outputs.

Connection for pressure switch and pressure gauge to the pipeline and accumulator

Two outputs are used to connect water pipes (one end towards the water consumers, the other towards the pump), one output is connected to the hydroaccumulator, and two small outputs are used to connect the pressure gauge and the pressure switch.

For connection to the water supply, the water pressure switch has a hole (usually ¼ "in diameter) with thread, so the relay needs to be screwed onto the union, so it should be ensured that there is enough space in the place of installation. It is also necessary to ensure the tightness of this connection, for example, using a tape FSM.

Also, the relay has two holes for supplying electrical cables - one cable goes to the pump, the other to the outlet. Next, remove the housing cover and connect the wires to the relay terminals.

Before you take on the connection of the relay to the mains, of course, all cables must be disconnected from the outlet. It is necessary to remove the power cable (which goes from the relay to the outlet) into one input hole in the housing, divided into veins (one wire - phase, the second - neutral, third - if there is, grounding), cleaned of insulation and connected to the terminals. Similarly, it is necessary to connect the contacts to the pump.

After connecting to the electrical network and the pump, you can proceed to configure the pressure switch and test its operation. To monitor the current pressure, a pressure gauge is used, which is connected to a separate outlet of the nozzle. There are also pressure switches that have their own built-in pressure gauge.

All together - pressure switch, pressure gauge, hydraulic accumulator and connection to the water pipe - the assembly will look something like this:

When all components are installed, you can start testing the system and, which consists in setting the desired thresholds for turning on and off.

- economical consumption of electricity;

- high productivity;

- low noise factor;

- wear resistance of parts made of stainless steel, brass and safe food plastic;

- the possibility of warranty or self-repair;

- small weight and dimensions corresponding to the borehole diameter;

- complete set, allowing immediately to start the installation.

- multistage pumping sector;

- electric motor, separated by a filter;

- capacitor box located outside.

- BCPE - household centrifugal submersible electric pump;

- 0,5 (l / s) - productivity;

- 100 (m) - nominal head at nominal volumetric feed;

- 60 (l / m) - the maximum productivity;

- 150 (m) - the height of water in the well at the highest head.

- diameter of the well;

- production rate of the well;

- water levels in the well (static and dynamic);

- estimated water flow;

- distance from the source to the house;

- pressure in the accumulator (damper tank).

- number of permanent residents;

- number of points of use inside the house (bathroom, kitchen, shower);

- the presence of points of analysis outside the house (watering the garden, a crane in the summer kitchen, a tap in the bath), etc.

- Accumulator with a set of adapters. Need for a small family (2-3 people) is enough unit of 100 liters: the larger the volume, the less the device will be turned off).

- Headline. It covers the mine well from street debris and atmospheric precipitation, serves as a place for fixing pipes.

- Pipe from pump to tank. Required for external use, with a diameter of 32 mm or 40 mm.

- Adapter from pipe to submersible pump. For the Aquarius pump and pipes with a diameter of 32 mm, an item of type 1 'with an outer cut of 32 mm is suitable.

- Steel cable with clamps. Eif the product supplied is not suitable for some reason.

- Underwater cable. It is used for electrical cables.

- tightness;

- strength;

- minimum length;

- absence of bends.

- check the presence of contacts in the outlet;

- we inspect the pump for sand contamination;

- we measure the voltage, if we connect a stabilizer with a defect.

- vibratory;

- centrifugal.

- the key element of the design is the membrane;

- it is deformed under the action of a vibrating mechanism;

- this leads to a difference in pressure, as a result, the water is pumped in the right direction.

- Gardena;

- "Kid";

- "Aquarius".

- universality of application;

- possibility of self-connection;

- savings in the arrangement of the water supply system in the suburban area.

- automatic control unit in the form of a remote control;

- presscontrol;

- control unit, equipped with a mechanism to maintain a stable water pressure in the system.

- pressure switch;

- level switch;

- a float switch.

- BRIO-2000M (cost - up to 4 thousand rubles);

- "Aquarius" (4-10 thousand rubles).

- "Aquarius";

- Grundfos.

- relatively affordable price;

- good quality of blocks;

- simplicity of installation.

Owners of plots with water well face a complex choice of pumping equipment. If the device is suitable for the characteristics and will be installed according to all installation rules, the owners will forget about the problems with the delivery of water for a long time. For summer residents and owners of country houses, we recommend paying attention to the Aquarius well pump, which, with proper care, can function for more than 10 years.

Easy to use and install the unit produced by the company "Promelectro" (Kharkov, Ukraine). Besides submersible pumps the enterprise produces drainage and surface pumping equipment, electric motors, feed grinders.

A series of pumps for deep-seated use includes products operated in wells installed "on sand" and "on limestone." The range of the distance from the intake of water before it reaches the surface from 20 to 200 m. The most powerful models can serve a large cottage or 2-3 cottages, as their productivity reaches 12 m³ / h.

Products of the company "Promelectro" is known since 1995 - from the moment of establishment of the enterprise. And since 1996 saw the light of equipment that has not lost popularity to this day - submersible and surface pumps

Among the advantages of the line of devices Aquarius can be distinguished:

Do not forget about IEC 335-1 (international safety standard), warranty service for a year and a half and the ability, if necessary, repair to purchase spare parts from the manufacturer. According to technical characteristics, the modifications are comparable with foreign analogues PEDROLLO and GRUNDFOS. The cost depends on the model - from 1800 rubles. up to 27 400 rubles.

Image Gallery

![]()

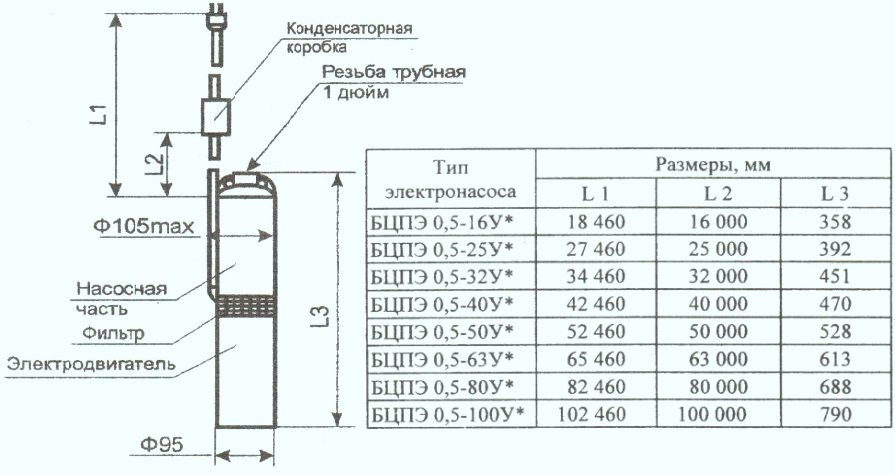

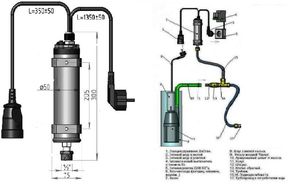

Features of the deep pump device

All wells submersible models Aquarius have a similar structure. The main parts are:

Under the hull is a pump unit - a monolithic box with rotating impellers and a drive. It is the size of the impeller responsible for one of the main characteristics of the unit - productivity. The larger its diameter, the more voluminous the portion of water supplied for a certain time period.

All parts are securely fastened with screw cap. It is also the fixation point of the cable, one of the elements of fixing the pump inside the well.

According to the table, it is possible to trace the ratio of the dimensions of the device and two important technical indicators - productivity and nominal head (click to enlarge)

The motor drives the machine with the rotor-stator combination and the bearings. It is filled with oil. Condensers and an electric cable are enclosed in a condensation box. To ensure that the equipment does not fail under force majeure (for example, with rapid dehumidification), automatic protection of German production is provided.

Control over the operation and control is carried out using a remote device. Knowing the pump device Aquarius will help with its repair.

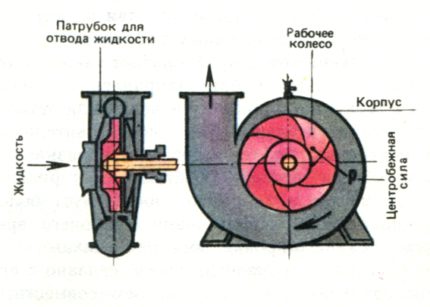

Principle of operation of the submersible apparatus

To feed water up and move it to the required distance, it is necessary to create pressure. The centrifugal pump type produces the required head by rotating the wheel (or several wheels), which is fixed to the working shaft (shaft) and connected to the engine.

When the wheel starts, kinetic energy is generated, transmitted to the blades, and from them to the fluid. As a result, water is scattered to the walls, then from the receiver it moves to the next (upper) chamber, and in its place under pressure comes another portion of water from the well.

Thanks to a simple but well-thought-out device, the water flows smoothly, in a sparing mode, first into the body of the apparatus, then through the pipes to the storage tank

A suction pipe is used for the intake of liquid, and a filter is provided to protect the internal parts of the device from clogging and rapid wear. The device is simple, but so effective that it makes no sense to look for a device with a different operating principle. All elements of the mechanism are placed in a fairly compact elongated "sleeve", the design of which is ideally suited for descent into a narrow wellbore.

Unlike vibrating analogs, centrifugal pumps work evenly and carefully, so they do not raise sand from the bottom and do not destroy the walls of the well.

Models overview: purpose and characteristics

To cover a large audience, the company "Promelectro" produces models of various modifications. For convenient orientation, some parameters of the aggregates are enclosed in their name.

For example, take the BCPE position 0.5-100U 60/150 and decode the digital data:

In accordance with individual requirements, you can choose a device belonging to one of four groups: 0.32 l / s, 0.5 l / s, 1.2 l / s, 1.6 l / s. Suppose that you own a well or a well (diameter 100 mm, 120 mm and above) with a limited production rate. Most likely, water consumption does not exceed 2 m3 / h. Obviously, the choice should fall on the BCPE model-0.32.

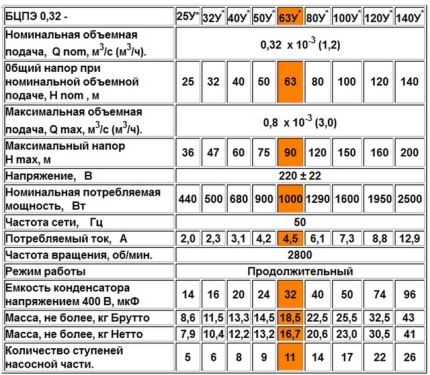

The table shows specifications all pump models Aquarius with a performance of 0.32: using data analysis it is easy to choose the device for your own use

Models with a performance of 0.32 are quite popular, since many visit the dacha irregularly, and the number of permanently resident people rarely exceeds 3-4. If you decide to purchase the device with the minimum performance, please note that other indicators may differ (for example, by the pressure parameters). This series consists of 9 models.

In the next series - BCPE 0.5 - only 8 models differing in the head (from 16 m to 100 m). Pumps can work with both manual and automatic control. The devices are equipped with a protective function that protects against overheating.

If the diameter of your well is at least 110 mm and the flow rate is from 2 m³ / h, you can choose one of the models in this series. The device can be useful for other purposes, for example, if there is a need to pump water from a pool, pond or natural water body. Pumping equipment with a capacity of 0.5 l / s is perfect for watering lawns, beds, flower beds or garden plantings.

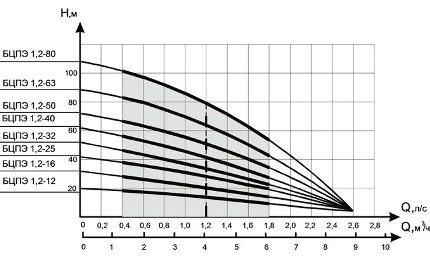

BKPE-1,2 Aquarius pumps achieve the maximum efficiency at a water supply of 1.2 l / s (4 m³ / h): the graph reflects the dependence of the volume of water on the head

The next series - with a capacity of 1.2 l / s - includes a line of 8 products that differ in pressure (from 12 m to 80 m). The manufacturer warns that hot water (with a temperature above + 35 ° C) can not be pumped, as well as too contaminated liquid.

The most productive models are BCEPS 1.6, which are represented by three modifications - with a head of 25 m, 32 m, 40 m. In their line they differ and are structurally - they have different number of stages of the pump part, from 6 to 8. Taking into account the technical characteristics of the Aquarius pump , you can choose the unit according to individual requirements.

How to connect well pump

Let's consider all stages of selection and connection of the pumping equipment of the brand Aquarius. These recommendations are general, with more detailed information you can find in the technical data sheet and installation instructions.

After specifying the technical data of the well and comparing the characteristics of the different Aquarius pumps, you can choose the model that is best suited for your site

Selecting a model for specific characteristics

Before buying it is important to take into account all the characteristics necessary for the right choice, namely:

The diameter of the well is very simple to determine - it is indicated in the data sheet, which is issued by the company that produces drilling and installation of equipment. Most likely, the diameter is typical, that is, it measures 100 mm, 133 mm, 152 mm. Pumps Aquarius is better to install in wells having a cross section of more than 100 mm.

The debit is also indicated in the passport, thanks to this parameter it is easy to choose a pump for productivity. It is important that the pump parameters do not exceed the figures specified in the documents. Suppose that the flow rate of the source is 3 m³ / h. This is a rather low indicator, which means that the models from the BCPE series of 1.2 (or higher productivity) need not be purchased, BCPE 0.5 is sufficient.

When using more powerful equipment, the water volume in the source will not have time to recover, the dehumidification and automatic shutdown of the device will occur.

The water level must be known to correctly determine the depth of installation of the pump. Usually the distance to the water mirror and from the surface to the bottom is indicated in the passport, however, it is necessary to remember a couple of nuances. The first relates to the installation of a submersible pump - it is lowered below the surface by 4-5 m. The second is the impermanence of the water level.

In the warm period, the level usually decreases, and the difference with the initial indicator can be up to 4-5 m. It turns out that for installation it is necessary to know the minimum level.

Even at the planning stage of the water supply system, it is necessary to draw up a diagram of the house with an indication of all possible points of water extraction - the data will be useful both for wiring and for selecting a pump

To calculate the total water flow, several factors must be considered:

On average, if you do not take into account additional objects, per person, a daily consumption of 200 liters is required.

The distance between the water source and the house is necessary to calculate the additional load on the pump. Standard calculation: 10 m of horizontally laid pipes is equal to 1 m vertically disposed (both - 0,1 atmosphere).

The pressure of the damper tank affects the trip threshold. Suppose, if you have a volumetric tank of 300 liters, then to switch it off, you need a pressure of 3.5 atmospheres (in translation in vertical meters - 35).

Image Gallery

Purchase of components for installation in the well

In addition to buying a pump, which is supplied with an electric cable and cable for suspension, you may need to purchase the following equipment:

Together with the accumulator and the pump, a pressure switch and a pressure gauge are acquired. The equipment of German and Italian manufacture has perfectly proved itself. For example, if the tank volume is more than 300 liters (8 atm.), The model MDR 5-8 Grundfos is suitable.

One of the options for mounting the pressure switch and pressure gauge - with the help of couplings, on the fitting coming out of the accumulator tank (accumulator tank)

Preparation and piping of pressure pipeline

To ensure that there are fewer problems with the delivery of water from the well to the house, the pipeline must have the following qualities:

Turns and bends can cause the formation of air bags that interfere with the movement of water. The shorter the tube, the less need for connecting elements: fittings, couplings, flanges. Do not recommend using threaded connection. Possible variant products - HDPE-32 pipe.

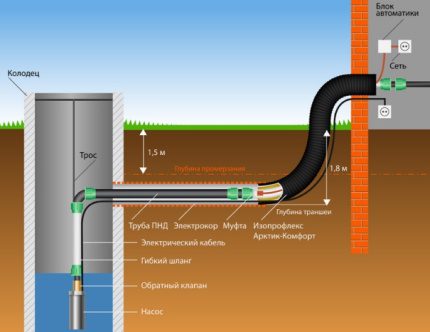

Layout of the pressure pipe when installing a submersible centrifugal pump: the pipeline is laid below the freezing level of the ground with additional insulation

The check valve does not come with the Aquarius pump, but its presence in the water supply of the house is necessary. The main purpose of the valve is to block the movement of water in the opposite direction. This means that during operation the valve is open and allows the fluid to move freely towards the parsing points. However, when the pump is turned off, it closes the water, preventing it from moving backwards.

The valve is installed directly at the outlet downhole pump. It is mounted in a pipe above the pump, in some cases at a small distance from it (not more than 1 m). When installing the valve, pay attention to the arrow indicating the direction of movement of the water. This is necessary not to cut the part by the back side.

Installation diagram check valve in the well, the pipe of the submersible pump. When installing a surface pump, the valve is fixed to the end of the nozzle

Fastening of the equipment on a cable

Kapron cable for mounting the pump is included, but some users note that over time, the elastic material loses its elasticity and stretches. To prevent deformation, you can use a stainless steel cable. It is passed through special holes in the upper part of the pump casing and firmly attached.

Together with the cable, it is necessary to lower the electrical cable into the borehole. To prevent mechanical damage and additional stress on it, you should make a kind of bundle of safety cable, pipe and electric cable. The cord is fastened not in a stretch, but loopy, with small allowances. It is forbidden to lift the pump out of the bore hole for an electric cable.

The pipe should look like this after the pump is lowered into the well. Electrical cable fix with special staples or adhesive tape

Connect the communications between each other carefully casing at a predetermined depth. The pump must never touch the bottom.

Electrical connection and testing

Remember that the operation of the Aquarius pump is possible only under the condition of observing the voltage parameters - 220 V. With other indicators, the normal functioning of the equipment is not guaranteed. If the network characteristics do not meet the manufacturer's requirements, connect the voltage regulator.

After immersing the pump in the well, make sure that its housing is completely in the water. The power cord must not be strung like a string. Only after checking the conditions, proceed to connect the Aquarius pump to the power supply. If the device began to pump water and turned off only when the automatic system was activated, everything was done correctly.

For trouble-free operation of the equipment, preventive disassembly is carried out. If after checking the shortcomings are noticed, they must be eliminated. For example, you can replace the bearings (with a tight course), change the oil, check the winding of the engine.

How to fix possible malfunctions

Despite the prevention, there may be a breakdown, so consider the most frequent ones.

Prophylactic cleaning should be done every 1-2 years, but emergency unscheduled repair is also possible, if the parts are worn out or the suction pipe is filled with sand ahead of time

If the pump does not turn on, we perform the following actions:

If productivity is suddenly reduced, we check whether there is a leak in the pipeline. At the same time we inspect and clean the filters. With a decrease in voltage, we use the stabilizer.

The pump will sooner or later be clogged with sand, therefore we make cleaning: we remove the mesh and protective trough, separate the pump part and the electric motor, check the work of the shaft, wash all the elements. We collect the device in the reverse order.

Video about the device, work and repair of the pump Aquarius

How to make calculations for a competent choice of a pump Aquarius:

Technical characteristics and capabilities of the model Aquarius BCPE 1.6 40u:

How to repair the device Aquarius (1/3):

How to disassemble and clean the Aquarius pump with your own hands:

Sequence of installation and connection of the unit:

As you can see, the Aquarius pump is convenient in installation and maintenance, an efficient device for water supply in an autonomous water supply system. Regular self-inspections and minor repairs will help prolong his life, but if you have difficulties with installing or choosing a new model - use the services of professionals.

Many owners of country houses try to equip them so that living was not less comfortable than in an ordinary apartment and there was central heating and water supply. And if you want to establish the work of all autonomous systems yourself, then you need to prepare for a long and painstaking work. And even when the water supply system is installed, it is necessary to make it work in an automatic mode at the level of the pumping system.

Today we will talk about how to create automation for depth pumps.

Before starting to create automation for a submersible pump, you first need to understand how such types of pumps are.

Submersible pumps fall into two categories:

Each of them, having an automatic control unit, put in the liquid itself, which will be pumped. Even the name itself indicates that the pump operates on the principle of immersion in a liquid.

Each of them, having an automatic control unit, put in the liquid itself, which will be pumped. Even the name itself indicates that the pump operates on the principle of immersion in a liquid.

Pumps of a submerged and superficial kind have the same specificity of work, but the mechanism is different, and the conditions of application are also different.

For example, submersible pumps can be used on deep wellsoh, where with their help it is necessary to increase the water pressure so that it can be pumped upward. However, the maximum depth of submersible pump application is only 10 meters. For deeper wells, professional systems are used. It should be added that surface pumps can not provide water pumping from deep wells.

Vibration models are more popularthan centrifugal. They are used in water wells, but centrifugals are more suitable for use in the agricultural sector. Principle of operation vibrating pump such:

According to this principle, the most popular models in our country are:

When buying a submersible pump, you need to clarify whether it is equipped with a so-called thermal switch. Also do not forget to check if it has the ability to take water by its lower part.

When buying a submersible pump, you need to clarify whether it is equipped with a so-called thermal switch. Also do not forget to check if it has the ability to take water by its lower part.

If you work in conditions where the soil is heavy, then you need to install a vibrating device lower so that when the pump is operating the well is not destroyed and was not contaminated by foreign bodies from the ground. Vibration models should only be installed in fortified wells to avoid problems. And to carry out dismantling of the submersible device in conditions of immersion in silt it is necessary only in the course of work.

The above models are convenient both in terms of installation and dismantling, and both can be performed independently.

In centrifugal devices the working mechanism consists of several wheels, attached to one shaft. When the wheels of the blade rotate, pressure is produced on them, so that the water is pumped in the desired direction.

Popularity centrifugal pumps in our country is conditioned by such factors:

Automation for deep pumps and its types

Automation for submersible devices is divided into three categories:

The first option is the simplest control unit in the form of a standard console. This the unit protects the pump against voltage drops, as well as short circuits that often accompany work pumping devices. To ensure full automatic mode of the device, the control unit of this type is connected to such devices as:

The first option is the simplest control unit in the form of a standard console. This the unit protects the pump against voltage drops, as well as short circuits that often accompany work pumping devices. To ensure full automatic mode of the device, the control unit of this type is connected to such devices as:

The average cost of such a control unit is about 4000 rubles, but remember that this control device will not work without additional devices, in particular, the same pressure switch or additional device protection against dry running.

Of course, some models of such control units are already equipped with all necessary systems for full-fledged work, but their cost will be about 10 thousand rubles. You can install such a control device yourself without consulting a professional.

Press Control

The next version of the automatic control device is press control. It is equipped with built-in systems for automatic pump operation and passively protects against dry running. The control in this case is determined depending on the orientation of certain parameters, in particular, the pressure level and the water flow. For example, if its consumption in the device is more than 50 liters per minute, then it will work continuously. And if the flow of water decreases or the pressure increases, the press control will turn off the pump, and this will be a protection against dry running of the pump.

If the liquid in the system does not reach the mark of 50 liters per minute, then the device starts when the pressure drops to 1.5 atmospheres, this is very important in a situation where the pressure rises sharply and the number of on / off switchings needs to be reduced. It is also provided for automatic shutdown of the device under conditions of a sharp and powerful increase in the pressure of the water head.

The most common on the market press control devices for control:

The cost of a backup accumulator for both devices most often varies within the limits of 4 thousand rubles. And remember that by purchasing a control unit of this type, installing it yourself will be more difficult than the previous one.

Block with pressure support

The last version of automation for submersible pumps is a control unit, which includes a mechanism, supporting a stable water pressure throughout the system. Such a mechanism is indispensable in those places where it is impossible to sharply increase the pressure, because if it constantly rises, it will increase the energy consumption and reduce the efficiency of the pump itself.

All this is achieved due to the rotation of the rotor of the electric motor of the control unit, but the regulation of the speed is automatic. The most famous models of such control units are:

It is worth noting that the brand "Aquarius" - the most popular in Russia and the near abroad in the market of control units for pumps. Devices of this brand attract buyers for the following reasons:

The cost of different models can vary significantly, naturally, devices equipped with subsystems and additional functionality will cost much less than conventional ones.

What you need to know when installing automation for the pump

If you purchased the device for the device and found out that the selected control unit is easy to install without the help of specialists, do not rush to install it. First, whether it is equipped with an electronic kit, or you need to buy it additionally. So, if you have a vibratory pumping system, you will need to buy additional expensive equipment in addition to automation, but for centrifugal pumps it will be sufficient to supply a tank with electrical contacts.

If you purchased the device for the device and found out that the selected control unit is easy to install without the help of specialists, do not rush to install it. First, whether it is equipped with an electronic kit, or you need to buy it additionally. So, if you have a vibratory pumping system, you will need to buy additional expensive equipment in addition to automation, but for centrifugal pumps it will be sufficient to supply a tank with electrical contacts.

Also, while working with the submersible pump, remember that it will work properly only in clean water . If the water contains solid impurities, they will fall into the blades, and this can provoke a breakdown of the pump motor.

Now you have an idea of what are automatic control devices for submersible pumps and, you know, how they differ from each other and how to choose them correctly.