Мгшв wire installation. Wire mgsv: characteristics mgshv, design, description -oooo "tatlon

IMSS

Normative document: TU 16-505.437-82

Elements of construction:

- The conductor is twisted from copper tinned wires;

- Isolation of polyester yarns;

- PVC insulation, color insulation: white, natural, yellow, orange, red, pink, blue, blue, green, brown, black, purple.

Note: at the request of consumers, the wires can be supplied with the number of cores from 2 to 5.

Characteristics

Humidity at 35 ° C [%] |

|

Pulse voltage [V] |

|

Testing aC voltage frequency of 50 Hz, 5 min. [kV] |

|

Maximum operating temperature of the conductor [° С] |

|

Operating alternating voltage with a frequency of 10 kHz [V] |

|

Working constant pressure [AT] |

|

Construction length, not less than [m] |

|

Ambient temperature, upper limit [° C] |

|

Ambient temperature, lower limit [° C] |

|

Electrical insulation resistance, not less than [MΩ * km] |

Application area:

The wires of MGSHV brand are intended for mobile and fixed installation of intra-block, interblock, intra-instrument and inter-instrument connections in electronic and electrical devices, as well as the output terminals of the electrical equipment for operating alternating voltage of 1000 V with a frequency of 10 kHz and a constant voltage of 1500 V.

The wires are designed for operation on land and at sea in all macro-climatic regions, except for the macroclimatic region with a very cold climate. The wires are resistant to sinusoidal vibration in the frequency range from 1 to 5000 Hz with an acceleration amplitude of 400 m / s 2, a single-action mechanical shock with a peak shock acceleration of 10,000 m / s 2, an impact shock duration of 0.1-2.0 ms, mechanical impact of multiple action with a peak shock acceleration of 1500 m / s 2 duration of shock acceleration of 1-5 ms, linear acceleration of 5000 m / s 2 and acoustic noise in the frequency range 50-10 000 Hz at a sound pressure level (relative to 2/105 Pa ) 170dB. The wires are resistant to low atmospheric pressure to 1.33x10-4 Pa for 24 hours and increased atmospheric pressure to 295 kPa. The wires are resistant to atmospheric condensed precipitation (dew and frost), static and dynamic dust (sand), salt (sea) fog, mold fungi and solar radiation. Wires do not spread the combustion in a single laying. The wires are exposed to short-term exposure to temperatures: 100 ° C for 96 hours, 130 ° C for 5 minutes, 150 ° C for 10 minutes (without further use).

The minimum operating time is 10,000 hours. The minimum lifetime of the wires is 15 years. 95% of the resource is 15,000 hours.

Cross-section of veins, |

Number and diameter |

Weight of wire, |

Outside diameter |

Resistance |

Buy MGSHV 1 * 0.2 at the lowest prices in the company "Clive". All products are in stock in Moscow. Supplied MGSHV 1 * 0.2 has all the necessary quality certificates. We deliver all over Russia. For detailed information on the delivery of MGSV 1 * 0.2, see the section "Delivery".

Description and decoding of MGSHV 1x0,2:

M - Installation wire

D - Flexible (stranded wire)

Ш - The vein is covered with silk polyester yarns

B - PVC insulation

Elements of construction MGSHV 1х0,2:

Low-voltage installation wire with copper tin-plated conductive high-class residential flexibility class 4 or 5, combined fibrous and PVC insulation.

Operating conditions MGSHV 1x0.2:

The wire is intended for intra-block and interblock connections electrical appliances and equipment.

Type of climatic performance

The wire is resistant to vibration, shock and linear loads, as well as to acoustic noise.

The wire is designed for operation in the temperature range from minus 50 to 70 ° C.

The wire is resistant to relative humidity of air up to 98% at a temperature of up to 35 ° C, lowered to 133 micropaels (1 micrometer Hg) for 24 hours and increased to 295 kPa (3 kgf / cm2) atmospheric pressure, mold fungi, static and dynamic dust, salt fog, solar radiation, atmospheric precipitation, gasoline, mineral oil and salt water.

The wire corresponds to TU 16-505.437-82.

Specifications MGSHV 1h0.2:

The wire is available in 7 colors: white or natural, yellow or orange, red or pink, blue or blue, green brown, black or purple.

The electrical resistance of the core at a length of 1 km corresponds to GOST 22483-77.

Test lead voltage:

- sections of 0.08-0.14 mm2 with a frequency of up to 10 kHz - up to 380 V;

- sections of 0.20-1.5 mm2 with a frequency up to 10 kHz - up to 1000 V;

- sections of 0.08-0.14mm2 with a frequency of up to 50kHz - 800V;

- sections of 0.20-1.5 mm2 with a frequency of up to 50 kHz - 2000 V.

Electrical insulation resistance of 1 m wire, MOhm - not less than 20000.

The wire does not spread the combustion in a single laying.

The 95% resource is 15,000 hours.

Service life - not less than 15 years.

Wire characteristics MGSHV 1x0,2

- Weight, kg: 3.9

- Diameter, mm: 1.6

Want to learn about MGSHV wire 1x0.2 more?

Our technical specialists will promptly answer any questions you are interested in. Such as:

- rated cable mass

- outer diameter

- construction length

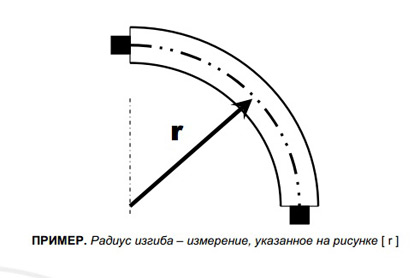

- minimum bending radius

- resistance of insulation and conductors

- long / maximum permissible current loads (continuous current)

- active / inductive resistance

- will help calculate the power of the cable (current), the rated voltage

Wire МГШВ 1х0,2 at manufacture has all necessary certificates and quality passports.

Produced according to TU 16.505.437-82.

Code OKP 358321.

Description and design of MGSV wire

MGSHV is an installation wire with a core of copper tinned wires, with fibrous insulation and PVC-plastic insulation.

Explanation of the designation:

"M" - installation;

"D" - flexible;

"Ш" - the first layer of insulation made of silk (currently made of polyester yarn);

"B" - the second layer of insulation made of PVC-plastic (vinyl).

Example designation: MGSHV 0.5 - wire MGSHV with a residential section of 0.5 mm 2

The range of produced cross-sections is from 0.12 to 1.5 mm 2.

The cores must be twisted from copper tinned wires. The design of the cores and the maximum outer diameter are given in the table.

The first layer of insulation is made of polyester threads superimposed by the winding.

The wires must be made in different colors.

If there is no indication of a certain color in the order, the manufacturer supplies the wires at his discretion, while it is allowed to supply wires with isolation of transitional and mixed colors (designation "SC").

Conditions of installation and operation of the MGSHV wire

Installation and operation are possible at temperatures from minus 50 ° C to plus 70 ° C. Does not spread the combustion in a single laying. Service life - not less than 15 years.

Technical characteristics of MGHV wire

The electrical resistance of conductors on direct current must be no more than indicated in the table.

The electrical insulation resistance per 1 km of length should be not less than 20 MΩ at a temperature of 20 ° C and not less than 1 MΩ at a temperature of 70 ° C.

The wires must withstand an AC voltage of 50 Hz for 1 minute, a value of 800 V for wires of 0.12 and 0.14 mm 2 and 2000 V for wires of other cross sections.

The wires must be resistant to vibration loads.

Requirements for wire wrapping MGSVV

The wires must be supplied in coils. The building length must be at least 50 m. In one delivery lot, no more than 30% of wires with a length of at least 5 m are allowed.

Requirements for marking the wire MGSHV

On the label attached to the bay or coil, the following must be indicated:

A trademark of the manufacturer;

- conventional designation of the wire (complete with indication of the section);

- length in meters;

- manufacturing date (year, month);

- designation TH.

Requirements for MGHV wire storage conditions

According to the climatic conditions, the wires must be stored in enclosed spaces.

Mass-dimension parameters of the MGSHV wire

Approximate weight of wires for packing and transportation purposes are given in the table. The values given can differ for wires of different batches and manufacturers by 10% on a smaller or larger side.

Available methods of wire quality monitoring MGSVB

The methods of control are given which, not being strictly consistent with the specifications, allow us to draw preliminary conclusions about the quality of the wire, if the measured values are significantly different from the regulated values. The final conclusion on the conformity of the TU wire can only be made after testing the wires in a specialized laboratory using strict procedures and in the volumes specified in the specification.

Visual inspection

Can be checked: the number of wires in the vein, the coloring and integrity of the insulation.

Measurement of structural dimensions Can be checked using suitable measuring tools outer diameter. Measurement of the wire diameter dp and calculation of the wire cross-section according to the formula 0.785d pr 2 N (where N is the number of wires in the core) is not a strict method of monitoring the cross-section of the wires. The electrical resistance is the confirmation of the cross-section, but a significant deviation of the calculated cross-section from the nominal cross section (by more than 10%) may serve as a basis for doubt in quality.

Measuring the electrical resistance of conductors

Can be carried out by an ohmmeter with an appropriate measuring range and recalculated to a length of 1 km. Special attention should be given good contact with the test leads.

MGSHV is a mounting wire with a copper multi-wire tin-plated wire in insulation made of polyester threads and a PVC plastic sheath.

The price of wire MGSHV depends on the cost of copper, tin and plastics used in its manufacture, the current price of the warehouse wire MGSHV is indicated in the section price list, discounts are given from the order quantity, specify the final cost of MGSHV wire from the manager.

Buy MGSHV wire can physical and legal entities for cash and cashless settlement, shipment of the warehouse wire MGSHV is made within one day after payment.

Explanation of marking MGSHV:

M - mounting.

D is flexible.

Ш - insulation from polyester threads.

В - a shell of PVC plastic.

Technical characteristics of the MGSHV wire:

The operating temperature of MGSHV wire is -50 to +50 degrees with relative humidity not more than 98%.

The impulse voltage is 700 volts.

The working alternating voltage is 1000 volts at a frequency of 10,000 hertz.

The electrical resistance of the wire insulation MGSHV is not less than 100 MΩ per kilometer.

Wire construction MGSHV:

1) Core - twisted from copper tinned wires.

2) Insulation - from polyester threads.

3) Sheath - PVC compound, color of insulation: white, natural, yellow, orange, red, pink, blue, blue, green, brown, black, purple.

The use of the MMSH wire:

Mounting wire MGSHV is designed for mobile and fixed installation of intra-block, inter-unit, intra-device and inter-device connections in electronic and electrical devices, as well as the output ends of electrical equipment for operating alternating voltage 1000 V with a frequency of 10,000 Hertz and a constant voltage of 1500 Volts.

The wires MGSHV have found wide application in radio electronics, the production of household appliances and in everyday life. Due to its good flexibility, reliable insulation and excellent physical characteristics, the scope of their application is constantly expanding. Therefore, in our article, we decided to consider this type of wire in more detail.

Decoding and structure of wires MGSHV

First of all, let's look at the decoding of the name and the structure of the wire. This will give us an understanding of the basic mechanical, and partly physical, properties of the wire.

Explanation of the name MGSHV

In general, the decoding of the name of the wires has certain standards. But for people who do not often encounter these abbreviations, this can be difficult. Therefore, we decipher each letter and number in the title.

So:

- The first letter is "M". But according to the standards the very first letter can only be "A". The absence of "A" at the beginning of the abbreviation suggests that the wire is made of copper. If "A" is, then it means that the wire is made of aluminum. Copper has higher conductive properties than, say, aluminum, which is a positive moment. But the price of such material is somewhat higher.

- The first letter "M" indicates that this wire is an installation wire. Unlike installation, it can be repeatedly reconnected and moved, which is an undoubted plus.

- The second letter is "G". She says that this wire is flexible. This means that the radius of its bending is small enough, and the wire itself is not lower than the fourth class of flexibility.

- The third beech "Sh". She says that the wire is made of silk. Now, of course, not natural material is used, but polyester threads, but in their properties they practically correspond to silk.

- Fourth letter "B". She tells us that the main insulation is made of vinyl. More correctly, this material is called PVC or PVC.

- But that is not all. In some cases, the wire may still contain the "E" marking. He talks about the presence of such a conductor screen. The screen is made of tinned copper conductors of small cross-section.

- After this, the abbreviation usually indicates the numbers. The first one indicates the number of cores in the wire. As the manufacturers' manual says, the MGSHV wires are made with single-, double- and three-core wires.

The last value is the wire cross section. For this brand of wire this series is not that great. This can be wires with a cross section of 0.12, 0.14, 0.2, 0.35, 0.5, 0.75, 1 and 1.5 mm 2.

Wire structure

Now let's take a closer look at the wire structure. Although, after decoding the name, it is already more or less clear with it.

Nevertheless, on some details it is necessary to stop in more details:

|

|

First of all, this is the current-carrying part itself. As we said above, this wire belongs to the products of the 4th or 5th class of flexibility. This means that the wire is made of at least seven separate wires, twisted together. And the smaller the diameter of each individual wire, the higher the flexibility of the entire wire. The minimum diameters of each individual wire are normalized to GOST R 53768-2010. |

|

|

The next material in the product is silk. Him specifications provide additional protection against abrasion, and act as the main dielectric. The thickness of individual threads and the whole insulation as a whole is normalized technical conditions, and different manufacturers can differ significantly. |

|

|

On top of silk, PVC insulation is applied. This material is flexible enough and reliable in operation. The thickness of this layer depends on the cross-section of the wire, but is usually not less than 0.7 mm. Although individual manufacturers produce products with lower indicators. |

|

|

If the wire has a screen, then it is made of copper wires. Their diameter is usually 0.15 mm. And for protection against corrosion, screen wire is usually subjected to tinning as in video. |

Now let's talk in more detail about the main characteristics of the wire. They can be divided into physical and electrical. So let's look at them separately.

Physical characteristics of MGSVW wires

Let's start our conversation with physical characteristics, which are more dependent on the structure of the wire and the materials used. And in this regard, MGSVV wire is not so bad.

So:

- One of the main characteristics of any wire is its flexibility. As this figure is higher, the smaller the bend radius can be at the wire. For our case, the minimum bend radius is at least 10 wire diameters.

- Another important physical parameter is the temperature range, in which the wire can be operated. It is -50⁰ - + 70⁰С. And if the lower limit is quite comfortable, then the upper limit is far from the best, and is due to the characteristics of PVC insulation.

Note! The wires of the MGSHV brand allow a short-term increase in the ambient temperature to + 150 ° C. But I would not advise abusing this feature. Especially if the wire is stretched.

- The positive thing is that the wire does not spread the combustion. But only with a single laying. In combination with such an indicator as resistance to oils, gasoline and sunlight, it looks quite convincing.

- Also worth noting is that the wire is resistant to single shocks, vibration and acoustic vibrations. For household appliances, this can be very relevant.

- As for the life of the wire, you can meet several indicators. This is 10, 12 or 15 years. In this case, the minimum operating time of the wires, in any case should be not less than 10,000 hours.

Electrical Characteristics

But for any electrical product, technical characteristics do not do without bringing electrical indicators. These include the conductivity of the product, the resistance of its insulation and the methods for conducting high-voltage tests.

- First of all, let's look at the losses in the wire. They are due to its internal resistance, and are strictly regulated by GOST. It is clear that they are directly dependent on the cross-section of the wire. For example, a wire with a cross section of 0.12 mm 2 should have a resistance of not more than 155 Ohm / km. But the product with a cross section of 1.5 mm 2, has a resistance of not more than 15 Ohm / km. This is a very worthy indicator - somewhat higher than the standard set by GOST.

- The next important aspect is the insulation resistance of the wire. It directly depends on the ambient temperature. According to the GOST standards, the insulation resistance is normalized at a temperature of 20 ° C and at 70 ° C. In the first case, it should not be less than 20 MΩ, and in the second - less than 1 MΩ.

- An important aspect is the stability of the wire in high-voltage tests. Of course, it's almost impossible to carry them out with our own hands, but we will trust the manufacturer who should selectively check his products.

- Wires cross-section up to 0.14 mm 2 inclusive must withstand a test alternating voltage of 50 Hz in 800 V for 1 minute. Wires with a large cross section are already tested with a voltage of 2 kV.

Note! This test voltage does not mean that the wires can be used for a long time in this mode of operation. Nominal for this type of wire are AC voltage up to 380V for cross-sections of 0.14 mm 2 and below, and 1000V for wires with a larger cross-section. For direct current, these figures are equal to 500V and 1500V respectively.

Conclusion

MGSVV wires are quite a good option for laying inside devices for low-voltage networks. At the same time, it is not entirely correct to use them for outdoor installation, in the automotive industry or for mobile electrical installations.

In an extreme case, this can be the withdrawal of electrical apparatus. But for laying inside the apparatus they are quite suitable, as they have good flexibility, tinning, and a rich color scheme.