Expansion tank for heating system. Calculation and volume of the expansion tank for heating

At work heating system A closed cycle causes a change in the temperature of the coolant-water or antifreeze. As the thermal radiation of the boiler impacts, the water expands, increasing in volume. If the heating system does not provide a mechanism for regulating the pressure of the coolant, an emergency situation may occur. The best way to avoid this is to install an expansion tank, the nuances of choosing which will be discussed.

Expansion tank Is a device that compensates for the pressure in the pipes during heating and expansion of the liquid in them. The indicators for increasing the volume of water depend on its composition and characteristics. For a normal liquid, the expansion index is 0.3% for each temperature increase of 10 ° C.

Tank constructions

To solve the issue of compensation, you can simply install a separate outlet pipe in the uppermost part of the pipeline. But it will not perform all the functions of the expansion tank in full. To understand why, it is necessary to consider different types of construction and this compensator.

Open type

This design, for the most part, is made by handicraft. Typical scheme tank open type is shown in the picture:

Open type tank design

It is a steel tank, which is mounted at the highest point of the heating system pipeline. The tank is connected to the system via an expansion pipe, and a circulation pipe is provided to ensure water flow.

As the system is filled with water, it reaches the signal pipe on which the crane is installed. To ensure control of water expansion, an overflow pipe is provided. It provides free movement of air inside the tank.

To calculate the volume of an open tank, you need to know the volume of water in the system. If there is no such information, you can start from the boiler's power - about 1 kW approximately corresponds to 15 liters of water. Ie for 24 kW of the boiler the maximum volume of the coolant will be 360 liters. When the temperature rises to 70 ° C, water at this volume will expand by 9 liters. And at a maximum of 95 ° C - 15 liters. The volume of the tank to the level of the overflow pipe must not be less than 15 liters.

Closed diaphragm tank

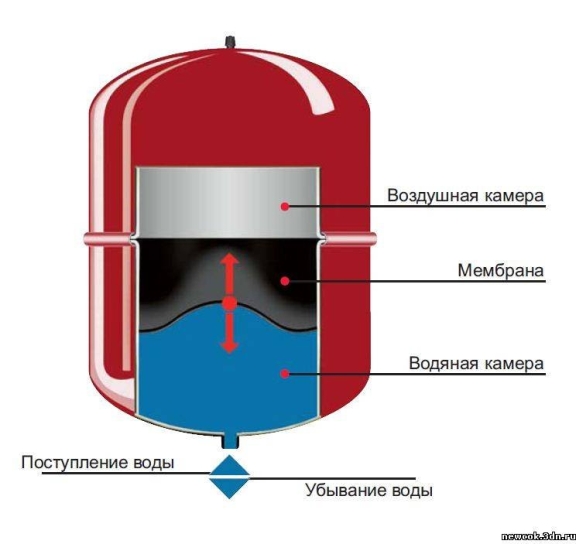

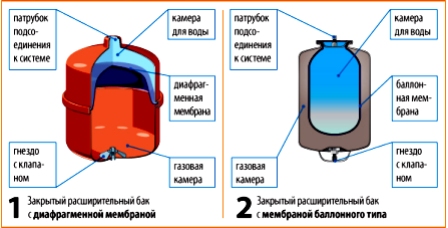

There is also a more perfect pressure compensation system in the system - a membrane tank. Its design is a closed steel tank.

Expansion Membrane Tank

The insulated housing is divided into 2 parts, one of which has a connection to the heating system. The second is filled with an inert gas - nitrogen. To set the pressure level inside it, there is a nipple with which it is possible to reduce (bleed) or increase (pump pumping) the amount of pressure inside.

When connected to and activate the system, water, after heating, enters the tank chamber. When a certain pressure is reached, the movable membrane increases the volume of the water chamber. This type of construction is more convenient both in operation and at installation works. The main advantages of the tank membrane type are:

- The absence of water contact with air, which significantly reduces the likelihood of corrosion.

- The tank can be mounted anywhere in the heat main.

- Since the system is completely sealed - the loss of the coolant is minimal.

- Reduction of heat losses, compared to an open type tank.

But for this system there is one obligatory factor - calculation of the optimum volume of the tank. This is an important stage in the design of the heating system as a whole.

Calculation of capacity

When calculating the volume of the expansion tank of the membrane type, the following parameters should be taken into account:

- Type of coolant. The coefficient of thermal expansion (E) for different liquids is different. Therefore, it is important to know this value.

- The total volume of the coolant in the system is C. The approximate calculation was indicated above.

- Initial pressure in the system Pmin.

- The maximum permissible pressure value is Pmax.

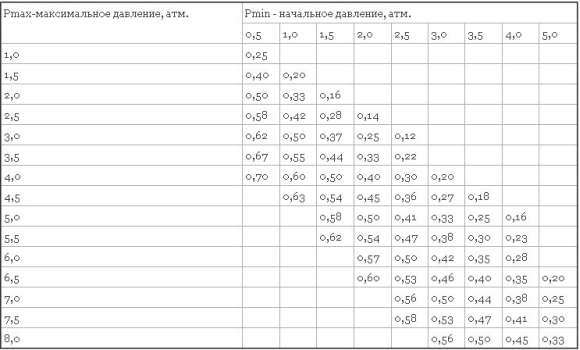

- Coefficient of filling the tank for different pressures (Kzap). It can be calculated according to the table:

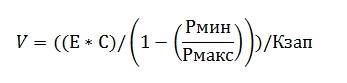

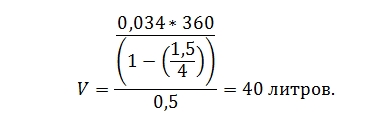

The expansion volume of the heat carrier can be calculated by the following formula:

Let's consider an example of calculation of the given formula for a concrete system:

- The coefficient of expansion for water E is 0.034 (at 85 ° C).

- Volume of the heating system C-360 l

- Initial pressure Рмин - 1,5 атм

- The maximum value of pressure Рмакс - 4 атм

- According to the table, the fill factor of the Kzap tank is 0.5

This is the standard tank volume for a small house.

When choosing an expansion tank, you must pay attention to the quality of the workmanship. It is best to consult with specialists, as there are a lot of manufacturers of these designs, and it is very difficult to determine the quality for this or that model without experience and practice.

Autonomous water heating systems are becoming more popular with domestic consumers every year.

Thanks to their constructive features, availability and the possibility of implementing a variety of schemes, such systems are interesting and effective in the work.

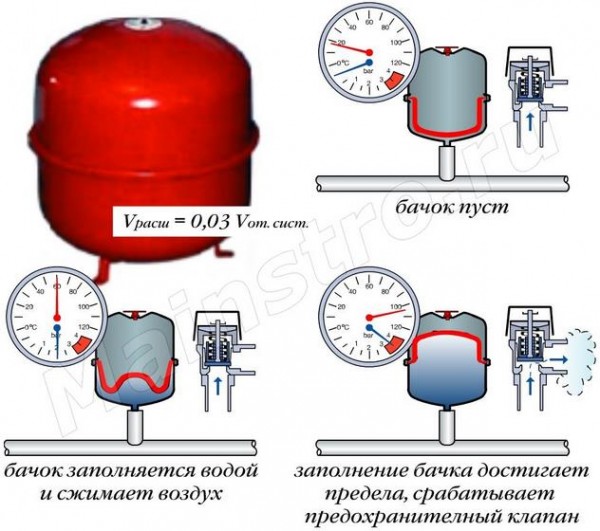

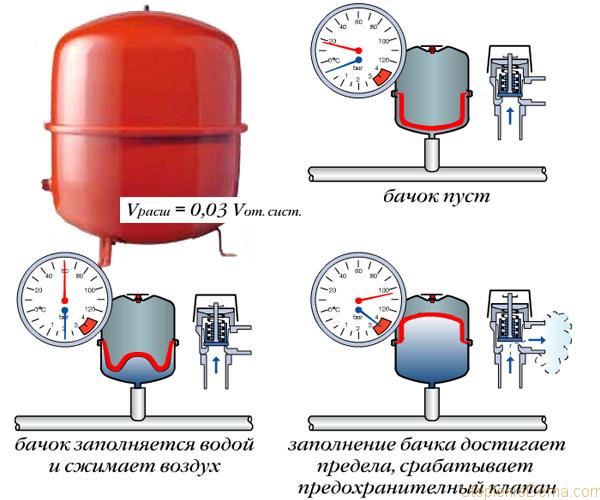

One of the components of almost any heating scheme for a private house is an expansion tank. This device helps to ensure a high level of system performance, protects it from increased pressure.

In order for the heating circuit element to function normally and perform its functions, it is necessary to know how to calculate the expansion tank for heating.

The main types of expansion tanks and their functions

Currently, the domestic market is represented by a huge number different types expansion tanks.

It should be noted that the price for many options is affordable and very low, and therefore the installation is possible in any system of autonomous heating, where water is used as a coolant.

Among the main types of expansion tanks, popular in the domestic market, there are several:

- Open - as a rule, they have a square or rectangular shape. Since the dimensions of such structures are quite impressive, and the efficiency is questionable, they are used comparatively rarely. The main feature can be called simple installation with your own hands without extra time and money;

- Closed - Membrane tanks, which are a flat or spherical container, hermetically sealed and strong. Structurally, these are the two halves of a heat-resistant membrane made in the form of a diaphragm.

The instruction assumes that the functioning of this type of tanks occurs due to the ingress of an expanded coolant in them and deformation of the membrane. Thus, the amount of air in the system is reduced, while the pressure is higher.

Choosing an expansion tank for any modern system heating is important to take into account the fact that the product must necessarily meet certain specific requirements - the pressure range, differ high-quality membrane, its characteristics.

In addition, the calculation of the tank is important, because the functionality and performance of the system as a whole depend largely on the parameters obtained.

How to calculate the expansion tank: the features of the process

In most cases, the procedure for calculating the membrane expansion tank of an autonomous heating system involves obtaining data relating to the volume, the minimum diameter of the pipes in the system, and the initial head and pressure.

It should be noted that the use of all sorts of complicated calculation techniques can lead to a number of overlays, including multiple activation of the check valve.

When calculating the expansion tank of the heating system, it is important to remember that the higher the maximum permitted compression, the smaller the dimensions of the capacity itself will be.

At the same time, the size of the tank depends on the temperature of the liquid, because it will be more significant, so the size of the structure will increase.

Calculate the volume of the tank (as can be seen in many photos and videos) using several basic values, in particular, the volume of the used coolant in the system, the coefficient of its linear expansion, and the efficiency of the tank.

In the form of a formula, such a calculation can be represented in the following form:

V = Vcc * K / D, where

VSS - the total volume of the coolant in the system,

TO - coefficient of expansion of the coolant;

D- efficiency of the tank.

In turn, the effectiveness of the expansion a membrane tank depends on several parameters: the initial and maximum pressure in the system, the initial air pressure of the chamber.

It should be noted that it is on the very high pressure the safety valve is adjusted.

Dimensions of tanks

After reading this material, you can once and for all leave behind the problem of calculating the expansion tank for closed and open heating systems. Below you can find the formulas. Also touched on the issue of possible problems due to improper selection of this equipment.

One of the key tasks to be performed is the calculation of the expansion tank for a closed heating system. In turn, in open circuits this is not so important. In principle, the calculation is simple, if you own the information. Despite the simplicity of the calculations, in practice, errors occur that lead to negative consequences. The most common mistake is a negligent attitude towards the choice. It happens that people do not pay enough attention to the calculation of the volume of the expansion tank for heating and begin to understand the nuances, only after the first problems appear and the system requires.

Potential problems "\u003e Possible problems

First, let's consider the consequences of an incorrect calculation of the expansion tank for a closed heating system. Perhaps you also have an unusable tank for your system, and you do not even know it. If the tank volume has been calculated correctly, the circuit will always have a stable pressure. It does not matter whether your system is open or closed, the calculation of the volume of the expansion tank for heating of both types is similar, since the principle of their operation is approximately the same. The bottom line is that the water in the pipes acts as a coolant.

That is, it carries heat throughout the circuit and gives it to the medium, and the walls of the pipes. Thanks to this, the room becomes warm. The amount of water always changes. After it heats up, it gets bigger, and after it cools down - less. It is impossible to pressurize water mechanically, which means that it is necessary to remove its excess from the circuit for a while. And it is necessary in such quantities that pressure in the system always kept at the necessary level, without changes. So we came to the main thing - these are the pressure drops.

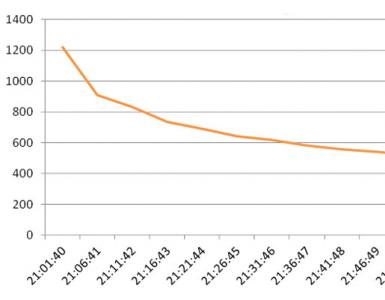

If pressure drops occur in the circuit, these are the first bells about malfunctions. This may be due to the incorrectly calculated volume of the expansion tank for the heating system.

How does the difference occur? "\u003e How does the difference occur?

Possible options:

- increase;

- lowering.

Both processes are interrelated. Increasing the pressure in the circuit means that the heat carrier has nowhere to go after it has increased in volume. One of the reasons, not the only one, may be incorrect calculation of the expansion tank for heating closed type. How does this happen in practice? Take, for example, a circuit containing one hundred liters of coolant:

- in the system is one hundred liters of cold liquid;

- the boiler switches on and heats the heat carrier;

- the water expands and becomes no longer one hundred, but about one hundred and five liters;

- excess fluid must go somewhere. To do this, the circuit is installed expansion tank;

- after the coolant cooled down, it was not enough in the circuit, as the part was pushed into the tank. Accordingly, the water in the pipes must be returned, which happens, if all is well.

Pressure drop

If the volume of the expansion tank for a closed heating system is less than necessary, then all the liquid that is not contained will be brought out. In the circuit, special valves, which eject the coolant in the event that the pressure rises to a critical level. These valves are equipped with modern boilers. This is a necessary condition for safe operation heating. Increasing pressure can even lead to an explosion. Imagine the consequences, when the pipe simply tears and hot water flies in all directions. In addition to the possibility of injury from a stroke, such an extreme event threatens to burn nearby people and animals.

Later, after cooling, the water decreases in volume. The liquid from the tank is forced back into the pipes, but the coolant is still not enough. This is because the withdrawn water did not return to the outside, it left irrevocably. As a result, the pressure in the circuit drops sharply. This leads to the following results:

- stop the boiler. The heaters have a certain minimum pressure threshold at which it can work. If this value is not maintained, it simply can not turn on, the automation does not allow it;

- defrosting the system. If the heating equipment stops in winter and you are not at home, a serious accident can occur. The system will freeze in a few hours, depending on the level of insulation of your housing;

- the need for recharge. It is necessary to pour the missing amount of water into the circuit.

These are the results of gross errors made in the calculation of the expansion tank for heating, or if you hoped for a tank built into the boiler.

In modern boilers there are built-in tanks, the volumes of which are often not enough. Be sure to consider this fact and, if necessary, install additional tanks.

It also happens that the tank is completely filled, the pressure continues to increase, but does not reach the critical level. The needle of the pressure gauge balances to the verge of the working maximum of the contour, while everything functions. Such cases can not be counted. People very often ask questions about such swings. Of course, such processes are of concern to them, since they are not the norm. With these increases, the circuit operates under extreme conditions, which leads to its rapid wear. Also, such processes adversely affect the boiler, and it costs money and not small.

Selection of volume "\u003e Selection of volume

Open tank

Dimensions of the expansion tank for open system heating, by and large, determine its volume, since the construction of such a tank is quite simple. It is made of sheet metal. It has a hole through which the coolant gets inside and leaves again in the pipes. They can also be equipped with a hole for overflow, through which excess water is discharged into the sewer.

It happens that the tank is automatically fed. But the main thing is how the expansion tank in the heating system is designed, or rather, its volume. We take the same system with a hundred liters of water. After heating, the liquid will increase by five percent, maybe more, depending on the temperature in the circuit. It turns out that the volume of the expansion tank for this open heating system should be at least five liters, or better. And the calculation of the expansion tank for the heating system is reduced to the following algorithm:

- five liters is the expansion of water;

- a couple of liters should always be in the tank - this is so that the air does not get into the circuit;

- liter three must be done for stock.

Based on the calculation of the volume of the expansion tank for heating, it receives ten liters. By the way, this is the most simple and common way of selection - ten percent of the amount of water in the circuit.

For closed systems, in addition to a simple, popular way of calculating the volume of the expansion tank of a heating system, there are more precise methods. To use them, you need to know a few values. These include:

- how much water (OB) increases with heating. Answer: five percent. The value is rounded to an integer without fractions, for convenience. If there is a non-freezing liquid circulating in your circuit, antifreeze, this value will be greater;

- how much water is in the circuit (VC). Such data should already be from the stage. Since the selection of the heater is based on this value. If it so happens that you do not know how many liters there are, it only remains to measure. The first thing that comes to mind is to drain completely all the liquid from the circuit and fill it again. The number of liters can be measured by buckets, or you can use a special counter that is installed on the flow;

- on what maximum pressure the circuit and the boiler (DK) are calculated. This value can be read in the heater's documents, or on it itself. It hardly happens that there are no documents or information on the boiler body. But if that's the case, then the Internet will help you;

- what is the pressure in the air chamber of the expansion tank (DB). This is also indicated in the technical documentation.

OV х VK х (ДК + 1) / ДК - ДБ

Based on the calculation of the capacity of the expansion tank for heating, you get the exact value. The question of the expediency of such complex calculations remains open. Undoubtedly, based on the results of this formula for calculating the expansion tank of the heating system, it will turn out to be less important than the results of the "popular" method. But the error in the larger side is not a mistake. If the tank is more than necessary - it's ok, just need to configure it properly.

Up to what level to inflate the air chamber "\u003e Up to what level to inflate the air chamber

It is important to properly adjust the expansion tank for heating the closed type. The calculation of roominess is, of course, a serious aspect, but even if it is done correctly, the tank can still work inappropriately. In order to understand this, let us briefly dwell on its construction. It consists of two compartments, between which there is a rubber gasket. There is no connection between the cameras. There is a nipple in the air compartment.

During operation, water fills the volume of the tank chamber, while the membrane is stretched. If the pressure in the air chamber is too high, it just will not let the rubber get deformed. In the end, the tank does not work. The air chamber should be two tenths of an atmosphere less than the working pressure of the boiler. Alternatively, use the manufacturer's recommendations to configure it.

Reflex Heating Tank

It plays the role of a balancing element. It equalizes the volume of the coolant when it expands under the influence of high temperatures, and also maintains the necessary pressure in the system. But the consumer always faces a question related to the volume of the tank. How to choose the right device for this indicator? To answer this question, it is necessary to calculate the expansion tank for heating. Business is not so simple, and here the formula is used, the components of which are determined by experience. But let's get everything in order.

Types of expansion tanks

Like the heating system itself, the tanks are divided into open and closed. Open devices are very cumbersome, and recently their popularity is practically reduced to zero due to low efficiency. Closed devices are more practical. It is hermetically made tanks, which are separated inside a rubber membrane. The coolant enters the lower part, changing in volume due to the increase in temperature, and in top air is pumped in, which is done in the factory during the manufacturing process. The air pressure inside is 1.5 atm.

When heated, the water increases in volume, and these excess fill the lower part of the expansion tank. At the same time, water presses on the membrane, which rises to a certain level. Pressurized air creates a pressure in the closed-type heating system equal to 1.5 atm, which is a necessary condition for its effective operation.

- The shape of the expansion tank can be rounded in the form of a balloon or flat.

- It uses heat-resistant rubber as a membrane. It can be diaphragm type or flat - balloon type.

- When choosing an expansion device, it is necessary to pay attention to the membrane, or rather, its service life and the ability to withstand the necessary pressure. Do not forget about the temperatures of the coolant that will act on it. Diffusion processes It can also be negatively affected by its quality.

Calculation of volume

And yet the basis of choice is volume. Let's dwell on the dependence of the volumetric parameter of the device and those indicators that affect its changes:

- The greater the volume of the coolant in closed system heating, the larger size it is necessary to purchase an expansion tank.

- The higher the temperature of the coolant, the greater the capacity of the device.

- The higher the coolant pressure (the acceptable value of the index is taken), the smaller the capacity can be purchased.

Three main dependencies. Now you can go directly to the calculation. Let's face it, it's not an easy thing, but it's worth investigating. Because a small deviation can lead to unpleasant consequences. For example, the safety valve will be permanently reset.

So, the formula for calculating:

Vb = (Vc * K) / D, where

Vb is the capacity of the device.

Vс is the volume of the heat carrier in the heating system.

K is the expansion coefficient of the coolant. For water, this figure is 4%, so the formula uses 1.04.

![]()

Table with formulas

D is the expansion efficiency of the tank itself. Made of metal and under the influence of temperature difference, it can slightly change its dimensional parameters. For the exact establishment of "D", you can use the following formula:

D = (Pmax - Pn) / (Pmax + 1), where Pmax is the maximum pressure inside the heating system, Rnach is the pressure inside the tank, planned by the factory parameters (usually 1.5 atm.). By the way, the maximum value is planned for setting the safety valve.

It turns out that the volume of the expansion tank depends on the strength and temperature characteristics of the device itself. Note that all these indicators and characteristics should not exceed the permissible standards. The volume of the expansion device must be equal to or be slightly higher than the results obtained.

- A container of 20-25 liters capacity is usually installed with circulation pump capacity of 1,2 kW. At a volume of 50-60 liters, the pump capacity is increased to 2.0 kW. There are expansion tanks in the market with a capacity of 100-200 liters. They can be used not only for their intended purpose, but also as a reservoir for warm water with small disconnections in the water supply system.

- Dimensional indicators of tanks fluctuate in a wide range. There are some that do not fit into the openings, so that you can put them in the interior. Therefore, advice - use a few small tanks than one huge. The correspondence of volumes is important here.

- There are a number of standard indicators that determine the amount of energy delivered to a particular volume to be accommodated. For example, a heating radiator - 10.5 kW, a water convector - 7 l / kW, a water heated floor - 17 l / kW.

Now you know what the expansion tank of a closed type is for. But where it can be cut? The question remains open. This is a closed device, and for it there is no difference how it will be installed. Here, more important is the ease of operation. So, it is better to mount the assembly in a place where the approach will be free. And it is not so important at which point the tank will be located - at the highest or not. This is its universality.