How to move an outlet or switch in an apartment

Designing an apartment, a home craftsman performs various housework. Quite often, rearranging furniture creates inconveniences in the use of household electrical appliances. Sockets and switches end up in hard-to-reach places. It becomes inconvenient to get to them. There is a need to transfer.

Such work is classified as dusty and dirty. She's also dangerous. Electrical current, if handled improperly, can cause serious harm to the body.

Therefore, the transfer of an outlet or switch should be carried out by a trained electrician or home craftsman who is well aware of the safety rules and has the necessary practical skills.

The apartment owner needs to prepare, solve organizational and technical issues.

How to prepare for relocating an outlet

Relocation Technical Issues

After planning the work, the home craftsman assembles the tools necessary to place the wiring on the walls or inside them and proceeds to install the wire, cable, and transfer the electrical point.

Features of work in open and closed wiring

The methods of routing the cable to a new outlet or switch inside the walls are more labor intensive than from the outside.

Most often, you will need to cut a new channel for it - to make a strobe.

To exclude damage to the hidden wiring with a drill when fixing furniture, it is customary to place strobes only without using the sloped corners of the tracks.

Concrete tools

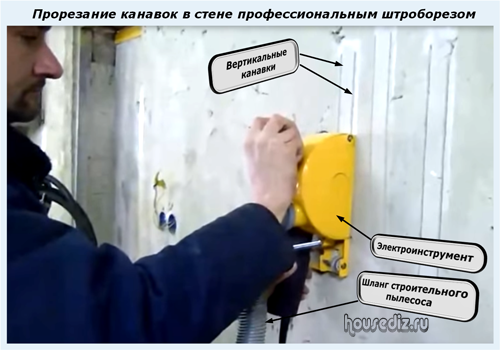

Wall chaser

It is convenient to handle long lines for hidden cable routing to the outlet with a professional wall chaser. Its cutting discs for concrete processing rotate in an enclosed space, and all generated dust and sand is immediately sucked off through the hose of the powerful construction vacuum cleaner.

With this work, a minimum amount of construction waste is generated. However, such a tool is quite expensive. It is used only by electricians who need to constantly process concrete walls.

You can make a single cable groove even in a concrete slab using:

- angle circular saw - grinders;

- bolts or chisels with a hammer.

Angle grinder

In this case, you will have to work hard and a lot of dust and sand will appear. Their distribution throughout the room will be significantly limited by the stream of water directed from the hose into the cut furrow. The smudges of the formed dirt will have to be removed with a damp cloth.

With an angle machine, first cut one groove, and next and parallel to it - the second. To form a continuous furrow, you will need to remove the concrete from the partition.

Puncher

Its chisel-like attachment allows you to quickly cut concrete partitions between the grooves cut by the grinder.

He can also use a concrete drill to knock out a sequential chain of holes and then remove the jumpers between them.

Hammer drill

With its help, you can also knock out holes for strobes. Only this process will be more laborious, long and noisy. It is difficult to process solid concrete in this way. An impact drill is best used on brick or foam block walls.

In all cases it is necessary to use protective goggles, a respirator, noise-dampening headphones. You will also have to pay attention to neighbors who clearly do not like the constant rumble and noise.

Changing the cable length

When relocating an outlet or switch, the existing cable line will most often have to be shortened or lengthened. If it has been in operation for a long time, then it is better to completely replace it. After all, the transferred socket must reliably power consumers for more than one decade.

When the old cable is long and reliable, then the issue of its use will not be difficult. Difficulty will only create the missing length. In this case, you can:

- replace a short piece with a whole normal one;

- install a junction box in a convenient place and build up the missing length through it;

- use the old socket outlet box to connect an additional piece of cable.

However, the third case is used as an exception. It is used when there is no other acceptable solution. The fact is that all the joints of wires and cables during operation will need to be inspected. Access to them cannot be limited, and the old locations of sockets and switches are usually tried to be masked with putty and wallpaper.

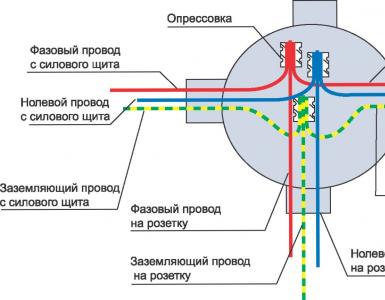

For this reason, you cannot connect the wires of different cables directly in the groove, insulate them and seal them with mortar. This is a direct path to the creation of leakage currents through the concrete of the wall, which is created when it is wetted. If either are not installed in the apartment panel or are faulty, then there is a high probability of electric shock.

![]()

The stripping of the cable ends and their insulation must be hidden inside the dielectric junction box. Previously, they were made of tin, which rusted over time, and the corrosion layer easily appears through the contacting wallpaper paper.

If it is not possible to replace such a box with a new one, then it is necessary at least to separate it with a layer of putty, and instead of a cover, install a plug made of fiberboard or drywall.

In case of malfunctions in the wiring, you will have to look for cable damage, hammer in the wall, pollute the room, and spoil its design. To reduce the destructive consequences of such work, it is necessary to accurately draw up a working sketch of the wall and put on it the coordinates of electrical points, cable routes. You will have to keep this document in a safe place.

Wire connection methods

The sockets are connected to operate from different electrical consumers. and cables must be guided by the current of the generated load, which is calculated by the power of the electrical appliance being switched on. Naturally, if you create a small stock, then it will certainly justify itself in the future.

Large currents will flow through the contacts of the socket. They will also flow through the junction of the wires, which must be done reliably. At the same time, attention is paid to the fact that it is required to observe the compatibility of the contacting metals to prevent electrochemical reactions in the places of contact.

For this reason, copper and aluminum cannot be directly bonded. In an extreme case, for them, contact is created through a layer of steel alloy, which prevents such processes from proceeding.

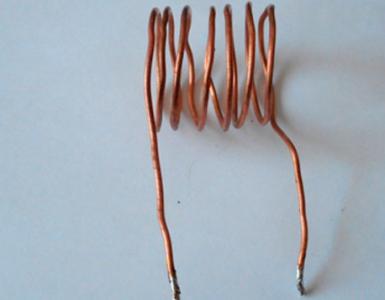

Stranding with welding

Previously, it was even used for aluminum wiring when connecting wires for an outlet and a switch.

Now the twisting of the veins is still a reliable method, but not all craftsmen can perform the welding of the ends due to the lack of a special welding machine.

Soldering twist

With proper observance of the technology, the twisting of modern copper wires will serve for decades:

- the insulation of the connected conductors is removed along a length of up to 8 ÷ 10 cm to ensure a sufficient contact area of the side surfaces;

- the cores are carefully stripped to a layer of pure metal of the wire;

- on both sides, the wires are captured with pliers and twisted tightly. You need to be careful. Do not overtighten the allowable force, otherwise the wire will break off. Practice is important in this matter;

- the connection of the twisted wires is soldered with solder with rosin. Acidic fluxes cannot be used: they will corrode the metal.

Connection with screw terminal blocks

This method is considered one of the most reliable. It has long been used even in the assembly of electrical circuits in critical circuits of industrial energy circuits, as shown on the left side of the picture. For household purposes, manufacturers release new models of terminal blocks of various designs.

When buying, pay attention to the quality of their implementation, the ability to securely clamp the wire and withstand mechanical forces when the screws are tightly tightened.

Ring connection via screw and nut

This is the most affordable way for a home craftsman. It allows you to connect even the ends of aluminum and copper wires through a steel washer.

When tightening the nut, the ring should work in compression and not unscrew. Grover creates additional force to eliminate the effects of thermal expansion of wires after heavy loads. This is especially true when using aluminum, which has increased ductility and its coefficient of linear expansion.

If you put a second nut, then it will prevent self-unscrewing, fix the connection of the wires.

Terminal blocks Wago

Their design allows for quick wiring. Good contact is created by an internal spring-loaded system. The products are certified according to European standards, widely distributed abroad, and are actively being introduced here.

Vago terminal blocks work normally when connecting wires for sockets. But they have one drawback that must be taken into account - the area of the created contact does not provide good heat transfer, the removal of its energy through their structure. At overestimated loads, exceeding the technical standards of the manufacturer, all the heat is transferred to the wires, the insulation of which begins to melt and burn.

Therefore, using the Vago terminal blocks to connect the outlet wires, it is necessary to select the right protections - that will prevent the development of emergency situations.

PPE insulating diggers

The wire contact created by this type of connector works quite well in lighting networks where the loads are planned and cannot exceed the nominal values. It is better not to use them to connect wires at outlets.

Also keep in mind that among such designs there are many fakes with a weakened internal spring.