Warm floor with your hands: leveling and laying the insulation. The device and installation of an electric warm floor - cable, on the base and infrared.

In the process of construction or repair, homeowners always think about how to make living more comfortable. Nowadays the device of a warm floor is very popular. But many people reject this idea, since installation works are very expensive. But you can save and make an electric warm floor with your own hands. How? - Read our article.

Types of electrical floors

The modern warm floor connected to the power grid is presented in the form of a system of cables, or TEN, connected in mats. A separate group consists of innovative designs, which include infrared rods, and film models.

But all these options have a number of common features:

- The floor must be dry before installation;

- Mandatory grounding and thermal insulation;

- The equipment has a thermostat;

- The service life is quite long.

But there are differences, presented by the features of installation, the quality of the heat produced, interaction with floor coverings.

Cable floor heating

- Such a system has already become a classic, as the design is very convenient and reliable.

- Such a floor consists of a cable cut by sections, a sensor for temperature control and a temperature controller.

- Thus, the system switches on only after the temperature has dropped below a certain level.

Important! You can use simple thermoregulators, and more sophisticated devices that monitor not only the temperature of the floor, but also the temperature on the street.

Thermomat (thin cable floor on the grid):

- At manufacturing use very thin cable fixed on a grid from fiber glass.

- The heating conductor in the cable is surrounded by a shield, insulation and protective sheath.

- Cable in mats can be single- and double-core. Two-core models are used to heat rooms in which people are constantly, because they are distinguished by a low level of electromagnetic radiation.

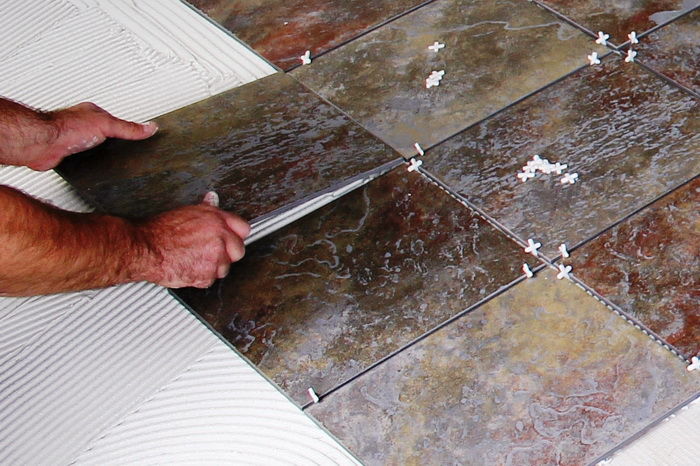

Important! A thin cable floor is laid on the old tile or the finished screed. For laying under the tile, this option will be the most optimal.

Infrared warm floor

In this type of floor heating element, through which passes electricity, begins to emit electromagnetic waves, due to which there is an increase in the temperature of all objects that are in their way. In this there is a similarity between the infrared floor and the sun's rays. Heat from the conductive element passes into the floor covering, which lies on top, and from it the heating of air already takes place.

Different kinds of floor heating require different finishing floor coverings:

- Cable flooring and thermometers - one should choose ceramic tiles, laminate or granite;

- Infrared film and carbon fiber rods - laminate, carpet, linoleum or wood.

What do I need for editing?

Before you learn how to lay a warm floor electric with your own hands, you should decide on the necessary tools and materials.

So, it is necessary to acquire:

- Thermal insulation (expanded polystyrene or polyethylene foam with a layer of foil);

- Dowels or special glue;

- Grid for plaster;

- Primer;

- Dowels with washers or clips made of plastic;

- Cable;

- Thermoregulator and mounting box for it;

- Thermal sensor;

- Corrugated plastic tube;

- Puncher;

- Alabaster;

- Sand and cement;

- Fibers and plasticizers;

- Mounting tape;

- Toothed spatula;

- The container in which the solution will be mixed.

When everything is prepared, you can proceed with the installation work.

Level the floor and lay the insulation

Electrical warm floor by hand, installation and laying starts with a thermal insulation layer:

- Most often in this case, use polystyrene foam of density 35.

- If there is a room below that is heated, its thickness should be 20 mm, and if not heated - 30-50 mm.

- The only exception is private houses with a concrete foundation laid on the ground. In this case, the thickness of the insulation must be at least 100 mm.

Lay the insulation layer after the floor is completely flat. It should be free of pits, cracks and distortions.

Important! If there are defects in the screed, they get rid of them with the help of cement. If there is a skew and significant damage, you need to make a new screed.

When the floor has become level, it's time to lay the insulation material:

When the floor has become level, it's time to lay the insulation material:

- The entire surface is treated with a primer. This stage is necessary in order to prevent the formation of fungus and mold.

- We glue the insulation or fix it with dowels.

- We lay the plaster mesh, fix it with the help of special clips made of plastic or dowels with hats.

Important! The length of dowels should be equal to the thickness of the layer of thermal insulation. With this fastening, the insulation is even better fixed.

We calculate the cable and prepare for laying

For heating to be productive, at least 80 percent of the room must be covered with a cable. Before the start of the laying process, the resistance of the cable sections must be checked, a deviation from the passport values of about 10 percent is allowed.

Important! The cable does not need to be stacked in places where heavy household appliances or furniture are.

When laying the cable from the walls you need to retreat by six to seven centimeters.

Important! Calculating the laying step of the cable, the following formula should be used: centimeters in step = heated area x 100 / cable length.

Installing the thermostat

We proceed as follows:

- Prepare a hole in the wall, shtrobim furrow to the floor.

- In the hole we insert the mounting box, fix it with alabaster.

- The corrugated tube leaving the box is placed in a furrow and covered with alabaster from above.

- The end of the tube is output to the heating zone and is located between the cable loops so that the thermostat is in the center.

Important! We lay the pipe without bends, in the location of the thermal sensor it is necessary to create an elevation with the help of a wooden bar. So do in order to achieve the location of the sensor immediately under the floor, and therefore - for the correctness of its readings.

- The end of the tube is tightly wound with an insulating tape so that no solution enters it.

We lay the cable

Before making a warm floor electric, you need to learn the rules of laying the cable. It fits in the form of a snake, while you must follow the previously measured step:

- We lay the cable, fix it with the help of screeds made of plastic.

- Check how well the system works.

- To mount the screed, a mixture of sand and cement is used, in the proportion of 3 to 1.

Important! The solution can be supplemented with suitable plasticizers or finished mixtures. It is possible to add fiber.

- The solution, which is laid on the mesh with the cable, should have a thickness of at least 4-5 cm.

- When the screed has dried, the floor covering is laid.

Important! For at least a month, the inclusion of a warm floor is prohibited, since the screed does not have time to dry completely.

Cable laying rules:

- When choosing a heating cable, the length is calculated based on the area on which heavy furniture will not stand.

- It is forbidden to cut the cable.

- Incorporation into the mains before full drying of the screed or glue solution will lead to a malfunction of the cable.

- The surface for laying the cable must be clean, for this you can use an industrial vacuum cleaner.

- The sensor should not be embedded in the solution - it is better if it is located in the corrugated tube, so it is easier to replace it in case of breakage.

- Where the cable is heated, there should be no air pockets in the screed. Otherwise - it can overheat and break.

As you can see, it is possible to install the warm floor yourself. But without the skills it is unlikely to succeed. If you are not sure that you will cope, it is better to call specialists for help.

A warm electric floor is considered a good alternative to water. Consider its types and features of work, popular systems in the modern market and, of course, installation - we will try to prevent some difficulties, and the most difficult steps will be duplicated by video materials.

1 Varieties of warm floor

If someone is sure that the concept of "warm" (more accurately - heated) sex has appeared recently, then let them prepare to be surprised: a system of such coatings were known even in prehistoric times. So, for example, one of the first mentions refers to Ancient Rome. Known from the 5th grade of the secondary school, the famous baths were equipped with a similar stone coating, in which hot air circulated through channels. Such inventions can also boast of world-famous Russian and Turkish baths. But at us not an antiquity, and time of new technologies, and therefore and ways of heating of floors in present apartments have left far ahead.

Today no one will already pull the pipes under the parquet and fill them with steam. The idea submitted by the ancients changed and exists as warm floors with circulating water or a heating cable. In short, the system is a system of flexible pipes laid under the upper layer of the floor covering, and the principle of operation is the same as that of ordinary cast iron radiator batteries installed under the windows. By the way, connection to central heating is one of the ways of functioning of such floor. The second way to raise the temperature under your feet - with the help of heating electrical cable. On its description, we will stop, we will analyze how the installation goes, we can not do without numerous videos.

2 What is the technology of heating the cable floor?

The subconscious fear that, despite all the guarantees of reliability, the floors with water heating can flood, if not you, the neighbors from below, makes you prefer the second option. The most difficult thing is laying, which is connected with the drawing of an electrical heating cable. It is necessary to accurately withstand the distance between the "steps" of the wire and handle it with care, without damaging the insulation braid and the central wire. After laying the heating element in accordance with the instruction, it is poured with concrete (the thickness of the layer is 3-5 cm). The power of the electrical cable can reach 18 W per 1 m. That's all. Installation in words seems elementary and understandable.

The wire can also be used with wooden flooring. In this case, the maximum power of the heating system should be a maximum of 10 W per 1 m.

More modern technologies It is no longer possible to arrange dances with tambourines when laying a single heating element, measuring a ruler with centimeters between turns. Significant progress was the installation of a warm floor with a reinforced mesh. It is a wide band of cellular material, inside which a cable is laid with a snake. Convenience consists in that it is not necessary to be excruciated, unwinding a bay with a wire, writing out them zigzags. You simply unwind the roll, cut off pieces of tape of the required length, and then connect the ends of the electrical cable located under the net. This type of warm floor is still called "matte", because the coating of reinforced parts reinforced with each other does create a sort of layer that looks like a mat.

And, finally, a more recent and, one might say, perfect invention - the infrared floor. It consists of two layers of polyester, between which are heating electrical strips of carbon. In appearance the film resembles solar cells. Its thickness is only 0.5 mm, that is a little more than a sheet of paper. It is fixed as an ordinary sticker, on any flat surface. This is the simplest method of installation, it is able to do it for each of us, and do not wait for the screed to set. The flooring is covered and furniture can be put on it immediately. Another advantage of the infrared electric warm floor is that it is the most economical and energy-saving alternative to other options.

3 Features of laying of a warm floor on electricity

If with the last kind of warm electric floors, there are no special problems in the field of installation, then laying the first and second will require skill. Let's analyze the general sequence of installation of cable heating.

How to lay a warm electric floor - step by step scheme

Step 1: Preparation

To begin with, all the manipulations with the floor are taken only after the repair of the ceiling and walls is completed. Installation should be carried out on a clean base and better that it was as flat as possible. Therefore, all sweep, wipe, and if necessary, then we are equal, even though we will make a screed. Its quality is important for the future floor covering, but for laying the cable, too, a surface without edges is very desirable. After this, it is necessary to walk along the contour with heat-insulating tape not more than 1 mm thick. Any artificial material can be used. So we isolate the walls from the screed heated in the future. The principle of tape application can be seen on our video. Naturally, you should not interfere with the plinth, but by this time you hardly managed to put them.

Step 2: Isolate

After hygienic and equalizing procedures, we proceed to laying the substrate of heat-insulating material. This is to ensure that the heat from the cable goes up, smooth flow and in no case warms the ceiling of the neighbor from the bottom. As such a basis, a special material with a reflective silver coating is used. For apartments located in multi-storey buildings, the thickness of such insulation in 3-4 mm will be quite sufficient. The material is secured with a stapler and a mounting tape. The main thing is that the joints between the sheets are minimal, and they themselves do not warp while laying. By the way, if you are planning to install a warm floor with a cable heater in a private house, the insulation can be taken and thicker.

Step 3: Stretching the Cable

Then, the cable is laid, which is fixed on the surface of the heat insulator with special clamps. There may be variations. So, for example, one technology provides for the stage of laying the waterproofing layer over the heat-reflecting material, on the other - the heating cable is placed on the plastic layer, and the top is fixed with polyethylene strips. Other kinds of works are quite possible, therefore here it is possible to tell only one: carefully read the instruction. And, of course, this stage of the work did not remain without a demonstration video, read it.

It is important to note that if it is decided to mount a reinforced cable, there should be no problems, but when using a single heating wire, the following parameters should be taken into account:

- the pitch of the electrical cable for the warm floor during laying should be 80-150 mm;

- the distance from the wall to the wire is 50-100 mm, from the water and gas pipes - 100-150 mm;

- bending of the cable during installation is not allowed less than 50 mm;

- connections of wires are always in the zone where the screed is filled.

Step 4: Screed

The next step is to fill the cable heater with a layer of screed, once the floor covering or the moisture barrier layer. Here it is necessary to look at many factors: the diameter of the wire, the characteristics of the room, the number of storeys, the floor material and so on. By and large, this is the main work on the installation of the cable floor ends. Next is the installation of a thermostat and control system. There are subtleties there, which are also indicated in the technical documentation, and how this will happen in general terms, look at the attached video. The rule is invariable: the test of the working capacity of the warm floor lasts about a day. If everything functions normally, you can proceed to the final part.

It should also be noted that when a small but very unpleasant trick may be waiting for: particles of air in violation of the proportion of substances for the preparation of a solution, they can form "pores" that can have a negative effect on the cable, and it may well overheat. To prevent this from happening, some cunning builders use the additive in the form of PVA glue in the proportion of 1 kg of substance per 1 bag of cement during installation. Thanks to this "compote", the layer becomes practically monolithic, and the heat emanating from the heating element is sent strictly to the destination.

Step 5: Finish

Now there is a final finish. If the floors were prepared for the tile, then the final pouring of the concrete screed. Then it remains to wait until it finally dries. There is one unpleasant moment: depending on the grade of material used for pouring, it will take a very long time to wait for it to harden. Sometimes it takes from 20 to 30 days! But do not be horrified at once, but just calculate all the options. Industry does not stand still, and it is quite possible that materials will soon appear, thanks to which the screed dries much faster. Finally comes a time when you can already make the final cover. There will be a tile, a linoleum, a laminate or a carpet - your business.

4 The most popular systems of warm electric floors

If some seven to eight years ago the Russian market was represented by three systems (Teplolux, Teplodor, Kailit), nowadays the list of companies whose products are installed in houses and apartments has significantly increased. Of course, we will not be able to talk about all of them, but there will not be any mention of some of them.

Three letters of AEG have already been seen by many of you, when you visited household appliances stores. Yes, these are the guys who invented the refrigerator in the early 20th century, and 50 years later - the first automatic washing machine!! Now, in addition to smart appliances, their company has mastered the production of equipment for floor insulation, which has its own characteristics:

- optional installation of concrete screed;

- does not require a moisture barrier layer;

- the thickness of the installed layer of reinforced mat is only 3 mm;

- self-adhesive base, eliminating the use of additional fasteners;

- teflon coating of conductors, increasing the warranty period.

Legrand - a famous French manufacturer, specializing in the production of electrical appliances. Take a look at the Leroy Merlin store closest to you and you will be amazed by the abundance of sockets, lanterns and accessories with this marking. As it turned out, there are also coatings for heating the floors in their catalog, and they have their own merits - aesthetics, simplicity, reliability.

Do not lag behind the European manufacturers and Koreans. So, RHE / GT company represents in Russia a floor heating system called Excel. Despite the "exclusive" name, the products can be called unique, and that's why:

- base - carbon rods, which allows you to significantly save electricity;

- automatically adjusts the heating;

- the stacking technology does not impose strict requirements on the coating, which will be above the warm electric floors further;

- ionizes the air;

- ideal for the "smart house" system.

The warm floor is now used almost everywhere. Most often it is equipped in bathrooms and children's rooms, on balconies. It is quite popular to use a warm floor based on an electric cable or an infrared film. Installation of an electric warm floor can be made independently. However, this must be done correctly. Otherwise, the system will not be effective.

Types of systems and recommendations for choosing floor coverings

Types of systems and recommendations for choosing floor coverings

There are such types of systems:

A small video, talk about the choice of electric floor heating systems:

What is necessary for installation?

In order to lay a warm floor on the basis of an electric cable, mat or infrared film, you must carefully prepare for work. First, you must choose the right components of the system. For example, you need to pay attention to the type of cable. It can be self-regulating or resistive. Both these types are successfully used in the installation of heating systems. But the second option should have good contact with the screed, and you can not put furniture on it. As for self-regulating cable, its only disadvantage is its high cost.

The thermostat is an important element of economical and reliable operation of the warm floor

The thermostat is an important element of economical and reliable operation of the warm floor Another important element of the system is. This is a special device with which the system maintains the set temperature. To choose it correctly, you need to consider such parameters:

- Type of product. The thermostat can be mechanical or electronic. The newer models are equipped with a liquid crystal display. It is best to use a device with the ability to program.

- Features of installation.

- Additional functions. Some models have built-in air temperature sensors, a self-diagnostic function.

- Power limit.

- Manufacturer and cost of the device. Naturally, in the market you can buy products of both domestic and foreign manufacturers. Advantage should be given only to popular brands with a good reputation. The cost of the product ranges from 50-200 dollars.

Features of installation of a cable floor

Installation of the cable floor

Installation of the cable floor Installation of an electric warm floor, which is based on a conventional cable, provides the following technology:

- Determine the plan for laying the cable. In order to install the system correctly, a circuit is needed. Draw it with the location heating elements and features of the construction of the room.

- Determination of the fixing point of the thermostat. At this stage, you need to knock out a hole in the wall and patch the channel for the wire. The thermostat can be installed in a special plastic box. Please note that it should be at a height of 0.5-1 m.

- Installation of plastic tubes for power wires of a heating element and a temperature sensor.

- Preparing the roughing surface. It should be smooth and clean. In addition, additional installation of a damper tape along the perimeter of the room is welcomed. It is desirable to spread a heat insulator equipped with a reflective layer on the base. The maximum thickness of thermal insulation is 2 cm.

- Fixing the mounting tape. The cable will be attached to it. Note that you need to mount it strictly according to the previously drawn diagram. In this case, do not forget that it is most convenient to fix the cable in the form of a snake. The step of fastening the tape is 50 cm.

- Cable installation. Before this, the power wires are pulled to the thermostat. The cable parts must not overlap.

- Pour the screed. It consists of sand and cement. The thickness of the screed ranges from 3 to 5 cm.

- Cable connection. Do this after the concrete has hardened. At this stage, the system is connected to the power supply. Test run of the warm floor can be carried out. This action must also be done before casting.

How to install heating mats correctly?

The technology of laying such a system involves the following actions:

- Preparation of the room. Naturally, the surface of the substrate must be carefully leveled and vacuumed.

- Install the thermostat. This process is performed in the same way as in the previous case.

- Heat mat flooring. In this case, a pre-prepared scheme is used. It should take into account that the mat should not be laid under furniture. It is best to lay it exactly in the area of the floor covering that will be used for walking. In this case, do not use thermal insulation materials. The fact is that they can lead to overheating of the system. The cable floor on the base must first be spread, taking into account the step between the strips and the distance to the walls. Naturally, parts of the mat should not touch or cross. The canvases are mounted with a "snake". To deploy the parts of the mat, they should be cut in the specified places. Note that you only need to cut the grid under the cable.

Technology of laying heating mats

Technology of laying heating mats - Fixation of the mat. To do this, roll the product back into the roll, remove the protective film from the adhesive tape and roll out the mesh according to the intended scheme. At the same time, do not forget that the floor must be cleaned of dust. Otherwise, the mat will not be fixed on the bottom as it should.

- Pour the product with a thin screed or tile adhesive.

Detailed video for styling:

Before you fill the system completely, you need to check its functionality and, if necessary, fix the problem.

How to lay the infrared floor correctly?

The technology of mounting this system is quite simple, so you can do all the work yourself. You just need to be very careful while the film is connected to the mains. So, laying an electric heated floor of this type provides such a sequence of actions:

As you can see, the technology of mounting an electric heating system is not very complicated. The main thing is to connect everything correctly, observe the installation step, insulate the contacts and connect to the mains. Leave your comments, additions and opinions!

The use of electric underfloor heating is actual in bathrooms for quick heating ceramic tiles, heating of the loggia, verandah or own bath. In addition, this solution is excellent as an addition to the main radiator heating.

Electric floors can be used in apartments where there is no possibility to install. Easy installation and commercially available options make it easy to assemble an electric floor heating with your own hands.

If you still have a question of choosing the type of floor heating.

Ways of installation of an electric warm floor

Variants of installations of electric warm floors can essentially differ:

- Mounting in the layer of the screed, after which the floor covering is laid;

- Laying of the warm floor over the screed under the tile;

- Laying directly under the floor covering (film floors).

The first option is suitable for heating in living rooms, in the bathroom, in the kitchen, on the loggia. This implies the installation of cable warm floors. Under the system itself, waterproofing and a layer of insulation are laid. A small layer of screed is formed from above.

If the floor below is a warmed room, then you can lay the electric warm floor under the tile without an additional layer of thermal insulation and mounting in the screed. The layer of the tile adhesive and the tile itself sufficiently protect the heating elements. However, it should be clarified in the instructions of the purchased product about the possibility of such a styling.

If it is necessary to install a warm floor under a laminate or linoleum, and there is no desire to carry out capital work related to the replacement of the screed, the best warm electric floor for this is film (infrared). In this case, a layer of insulation in the form of foam polyethylene with a foil surface over the existing screed is laid. Further - electroelements. If necessary, a layer of waterproofing and a direct floor covering are added.

Types of electric underfloor heating:

1 - Cable; 2 - Cable with reinforcing mesh; 3 - Film (infrared).

Important: Use a film warm floor under the tile can not, as well as mount it in the screed.

What will be required for the work?

So, the following elements and materials are required for laying the electrical floor:

- System of warm floors (heating cable, separately or in combination with reinforced mesh);

- Connecting wires;

- Fasteners;

- Regulator, temperature sensor;

- RCD protection system;

- Copper cable for grounding.

Distribution of heating elements and control units

First, a plan for installing a warm floor on paper is created. At the same time it is taken into account that the heating wire or the film should not be mounted in places where there will be massive furniture and household appliances. In places where heating pipes or other heat sources pass, it is also worthwhile to provide a buffer zone without heating elements. This is due to the peculiarity of electric underfloor heating. Unlike hydraulic systems all the heating elements of the same circuit are heated equally, and if there is a restriction on the release of heat in the form of furniture without legs or additional heat comes from outside, the elements overheat and fail. Furniture in this case can also be damaged by overheating.

As a result, you get the wrong figure, inscribed in a rectangle representing the room. And it is on the contour of this figure and inside it will be laid electric warm floor.

With this is connected just the biggest drawback of the warm floor. The rearrangement of furniture can significantly affect the performance of the system.

Schematic example of the installation of an electrical system in the bathroom

For different rooms, even if they are demarcated symbolically, it is better to form separate contours of the warm floor with their own individual regulators and power supply. In the case of pouring screeds between them, a damper tape is laid over the floor surface.

When the layout is already planned on paper, you can transfer the markup directly to the floor.

In a convenient place on the wall, the position of the regulator for the warm floor is marked. At this point, a hole is made for the mounting box and the shtroba goes down to the floor. After preparatory work and planning, you can start calculating the required amount of materials.

Film warm floor

Calculation of materials

You can use the ready-made tables from the manufacturer of the cable floor heating, and according to the calculation of the heat loss of each room, the necessary step of laying the wire and its total length for the room is selected.

For film (infrared) systems, calculations are even simpler: the number of elements that will cover the required area should be selected.

The calculation also includes a wire for connecting the regulator and the warm floor from the meter and from the controller directly to the elements of the system.

Important: It is forbidden to use a direct connection to the outlet for the electric underfloor heating.

According to calculations and the obtained power of all warm floors, it is necessary to check the total electrical input for the ability to withstand such a load. If input is insufficient, then replace it and install suitable fuses.

Surface preparation. Features of base insulation

If necessary, the old layer of screed is completely dismantled to the base. The entire surface is cleaned.

Next, a layer of waterproofing is laid in, with a wall approach approximately 10 cm. A damper belt is fixed to the wall along the entire perimeter of the floor. It will compensate for the thermal expansion of the floor when heated. As a result, you can cut the excess waterproofing and damping tape.

In order to thermal energy Do not go down, you need to isolate the base of the floor. Depending on the location of the room and the type of surface, as well as the target orientation of the heating system, appropriate insulation is selected:

- If the warm floor is a supplement to the basic heating system, then it is sufficient to use foamed polyethylene with a reflective foil-coated coating as a substrate for the warm floor (penofol).

- For apartments with heated rooms the floor below are suitable sheets of expanded polystyrene or extruded polystyrene foam with a thickness of 20 to 50 mm or other strong insulation of suitable thickness.

- If the installation of a warm floor is performed on a previously unheated loggia or veranda, a more basic layer of insulation up to 100 mm of expanded polystyrene or a similar layer of mineral wool is formed.

The reinforcing mesh is laid on top of the heater. You can do without it, since the layer of the screed will be thin and it is enough to add plasticizer and microfiber to the solution. (On how to form a semi-dry screed with reinforcement of synthetic fibers -).

![]()

Mounting process

Before laying the wire, check its resistance and check with the passport. Approximately 10% of the passport data is allowed to run. Installation of an electric warm floor can be made both with fixing it to the reinforcing mesh with the help of ties (without tightening), and with the help of special fastening tapes.

In the case of mounting a warm floor in the bathroom or in a bath, it is necessary to ground the reinforcing mesh underneath it and to connect the ground to the regulator. For this, tin copper wire. Actually, this is the answer to the question whether it is possible to lay electric heated floor in a bath? Yes, only necessary and.

The infra-red warm floor simply spreads over the insulation layer. The technology proposed by the manufacturer may require fixing with special tape or special lugs on the strip.

Layers of the film floor when laying directly under the laminate

In places where the wire passes over the dividing line of the two floor slabs, it should be hidden in a section of the corrugated tube, 10-15 cm long. This will reduce the risk of cable breakage with possible thermal expansion of the plates.

The connection point between the heating cable and the power wire is located at a distance of 10-15 cm from the strobes so that the connecting clips are subsequently dug into the screed.

Important: Be sure to mark the position of the connection point on the apartment plan. This may be necessary later in case of forced repair of the underfloor heating.

When all the elements are placed in their places, the resistance of the wire is checked again. Only if it is slightly different from the previous measurements, you can test the heating elements, including the warm floor.

A corrugated pipe is lowered from the regulator by the strobi, the other end of which is located in the middle between the nearest strips of the heating cable. Inside corrugated pipe the thermal sensor is pushed through with which it is possible to regulate the work of the warm floor. Once again it is worth checking that the sensor easily gets there and there will be no problems with its replacement.

If everything is normal, then the whole system is de-energized, and the regulator is removed before the completion of all the finishing works. Forming screed of the warm floor. After it is completely dry, the system is checked once again and, if it's okay, the floor covering is installed. If the screed is not needed, as in the case of a film warm floor, then immediately fit a laminate or linoleum.

More about the device of traditional concrete or cement screeds.

As you can see, making a warm floor with your own hands is quite simple and much easier than.

Video: laying a simple cable floor heating

Video: laying the cable floor with a reinforcing mesh

Video: laying of film (infrared) warm floor

Alexey Shamborskiy, September 6, 2014

Many owners of apartments and private houses during the construction phase and during repairs decide to equip more comfortable living conditions. Particularly popular recently is the installation of warm floors of various modifications. From the point of view of safety, ease of use and cost, the electric warm floor is beyond competition.

The only thing that confuses the owners of dwellings, it's quite a large cost of work, the main component of which is the payment of installers. But in this case, there is an opportunity to dramatically save on the services of hired workers by performing an electric heated floor with their own hands. For this purpose, there are many different sets of electric floors of various capacities suitable for all types of coatings and for different sizes of the floor, from which it is possible to choose perfectly suitable for your home.

Installation instructions for electric underfloor heating

Consider the option self-assembly electric underfloor heating in a private house (similarly it is carried out in an apartment). Beforehand, you need to make sure that the wiring harnessed in the house will cope with the loads from the floor heating elements, and also you have installed automatic switches corresponding power.

Thermal insulation

Before installing a warm floor, it is necessary to lay the thermal insulation of foamed polystyrene foam 20-50 mm thick, this is especially important when the floor is located in a cold room. The thermal insulation must be laid on an aligned base, it is possible to lay it on a special glue for reliability.

Reinforcement

After this, it is required to perform a reinforced screed from a solution 10-20 mm thick. It can be reinforced with galvanized plaster mesh, and plastic. The foil is placed on top of the screed to reflect the infrared radiation from the heating elements.

Pouring the floor

Starting the installation of an electric heated floor with your own hands, the location of the heating cable is determined taking into account the arrangement of different furniture, making sure that the wires will be located at a distance of up to 5 cm from the edge of the furniture. When laying the heating cable, it is necessary to attach it to the lower base with a special mounting tape, then pour cement-sand screed from the mortar or the finished mixture.

Various technological adjustments arising during installation can be seen by viewing the video work on laying the electric underfloor heating with our own hands on our website where they are performed by professional masters. Simultaneously with the cable laying, the sensor of the temperature control system is mounted in the thickness of the screed, and a temperature controller is installed in a convenient place, which makes it possible to adjust the floor temperature at its own discretion.

Nuances

Photos of the laying of an electric warm floor with their own hands are reflected in our article and will help in the execution of works. The difference in the laying of a warm electric floor under the tile and under the laminate is that the tile can be mounted on a minimal screed directly to the heating cables, while it is recommended to make a layer of screed between the cable and a coating of at least 20 mm under the laminate to ensure that the laminate does not deform.

Having arranged a warm floor with the help of our recommendations at home, you can safely give recommendations to your relatives and acquaintances how to install an electric heated floor with your own hands without attracting strangers. At the same time, the quality of work will depend only on your diligence, and the reward will be a warm, comfortable floor, the heating system of which is the most natural and environmentally friendly. The pleasure from the result obtained will outweigh all the inconveniences associated with the performance of the work.