How to make an induction heater with your own hands according to the scheme

Appliances that heat with electricity rather than gas are safe and convenient. Such heaters do not produce soot and unpleasant odors, but consume a large amount of electricity. An excellent way out is to assemble an induction heater with your own hands. This saves money and contributes to the family budget. There are many simple schemes according to which the inductor can be assembled independently.

In order to make it easier to understand the circuits and assemble the structure correctly, it would be useful to look into the history of electricity. Methods for heating metal structures with an electromagnetic coil current are widely used in the industrial manufacture of household appliances - boilers, heaters and stoves. It turns out that you can make a working and durable induction heater with your own hands.

The principle of operation of devices

The principle of operation of devices

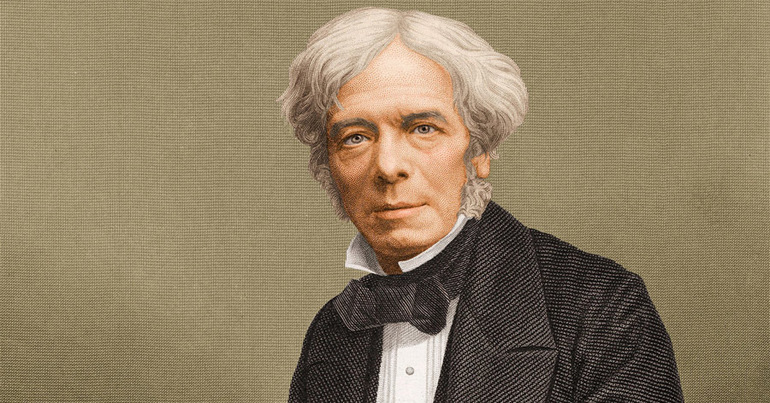

The famous 19th century British scientist Faraday spent 9 years researching to convert magnetic waves into electricity. In 1931, a discovery was finally made, called electromagnetic induction. The wire winding of the coil, in the center of which there is a core of magnetic metal, creates a magnetic field under the power of alternating current. Under the action of vortex flows, the core heats up.

An important nuance is that heating will occur if the alternating current supplying the coil changes the vector and sign of the field at high frequencies.

Faraday's discovery began to be used both in industry and in the manufacture of home-made motors and electric heaters. The first foundry based on a vortex inductor was opened in 1928 in Sheffield. Later, according to the same principle, the workshops of factories were heated, and for heating water, metal surfaces, connoisseurs assembled an inductor with their own hands.

The scheme of the device of that time is valid today. A classic example is an induction boiler, which includes:

- metal core;

- frame;

- thermal insulation.

Lighter weight, smaller size and higher efficiency are achieved through thin steel tubes that form the basis of the core. In kitchen tiles, the inductor is a flattened coil located near the hob.

The features of the circuit for accelerating the frequency of the current are as follows:

- industrial frequency of 50 Hz is not suitable for home-made devices;

- direct connection of the inductor to the network will lead to hum and low heating;

- effective heating is carried out at a frequency of 10 kHz.

Assembly according to schemes

Anyone familiar with the laws of physics can assemble an inductive heater with their own hands. The complexity of the device will vary from the degree of preparedness and experience of the master.

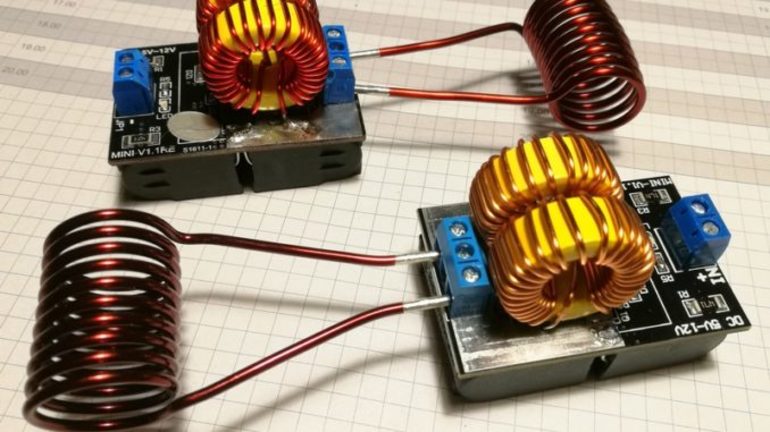

There are many video tutorials, following which you can create an effective device. It is almost always necessary to use the following basic components:

- steel wire with a diameter of 6-7 mm;

- copper wire for the inductor;

- metal mesh (to hold the wire inside the case);

- adapters;

- pipes for the body (made of plastic or steel);

- high frequency inverter.

This will be enough to assemble an induction coil with your own hands, and it is she who is at the heart of the instantaneous water heater. After preparing the necessary elements you can go directly to the manufacturing process of the device:

- cut the wire into segments of 6-7 cm;

- cover the inside of the pipe with a metal mesh and fill the wire to the top;

- similarly close the pipe opening from the outside;

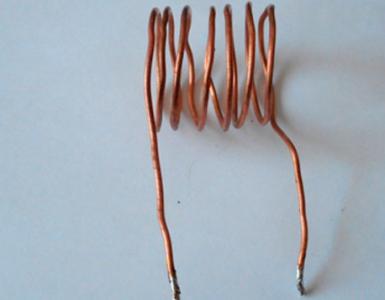

- wind copper wire around the plastic case at least 90 times for the coil;

- insert the structure into the heating system;

- using an inverter, connect the coil to electricity.

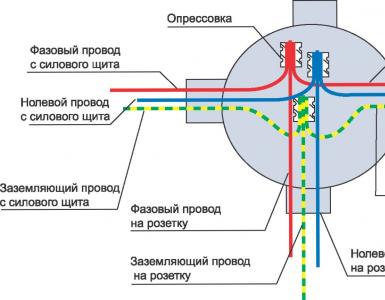

It is advisable to first ground the inverter and prepare antifreeze or water.

According to a similar algorithm, you can easily assemble an induction boiler, for which you should:

- cut blanks from a steel pipe 25 by 45 mm with a wall no thicker than 2 mm;

- weld them together, connecting them with smaller diameters;

- weld iron covers to the ends and drill holes for threaded pipes;

- make a mount for an induction stove by welding two corners on one side;

- insert the hob into the mount from the corners and connect to the mains;

- add coolant to the system and turn on the heating.

Many inductors operate at a power not higher than 2 - 2.5 kW. Such heaters are designed for a room of 20 - 25 m². If the generator is used in a car service, you can connect it to a welding machine, but It is important to consider certain nuances:

- You need AC, not DC like an inverter. The welding machine will have to be examined for the presence of points where the voltage does not have a direct direction.

- The number of turns to a wire of a larger cross section is selected by a mathematical calculation.

- Cooling of working elements will be required.

Creating sophisticated fixtures

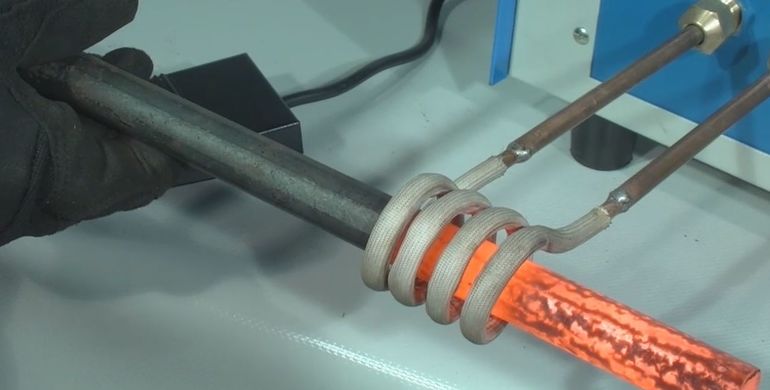

It is more difficult to make an HDTV heating installation with your own hands, but it is subject to radio amateurs, because to collect it you will need a multivibrator circuit. The principle of operation is similar - eddy currents arising from the interaction of the metal filler in the center of the coil and its own highly magnetic field heat the surface.

Design of HDTV installations

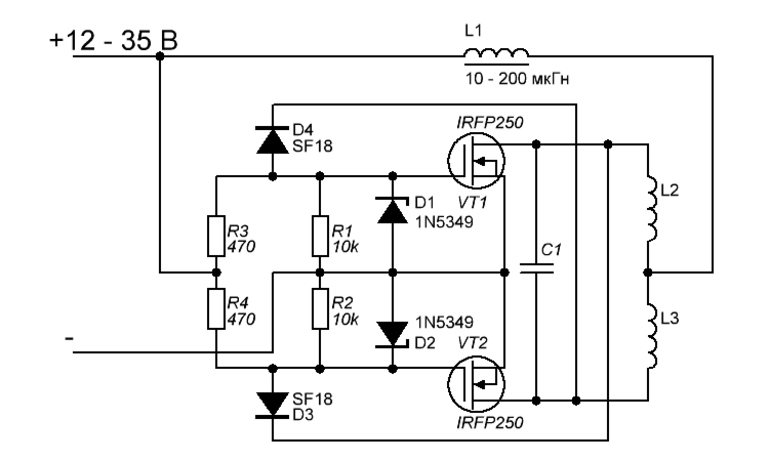

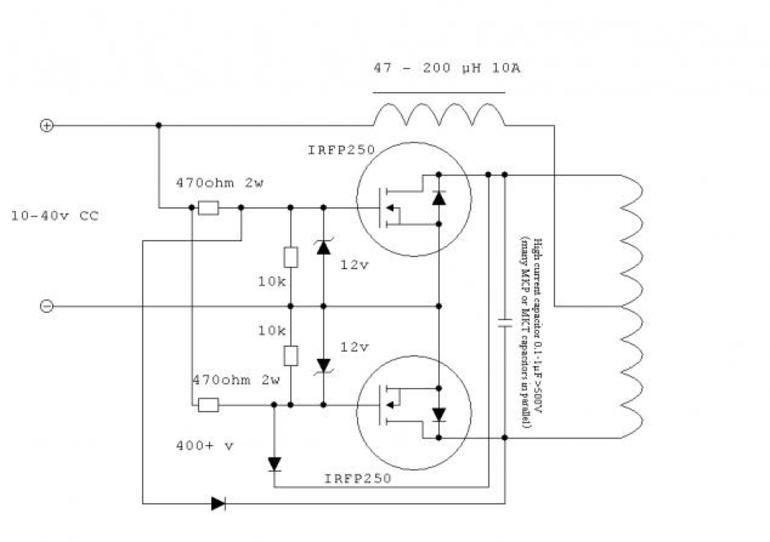

Since even small coils produce a current of about 100 A, a resonating capacitance will need to be connected with them to balance the induction thrust. There are 2 types of working circuits for heating HDTV at 12 V:

- connected to mains power.

- targeted electrical;

- connected to mains power.

In the first case, a mini HDTV installation can be assembled in an hour. Even in the absence of a 220 V network, you can use such a generator anywhere, but if you have car batteries as power sources. Of course, it is not powerful enough to melt metal, but it is able to heat up to the high temperatures needed for fine work, such as heating knives and screwdrivers to blue. To create it, you need to purchase:

- field effect transistors BUZ11, IRFP460, IRFP240;

- car battery from 70 A / h;

- high voltage capacitors.

The current of the 11 A power supply is reduced to 6 A during the heating process due to the resistance of the metal, but the need for thick wires that can withstand a current of 11-12 A remains to avoid overheating.

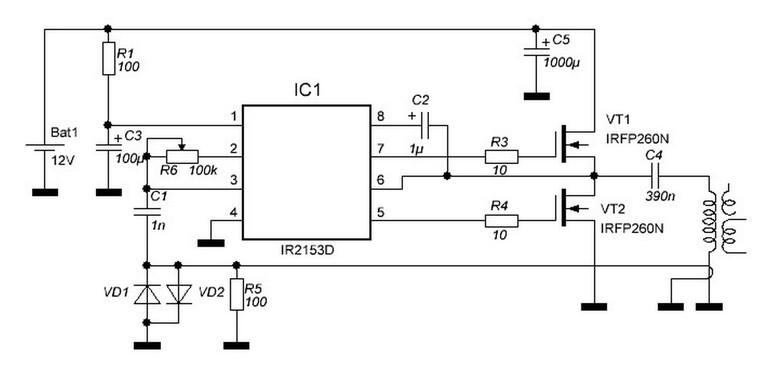

The second circuit for an induction heating installation in a plastic case is more complex, based on the IR2153 driver, but it is more convenient to build a 100k resonance over the regulator using it. It is necessary to control the circuit through a network adapter with a voltage of 12 V or more. The power unit can be connected directly to the main network of 220 V using a diode bridge. The resonance frequency is 30 kHz. The following items will be required:

- ferrite core 10 mm and choke 20 turns;

- copper tube as an HDTV coil of 25 turns per mandrel 5–8 cm;

- capacitors 250 V.

Vortex heaters

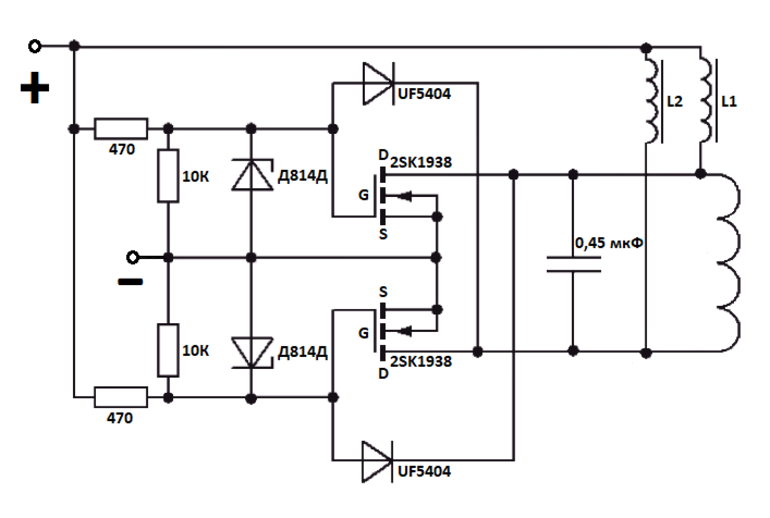

A more powerful installation, capable of heating the bolts to yellow, can be assembled according to a simple scheme. But during operation, the heat generation will be quite large, so it is recommended to install radiators on transistors. You will also need a choke, which you can borrow from the power supply of any computer, and the following auxiliary materials:

- steel ferromagnetic wire;

- copper wire 1.5 mm;

- field-effect transistors and diodes for reverse voltage from 500 V;

- zener diodes with a power of 2-3 W with a calculation of 15 V;

- simple resistors.

Depending on the desired result, the winding of the wire on the copper base is from 10 to 30 turns. Next comes the assembly of the circuit and the preparation of the base coil of the heater from about 7 turns of 1.5 mm copper wire. It connects to the circuit and then to electricity.

Craftsmen familiar with welding and operating a three-phase transformer can further increase the efficiency of the device while reducing weight and size. To do this, it is necessary to weld the bases of two pipes, which will serve as both a core and a heater, and after winding, weld two pipes into the body to supply and remove the coolant.

Focusing on the schemes, you can quickly assemble inductors of various capacities for heating water, metals, heating a house, a garage and a car service. It is also necessary to remember the safety rules for the effective service of heaters of this type, because a coolant leak from a home-made device can result in a fire.

There are certain conditions for organizing work:

- the distance between the induction boiler, walls, electrical appliances should be at least 40 cm, and it is better to retreat 1 m from the floor and ceiling;

- with the help of a pressure gauge and an air release device, a security system is provided behind the outlet pipe;

- it is desirable to use devices in closed circuits with forced circulation of the coolant;

- application in plastic pipelines is possible.

Self-assembly of induction generators will be inexpensive, but not free, because you need components of a fairly good quality. If a person does not have special knowledge and experience in radio engineering and welding, then you should not independently assemble a heater for a large area, because the heating power will not exceed 2.5 kW.

However, self-assembly of the inductor can be considered as self-education and advanced training of the owner of the house in practice. You can start with small devices according to simple schemes, and since the principle of operation in more complex devices is the same, only additional elements and frequency converters are added, it will be easy and quite budgetary to master it in stages.

In contact with