Choosing a solid fuel boiler for home heating: types, advantages and disadvantages

A rational owner always thinks about how to wisely invest in the purchase of a solid fuel boiler for a private house and reduce the cost of its further operation during the heating season. Which is better, more profitable, more convenient? What are the boilers for heating, their types, advantages and disadvantages will tell this article.

Types of solid fuel boilers for a private house

Prices for electricity and gas are rising from year to year, moreover, it is not always possible to connect to the highway. Thus, a solid fuel boiler can be considered a reliable, autonomous and economical option for heating a house. With its pros and cons.

Domestic heating boiler

All existing solid fuel boilers can be divided as follows for convenience:

- Boilers, in the furnace of which fuel is supplied automatically, are pellet solid fuel boilers. They run on solid granular fuel. Pellet boilers are often referred to as long-burning boilers.

- Boilers that require manual loading of fuel. They can also be divided into groups:

- classic or traditional boilers;

- pyrolysis boilers of upper combustion;

- long burning boilers.

The general parameter by which boilers are usually selected is the fuel combustion time at one load, as well as the type of fuel on which they operate efficiently.

Solid fuel boiler with hob

When choosing a solid fuel boiler for heating a summer house or a private house, you should pay attention to the following parameters:

- the number of working circuits. A double-circuit boiler will allow you to heat the room and provide hot water;

- the presence of a cooking burner will help solve the problem with cooking;

- boiler power and efficiency. A boiler with a capacity of 5-12 kW will be able to heat a house with an area of 100 square meters. m;

- dimensions, weight and ease of installation;

- boiler arrangement and fuel loading method;

- used fuel.

Advice. Solid fuel boilers are produced only on the floor, it is impossible to hang such a boiler on the wall.

Classic solid fuel boilers

This is the most common type of boilers. Made from cast iron or heat resistant steel. Heat is generated by burning solid fuel. Solid fuel boilers operate on coal, wood, peat, heating pellets. Used for heating, as well as for heating water. Most often they are heated with coal, as firewood burns quickly. The temperature sensor is responsible for maintaining the temperature in the boiler and regulates the air damper. When the temperature drops, the sensor opens the damper slightly and vice versa.

Classic solid fuel boiler

On one load of fuel they work from 2 to 6 hours. Absolutely autonomous: do not depend on the electrical network and the presence of gas. In more modern versions, electronic temperature sensors and a control panel are built-in, as well as a boost fan, which makes the operation process more comfortable.

Advantages:

- time-tested technology;

- simple and reliable in use;

- relatively low cost, a wide range of manufacturers, models and prices for boilers;

- the ability to use fuel available in your area;

- autonomy - connection to the power grid is not required;

- low level of efficiency;

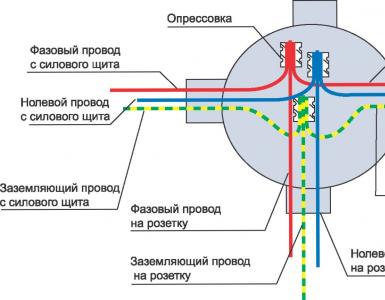

- simple boiler piping;

- low cost of fuel compared to energy carriers and gas tariffs.

Be prepared for the fact that you will need a significant amount of fuel storage space

Flaws:

- it is necessary to equip a warehouse for storing fuel reserves;

- small depth of temperature regulation;

- inertia of the fuel combustion process;

- the need for fuel delivery and preparation.

Advice. Coal flares up slowly and gradually, maintaining approximately the same temperature in the furnace. Firewood and its by-products ignite faster, so they cannot immediately fill the entire firebox. This will lead to a short-term release of a large amount of heat and overheating of the boiler, which is very dangerous.

Pyrolysis solid fuel boilers

Pyrolysis boilers are a relatively new technology. This type of boiler is used for heating and heating water. They have two combustion chambers. In the first chamber, the fuel itself burns with artificial oxygen deficiency. During combustion, volatile substances are released, which burn in the second chamber.

Pyrolysis boiler device

Pyrolysis boilers work on wood, fuel briquettes, pellets, brown coal, there are models with the consumption of coke and coal. The fuel must be dry, otherwise water vapor entering the second chamber can extinguish the boiler. Some pyrolysis boilers are equipped with a thermostatic air regulator and devices that protect the boiler from boiling. In case of boiling, the thermostatic valve will release water by opening the damper, and the temperature inside the boiler will drop.

Advantages:

- Efficiency not less than 90%;

- minimum amount of ash and soot formation;

- 2-4 times additional fuel is required;

- convenient and reliable in use;

- the fuel burns completely, the ash pan does not need to be cleaned often;

- reduced emission of harmful smoke into the atmosphere;

- you can burn large unchopped firewood.

Pyrolysis boiler afterburner

Flaws:

- complex design of the boiler;

- high price;

- wood must be dry (no more than 20% moisture);

- connection to the mains is required;

- at a load of half the power, combustion is unstable, tar is formed in the gas ducts;

- there is no way to automate the process of fuel supply.

Advice. The boiler can be installed in almost any technical room with an organized air supply. The chimney is organized internal or external.

Pellet solid fuel boilers, boilers with automatic fuel supply

In Europe, this type of boilers is very popular. They are used for heating, as well as for heating water for domestic needs. Pellets are used as fuel for these boilers - pressed shavings, sawdust from wood. The main important convenience is automation. They do an excellent job of maintaining the set temperature. All that is required of you is to fill the bunker with fuel at the beginning of the heating season. An auger is built into the boiler, which independently feeds pellets into the furnace. The only disappointing thing is that, apart from pellets, nothing can be burned.

Automatic pellet boiler

Advantages:

- durability, service life more than 20 years;

- fuel refueling automation;

- automatic ignition;

- Efficiency 90%;

- keep the set temperature stable.

Flaws:

- works only on wood pellets;

- high cost of fuel and equipment;

- connection to the mains is required.

Important. The use of unsuitable fuel leads to excessive fuel consumption and may cause damage to the equipment.

Long burning boilers

This type of boilers is able to work on coke, brown and hard coal, peat briquettes, firewood, wood chips, sawdust. Those models that are designed to work only on wood differ only in the air supply system and the materials from which the combustion chamber is made. Up to 50 kg of fuel can be loaded at one time. Firewood burning time from 12 hours to two days. If the firebox is filled with coal, then the burning time will be from four days to a week. If it is warmer outside, and there is no need to heat much, then you can reduce the boiler power by 10% by simply lowering the fuel burning rate.

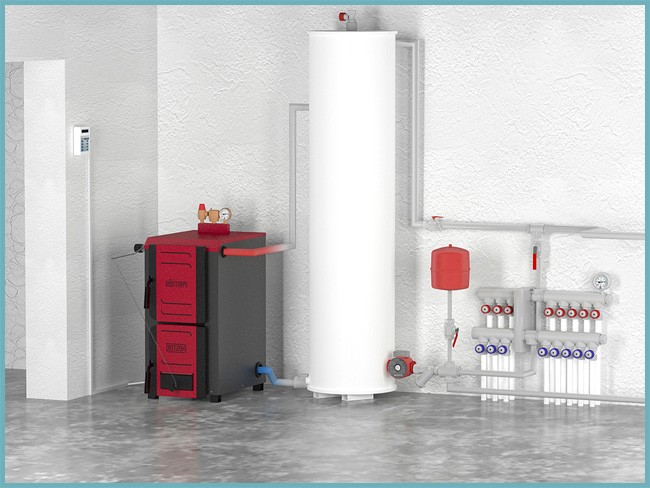

Long-burning boilers are very convenient because they do not require constant fuel tossing.

Long-burning boilers are boilers of a new generation. In many models, the boiler has a bottom, which indicates complete tightness. Solid fuel burns in such a boiler from top to bottom. That's why they can run for so long on a single load. The fuel does not burn all at once, but only the first 10-20 cm. The air that is supplied to the furnace is heated by the outgoing smoke, and then enters the combustion zone with the help of a recuperator. The air distributor is always at the combustion level of the fuel.

Advantages:

- non-volatile;

- with one load of coal they work up to 5 days, and with firewood - up to 2 days;

- deep power adjustment;

- ash is taken out 2-3 times a month;

- the price of such a boiler is lower than the pyrolysis one, but higher than the classic solid fuel boiler for long burning.

Installed long burning boiler

Flaws:

- The efficiency is low;

- full cycle operation without the possibility of refueling;

- in addition, it is necessary to install a circulation pump that operates from the network.

Advice. Some manufacturers provide interchangeable burners, which allows the user to easily switch from one type of fuel to another (for example, from coal to pellets) without losing the comfort of using the boiler. The user only needs to change the burner and reconfigure the automation.

How to heat a house with a solid fuel boiler: video

Solid fuel boiler for home: photo