What is the plug for the outlet. Electrical outlets

Sockets are in each house: with their help connect electrical appliances to the network. They are part of the plug connection, which also requires a plug. Among the plugs are different types, electrical outlets exist no less. Outwardly they are all similar to each other, so it is difficult to understand the choice. Consider the variety of sockets that occur in everyday life.

All outlets can be divided into several classes according to the following criteria:

- Type accepted for operation within the country;

- A way of ensuring security;

- Method of installation;

- Additional features.

According to these criteria, more than 20 species can be identified electrical outlets, which are found in everyday conditions. Modern models provide not only a strong plug connection, but also are multifunctional. They are distinguished by high safety indicators.

Types of sockets used in Russia

Within our country the following types of electrical outlets are widely used:

- Overhead;

- Built-in.

Separately designate sockets, intended for connection to the network of electric cookers.

Overhead

They are external electrical outlets (open type). For their installation, there is no need to make a hole in the wall. They simply harden to its surface: the box strongly protrudes. The female connector is surrounded on all sides by a protective housing. Therefore, the contacts are completely isolated from the external environment. This is one of the main differences from the built-in sockets.

Built-in

Radio-controlled

Using the remote, you can control the operation of household electrical appliancesconnected to the network through sockets, mounted in hard-to-reach places: behind a sofa, a closet, in the corridor or in the attic. Remote control allows you to turn on and off the heating or watering system, lighting, boiler at a distance of up to 25 meters.

Using the remote, you can control the operation of household electrical appliancesconnected to the network through sockets, mounted in hard-to-reach places: behind a sofa, a closet, in the corridor or in the attic. Remote control allows you to turn on and off the heating or watering system, lighting, boiler at a distance of up to 25 meters.

Other types of sockets

Among other things, the following types of electrical outlets can be distinguished:

- With a light bulb. When the appliance is connected, the light is on. And it does not shine if the network is de-energized.

- With screw clamp, providing a strong connection of the socket contacts to the wiring. During installation, the installer places the wires between two blades, which are clamped tightly with a screw.

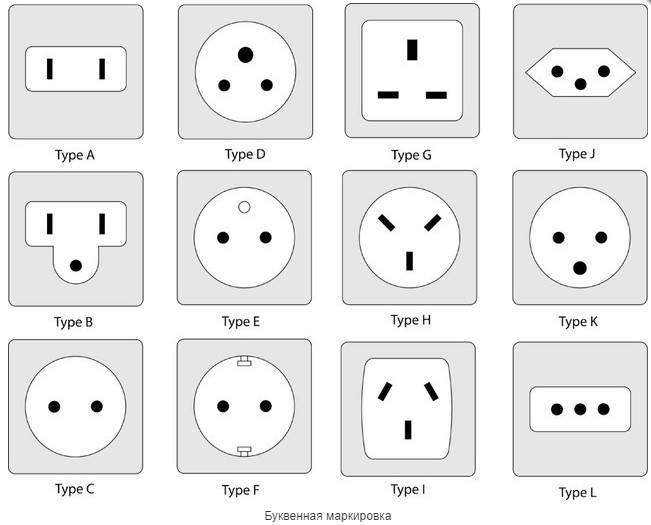

- A is an American device. At the moment, in addition to the US, similar outlets can also be found in Japan. A grounding contact is completely absent.

- B is also an American model, but it has a grounding.

- C is a European standard. Find similar outlets can be not only in Europe, but also in the CIS. The only drawback of this design is the lack of grounding. However, it should also be noted that the ground is present on the C6 model.

- D - this type at the moment can be found in Britain.

- E - French version.

- F is an earthed socket with ground. This option can be found not only in Europe, but also in the CIS.

- G - English version.

- H - Israeli.

- I - Australian.

- J - Swiss.

- K - Danish.

- L - the original socket, which is used in Italy.

- M - South Africa.

- Waterproof. Such sockets are therefore able to provide reliable protection against moisture and dust.

- A model that has a protective shutdown function. If a leakage is detected, then the device will shut itself down.

- Socket with wattmeter. This is the original solution for your home. With its help you will learn how much power a certain device consumes. The display can change automatically depending on the power that will be consumed.

- Device with automatic fork pushing function.

- Euroset with backlight. Thanks to this in the dark, you can see the design of the outlet.

- Socket with USB. These are the most common devices, which are currently very popular.

- with or without ground;

- built-in sockets and sockets;

- with screw fastening of the wire or without it;

- with protective curtains and for operation in conditions of high humidity;

- with fork ejectors, universal (for any type of plug), outdoor, with timers and indicators, etc.

- A - the United States and Japan - sockets designed for 110 volts.

- B - Same type A, only with grounding contact.

- C - For operation in 220 V and 50 Hertz networks. Distributed in the CIS countries and a number of European countries.

- D - British female connectors. Almost the same are used in South Africa.

- E - French version of the socket type C, but with a grounding contact.

- F - German version of type C for wiring with earthing

- G - Another standard from Britain.

- H - Standard in Israel.

- I - Devices installed in Australia.

- J - Swiss female connector.

- K - Danish version of the C type outlet for grounding.

- L - Italian simplicity and functionality.

- The base is made of dielectric - ceramic or plastic. The ceramic base withstands high temperatures, in case of contact overheating, but more fragile. In the base there are landing nests for contacts, the mechanism of fastening and a hole in the thread for screwing the lid.

- Fixing mechanism. In the case of internal sockets, these are spacer legs, while in the outer sockets there are simply holes in the base for screws.

- The main contacts are for phase and zero. The part that clamps the contacts of the plug can be additionally spring-loaded to make the contact more dense. In addition, they have a fastener for the wire.

- The grounding prong is not an obligatory component, but in most devices it is.

- Cover made of plastic - closes the live parts and protects them from dust and water. It can consist of two parts - decorative and fastening.

We already had an article about that, and there you could notice a brief description of the species. Now we decided to dwell in detail on the discussion of this issue and provide you with information on what kind of electrical outlets there are.

If you switch to a modern market, then you can see just a huge number of different outlets. In domestic conditions the most common are the plug devices. Also in this article you will find out what are the different types of sockets in Russia and other countries of the world.

Connector type

During the purchase of the sockets, you will notice that the main difference is considered to be the socket device of the socket for connection electrical plug. At the moment, each state has its own dimensions and connector standards. In the photo below you can visually examine the types of sockets in all countries of the world:

The photo is not always understandable and so below we decided to present to your attention a detailed description of each type:

Now you know exactly which rosettes are in different countries of the world. Now it's time to consider the types of electrical plugs type C and F.

Specifications

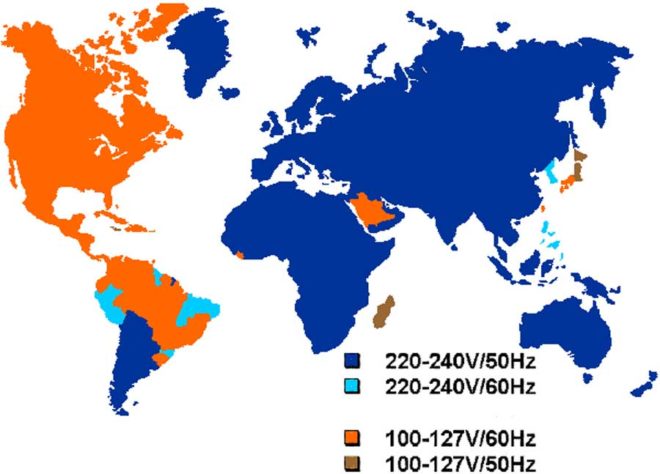

At the moment, the voltage in the outlet can be not only 220 or 380 Volts. For example, in America it is now common to use a voltage of 100-127 volts. Euro-outlets for 220 volts can be used to connect electrical appliances with a power of no more than 3.5 kW. This is due to the fact that power sockets can not withstand a current that will exceed 16 A. Such models are perfect for connecting weak electrical appliances.

Industrial three-phase sockets are designed for a current of 32 A. Thanks to this, they are perfect for connecting powerful equipment.

Such sockets are in most cases designed for a current frequency of 50 or 60 Hz. In Russia or CIS countries, the first type of performance can be used.

type of instalation

The following type can be referred to the type of housing that is used in the outlet. At the moment, you can find overhead sockets that are used for. Also you can find recessed sockets, which are suitable for flush mounting.

Recessed sockets for today can be panted not only in the wall, but also in the floor. Below you can see what this version looks like.

To a separate kind of devices now it is possible to carry portable sockets. This is a fairly convenient option, but in Russia it has not yet gained its popularity.

Additional functions

Also, many sockets at the moment can be divided depending on additional functions. For example, these functions are:

In the video below you can get detailed information about these devices.

We hope that this information was useful and now you know what are the electrical outlets in all countries of the world.

The most important element of home and office electrical facilities. They deal with everything, their proper quality and correct choice depends on the proper operation of the power grid, safety and correct use of electrical appliances.

Choose the power outlet correctly

It's not difficult to buy a power outlet. But it is desirable to understand in what conditions it will be used and choose the right model. Manufacturers offer a wide range of power outlets for all occasions. Power outlet can be:

All these products can be purchased on our website. You can collect a complete set of electrical equipment, including buy outlets, the online store "Prestige" is ready to provide you with everything you need.

Observe the operating conditions and specifications of the electrical outlet

When planning to buy electrical outlets, pay attention to what kind of load will be included in it. Power socket, the price for which a little more can be better, because it is designed for more current. If you plan to turn on devices that require the presence of a third wire - grounding, then you should buy an electrical socket, the price for which will be slightly larger, but there are all the necessary contacts.

For rooms with complex conditions (for example, bathroom), a special electrical outlet is required, the price for which is higher than for standard products. The fact is that they are equipped with a body with protection corresponding to a certain class of IP. The level of protection, which has a power socket, which you plan to buy for a bathroom, is indicated on its case.

Use high-quality equipment

Choose the right and convenient package for the power supply system. If there are difficulties in choosing, do not hesitate to seek advice from our online consultant. He will help you with competent technical advice on all positions.

A quality outlet, the price for which is not so great, after correct installation will be used by you on a "put and forget" basis. It will not crack, spark, it will not loose contact. Do not save on the equipment and put with the power supply system only high-quality and appropriate for all characteristics of components.

The main task of the outlet is to create a reliable electrical contact with the mains plug of the device after switching on, and the outlet must be absolutely safe for the person

Electricity is used literally everywhere. That's why you need reliable devices that provide access to it. In the household, electrical outlets are used to access the power grid. They can work regularly for many years, but sometimes they become unusable.

Electrical outlets They are used to connect electrical appliances and electric machines to the electrical network. The main task of the socket is to create a reliable electrical contact with the mains plug of the device after switching on. In addition, the sockets should be completely safe for humans, and their design should completely prevent unintentional contact with wires and parts that are or may be under voltage.

The requirements to the safety and appearance of the outlets have grown substantially. Specific conditions dictate the color and shape of the parts protruding above the wall, more and more often the sockets must be assembled into the module (it can include connectors for telephone line, television cable and computer network).

Arrangement of electrical outlets

When designing sockets, the so-called modular method is used. In this case, the mechanism of the device is designed as a separate unit (a functional module), which can be installed in any type of devices. In this case, the decorative module (patch) can be changed, following the fashion, tastes or interior of the room. At the same time the mechanism of replacement does not require. This is all the more convenient because it is the mechanism that is attached to the supporting surface (for example, to the wall).

The base of the functional module and the decorative details of the sockets are made of special plastics. They are good dielectrics, have high strength at normal and elevated temperatures, do not support combustion, do not change color and are not destroyed under the influence of electromagnetic fields and ultraviolet light. In the EU countries, for example, high-strength ABS plastic and polycarbonate are used for this purpose. But porcelain in these countries for the production of outlets and other similar devices is prohibited, as not the most reliable of dielectrics.

So, any electrical appliance having a connecting cord with a mains plug can be connected to a power source. It is enough to insert this plug into an electrical outlet of the appropriate design. However, this connection can be considered correct only if the contacts formed by the plug and the socket do not heat up and spark when the current flows. This can be ensured if the socket electrodes reliably contact the fork pins, tightly fit them, providing a large contact area. Each such electrode is made in the form of a spring receiving receptacle. Its initial diameter is slightly smaller than the diameter of the fork pin, so when it is plugged into the socket, we must exert some effort to overcome the elasticity of these sockets.

The design of the socket receptacles and the material from which they are made must provide a sufficiently large number of repetitions of the "turn on / off" cycle without degrading the quality of the contacts. Rosettes from the company, which are considered leaders in their industry, allow at least 5000 such cycles, which is equivalent to a period of operation for 6-10 years (provided that the outlet will be used 1 to 2 times a day).

The socket receptacles of the socket are connected to its terminals, to which the wires of the electrical wiring are connected. At what in modern devices this connection is carried out not as a separate detail, but as a branch of a monolithic plate from which the receiving socket is made. Thus, it is possible to avoid undesirable from the point of view of reliability of additional connections in the path of electric current flow.

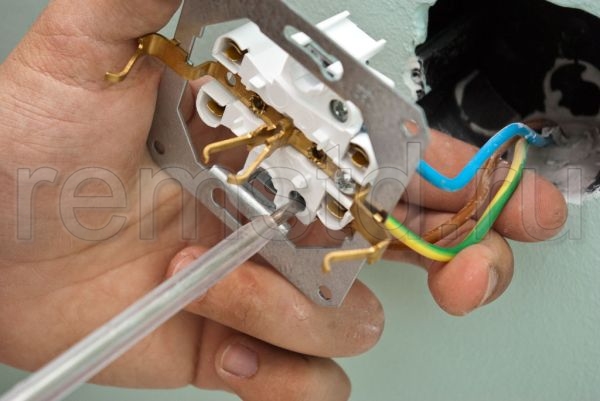

Of great importance for the reliability of the outlet is the quality of the mechanical connection of the supply wires to its terminals and the reliability of the electrical contact in this connection. In other words, the terminals must firmly hold the wires and ensure reliable contact with the live parts of the outlet. The most famous and, perhaps, still the most reliable for power wiring and sockets are screw terminals. In them, the wires are pressed against live parts using screws. Their main advantage is that the force with which the wires are clamped in the terminal can be very significant, and this ensures both good wire retention and reliable electrical contact. However, to prevent loosening of the clamp due to vibration or heating, the screws in the terminals are desirable to be used together with spring washers, which prevent spontaneous unscrewing of the fasteners.

Spring terminals are often used in the design of household electrical outlets. Their advantage lies in the fact that they greatly facilitate the connection of wires. To do this, simply bend the bare end of the wire with some effort into a special hole on the socket housing. The spring-loaded "knife" inside the terminal locks the wire and presses it against the live parts of the socket. But the power of this "clamping" is difficult to control, and if for some reason it weakens, the unreliable contact of the wire with the socket will remain unnoticed at the stage of installation and lead to premature failure of the outlet.

The installation conditions of the outlets are often forced to connect to each terminal not one but two wires. With this in mind, both in the screw and spring terminals are provided with two seats or holes for the wires. But when pairing up the wires, you need to make sure that their diameters are the same, or differ very little. Otherwise, a wire with a smaller diameter will be poorly fixed. For example, it is practically impossible to clamp a 1.5 mm² wire with a single screw if a 2.5 mm² wire is connected to it at the same time.

As you know, to connect household electric appliances you need two single-core wires or one two-wire. Therefore, each socket has at least two insulated terminals and receptacles, and if the wiring is made with a three-wire cable, in which the third conductor is ground, then it is advisable to install sockets with additional earth electrodes (so-called "grounded sockets") on such electrical wiring. For safety requirements, these electrodes are located in the socket design so that when the plug having similar electrodes is turned on, the grounding electrodes on the plug and socket come into contact earlier than the fork pins come into contact with the receptacles of the socket. Therefore, the grounding electrodes are always clearly visible on the outlet. This is either two metal plates on the sides, or one metal pin, very similar to the pin of the power plug. The grounding electrodes are connected to its terminal, to which the grounding wire of the electrical wiring is connected.

The most important technical characteristics electrical outlets are the permissible electrical current and operating voltage. As a rule, in internal wiring of residential and office premises, sockets designed for 10 or 16 amperes and operating voltage up to 250 V are used. In order for current carrying details of the outlets to be able to pass such a current with minimal heat release (in other words, not warming up), for them production of special metal alloys with a relatively large content of copper (10-60%.). The electrical conductivity of such alloys is quite high and allows us to fulfill this condition without significantly increasing the dimensions of live parts and the sockets themselves. At the same time, these alloys are harder than pure copper and have the elasticity necessary for the proper functioning of the receptacle sockets.

Obviously, the above-mentioned permissible outlets for the outlets correspond to the range of values consumed electrical power, in which the vast majority of household appliances operate. And only for kitchen electric stoves will require special, more powerful sockets (connectors). But even more often they are connected at all without sockets - through terminal boxes.

Types of electrical outlets

Electrical outlets are overhead, built-in and portable. Concerning the latter, it will suffice to say that they are designed as a portable device with a dielectric casing that protects it well from the influence of the external environment. Such cases are used on all sorts of electrical extensions. Typically, the other end of the extension cord is fitted with a power plug.

Overhead outlets mounted on open electrical wiring, when the wires are laid on the surface of walls, ceilings and other building structures. These sockets are attached to the wall in the right place with the help of screws or screws, passed through the fixing holes in the bottom of the socket housing or in a monolithic base. The wires are connected to the terminals through an opening in the side wall of the housing.

Although the method of attachment used in overhead outlets is simple enough, it ensures reliable fixation of the sockets on the supporting surface. More often some difficulties with fastening arise when installing the built-in sockets. There are two reasons for this. Firstly, their installation and fixation mechanism is really more complicated than for invoices. Secondly, built-in sockets are used at the device concealed wiring, applied almost everywhere. To the built-in sockets and to the quality of their installation, higher demands are made.

It is installed so that its functional module (mechanism) completely hides in the wall. On the surface there are only decorative lining. This socket is fixed in the wall with the help of spacer feet and screws, which are passed through the holes in the mounting plate. Many people know the situation when, when you turn off the power plug, the outlet falls out of the wall and hangs on the wires. This trouble most often occurs with built-in outlets that are ineptly fixed with the help of just the feet.

Always unpleasant when something does not go well. And it is doubly insulting when simple and seemingly more than reliable things are brought, for example, rosettes. In fact, everything has its own resource of trouble-free operation, and electrical outlets too. Under the influence of electromagnetic fields are subjected to slow destruction and plastic parts lose their strength, electrical contacts deteriorate with time. In the process of prolonged use, the screw connections are weakened, the rosettes are loosened and even fall out of the wall. In the end, they just become unusable, and we exclude them from the number of useful things. These sockets must be replaced.

But often the cause of the failure of the outlets are errors in their installation or improper operation. In this case, you can try to repair them. Let's consider some typical situations. If, after connecting electrical appliances, especially powerful ones, the outlet spreads a sharp smell of burnt plastic, it means that somewhere in the socket there is a bad electrical contact, on which too much heat is released. After taking out the plug from the outlet and waiting for 30 seconds, touch the plugs of the power plug. If they are hot, then this indicates that, most likely, the receptacles of the socket, which are not loosely adjacent to the fork pins, have lost their elasticity. This is indicated by darkened from the high temperature edge of the holes for the plug in the front panel of the outlet.

If the pins are only slightly warm or completely cold, then contact breakage should be sought in the place of connection to the outlet of the supply wires. It is possible that one or both of the terminals do not press the wires to the live parts of the outlet well enough. In new sockets (or those that are used for less than a year), the clamping screws on these terminals are simply not suitable for installation.

The socket can overheat and even ignite, if through it energize a too powerful electrical appliance or several electrical appliances, the total power of which creates a current that exceeds the permissible current of the outlet. By the way, the value of the permissible current and the operating voltage, as a rule, are indicated on the front panel of the socket. For example, there you can read: 10 A, 250 V. This means that it is possible to include electrical appliances with a total power of not more than 2.2 kW into the socket. In a socket designed for a current of 16 A, you can turn on electrical appliances with a power of up to 3.5 kW. The outlet, which is heated, you can try to repair.

Without fail, disconnect all electrical wiring of the apartment or the part of it in which the outlet to be repaired is installed from the power supply. Note that repair it makes sense only if the reason for the heating was the screw terminal. All other problems are not fixed by themselves. Receiving pockets that have lost elasticity, weak spring terminals - all these are sufficient grounds for replacing the entire outlet (or its functional module). Thus, disassemble the outlet for repair is only meaningful when everything indicates a poor contact of the wires with the sockets of the outlet.

If this is the case, unscrew the screw holding the front panel of the socket with a suitable screwdriver and remove it. Together with it, the decorative frame is easily removed. Under them is the outlet mechanism. If it uses screw terminals, then on its lower or upper edge will be noticeable two identical spikes located symmetrically on the sides of the vertical axis of the socket, possibly leading to them wires. Screw to the point of failure (but still do not cut off the thread), both screws. Replace the frame and the front bezel. Everything, the repair is over. Otherwise, if you open the outlet mechanism, you will find that the terminals are spring-loaded. In this case, replace the entire outlet. How to do this will be described below.

In obsolete models of sockets with a porcelain base screw terminals are located on the bottom and are not visible from the front of the outlet. To tighten the screws of these terminals, it is necessary to remove the socket from the installation box. Better yet, just buy and install a new outlet.

Repair of the built-in socket

1. Built-in socket with cut halves and front panel. In the middle, you can see the screw securing the panel to the socket mechanism

2. Remove the decorative pads and, if necessary, cut off the wallpaper with a sharp knife, hiding the mounting frame

3. To remove the mechanism from the installation box, it is necessary to unscrew the screws securing the mounting frame

4. Before connecting the outlet, be sure to check the lead wires for broken wires

5. After checking, remove the chip from the spring terminal and insert into it the bare end of the whole wire

6. Screw the screws into the edge of the box, pass their heads through the slots in the mounting frame. Turn the mechanism clockwise

7. If the terminals are screwed, then the bare end of the entire wire is clamped with the terminal screw

8. A double socket can be installed in one installation box, which is repaired in the same way.

Quite often the socket just does not work. That is, connecting electrical appliances to it does not mean connecting to a power source. And if you turn on the power plug in such a socket there is no sparking, then the cause is one - somewhere there was a break in the phase or zero (less often both) lead wires. Check which one is easy. It is enough to touch the phase indicator (phase detector, voltage indicator) to one, and then to another electrode of the socket. If, at one of the touches, the indicator light is on, you should look for a zero wire break. And if not - then phase or both.

It is possible that the wire is broken or damaged during installation of the outlet. Then the breakage place can be found in the installation box. After disconnecting the power supply of the apartment or the corresponding piece of electrical wiring, remove the outlet from the box (as will be clear from the discussion below) and check the lead wires. If visually they seem whole, touch them, try to bend gently (hidden under the insulation, the wire is invisible to the eye, but it can be detected by touch), finally check if they stay in the terminal well. Having found out a bummer, cut off the broken off end, clean the remained whole wire and pinch in the terminal. To remove the debris from the spring terminal, you must press the button above it.

Spark when the appliance plugs into the socket means that the receptacles of the receptacle have completely lost their elasticity. This outlet requires replacement.

It is dangerous when the built-in socket falls out of the wall and hangs on the wires. Current-carrying parts of the sockets and exposed wires near the terminals are accessible for accidental contact and may cause damage electric shock. If the socket itself is not damaged in this case, then it is easy to install it and strengthen it.

All built-in control and switching devices of modular design, including electrical outlets, have the same type of attachment points. These are the mounting slots on the four sides of the mounting frame and the spacer tabs on the sides of the function module that are diverted from the monolithic base of the module when the corresponding screws are screwed.

For (including rosettes) in the wall, a hollow cylindrical drill ("crown") is drilled with a perforator or drill in it, in which a mounting box is fixed in one way or another (most often with alabaster). It can have different shapes, but it should allow the functional module of the device to be completely immersed in it and strengthen it there with spacer paws. In addition, at the top edge of the box must have holes, designed to fix the mechanism of the socket (self-tapping screws through the slots in its mounting frame).

After disconnecting the power supply to the apartment or the corresponding part of the wiring harness, the front panel and the decorative frame should be removed from the protruding socket (the retaining screw is usually well visible in the center of the panel), release the screws of the spacer legs, press the tabs to the base of the socket mechanism and insert it into the installation box. In this case, the slots in the mounting frame must be above the holes for the screws in the edge of the box. Screw in the screws can be done after installing the socket in the box or before - slots in the mounting frame in one of the positions pass the screws with the cap. When the function module of the socket is correctly oriented (the sides of the mounting frame are located strictly horizontally or vertically) and fixed to the box with self-tapping screws, fix it with the spacer tabs also by tightening their screws.

Naturally, the rosette returned to its place in the wall should be closed with a decorative frame and a front panel that were previously removed.

Sockets are not the most complex commutating devices of those used in electrical engineering. However, the multiple connections to them of electrical appliances significantly affect their performance. Given that one of the consequences of socket failure can be abundant heat generation and even fire, it makes sense to carefully monitor the status of outlets, repair them in time or replace old outlets with new ones.

Tip: not having the necessary skills and qualifications, do not start work with wiring - it's dangerous! Handle this work to a qualified technician.

Despite the existence of uniform global standards, they are not always widely used in different countries, which should be taken into account, for example, when traveling on a business trip. The same types of outlets that are common in the CIS countries and parts of European countries can not be used to charge the phone or connect a laptop brought from the USA or Japan. In addition, even if you choose an outlet on the domestic market, then for different tasks there are devices with their connectors and functionality.

General details and design differences in different countries

The laws of electrical engineering work everywhere the same - on the ground, under water or on the moon, so the basic device is always the same everywhere, regardless of which outlet is used for the type and purpose. Its main task is to ensure a simple connection and disconnection of the appliance to a stationary electrical network. As a result - the elements and materials will be the same everywhere, and the main difference will be in their form, which is historically applied in different countries.

Main types of sockets used in different countries:

This video details the features electrical networks and in particular sockets in different countries of the world:

From what parts are the sockets assembled

According to the above devices, it can be seen that all types of household outlets, despite the different designs, have a common structure. The design of the standard socket includes two main connectors for phase and zero, and if the model allows for grounding, there will be three contacts. Accordingly, if the voltage applied to it and the frequency of the current approach the device to be turned on, then it will work if an adapter is available.

The outlet device, regardless of its type, type and characteristics, includes the following elements:

These are common parts that are in any outlet, but there are also devices on the market with additional functions, in which this list will be wider.

Differences by type of installation

According to this criterion, the types of electrical outlets are divided into two main categories: internal and external.

The first type of device is used most often, despite the certain difficulties associated with their installation - the installation takes place in the wall, for which it must cut out a hole for the outlet itself and a groove for the wire that will fit it. These shortcomings are covered by undoubted advantages in terms of aesthetics and fire safety - you do not have to stumble on the wires, risking them to spoil, and if there is a short circuit, then in the thickness of the wall it's not scary.

External types of outlets are most often used, if necessary, to lay temporary wiring or wooden houses, where the installation of internal wiring is subject to very stringent restrictions and is not practically applied. Also, the outer method often attached power sockets, which are large in size.

Technical characteristics - power and household sockets

Worldwide, only two standard frequencies are used alternating current - 50 and 60 Hertz. These values are absolutely not important for the sockets themselves - only the amount of current loss depends on them when it is transported over long distances.

The voltage standards are also a little bit - 100, 110, 115, 120, 127, 220, 230 and 240 volts. Given that the permissible deviations are +/- 10%, we can assume that the main standards are two - 127 and 220 volts.

Much more attention should be paid to what are the sockets by the current strength, on which their contacts are calculated - in modern household devices this is 10 and 16 Amperes. If you want to connect a device designed for a large current, then you need to install it power outlet - they are usually designed for 32 Amps. The principal difference in them is in the thickness of the contacts, due to which a large area of their contact is obtained.

Species by designation

If initially the sockets were used exclusively for powering electrical appliances from the power grid, then with the increase in the number of wires in the average house, it became necessary to hide some of them in cable channels and draw conclusions. As a result, new types of outlets have appeared that have become the outputs of antenna wires for TV, cables for Internet connection of computers, radio and fixed telephones. Recently, they even install female terminals to which you can connect speakers from the audio system and a USB cable to charge the phone.

Regardless of what the socket is used for, its main components remain the same - the base, the fastening mechanism, the contacts and the isolating (part-decorative) cover.

Additional functions

When pressing issues are resolved, they begin to engage in comfort - the following types of outlets are a premium device with additional functionality that allows improving the conditions of their operation.

As a result

Regardless of how the rosette is arranged externally, its main components are always the same. Thanks to this, when traveling to other countries, it is often possible to use (or make yourself) an adapter to use the charging of a mobile phone or laptop. The truth before this is to find out which country has adopted a standard for the frequency and voltage of electric current.