Exhaust ventilation system

The exhaust ventilation system in Russia is implemented by INTECH (Moscow). To get a quotation for exhaust ventilation, call: +7(495) 118-27-34. Submit an application

The main task of exhaust ventilation is to remove exhaust air from the room. In residential premises, exhaust ventilation is used mainly in combination with supply ventilation as part of general ventilation, however, at production facilities it can be used for point removal of polluted air with a high concentration of gases, smoke, dust or excess heat in places of highest concentration - in especially hazardous production areas, in installation sites for industrial equipment, etc. A typical example of local exhaust ventilation is a kitchen hood.

Our advantages:

10 years of stable and successful work

More than 500,000 m2 completed

Why do we have the best price?

Minimum terms

100% quality control

5 years warranty for work performed

1500 m2 area of own warehouses

Types of exhaust ventilation

Depending on the method of motivation, the following are distinguished: types of exhaust ventilation:

- natural ventilation

- Mechanical (forced)

According to the volume of the serviced area, exhaust ventilation systems are classified into:

- Local (removal of air in a specific area)

- General exchange (ensuring full air exchange throughout the house / apartment)

Any exhaust ventilation system works in conjunction with supply air: they provide air exchange in the room and create a microclimate that is comfortable for life and work. Absolutely all types of exhaust ventilation are ducted, since the exhaust air is removed through an extensive network of air ducts.

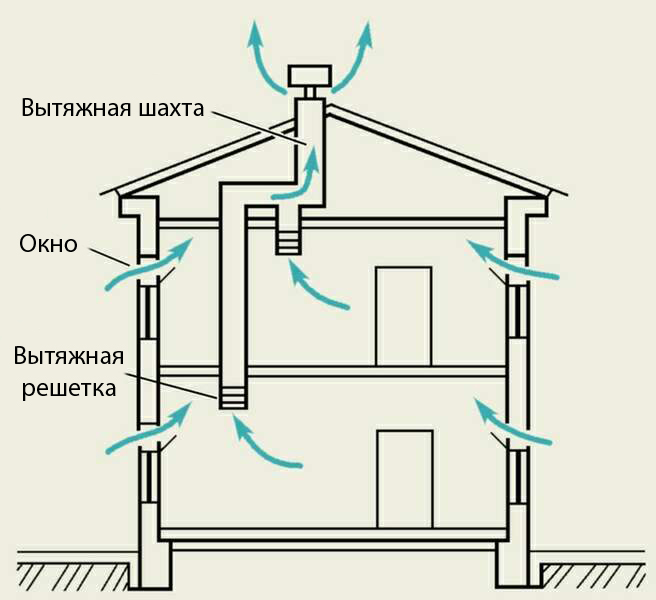

Natural exhaust ventilation systems

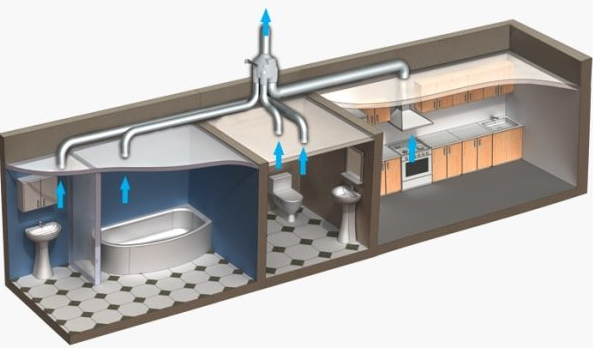

natural ventilation designed during the construction phase of the building. It is a system of channels into which air enters through the vents in the kitchen and bathroom, and then is discharged into the atmosphere through a pipe on the roof of the building. The advantage of such a system lies in its durability - no additional equipment or power supply is required to ventilate the premises. The main disadvantage of natural ventilation is strong meteorological dependence; under certain conditions (in warm, calm weather), air circulation stops completely.

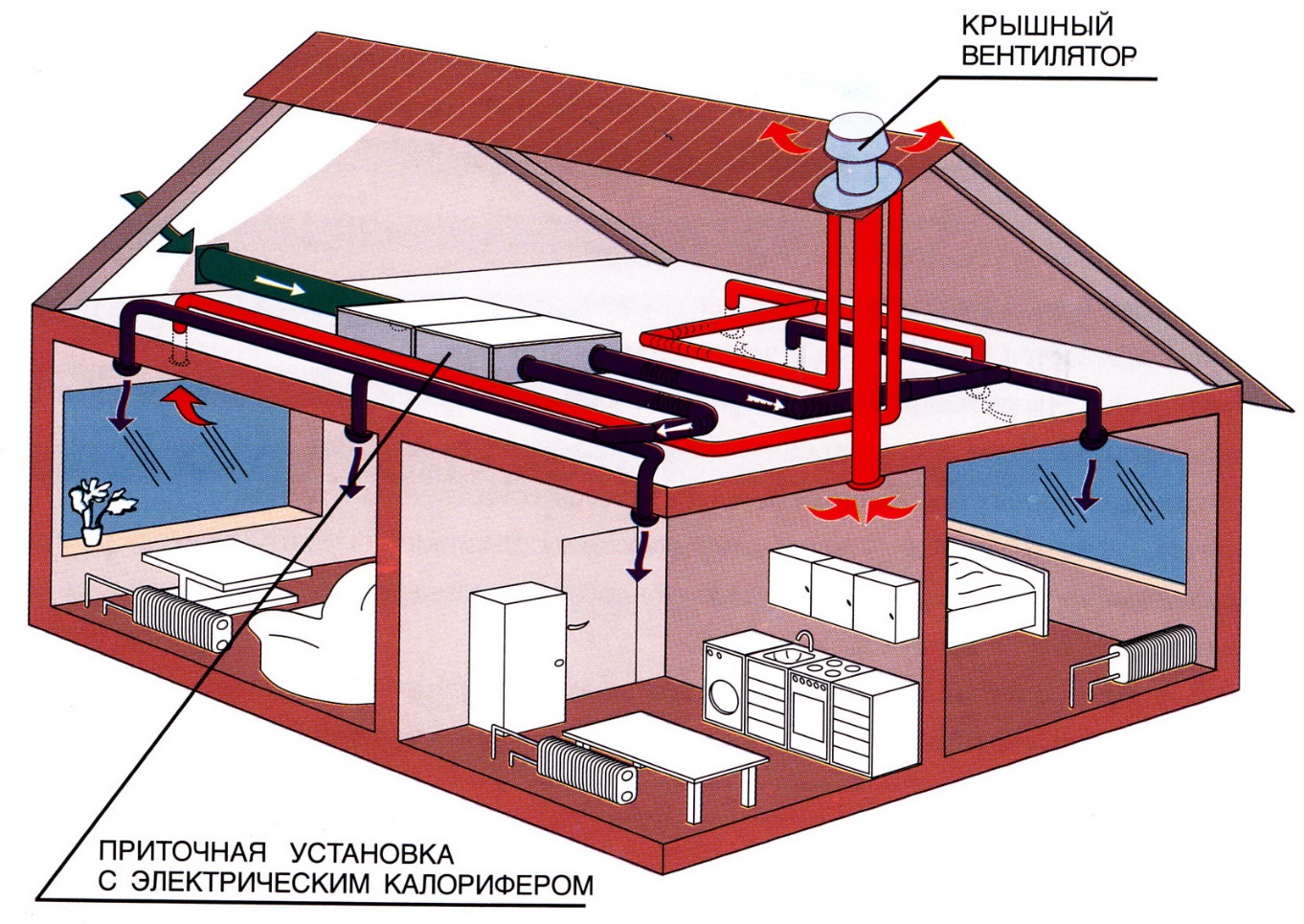

Fig 1. Scheme of operation of natural supply and exhaust ventilation

This diagram clearly shows the direction of air flow during room ventilation: fresh air enters the room through the pores and slots of the building envelope (windows, doors, walls), and displaces the exhaust air masses through the exhaust ventilation channels.

Air intake grilles are not accidentally installed in the kitchen and bathroom: air flows move in their direction and "lock" odors, steam, humidity, preventing them from spreading through the living quarters.

Such systems are extremely easy to maintain and do not require additional financial costs, however, they have a number of significant drawbacks:

- Meteorological dependence, you can control (not always) only the traction force, but not its presence.

- The use of heat and noise insulating building materials can stop air exchange.

- In winter, the direction of flow in the mines may change, and cold air from the street will begin to flow into the premises.

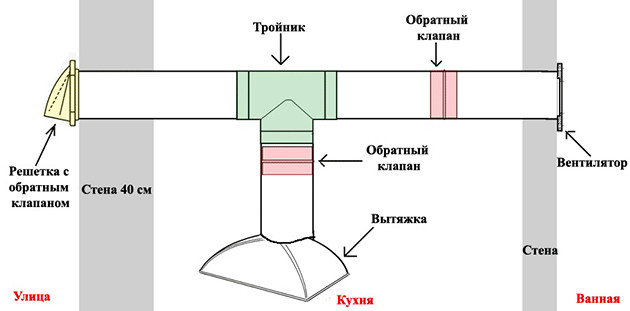

The exhaust ventilation system can be optimized. If natural draft is not enough for proper air exchange, then specialized equipment is installed at the most important points instead of a conventional ventilation grill - an exhaust fan in a bathroom or toilet, an exhaust hood in the kitchen, etc. At the same time, the system of ventilation ducts is equipped with valves so that the polluted air is vented to the street and is not squeezed into neighboring rooms.

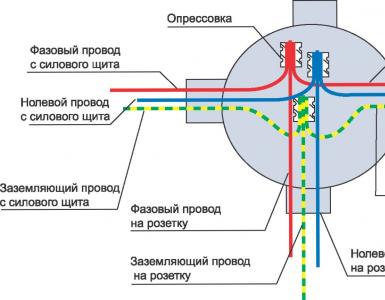

Fig 2. Ventilation system with natural and artificial stimulation

Inserting a kitchen hood into a general house / apartment network of ventilation ducts is a typical example of combining general and local ventilation systems.

Stable operation of exhaust ventilation can be ensured by using a mechanical supply ventilation system: fresh air enters the room through special channels or shafts (depending on the type of system) and automatically displaces the exhaust air masses. This combination eliminates all the disadvantages of natural exhaust ventilation and is one of the most popular solutions in Russia.

Fig 3. Combination of ventilation systems: forced supply and natural exhaust

A small supply of air in addition to that supplied through natural ventilation systems can be obtained from an air conditioner if it has a "fresh air supply" in the list of its functions. Most often, this option is found in expensive models and can be supplemented with ultrafine filtration and air ionization systems. Not to be confused with conventional recirculating air conditioners.

Forced exhaust ventilation systems

At the core forced exhaust ventilation systems lies the thrust created by the ventilation equipment in the outlet shaft of the system. However, it is important to take into account that such a system will only work fully if there is a sufficient flow of air (into the room) from the outside, otherwise the fan will run idle.

Figure 4. Mechanically driven exhaust ventilation system

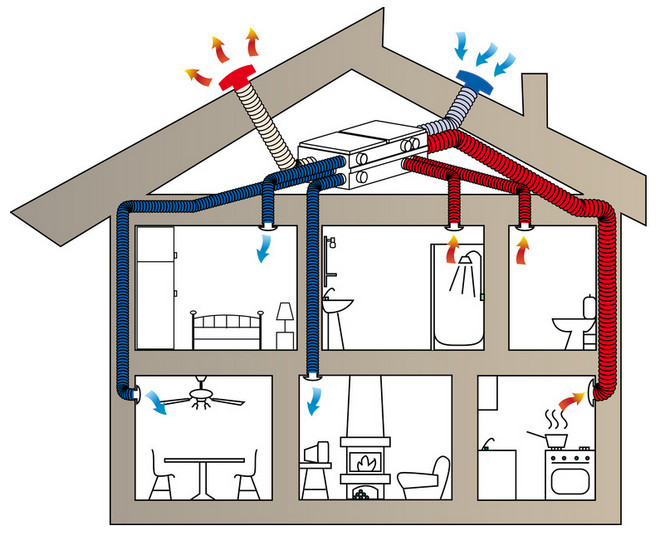

The most popular are supply and exhaust ventilation systems with mechanical motivation. They provide full air exchange in all rooms and premises (in accordance with the project), while the system is completely balanced: air is removed from an apartment or house at the same rate as it enters, without creating an excessive load on the exhaust ducts.

Fig 5. Scheme of forced ventilation

What you need to know to design a full-fledged supply and exhaust ventilation system:

- The volume of air exchange is calculated based on the size, purpose of the premises, the number of residents, the characteristics of kitchen and sanitary equipment. Normally, all the air in the room should be replaced in one hour. The performance calculation is always carried out according to the supply ventilation system.

- If the ventilation shaft is taken outside, you can choose a system of any capacity. If the exit cuts into a riser of a centralized ventilation system, avoid models that are too powerful - in many multi-storey buildings, ventilation shafts have prefabricated ducts, and you can transfer your air to your neighbors' apartments.

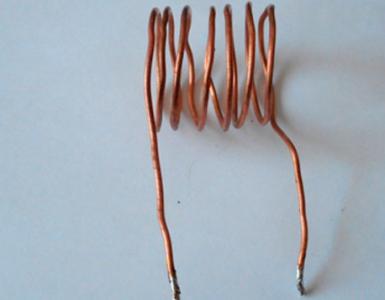

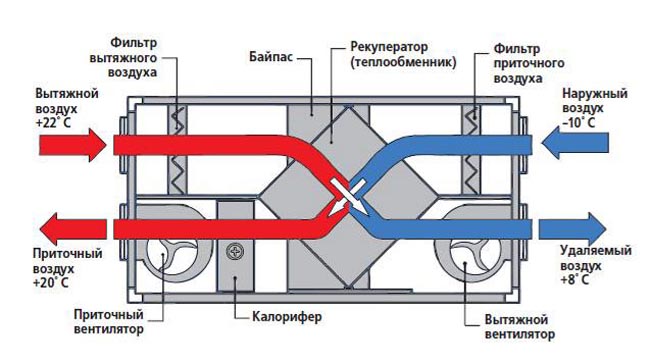

The supply air temperature must comply with SNiP 41-01-2003. At the same time, heating such a large volume of air masses in winter requires high energy consumption. It is possible to reduce energy consumption by using a plate or rotary heat exchanger: when the exhaust air is removed from the room, it passes through a heat exchanger and gives off its thermal energy. In parallel, supply air enters through the same heat exchanger, heating up from the energy of the removed air masses. The efficiency of some models exceeds 90% (cellulose), however, due to their low durability in conditions of high humidity or low temperatures, less energy efficient (within 80%), but more durable designs with a ceramic or copper heat exchanger are usually used.

Fig. 6. Design of a ventilation unit with a heat exchanger

Ventilation and air conditioning systems

After heating in the heat exchanger, the supply air can enter the room immediately or be additionally heated to the required temperature using a heater (electric or water) or cooled in a heat exchanger (freon or water).

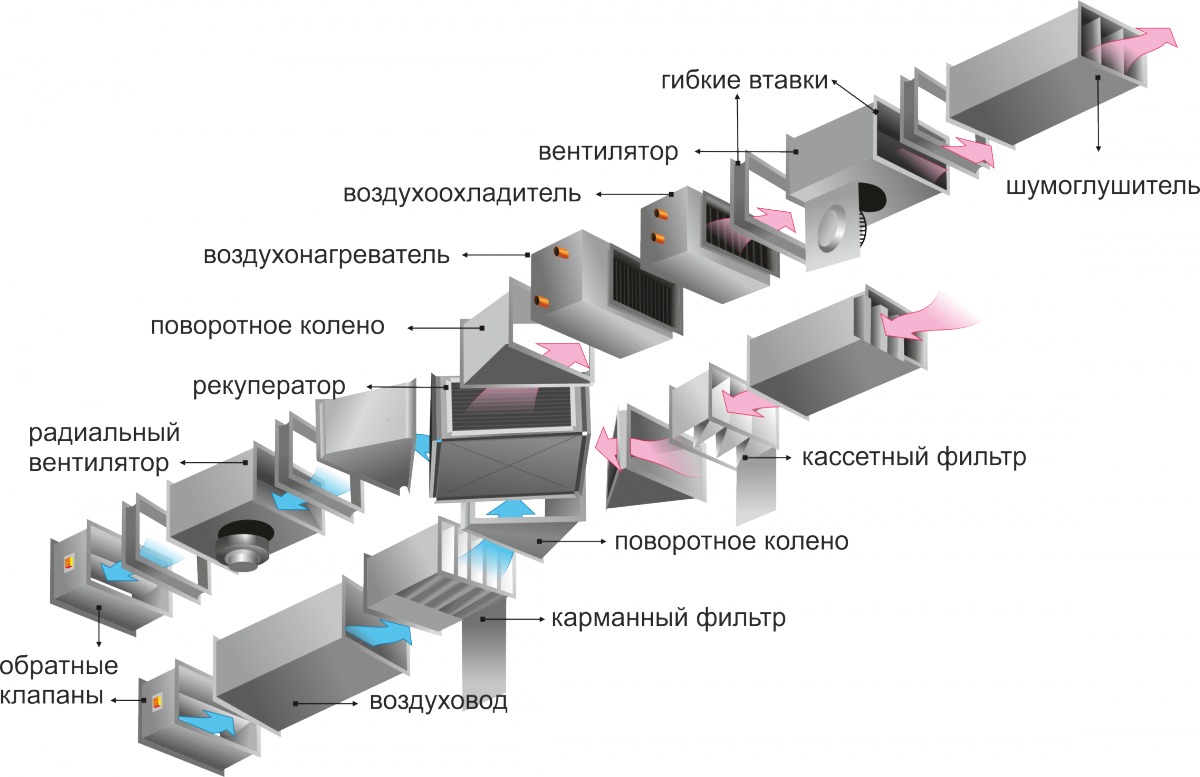

Most recuperation units are equipped with an additional low-power heater. Such monoblock ventilation units occupy a minimum of space and can be easily placed in a loggia or on a balcony. A separate unit is required for air cooling - most often it is used in stacked ventilation units consisting of separate components: a fan, a silencer, a filter, an automation system, etc.

Such type-setting ventilation and air conditioning systems are quite difficult to install and maintain, but they provide an ideal microclimate in the room.

Fig 7. Principal arrangement of the ventilation and air conditioning system

Local exhaust ventilation

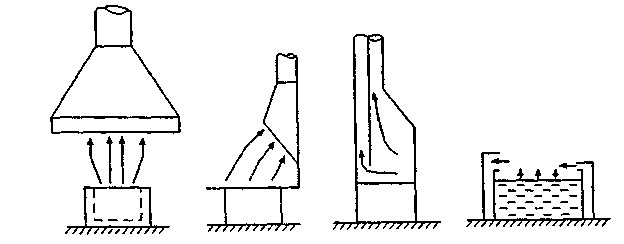

Unlike general exhaust ventilation systems, which are involved in total air exchange, local exhaust ventilation solves point problems when areas of air pollution are localized, and it is necessary to prevent the spread of harmful emissions throughout the room. Typical examples: kitchen hoods (except for recirculating ones), fume hoods in laboratories, air intakes in certain areas of "harmful" industries.

Fig. 8. Types of local ventilation: 1, 2 - exhaust hood, 3 - fume hood, 4 - double-sided onboard suction

Local exhaust ventilation systems are almost always equipped with a filter designed to trap certain impurities that are typical for a given area - dust, reagents, etc. Example: kitchen hoods are equipped with a grease and / or carbon filter, lathe casings have several degrees of dust retention.

Purified air can be discharged directly to the street or to the general exhaust ventilation network.

Receive a commercial offer by email.