Water heating systems. Principle of installation. Installation of the boiler. Open and closed heating systems

Water heating is the most common method of making individual heating of apartments and houses. Everyone can make water heating by their own hands. It is necessary to consider the sequence of works, starting from the design and purchase of construction material and ending with the launch of an already ready system.

Heat in the house. Where do you get it from?

Several boilers can act as a heat source for water heating, namely:

- A gas boiler.

- Liquid fuel boiler.

- Solid fuel boiler.

- Electric boiler.

- A wood-fired boiler.

It should be noted that the choice of the boiler largely depends on your capabilities. However, there is one rule that must be considered when choosing a boiler - this is its capacity. The power of the boiler must necessarily exceed the heat loss of housing by 20%. Accordingly, you need to calculate all the heat loss that occurs in the openings of windows, doors, roofs, etc. Already starting from this, it is necessary to choose a boiler with one or another power.

Circulation of the coolant. Choice of scheme

Before starting the installation work, it is necessary to determine the choice of the water circulation scheme. There are three types:

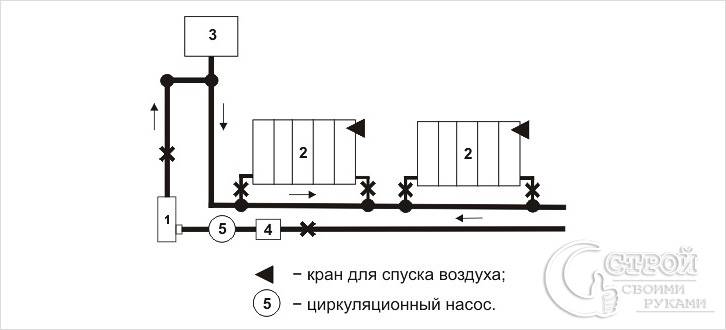

Forced system circulation of the heat carrier is carried out by means of a circulation pump. In this case, their number can be unlimited: one, two or three. Using this water system heating, you can increase the efficiency by 30%. Using a circulating pump will allow you to not observe a certain slope of the pipes when laying them. But on the other hand, the system will be completely dependent on electricity. It should be remembered that it should be closed type at an operating pressure of 1.5 bar.

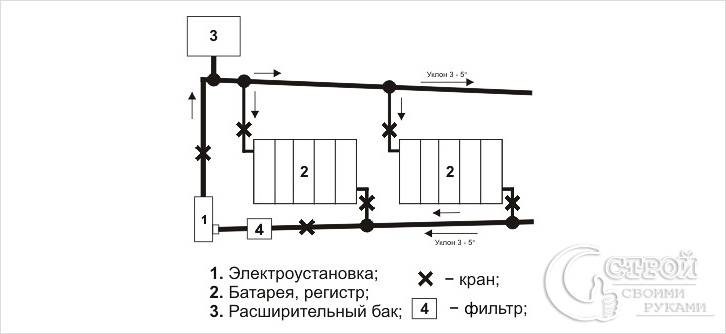

Concerning natural circulation, it is fully tested and is a reliable method of heating the housing. In this case, the slope of the pipe during installation is strictly observed, within 3-5 °. If this is ignored, then the water heating system will be inefficient, or rather, it will not work at all. Most often it is used for systems with solid fuel boilers, although there are options with gas boilers.

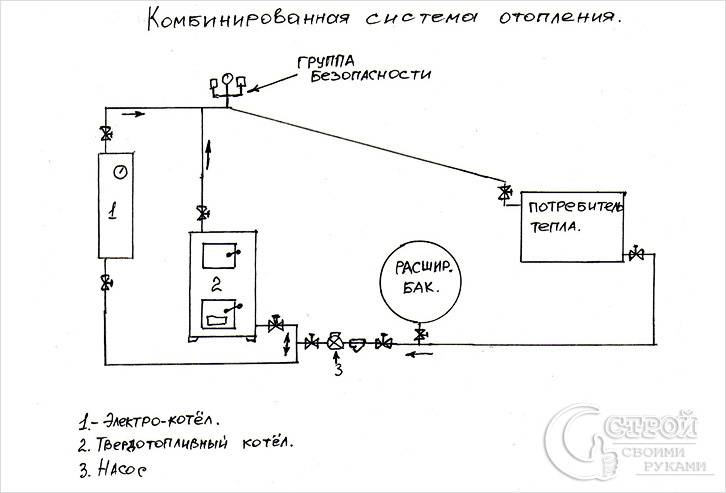

Well combined circulation system (KSC) implies the ability of the water heating system to work both compulsorily and naturally. For example, if heating season the electricity is cut off, then the system can be switched to natural circulation. For this reason, despite the possibility of installing pumps, the installation of pipes must be performed at an incline. In most cases, a combined heating scheme is used in combination with solid fuel boilers.

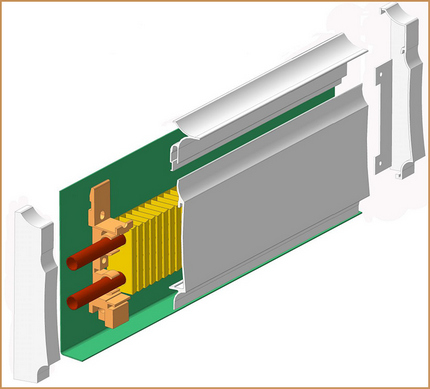

Selection of radiators

An important factor in preparing the installation of a water heating system is the choice of equipment. The main constituent part of the heating is the radiators. Their choice should be based on their power or heat transfer. In most cases, the main power characteristic is indicated in the instructions attached to the battery itself. It is also necessary to determine the number of sections for a particular room. All this can be calculated in the project. It is desirable that the radiator covers most of the window opening. This will artificially create a heat curtain. Moreover, this will prevent fogging of windows and the emergence of drafts. An important factor is the operating pressure of the batteries. Although this indicator plays a big role in a centralized heating system, and for an individual one it does not matter much.

So, there are several most common types of radiators. They are made of the most different materials: aluminum, steel, cast iron and bimetal. The latter combines aluminum and steel.

Aluminum radiators. This is one of the most common and at the same time available radiators. They have good heat transfer per unit area. In most cases, these radiators have separate sections so they can be combined, adding sections depending on the needs of the room. As for their operation, aluminum is a soft material, for this reason, when transporting them, you must be extremely careful. Moreover, during installation stop valves it is very easy to break the thread.

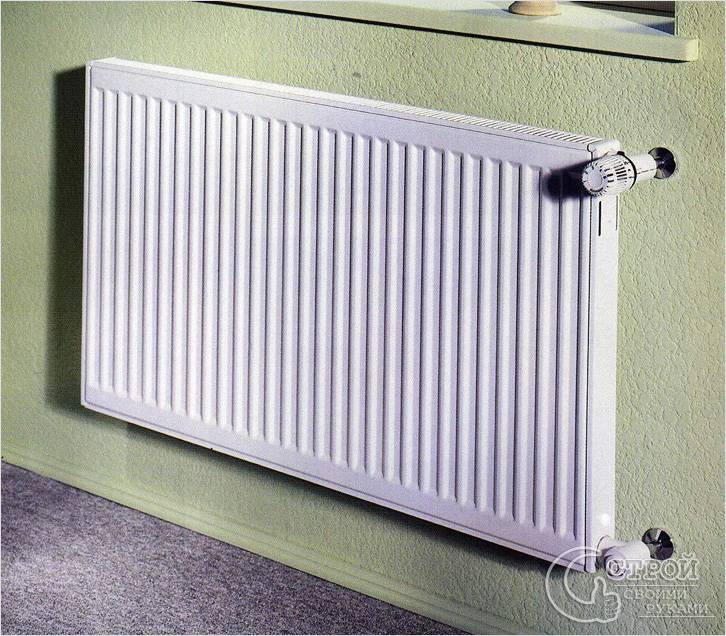

Steel radiators. As for this kind of batteries for water heating of premises, in this case it is impossible to increase sections. There is a large selection of steel radiators in size in width and height. One can note their high heat transfer.

Cast iron radiators. This type of radiator is distinguished by its durability. Fans of vintage style appreciate with dignity their original look. Cast iron radiators for a long time are heated, and also cool for a long time. Based on the requirements modern system wiring, as well as the use of thermal heads, their use is irrational.

Bimetal radiators. As for this type of battery, they have separate sections. They are made of steel, and are covered with aluminum. Due to this, high strength and, accordingly, the duration of operation is achieved.

Configuration of the heating system. Two-pipe and one-pipe

In its specific features, the heating system can be divided into:

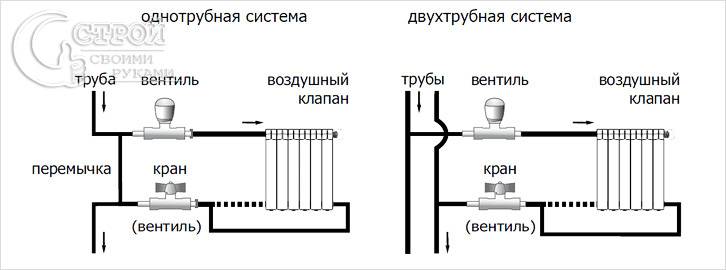

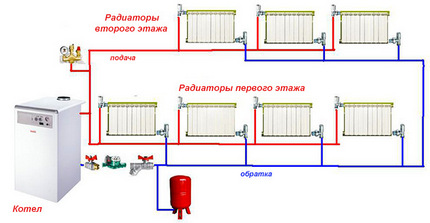

- one-pipe and two-pipe. The two-pipe system is organized by the principle of supplying two pipes to the battery, namely, return and supply. As for the one-pipe system, one pipe is laid. From it to each battery two nozzles are stretched, one branch pipe delivers water, the other, accordingly, withdraws.

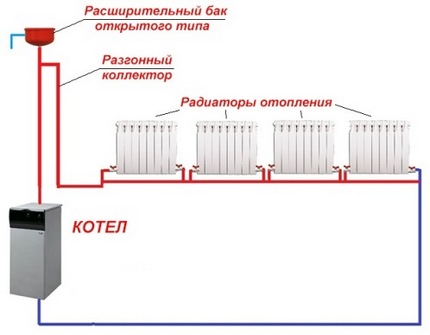

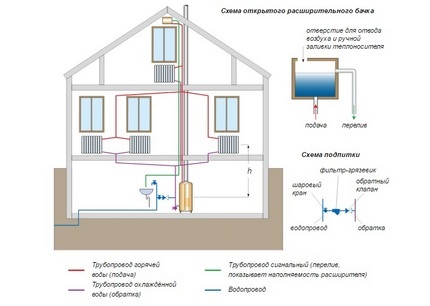

- closed and open system heating. Open at the top point has an expansion tank that receives heated water, which when heated, expands. Thanks to the open barrel, a natural circulation is formed.

Note! Modern heating boilers equipped with a closed flank. In this case, it is completely sealed. If an extension is required, it is carried out by means of a diaphragm. The system with the closed flank operates exclusively in forced mode by means of a circulation pump. Due to this, the metal parts of the system do not rust due to lack of contact of water with air. Their differences lie in the fact that closed systems are electronically controlled, and open systems are characterized by the simplicity of the device.

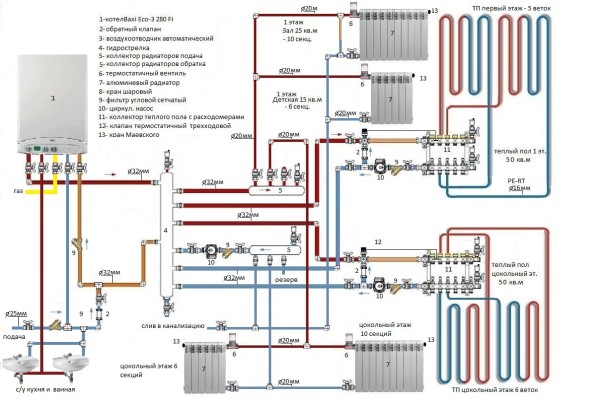

Having made a decision on all the above issues, you can proceed installation work, namely the installation of a boiler, radiators, shut-off valves and heating pipes. Now everything is consistent.

Principle of installation. Boiler installation

Installation of heating in any case begins with the installation of the boiler. As a rule, the place for its installation should be easily accessible for the supply of pipes to it. If a gas boiler is chosen, it should be installed near the gas source. As for the electric boiler, the possibility of cable laying plays an important role here. Well, in those cases where solid fuel boilers are installed, they are guided by the location of the chimney. The basic value of the boiler installation is only for water heating systems, which are based on the principle of natural circulation. In this case, it is important that the return is as low as possible. If you bought a wall-mounted boiler, then its installation is carried out on special mounting plates, which are fixed to the wall by anchors or dowels. If floor - it is put on stationary feet.

Installation

So, before beginning the laying of pipes it is necessary to install all purchased radiators in place. In most cases, the place of their installation is under the window and near the entrance to the apartment. From the type of radiator you bought, the method of installation will depend. Accordingly, if the radiator is heavy, then the mount should be selected more powerful. Exist general rules on how to properly install radiators. For this, it is important to use the level, since they require an ideal horizontal line. The minimum distance from the floor should be 60 mm, and from the window sill at least 100 mm. Also it is necessary to connect to the radiator all the necessary shut-off fittings, which will allow to disconnect and dismantle the radiator if necessary.

When the radiator is installed it is necessary to connect it correctly. The connection will again depend on the type of batteries. If they are paneled, then they have only two outputs, and there is no particular choice. In the other case, if the radiator is sectional, then there are already four holes. If you decide to single-pipe system heating, it is best to use the lower holes. If you use one upper, then the cooled dense water will stagnate in the radiator.

In the event that you decide to use a two-pipe heating system, you can choose several options. For example, you can use both holes on one side. At the same time in the upper - water will flow, and in the lower - go. In this variant, it is possible to mount a bypass, which is a jumper between the output and the inlet branch pipe.

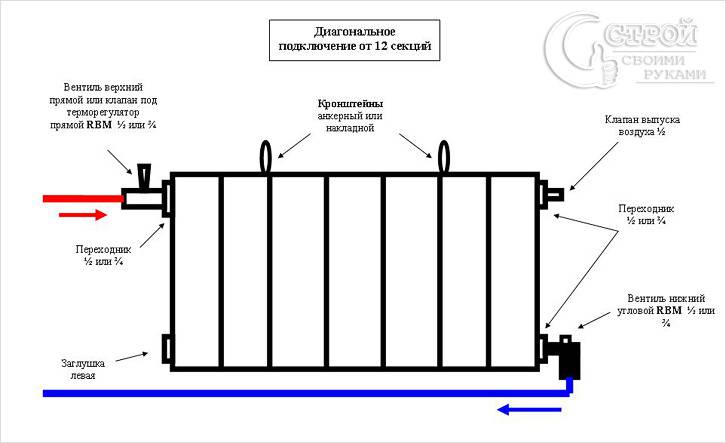

Note! There is a variant of connecting diagonally. However, this connection is preferred when using long batteries consisting of at least ten sections. The result will be as follows: the input of warm water at the top left, and the exit - at the bottom right.

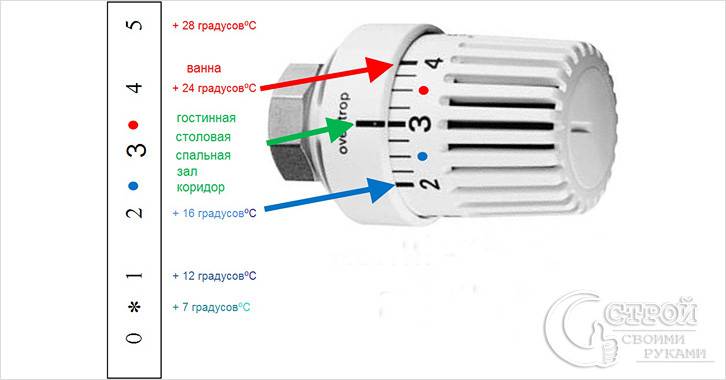

Installation of cranes and thermal heads

Deciding how to connect the radiator, think about installing the cranes. The crane is installed at the entrance and exit. In most cases, they will be useful in case of an accident, moreover, they can regulate the level of heat transfer. If you use a single-pipe system, you can adjust the temperature of all the radiators evenly using the valves. A great advantage can be brought by thermal heads, which cut off the flow of the coolant when the specified air temperature is reached. However, you will not see the temperature scale on it, the maximum is incisions or numbers. Using the experiment method, you can adjust the thermal head to the desired temperature.

Their special benefit is felt in those rooms or rooms where there is a risk of overheating. How can I explain this? For example, you heat your two-story house method two-pipe system. In this case, the coolant heats up first of all the radiator installed in a small dressing room on the second floor, and only then falls to the first in a large room. Accordingly, until the temperature on the first floor reaches the required level, the second one will be "Tashkent". However, if there are thermal heads installed, then overheating of a room is prevented. The heat will be diverted to a colder room, and for a certain time there will be a stable one temperature.

Now that the boiler, batteries are installed, and the thermal heads and bypasses are mounted, pipes can be started. However, first we will consider which pipes are best to choose, and then we will talk about the technology of their installation.

Pipe Selection

So which pipes to choose for water heating? Today there are several options, each in its own way best. However, as far as prices are concerned, then the spread is great. For example, copper pipes can be called the best option for heating. They have a number of advantages, and not one pipe can compete with them on an equal footing. But there is one big drawback - not everyone is ready to pay a lot of money for them, moreover, do the installation of heating from copper pipes it will be difficult on its own. This also applies to metal pipes, which are expensive and troublesome to install. However, there is one the best option, namely polypropylene pipes.

Note! Polypropylene pipe and all component fittings must be marked with PH25. This plastic has reinforcement. Its presence makes it possible to keep the pipes when they are heated unchanged.

Reinforcement on polypropylene pipes can be made of metal or fiberglass. Great demand use pipes with fiberglass. They are easier to install, because they are soldered with special equipment.

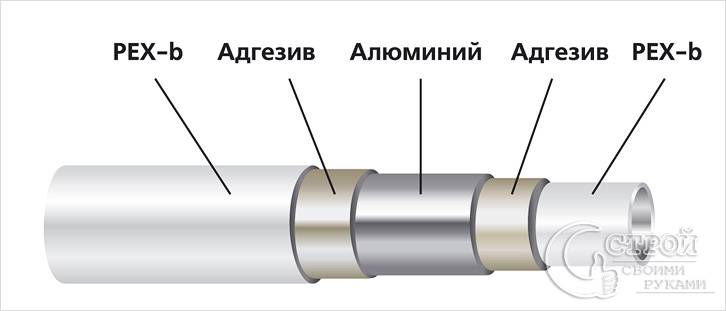

There is a cheaper option - metal-plastic pipes. They have a thin layer of foil or metal. This reinforcement is in the middle between two layers of plastic. It is best to buy pipes in which the reinforcement is closer to the middle, since it will be much easier to solder them. If the foil is located closer to the outer wall, then before soldering it will be necessary to peel the foil or buy the compression fittings, which will be much more expensive.

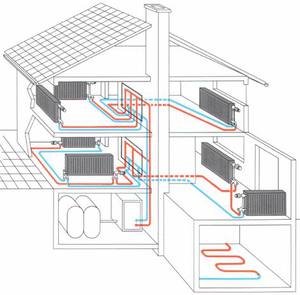

Sequence of pipe routing and installation of additional equipment

![]()

Regardless of what type of pipe you bought, start their installation from the boiler. First, the boiler is tied up, and then with the help of special tees, corners and other connections, the whole pipeline is assembled from the radiator to the radiator. It should be noted that there are two methods of wiring, hidden and external. Hidden refers to the drowning of pipes in the wall. To do this, preliminarily stitched ditches, which are then covered. The open wiring speaks for itself - the pipes remain on the surface.

As the wiring is performed, the batteries that already have a stop valve are connected, other necessary equipment is installed. For example, it could be a circulation pump, a pumped storage tank, air valve, filters, safety blocks, expansion tank, etc. The completeness of the equipment will depend on which heating system you have - single-pipe or two-pipe.

That's how the installation of water heating. At first glance it is very difficult. However, if there is a strong desire, it will help to understand all the schemes, in connection technologies, in the choice of material - batteries, boiler, pipes. If you have already made this or that heating system, we will be happy to receive your valuable recommendations in the form of comments on this article. Conversely, if you have any questions or you have a problem, write to us.

A photo

Two-pipe with natural circulation

Two-pipe with natural circulation

If a country house is actively used not only in the summer period, but also in the cold season, the creation of a qualitative heating system in it is an urgent need. In heating systems, different heat carriers can be used: air heated to 60 ° C, water vapor at 130 ° C and water at 105 ° C. Sometimes water can replace the antifreeze. The topic of this article is the water heating system.

Depending on the location of the place of production of heat, water heating systems subdivided into centralized and local.

In a centralized manner, heat is supplied, for example, apartment buildings, all kinds of institutions, enterprises and other facilities. In this case, heat is generated in CHP (combined heat and power plants) or boiler houses, and then delivered to consumers through pipelines.

Different systems of water heating differ from each other by the type of wiring and the way in which the devices are connected. Combines their type of coolant, which transfers heat to heaters

Local (autonomous) systems provide heat, for example, private homes. It is produced directly at the heat supply facilities themselves. For this purpose, furnaces or special units operating on electric power are used, natural gas, liquid or solid combustible materials.

Depending on the way in which the movement of water masses is ensured, the heating can be forced (pump) or natural (gravitational) movement of the coolant. Systems with forced circulation can be with ring circuits and with circuits of primary-secondary rings.

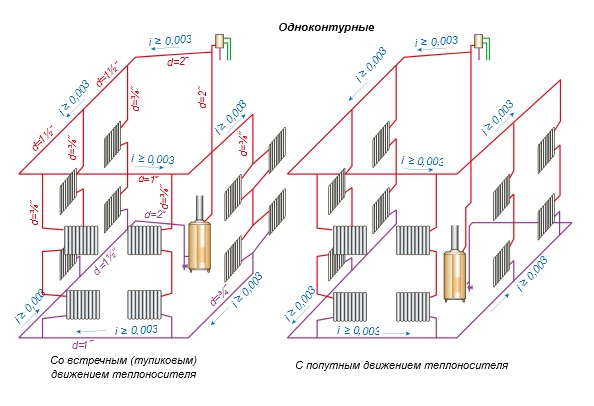

In accordance with the direction of water movement in the supply and return lines, the heat supply can be with the associated and deadlock motion of the coolant. In the first case, water moves in the roads in one direction, and in the second - in different directions.

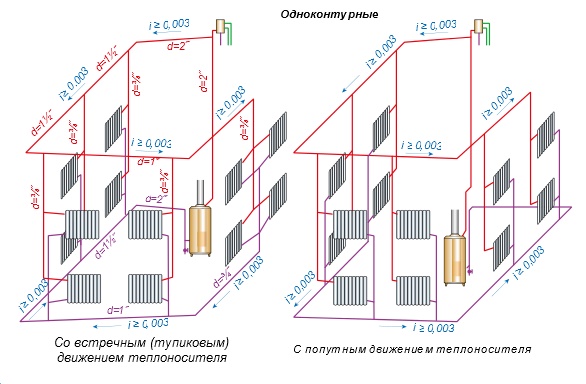

In the direction of motion of the coolant, the systems are divided into dead-end and counter-flow systems. In the first, the flow of heated water is directed in the direction opposite to the direction of the cooled one. In passing schemes, the motion of the heated and cooled coolant occurs in one direction (+)

Heating pipes can be connected to heating devices in different circuits. If the heating devices are connected in series, this scheme is called single-pipe, if in parallel - two-pipe. There is also a bifilar scheme, in which all the first half of the devices are firstly connected in turn, and then, in order to ensure the reverse outflow of water, their second halves.

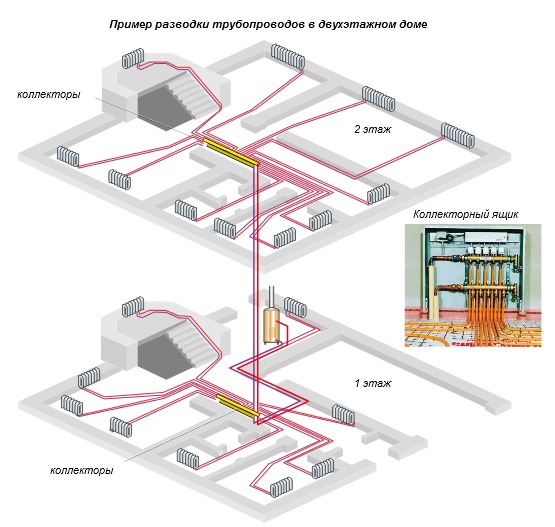

The location of the pipes connecting the heating devices gave the name to the wiring: it distinguishes between its horizontal and vertical variety. By the method of assembly, collector, tee and mixed pipelines are selected.

The schemes of heating systems with top and bottom wiring differ in the location of the supply line. In the first case, the feed pipe is laid over the devices receiving the heated heat carrier from it, in the second case the pipe is laid below the batteries (+)

In those residential buildings where there are no cellars, but there is an attic, heating systems with a top wiring are used. In them, the supply line is located above the heating devices. For buildings with a technical cellar and a flat roof, heating with a lower wiring is used, where the water supply and discharge lines are below the heating devices.

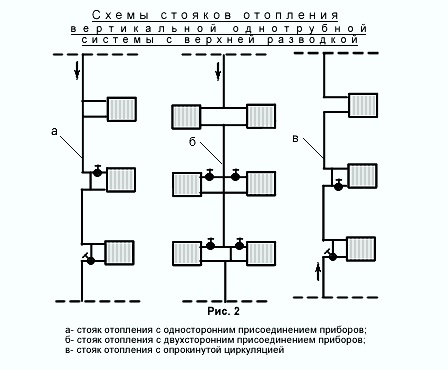

There is also a wiring with an "overturned" circulation of the coolant. In this case, the reverse heat main is located below the appliances.

By the method of connecting the supply line to the heating devices, the systems with the upper wiring are divided into circuits with a two-sided, one-sided and overturned motion of the coolant

Requirements for the operation of water heating

With a wide variety of water heating systems, a number of general requirements are imposed on their operation.

They have to:

- evenly heat all air in the rooms;

- be repairable;

- do not create difficulties in the process of operation;

- to be connected with ventilation systems;

- to be regulated.

The principle of the heating system is common: the water is heated, after which it circulates through the pipeline and gives the received heat, warming the rooms.

The coolant in winter can serve as an antifreeze liquid - antifreeze. That the existing in its composition of ethylene glycol does not cause corrosion of pipelines,

Calculations of equipment capacity

The temperature inside the premises depends on the following factors:

- from the outside air temperature;

- from the thickness of the walls of the house and the quality of its individual elements;

- from the ability of the materials from which the house is made, to keep the heat.

Counting the need for your home in heat, you need to consider all factors, including heat loss through windows and doors, walls and floor with a ceiling. Special standards required in the calculation process should be applied taking into account the climatic conditions of the terrain in which the residential facility is located and the degree of existing thermal insulation.

The general sense of the calculation is to calculate the total heat loss corresponding to the minimum air temperature in your region in order to purchase equipment capable of compensating these losses

The greatest heat loss occurs through the exterior walls of the house. With the increase in the temperature difference inside the house and outside the building, heat loss also increases. If we take into account the material from which the outer walls were erected and the thickness of these walls, then for external air temperature - 30 ° C, the heat loss will be different and will be:

- Brick with internal plaster - 89 W / m² (in 2.5 bricks), 104 W / m² (in 2 bricks);

- Chopped with inner lining (250 mm) - 70 W / m²;

- Of the timber with internal lining - 89 W / m² (180 mm), 101 W / m² (100 mm);

- Frameworks with expanded clay inside (200 mm) - 71 W / m²;

- Foam concrete with internal plaster (200 mm) - 105 W / m².

However, heat loss occurs not only through the outer walls, but also through other enclosing structures. At the same - 30 ° C they will be for:

- Wooden floors of the attic - 35 W / m²;

- Wooden floors of the basement - 26 W / m²;

- Double wooden doors without insulation - 234 W / m²;

- Windows with a double frame made of wood - 135 W / m².

To calculate the total heat loss of the building, you need to calculate the area of all enclosing structures in square meters, multiply by the standard of heat loss by types of structures, taking into account the materials from which they are made, and summarize the results.

Calculations should be made based on the minimum seasonal temperature of a specific area. The loss of heat through the walls is calculated separately, because it is necessary to take into account the area of the glazing and doorways. Losses through ceilings without hatches in the attic or in the underground are calculated for the entire area as for single structural elements.

The heating boiler is chosen taking into account the fact that its capacity should be sufficient to compensate for heat loss with 20-30 percent reserve.

The procedure for calculating the thermal capacity of the equipment that will be used to install the heating system is given in the video clip in the final part of the article.

Water heating systems

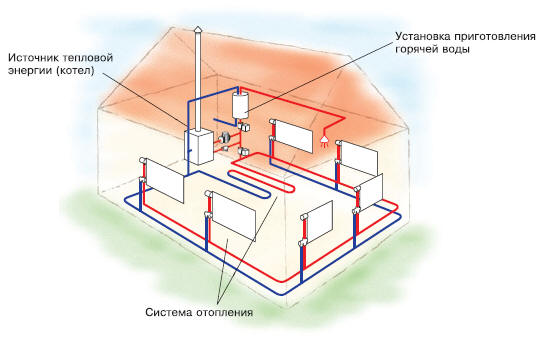

With all the external differences and different connection schemes, the basic principle of operation of water heating systems is the same. Heated in the boiler coolant is transported through the pipeline to the heating appliances. Cooling down, the water transfers the environment to the heat, then returns to the place where it will heat up. This cycle is repeated again and again.

Natural and forced circulation

In private houses, the following types of heating systems are used, which should be carefully considered:

- with natural circulation;

- with forced circulation.

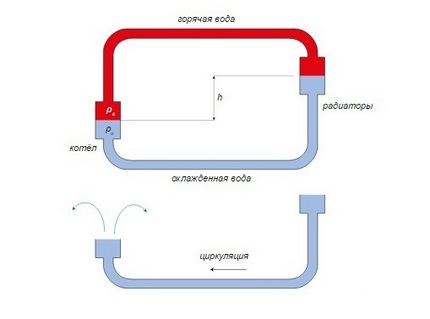

Hot and cold water have a different density - this is the basis of the principle of natural circulation of water masses. The top positions of this system are warm water, and the bottom - cold. Cooling down, warm water moves downward, and warming up. The second factor that ensures the natural circulation of water masses is the slope under which the pipes are installed.

Thus, the sources of circulation pressure are represented graphically. First, its appearance is due to different water temperatures, and, secondly, the slanting position of the pipes

The advantage of natural circulation is its complete independence from energy supply. She has much more flaws:

- a short range, not exceeding 30 m in the horizontal dimension;

- a long period of achievement of operating temperatures in all points of the system at start-up after a long break;

- the risk of stopping work due to the formation of ice in the open expansion tank.

The diameter of the pipeline must be sufficiently large due to the low circulating pressure in the circuit. This factor also affects the choice of batteries, because modern radiators They have a too narrow section, which creates additional resistance, which counteracts the circulation by "gravity".

In order to further stimulate the movement of the coolant, the pipeline is built with a slope so that by 1 running meter accounted for an average of 3 mm. Proper installation pipes at the right angle - the task is not easy, but without solving it the system will function much more slowly and efficiently.

Due to the fact that the coolant is sequentially moved along the devices to the nearest to the supply line of the battery, it comes with a higher temperature (+)

To the distant radiators of gravitational systems, the coolant leaks already substantially cooled. To maintain the heating temperature, it is necessary to use cast-iron radiators. To balance the difference in temperature, long-range batteries should have more sections than those closest to the boiler.

Forced circulation provides a pump. There can be one or several pumps in the circuit. The use of several pumps is preferable: an emergency shutdown of one of them will not disable all the heating. The heat carrier is cycled along a closed loop, into which the expansion tank is connected, which eliminates the evaporation of water.

A distinctive feature of the water heating system with forced circulation of the coolant is the presence in the pump circuit, which facilitates the movement of water

Benefits forced circulation are as follows:

- for the installation of heating you will need more pipes, but smaller diameter;

- it is possible to use radiators of different types and heat pipes with small diameters;

- the temperature of the heaters is easier to adjust;

- the range of action is significantly extended due to artificial stimulation of the coolant motion;

- the possibility of using heating units with increased characteristics of the coolant.

Minus enforcement systems depends on the energy supply. In order to avoid incidents with complete inactivity of heating, it is recommended to stock up a diesel or gasoline generator. In addition to the shortcomings can be attributed:

- need for an accurate calculation of the diameter of the pipeline; too narrow channels will dramatically increase the hydraulic resistance, and when circulating over excessively wide pipes, the coolant will "make noise";

- considerable cost of the construction due to the almost double length of the pipeline, the inclusion of one or two circulating pumps, if necessary, the boost pump;

- mandatory use of non-expensive devices to regulate the flow of the coolant, its temperature and pressure in the system.

The correct choice of the type of circulation depends on the individual characteristics and location of the building in which water heating will be installed. However, to schemes with natural movement Recently, they have become less and less used, using them mainly in buildings for temporary residence. More often than not, private houses are equipped with systems with artificial coercion of coolant movement due to significantly greater possibilities.

Combined circulation systems

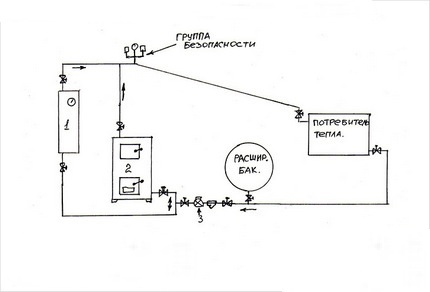

The combined system can function both in natural and in forced mode. This means that when installing it, it is necessary, as in the case with the use of natural circulation, to provide for the slope of the pipes by 3-5 mm per running meter, and also the installation of the pump, both for forced circulation. Usually in such a heating scheme there is a solid fuel boiler.

The scheme includes: 1-electric boiler, 2-solid fuel boiler, 3-pump. This scheme combined system heating, in which besides the pump there is an inclined system of pipelines, and the electric boiler is duplicated by solid fuel so that the system can work without electricity

The sense of using the combined system is that it will continue to operate even in the event of a power outage. But the sudden stoppage of heating work in winter threatens not only by lowering the temperature in the room.

Elements of the heating system can simply exit their system, since water, expanding when frozen, will break their tightness.

Ways of installation of water heating systems

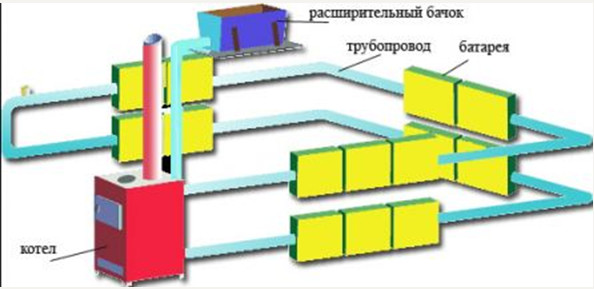

Let's consider two basic schemes of installation of heating systems.

The design of the pipeline in a single-tube version is characterized by a direct sequence of the coolant supply to the radiators. The heat carrier fills and warms first the first battery, then the next, and so on. From one pipe to each radiator two nozzles are supplied: the first one is needed for the supply of a coolant, and the second one for the removal of partially cooled water.

Single-pipe heating system is characterized by the consecutive connection of all radiators, in which the coolant, after passing the first heater, enters the next

The peculiarity of this scheme is a relatively low heating of the last battery in comparison with the first one, since water "reaches" before it, having already given part of its heat. Another disadvantage of the one-pipe variant is that it is impossible to stop the delivery of the coolant to one particular radiator, in the event of a breakdown. I'll have to disconnect the entire system.

Two-pipe system and its variants

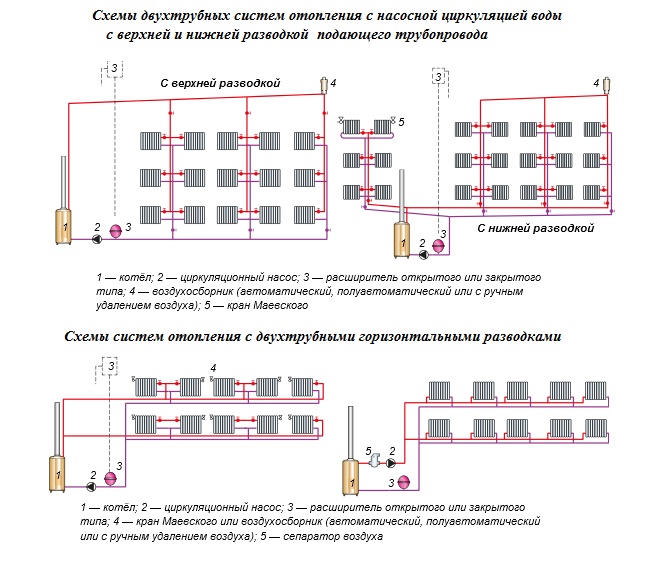

In the two-pipe heating scheme, as it is already clear from the name, not one, but two pipes are involved. At the same time, each of the batteries is connected to the main line by a single branch pipe, along which the coolant is supplied, and the second - to the pipeline with a return flow. It turns out that separate pipes are provided for the hot and cooled coolant.

In this system, two pipes are involved: one goes hot water entering the radiators through the branch pipes, and the second of the batteries is followed by a cooled coolant

Thanks to this heating design, the water in all radiators has practically the same temperature. The operation of such a system is easier to control, adjust and automate.

The two-pipe system, in turn, is divided into two types:

- with the upper gasket of the supply pipe, i.e. with the top wiring;

- with the lower gasket of the supply pipeline, i.e. with a lower wiring.

Two-pipe systems with top wiring are built mainly in multi-storey houses with an attic space. Schemes with a low wiring in priority in private low-rise construction, because they allow to hide the gas pipeline as much as possible and to eliminate or reduce the number of risers.

A two-pipe heating system for a private house is often carried out by collector circuit, although the latter can be single-tube. The radial location of pipeline sections allows to significantly reduce the cost of heating the coolant (+)

Comparative characteristics one-pipe and two-pipe heating system is given in the video material, which is located at the bottom of our article.

Open and closed heating systems

In addition to the types of water heating systems we have already considered, there is a division into an open and closed structure.

The open heating system consists of a boiler (any one is used except electric), pipelines, radiators and expansion tank, which receives excess water during its expansion during the heating process. The tank is not sealed, the water from the system can evaporate, so its level should be monitored and topped up if necessary.

In order for the open heating system with the upper wiring and natural circulation of the coolant to work more efficiently in winter, the feeding riser is recommended to be insulated. This measure will exclude cooling of the coolant and, as a consequence, slowing its movement

The pump is not used in open design. The heating boiler is located at its lowest point, and the expansion tank is at its upper point.

The closed design is hermetic. It includes all the same elements as in the open. But since the movement of the coolant in it is forced, the mandatory list of elements is supplemented by a circulation pump.

The expansion tank, which is part of the closed structure, consists of two rolled parts separated by a diaphragm. If there is a surplus of dilated fluid in the system, it enters one of the chamber chambers, pushing the diaphragm into a second chamber filled with nitrogen or air.

With the expansion of the coolant, the pressure in the system rises, part of the tank filled with water, strives to displace and compress the gas mixture. When the limit value of the pressure is exceeded, the safety valve in the reservoir triggers the excess coolant.

Closed heating system is characterized by forced movement of the coolant and the presence of a closed expansion tank with a membrane; this system is more complex than the open one

Each of the heating systems has its own advantages and disadvantages. They differ in a number of characteristics and are suitable for different objects. If you need to heat a small private house or cottage, use a simple and reliable open structure. More complicated in installation and operation, closed system is more often used in solid cottages and in multi-storey buildings.

Elements of the heating system

Since we are going to install water heating in the house with our own hands, we need to have an idea of the constituent elements of the proposed design.

Choosing the right boiler

The boiler is the heart of the heating system. It is very important to choose it correctly, since the reliability of the heat supply depends to a large extent on it.

Heating boilers can be used as one, or steam, for example, in addition to an electric boiler, a solid fuel can be introduced into the circuit in the event of a power outage

Depending on the fuel used in the boiler, the following types of these devices are distinguished:

- Gas. This boiler is most popular with consumers. It is easy to install, it works without unnecessary noise. Gas costs relatively inexpensively and generates a lot of heat when burned. But for its use you need to get permission, order the installation of the supply line and organize the exhaust ventilation in the boiler room.

- Electric. These boilers are the safest. The place of their installation does not need to be additionally equipped. At their work, there is no open flame and products of combustion, which could be poisoned. But the efficiency of this device is relatively small, electricity is expensive, and an energy-intensive boiler requires a reliable electrical network.

- Liquid-fueled. Unlike gas, these boilers are equipped with burners of a special kind. A special boiler room is needed for this equipment. Liquid fuel quickly pollutes the boiler.

- Solid fuel. These devices burn coal briquettes and other types solid fuel. A special pedestal is needed for these boilers.

- Wood. If you are ready to harvest firewood for the entire cold season, then you can use a wood-fired boiler.

The most reliable are considered combined boilers, in which different types of fuel can be used. The disadvantage of such equipment is only one - such boilers are expensive.

What are the radiators

In order not to be disappointed as a result of the work done, it is necessary to approach the selection of radiators responsibly. Orientation in this case should not be so much aesthetic qualities as specifications batteries. And technical properties largely depend on the material of manufacture of these products.

Modern cast iron radiators can look very attractive, especially if the interior of the room as a whole is consistent in one style with them

Radiators are:

- Steel. These inexpensive products are too prone to corrosion. If in the summer when the heating is not used, the water from the system is drained, the life of the steel radiators can be significantly reduced.

- Aluminum. These attractive radiators warm up rather quickly. Negatively, only significant pressure drops affect them. In private homes, this danger does not threaten them.

- Bimetallic. Such batteries from aluminum got resistance to corrosion, and from steel - high heat transfer.

- Cast-iron. These products are expensive, but they will last a very long time. They are heated for a long time, but they cool down for a long period of time. A significant weight of cast iron products is not an obstacle in their operation, but can slow down the installation process.

There are new models of radiators, the inner surface of which is covered with a protective coating. Such batteries stand a little more expensive, but the money spent on them pays for themselves.

How not to go wrong with the pipes

Many pipes are required to install the heating system. Which of them should you prefer?

When installing a water heating system, you may need a lot of pipes, so you need to calculate the appropriateness of purchasing expensive products and focus on your real capabilities

- Metal. The service life of such pipes is not too great. Over time, metal products can rust. They are mounted using threaded connections.

- Copper. This is a very expensive material, but the cost of it justifies itself. Such pipes are reliable and durable. They tolerate the rise in temperature and pressure well. For their installation use soldering - silver-containing high-temperature solder.

- Polymer. This is an inexpensive, but sufficiently reliable material, characterized by resistance to corrosion. Even an amateur can mount these pipes. Serves as a pipeline from polymer pipes a very long time.

- Metal-plastic. As part of these pipes, aluminum and plastic. Piping from them is collected on threaded or compression joints. As a side effect of the high coefficient of thermal expansion of these pipes, they can crack when the temperature of the water changes drastically.

All that we told you above, concerned the radiator water. But water as a coolant can be used in other heating systems.

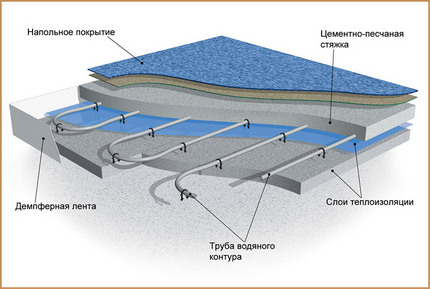

Water system "Warm floor"

"Warm floor" can both successfully supplement the radiator water heating, and become the only source of space heating, if it is a low-rise house. The huge advantage of the "Warm House" is that this system provides conditions that fully meet the sanitary and hygienic standards of the premises. On the height of the room the air is warmed unevenly: it is colder in the upper part of the rooms, and warmer in the lower part.

The warm floor is a remarkable invention that allows the room to warm up in height in full accordance with the sanitary and hygienic standards imposed on it

The system temperature is only 55 ° C, which corresponds to the design noma. Installation of "Warm Floor" pipes is carried out on the entire floor area of each room. This is quite a difficult job, which can be done qualitatively only at the stage of building a house. The operation of the "warm house" also causes a number of difficulties.

Plinth heating system

If the installation of the "warm house" is difficult, and the radiators spoil the interior of the room, you can use the baseboard heating system.

At this type of heating, the pipes are installed behind the plinth, that is, just above the floor level. In this case, the room, like in the case of "Warm Floor" warms up in the right order.

Due to plinth heating, there is no need to puzzle over how to fit into the interior a country house pipelines, collectors and radiators, so they are not conspicuous

At the same time, there is heating of the floor, which creates favorable conditions at any time of the year. Heating under the plinth is becoming more popular and gradually comes into fashion.

Additional video materials

Correctly choose the system of water heating, which will be most effective for your home, this video will help, in which two-tube and one-pipe designs are compared:

When you have already chosen the suitable installation scheme for you and are ready to start creating water heating yourself, you will need to perform a calculation of the thermal capacity of the equipment used to install the system. Look at this video and the calculation will not cause you any difficulties:

The house in which you are going to live all year round, needs heating during the cold period. To ensure that the living conditions are comfortable, you need to choose a water heating system that is most suitable for your individual conditions. We hope that the information contained in this article will help you make the right choice. After all, high-quality heating is not only comfort and coziness. This is also a prerequisite for maintaining your health.

To equip a comfortable life away from a dusty, dirty city, traffic jams and eternal ceaseless noise, every citizen dreams in his soul. No neighbors, clean air, coziness and nature around. For a comfortable life in a country house necessary modern amenities provided by civilization: light, heating, water. There are no problems with light, electrification in the country at a level, a well is being drilled for water. But with heating is more difficult. To stoke every day a Russian oven made of bricks is not modern. A good solution will be water heating private house , made by own hands, its schemes are simple and understandable.

The principle of operation of water heating is as follows: the house is stretched out metal pipes and radiators (batteries) are installed. The pipes flow hot water, getting into the batteries, it gives heat to the surrounding space, heating the home.

Within the city, the houses are heated with the help of heated water, which is piped through the boiler room throughout the city. For a private house you will need your own system and boiler room.

The simplest system of water heating consists of the following parts:

- Boiler;

- Pipes;

- Radiators;

- Pump;

- Expansion tank.

Boiler

Without a boiler, the heating will not work. It heats the water, the right choice depends on whether there is enough heat, whether the system is really economical. As a result of burning fuel, the boiler heats up, water flows through it, takes heat and sends it to the heating system of the house.

Boilers differ in design, type of fuel, the availability of computer control and even the ability to automate the supply of fuel.

The most popular boilers for the conditions of Russia operate on wood fuel and gas.

The main parameter of the boiler is its power, it is measured in kW and is calculated based on the area of the house. The fuel type is chosen from personal preferences and storage options.

For gas-fired boilers, a gas storage tank is installed in the land on the site for the house, which can be filled with a special equipment. Capacities are calculated for the season. The presence of a pressure vessel on the site is safe enough. Gas is much cheaper than all existing fuels.

For wood-fired boilers (firewood, coal, pallets), a boiler plant, fuel storage and a safe storage for ash will be needed. Ash Are unburned residues of wood fuel, which eventually contaminate the boiler. Periodically, such a boiler must be cleaned of carbon, unload the ash and unload into a non-burning container.

The ash outside the boiler can smolder within three to four days and can cause a fire. Cooled ash is used as a fertilizer.

To maintain the combustion of the boiler must be loaded with fuel. Depending on the design of the boiler, capacity and size, this will need to be done once an hour or several days. The boiler room should be equipped with a fire-extinguishing system and an alarm system. If everything is done correctly and with proper operation, the solid fuel boiler is absolutely safe.

Modern boilers are not just stove-burzhujki. Their design is much more complex and it provides the maximum efficiency, the more advanced the boiler in terms of technology, the better and more completely burns fuel and less remains unburned parts. Technological boilers can require a certain type of fuel. The boiler working and designed only for expensive Finnish pallets, on local analogues will not flare up and reach the working, economical modes.

Modern boilers are equipped with electronic and computer control systems, which allow you to monitor the temperature in the room. On their basis, you can realize even a kind of "smart house" - organize the management of the boiler based on the application for a smartphone or via SMS. Such a house will be able to save heat while the owner is not at home and warm up before his arrival.

Boilers with automatic fuel supply are equipped with tanks and mechanisms, which themselves load the boiler with fuel, for a while, relieving the owner of the stoker's work.

Heating water can be and electric boiler, they are the easiest to use and maintain. They only need to connect to the network. But the energy consumption will be very large, and electricity bills shock the owner of the house.

The cost of heating electricity at least 4-6 times more expensive than gas or wood.

Any boiler can also perform the function of separate heating hot water for domestic needs. Either in conjunction with a fuel boiler for such a case can be installed electric.

Pipes

Used steel or plastic, the difference in the method of installation. The only thing worth considering is their diameter - it should be sufficient to pass through them the right amount of water. When installing pipes it is necessary to take care of the necessary quantity of stop valves and the organization of a water discharge system. If the boiler is broken, the water in the pipes can freeze. Of course, this does not happen instantly, in a warm house, the process will take several days. But if it does happen, it's impossible to start the heating system with frozen water in the pipes. Remains only to cut them and mount new ones.

To prevent such troubles, it is necessary to monitor the condition of the boiler, isolate the pipes that are on the street and drain the water in any doubtful situations.

Some home owners fill the pipes with antifreeze. But this is not a panacea either - antifreeze can turn out to be substandard and diluted with water and freeze already at minus 12 degrees Celsius.

Connecting pipes or wiring may be single-tube or double-tube.

- In the first case, both outputs of the radiator are connected to one pipe, water flows both through the radiator and simultaneously through the pipe further. This scheme is simpler, but its efficiency is less, since some of the hot water will return without heat emission. Water will be easier to flow through the pipe than through the radiator.

- Two-pipe circuit connects the output and the input of the radiator to two different pipes: supply and return. The whole stream of heated water passes through the radiator and rushes along the other pipe back to the boiler. Such a system will require more wiring, but its efficiency is incommensurably higher.

Radiators

Radiators -these are devices for transferring heat from the coolant, they are calculated based on the parameters of the system. Their areas should be optimal, water must pass through them and give the maximum amount of heat.

Heat transfer is an important characteristic that shows how efficiently the radiator radiates heat to the surrounding space.

Pump

For heated water to be sent to pipes it is necessary circulation- movement of water. Natural circulation Is the movement of water without the influence of artificial factors. Considering that one part of the water is constantly heated, and the other is cooling off, this movement occurs on its own. But too slow. A boiler without water movement will overheat, which can lead to its explosion or triggering of emergency equipment. In order to achieve good water circulation, additional pump. It transports water from one part of the system to another, in a closed circle. Its characteristics are calculated based on the parameters of the heating system. Too powerful a pump will drive water too quickly, and it will not have time to give up its heat on the radiators. Insufficient power pump will not take enough water, it will be cold in the house, and the boiler will overheat.

It is better to install two pumps, in case one burns. Without the heating pump it will stop.

Expansion tank and make-up system

Expansion tank or accumulator tank, is a metal barrel that connects to the heating system. If the water pressure in the heating system falls (leaking), some of the water is taken from this tank and the system continues to operate normally. If the pressure rises (the boiler starts to overheat), the tank first accumulates water in it, and then pushes it through the safety valve, which opens when the pressure is exceeded and protects the pipes from ruptures.

Manometer- a metrological instrument that measures the pressure in the pipe section or in the boiler. The more they are installed, the better. With the passage of time, they fail and begin to lie ungodly, so they should be checked at least once a year. If there are problems in the operation of the heating system, the pressure gauge will help determine where.

For the normal implementation of the water heating system, specialists will need help. It will be necessary to accurately calculate the area of the house, the thickness and material of walls, windows, doors, the effect of cold wind on the premises. After this, the calculation of the boiler and pump power, the length of the pipelines, necessary equipment. The installation of the entire system is a complex procedure that requires knowledge of the nuances and experience.

Thermal circuit

For heating to work economically, it is necessary to create thermal circuit. This is a closed room where heat accumulates.