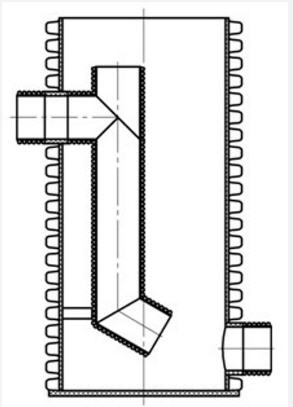

Modern device of a sewer well: differential, with a riser, plastic

Since sewer systems have been created and used for thousands of years, the technology of their equipment has been worked out to the smallest detail. This article describes the correct arrangement of a sewer well, as it is prescribed to comply with building codes.

Here, the locations and types of wells, their sizes and the requirements for these structures are regulated.

In the case of a private household with a local treatment plant (septic tank), a viewing well must be equipped in the area between the outlet of the internal sewerage from the building and the receiving chamber of the device. Also, one of the options for disposing of wastewater after a septic tank is this.

An observation well is also provided before the entrance of the local sewer system to the intra-quarter network or the central collector, outside the red development line (a conditional border separating the territory for placing buildings from streets, driveways, etc.).

Important information! According to SNiP, sewer wells (inspection) with an external sewer pipe size of up to 150 mm should be arranged after 35 m, at 200 - after 50 m on straight sections of pipelines, as well as:

- When turning the system

- When changing pipe diameter or slope

- At branch entry points

The requirements for sewer wells and their components are set out: for reinforced concrete products - in GOST 2080-90, for polymer wells - in GOST-R No. 0260760.

For plastic devices, many manufacturers also develop their own specifications (technical specifications).

Stone wells for sewerage can be made of prefabricated and monolithic concrete and reinforced concrete, bricks, and filter wells can also be made of rubble stone.

When constructing sewer wells from polymers, polyvinyl chloride (PVC), polypropylene (PP), or polyethylene (PE) are used.

In addition, some models are made by combining some of the listed materials.

The dimensions that sewer wells SNiP should have are as follows:

- On pipelines with a diameter of up to 150 mm - at least 70 mm

- Up to 600 mm - 1000 mm

- 700 mm - 1250 mm

- 800-1000 mm - 1500 mm

- 1200 and more -2000 mm

- Not less than 1500 mm for any diameter and depth of 3 m and above

At the same time, the volume of the sewer well is not separately regulated, but, based on the given depth and diameter, it is not difficult to calculate it.

Any construction of sewer wells begins with earthworks - fragments of a pit and a trench. Before this, a set of preparatory work is carried out.

It includes:

- Breakdown (marking) of the territory where the well will be located

- Demolition of trees, shrubs, other vegetation at the work site

- Demolition / relocation of buildings that interfere with construction

- Arrangement of a temporary road/exit to the construction site

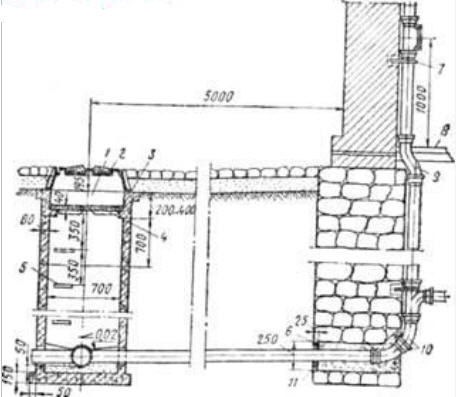

When constructing a pit for sewer wells, a typical project provides for the following work order:

- Held his excerpt

- The bottom is being cleaned

- The level of laying and the angles of slopes of the walls are checked against the project

- For masonry structures: a device at the bottom of the waterproofing (usually with bituminous mastic) with a layer of 20 cm, with a dense compaction

stone wells

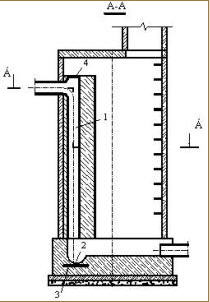

After that, the following work is performed for a concrete or reinforced concrete well:

- Foundation preparation. Laying a slab or placing a concrete pad 100 mm thick from concrete M-50

- Arrangement of a tray of the desired shape made of M-100 concrete with steel mesh reinforcement

- Concrete and bitumen sealing of pipe ends

- Bitumen insulation of the inner surface of concrete rings

- Rings of sewer wells are installed (carried out after the curing of the concrete of the tray, 2-3 days after laying) and the floor slab on the M-50 solution

- Grouting with cement mortar the joints between the prefabricated parts of the well

- Waterproofing joints with bitumen

- Finishing the tray with cement plaster, followed by ironing

- Arrangement at the entry points of pipes of a clay lock with a width of 300 mm and a height of 600 mm more than the outer diameter of the pipes

- Well testing (carried out during the day by filling with water to the upper edge, with the installation of temporary plugs on the pipes). Considered successful if no visible leaks are found

- External backfilling of the walls of the well, followed by tamping

- The device of a concrete blind area 1.5 m wide around the neck of the well

- Insulation of all remaining joints with hot bitumen

Similarly, brick sewer wells are installed, but here, instead of installing prefabricated elements, masonry is made.

Waterproofing is done in exactly the same way.

Thus, the installation of wells made of stone materials is carried out for all types of sewerage: domestic, storm or drainage.

However, in the case of a storm well, lattice hatches can be installed on the well, which simultaneously perform the function of a catchment area.

For drainage - the well itself can be an element of drainage, through special holes in the walls, but this design requires a special calculation.

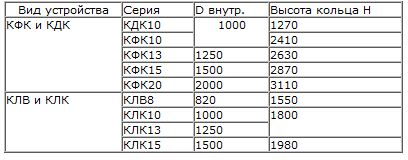

At the same time, there are slight differences in the components that the series defines: sewer wells KFK and KDK - for domestic wastewater, KLV and KLK - for storm water, KDV and KDN - for drainage.

The table of sewer wells by standard sizes is as follows:

The process for differential wells looks a little more complicated due to their more complex configuration.

Here, depending on the specific design, in addition to the tray device, in some cases it is necessary:

- Riser installation

- Water breaking equipment

- Installation of a water barrier wall

- Create a practice profile

- Pit device

The very installation of the body of the mine, base and ceiling is carried out according to the same rules.

The only exception concerns a drop well with a riser - at its base it is supposed to lay a metal plate that prevents the destruction of the concrete part of the structure.

It looks like this:

- Riser

- water cushion

- Metal plate at the base of the pillow

- Riser intake funnel

The intake funnel is designed to compensate for the vacuum that can be created in the riser due to the rapid movement of wastewater.

It is necessary to create differential sewer wells with your own hands using a practical profile only in exceptional cases - a similar design is provided for pipelines with a diameter of 600 mm and a drop height of up to 3 m.

Similar pipe diameters are not used in individual drainage systems. But other types of wells can be used in local sewage with success.

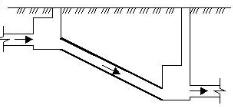

In accordance with the requirements of SNiP, sewer overflow wells are installed:

- If necessary, reduce the depth of the pipeline

- At intersections with other underground utilities

- For flow control

- In the last flooded well before the discharge of waste into the reservoir

Typical cases when the installation of a drop well in a suburban area is advisable:

The meaning of such a drop is that due to the creation of a large slope in a short section of the system, the drains begin to move much faster, not having time to cling to the inner walls of the pipe.

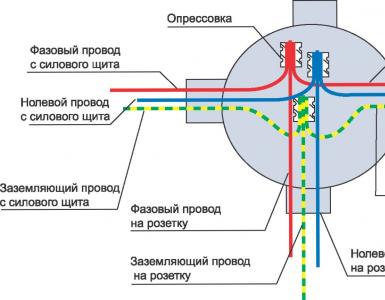

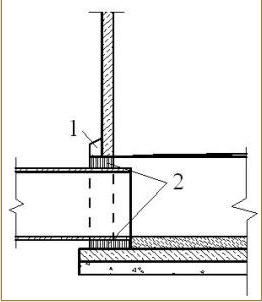

The device of pipeline entrances to wells

Depending on the specific soil conditions, the entry of pipes into the well can be performed in different ways.

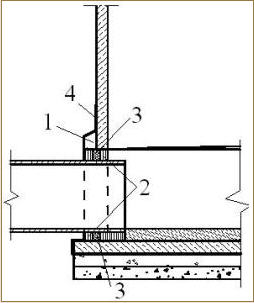

For dry soil, it is easier to perform. Only two types of materials are used here: cement, indicated in the figure by the number 1, and asbestos-cement mixture, indicated by the number 2.

For wet soil, a resin strand 3 and a waterproofing layer 4 are also added to these materials.

Both methods are designed for non-sagging soils.

In regions where soil movements are possible, the connection is made movable, using a pipe winding with a plastic waterproofing packing.

Sometimes a metal sleeve is inserted into the hole in the hatch wall, and the packing is already arranged inside it.

Plastic wells - a modern alternative

A reasonable and practical replacement for stone viewing chambers are polymer counterparts.

Moreover, plastic wells can significantly reduce the amount of excavation, the construction of sewer wells made of these materials speeds up and simplifies the process of installing drainage systems.

There are rumors about the compressive strength of plastic wells - but they are not confirmed by the facts. This is especially true of the simplest wells for intra-yard networks.

As a rule, there are no such loads that are able to damage the plastic.

Among other things, a concrete well with a diameter of a meter can replace a plastic well, starting from 30 cm in diameter, despite the fact that, despite the difference in size, the maintenance of sewer wells made of polymers will be even simpler than their giant concrete counterparts.

After all, they are produced with releases that clearly comply with the standards of pipes from any material - plastic, cement, asbestos.

Therefore, immediately after installation, such shafts can be connected to any within minutes. If plastic pipes are used, then the process will be even faster.

Therefore, before building a sewer well, it is worth weighing the pros and cons, the seeming cheapness of some solutions is deceptive. For a private area where one, two, maximum three wells are equipped, it will be much cheaper to arrange wells made of plastic than trying to save money by using concrete rings. The enormous weight and the need to order heavy equipment will nullify the seeming cheapness of old solutions. And the modest diameter of the plastic well, the speed of installation are not the last arguments.