How to install a gas boiler in an apartment and a private house

Despite the growing popularity of solid fuels, mains gas remains the main energy carrier consumed for space heating. Accordingly, homeowners continue to purchase gas-using equipment. The next step is the installation of a gas boiler, which is carried out in an apartment or a private house in accordance with regulatory and technical requirements. We offer to go through this procedure virtually, starting with the choice of the heating unit.

Homeowner Procedure

The device or replacement of gas heating in country cottages or premises of an apartment building is carried out with the permission of the relevant service. Moreover, you can install the boiler and make the strapping with your own hands, subject to current building codes. Employees of the gas supply organization perform 3 types of work: project development (with approval), gas connection and start of the heat generator.

Reference. Design and installation are usually ordered by the fuel supplier company, although the law does not prohibit hiring third-party companies. The issue is the cost of services and the duration of the approval procedure.

How to proceed correctly in order to install a gas boiler in your home:

- Allocate a room for the installation of a heat source.

- Buy a heat generator of the required power, compatible with the heating system.

- Apply to the gas supply organization with a package of documents. Obtain technical specifications (TU) for the connection of a gas-using installation.

- Based on the specifications, order the production of project documentation and coordinate it with the relevant service of the gas supplier company.

- Following all the rules and requirements set forth in the project, mount and connect the boiler to the heating.

- Call Gorgaz specialists who will connect to the fuel line and start the heat source for the first time.

In general, the specified procedure for installing and connecting boilers is valid in all countries of the former USSR. In any case, the homeowner receives a technical specification that lists the requirements of the regulations in force in the state. Let's consider each stage separately.

Installation room

According to the requirements of SNiP and other sets of rules, the installation of gas-using heaters is allowed in the following rooms:

In most cases, gas heating boilers are placed in a separate furnace room. In apartments and small country houses, heating units are located in the kitchen, less often in the passage corridor (applies to wall-mounted versions of heat generators).

Placement of the heat generator in a separate room

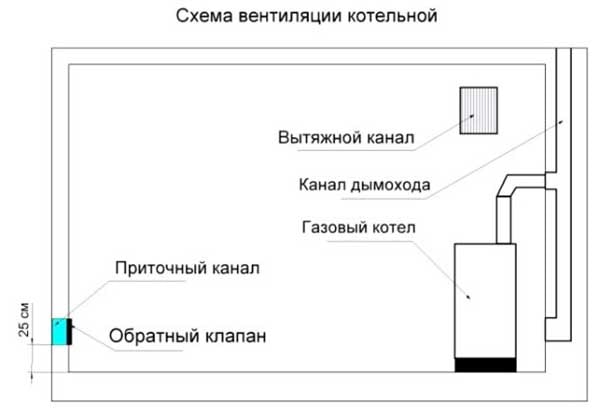

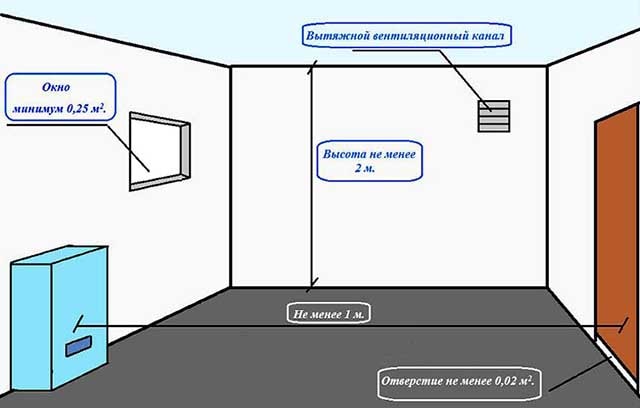

What are the requirements for the premises:

It is difficult for an ordinary homeowner to calculate ventilation by air flow in 1 hour. Hence the advice: arrange an exhaust through a channel with a minimum section of 14 x 14 cm, the optimal size is 28 x 14 cm. A detailed description of the premises of the gas boiler house is described in the video:

Selection of a heating unit

The first criterion for choosing a gas boiler is the heat output required for heating. Depending on the operating conditions, the performance of the heat generator is calculated as follows:

- In a temperate zone, the power is calculated by multiplying the heated area by 100 watts. A multiplying safety factor of 1.2 (+20%) is applied to the resulting figure.

- With a ceiling height of 3 m or more, the performance is calculated by the volume of the building - the cubic capacity is multiplied by an average value of 40 watts.

- In the southern regions, the area is multiplied by 80, in the northern - by 200 watts. The safety factor is maintained.

- The calculated output of double-circuit versions and conventional boilers working together with an indirect boiler is multiplied by a safety factor of 1.5 (+50%) instead of 1.2.

- If the heat generator is connected according to the scheme with a buffer tank - a heat accumulator, the power reserve is doubled (+ 100%).

The type of unit depends on . Self-flowing open systems are suitable for non-volatile models of gas boilers - floor and parapet. Closed circuits operating under pressure are best connected to wall-mounted heaters equipped with their own circulation pump and expansion tank.

In apartments and private houses, where for various reasons it is impossible to remove flue gases in the traditional way, it is recommended to install a gas boiler with a closed combustion chamber and forced air. Such heat generators are equipped with a coaxial chimney laid out through the wall. The principle of operation is as follows: air is drawn in by the turbine through the outer channel of the double-walled pipe, and combustion products are ejected through the inner passage.

Registration of permits

Let's clarify the sequence of actions a little: first you need to contact the gas workers for permission to install the boiler, then buy a heating unit, then request technical conditions and order a project. To obtain technical specifications and contact the designers, prepare a package of documents:

- ownership of a dwelling - an apartment or a private house;

- the current layout of the building;

- passport and instruction manual for the gas heat generator;

- product certificate.

Note. The certificate and documentation of the heater is provided by the equipment manufacturer.

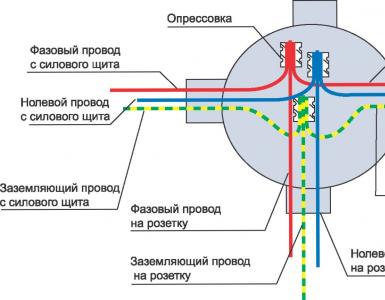

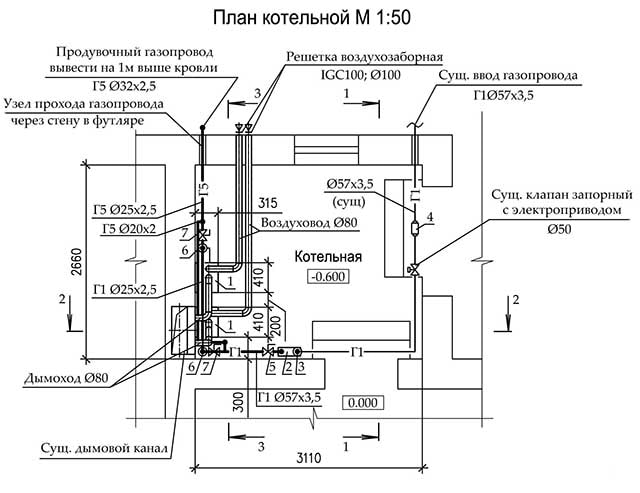

Boiler project example

Having received the technical conditions, pass them on to the design engineers, supporting them with the drawings of the building and your own wishes regarding the installation site of the boiler. In the absence of layouts, you will have to pay extra for an on-site examination - the technician will draw up a drawing after the fact.

Advice. Scrupulously discuss with the designers the main points - the exact location of the heating unit and the design of the chimney. This will save time and start installation work without waiting for the approval of the project.

Ready project documentation (at least 3 copies) is endorsed by the responsible persons of the gas supply organization. At this stage, it is worth ordering the laying of external and internal gas pipelines. Contact the same office or another licensed company.

Furnace room requirements

Installation Requirements

When installing a floor-standing boiler that burns natural gas, it is recommended to observe the minimum distances to walls and other building structures:

- the width of the free area in front of the frontal part of the heater - 1250 mm;

- side passages for maintenance and troubleshooting - 700 mm;

- the minimum clearance at the rear of the unit is 50 cm.

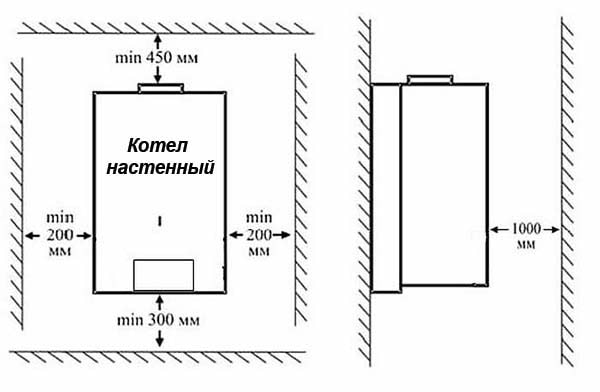

For hinged gas boilers, the requirements are softer - you need to leave at least 1 m of free space in front, 20 cm on the sides, and 300 mm on the bottom. The structure overhanging the heat generator must be no closer than 45 cm, as shown in the diagram.

Before installing a stationary boiler on wooden floors, be sure to place a fireproof gasket made of basalt cardboard and roofing steel, protruding 100 mm beyond the body dimensions, 70 cm in front. If, for various reasons, the heater is close to the walls of a wooden house, they should be sheathe with non-combustible materials:

Similar precautions are taken when mounting a suspended heat generator on a wooden wall. The simplest fire-fighting measure is to place galvanized metal under the body, protruding 10 cm (down - 70 cm), as shown in the photo.

Chimney and heating connection

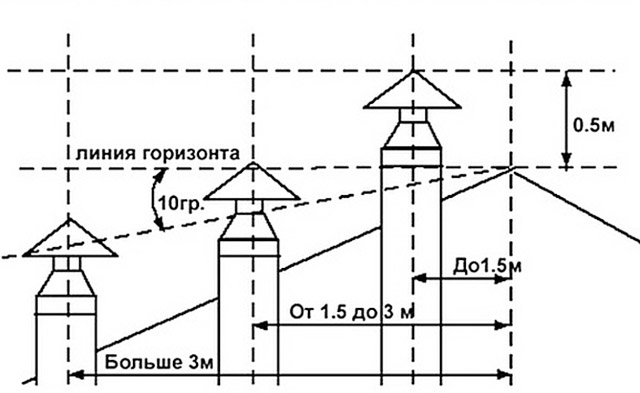

Gas heating units with an open combustion chamber require connection to a chimney with good natural draft. Its head should not fall into the zone of wind backwater, otherwise the traction force will drop to zero. The minimum height of the chimney is 5 m (counting from the burner), the optimal one depends on the location and distance from the ridge of the pitched roof (shown in the diagram below).

An important point. It is strictly forbidden to connect a gas boiler pipe to brick ventilation ducts made in the wall of an apartment or a country house.

General requirements for chimneys and connection of gas boilers look like this:

- The diameter of the pipe is not less than the size of the branch pipe of the unit, intended for the removal of combustion products.

- The material of the chimney channel is galvanized steel, stainless steel, brick or ceramic. No aluminum corrugations.

- The total length of a horizontal section cutting into a vertical pipe is no more than 3 m; An inspection hatch is arranged below the insertion point with a minimum indent of 25 cm.

- The distance from the metal smoke channel to the wooden structures is 0.5 m. If the combustible material is covered with asbestos or roofing iron, the indentation can be reduced to 100 mm.

- The maximum number of chimney turns of 90° must not exceed 3. This does not include 30° and 45° bends used to bypass the roof overhang.

The requirements for the installation of coaxial pipes of turbocharged boilers are simpler: the channel is made with a slight slope to the street, plus compliance with fire safety measures when passing through wooden walls. The arrangement of chimney pipes is described in detail.

The piping of the boiler is carried out according to the following recommendations:

- the wall-mounted heat generator is simply connected to the heating system through shut-off taps with American women;

- install strainers at the gas and coolant inlet;

- for a floor heater, it is required to assemble a circuit corresponding to the heating system: install a circulation pump, an expansion tank and a safety group;

- connect the make-up from the water supply network to the return pipeline with the coolant;

- when working with a wood or electric boiler, provide for the installation of check valves.

Under a turbocharged heater with high efficiency, equipped with a fan and automation, install a socket with a supply voltage of 220 volts and a ground wire. Make sure that in case of an accident it is not flooded with water. When connecting through a stabilizer or uninterruptible power supply, organize a special shelf or cabinet for these devices.

Conclusion

Upon completion of the work, the gas service personnel will check the correct installation and compliance with the project. If there are critical comments, the shortcomings will have to be eliminated - without this, the company will not allow commissioning and gas supply to the facility. If there are no complaints, the specialists will connect the gas pipe, set up and start the equipment. It remains to take the last step - to conclude a contract for the supply of fuel.