Making a hidden hatch for tiles with your own hands

The arrangement of the invisible hatch helps to make the appearance of the bathroom more attractive. It is in the hatch that all the communication elements of the bathroom are hidden. Buying a hatch in the bathroom is an expensive process, and not everyone can afford it. But making a hatch with your own hands is much cheaper, although it requires considerable effort and time. About how to make a hatch under the tile and how to install a hatch under the tile, we will consider further.

Tile hatches: features, purpose and installation benefits

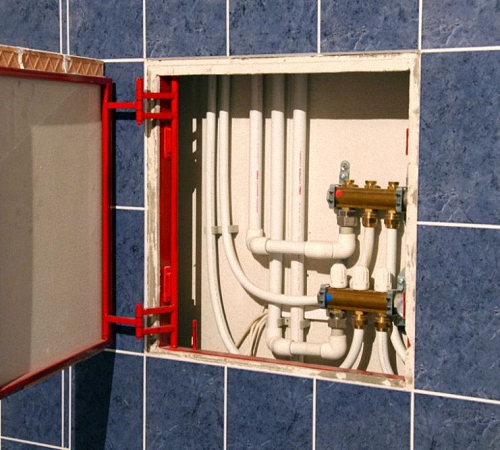

The main function of the invisible plumbing hatch is to hide all communications in the room and provide free access to them at any time.

The main advantage of the tile hatch is its invisibility against the background of the main interior. In addition, they combine the qualities of functionality and simplicity.

Among the advantages of installing hatches under the tile should be highlighted:

- complete harmony with the interior of the room;

- maintaining the integrity of the cladding;

- the presence of durable doors allows the use of various kinds of finishing materials, including tiles;

- stealth;

- duration of operation;

- ease of installation and construction;

- high level of reliability;

- providing free access to the equipment of communication systems.

Varieties and photos of hatches for tiles

There are several types of tile hatches:

1. Hatches for sliding type tiles.

This variant of the hatch consists of:

- frames;

- doors;

- castle;

- outer finishing layer;

- loops that connect it to the wall;

- adjustment mechanisms.

The main element of the hatch is a frame mechanism, for the manufacture of which tubular steel or aluminum is used. Aluminum is most commonly used, as it is resistant to corrosion, however, in cases where the hatch must withstand heavy loads, it is necessary to make it from steel.

Doors are most often made of the same materials as the frame. Its upper part is finished with moisture-resistant gypsum fiber or drywall. And finishing materials are applied to it. The perimeter of the door is equipped with an insulating material that prevents moisture or air from entering the hatch. In addition, its presence protects the inside of the hatch from the appearance of mold, dust or fungus.

The sliding version of the hatch differs from its other variations in the presence of a three-link hinge design. Thus, frontal and lateral opening of doors is provided. The hinges allow you to adjust the position of the door in two variations.

An important element is the presence of a pressure lock, with which the door opens very simply and without much effort.

The use of sliding hatches is recommended if it is installed in a small room. This type of hatch is great for finishing with tiles, porcelain stoneware, mosaics and other finishing materials. If it is necessary to provide free access to the communication system, this type of hatch is used. Opening of this type of hatch is carried out by minimally pulling the door and moving it to the side. Installation of this hatch is carried out in the surface of vertical wall partitions, foam blocks, plasterboard walls, concrete, etc.

Such designs are great for residential and public buildings, as well as for installation outside buildings. There are two options for sliding sunroofs:

- hatches that open with a suction cup handle are installed in the case of finishing the room with materials;

- hatches, click-type - are used when finishing with mosaics, tiles with a relief or matte surface, a click handle is not needed to open this type of door, it opens with one click, in order to close this door it is necessary to ensure its opening with a characteristic click.

2. Hinged hatch type - this option is particularly popular, since its design is the simplest and resembles ordinary hinged doors. Such hatches are used in the case of finishing the walls in the bathroom or bathroom with semi-matt or smooth tiles. Inspection hatches for swing type tiles have tremendous advantages over other types of hatches. It is this type of hatch that is most invisible after its installation. The tile is installed directly on the surface of the door.

This type of hatches is widely used for hiding water meters, thermostats, filters, siphons, etc. In addition, such a hatch will be an excellent place for arranging a safe or a secret shelf.

The design features of such a hatch include the following elements:

- welded frame;

- door frame;

- gypsum board;

- holes for installing dowels and screws;

- hinges connecting the outer frame structure to the door.

In addition, to fix the hatch in a certain position, it is equipped with special lock latches.

3. Tile hatches have high load capacity characteristics. With the front opening of the door, it is possible to prevent mechanical damage to the finishing material, in our case, tiles.

In relation to the technical design features, such hatches consist of:

- steel frame, fixed in the opening with self-tapping screws;

- frames for the door, which is finished with gypsum fiber;

- a two-link hinge that regulates the opening of the door in different positions;

- locking mechanisms.

With the help of hinges, this type of hatch opens with one click. The door, as it were, is pulled out of the wall, thereby ensuring the invisibility of the hatch on it. The hinges are designed in such a way as to ensure that the door is finished with any of the materials, including tiles. This type of door opening is the safest of all of the above.

In relation to the location of the hatches, they are:

- wall-mounted - the most popular option, access to which is most easily provided;

- floor hatches for tiles are more difficult to arrange and operate;

- ceiling - are used extremely rarely, although their arrangement is also possible.

The dimensions of hatches for tiles directly depend on its internal content, the number of communications and items that are planned to be placed in it.

Making a hidden hatch for tiles with your own hands

To complete this work, it will take a lot of time and effort, in the absence of skills in the manufacture of such devices, we recommend that you work with at least two people.

The easiest way to build an inspection hatch is to use furniture fittings, which are converted to fit the locking mechanism of the hatch itself. From the system you will need the presence of canopies and a pressure system, which will ensure easy opening of the hatch.

For the manufacture of the door, drywall or gypsum fiber with moisture resistant characteristics is required. If you plan to further tile the surface, then it is better to choose the gypsum fiber option. It is this material that has a higher adhesion with tile adhesive, and, accordingly, with the tile itself.

The assembly of the hatch is carried out directly at the place of work, as this procedure requires careful measurements and adjustments in the course of following all instructions.

First you need to decide on the size of the plumbing hatch for tiles. When choosing a size, you should take into account the fact that the hatch should be made as small as possible. Since the arrangement of a large structure does not make any sense.

The size of the hatch directly depends on the type of communications to which access is required. For example, if you plan to equip a hatch to service the water meter, then for these purposes an area of \u200b\u200bone standard tile, 10x10 cm in size, is quite enough.

If it is necessary to check communications in the form of a siphon, pipes, and so on, then the size of the hatch must be increased to such a size as to ensure unhindered access to them.

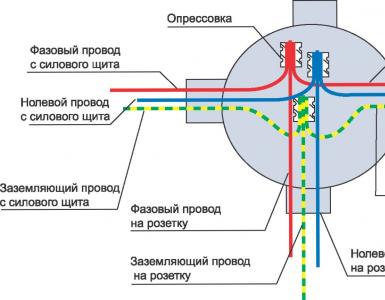

After determining the optimal size of the hatch, direct work begins on its creation. The easiest way to start is by making a frame that will be inside the hatch. Its manufacture is a fairly simple process that requires care in taking measurements. The frame is made of steel or aluminum corners and profiles. To connect them, you will need a welding machine and experience with it.

Next, the finished structure is installed in a niche and fixed in it with self-tapping screws. The next stage involves the manufacture of a door, for the frame of which it is enough to use OSB, sheathed with gypsum fiber or drywall.

The door must have the same dimensions as the hatch.

Tip: Choose the dimensions of the door, taking into account the fact that whole tiles should fit on it, with joints between them. That is, the door should be designed for one, two, four, six tiles.

When using OSB, try to choose a material with a high density and a minimum thickness of 12 cm, since the tile requires a certain rigidity to fix it to the surface.

After the door is made, the process of attaching canopies to it follows, on which it will hold. Please note that such a hatch is installed at the same distance from the wall, it cannot be deepened into it, as the integral appearance of the wall will be violated.

Please note that the door stop should be as rigid as possible. After installing the door and locking mechanisms, the tiling procedure begins. The first tile is laid directly below the door. Take care to carefully calculate the vertical and horizontal rows of tiles. For these purposes, it is desirable to use a laser level. Do not grout joints between tiles laid on the door. It is in this that its only difference from the general interior will consist.

Making a hatch for tiles with your own hands will be done with high quality only if all of the above conditions are met.

Installation of a hatch under a tile: technology and instructions

There are several stages of installing a hatch under a tile:

1. Preparation of the opening.

The opening under the hatch must be cleaned of dust and dirt, and its dimensions must exactly match the parameters of the hatch itself.

2. Installation work.

Install the hatch in the previously prepared opening surface in such a way as to ensure that the plane of the door coincides with the wall on which the tile will be located.

Please note that during the installation of a universal hatch with spring locks, you should extend the hatch two or three millimeters above the wall. Thus, after pressing the hatch, its tightness will be ensured.

3. Fixing the hatch.

This process requires fixing the hatch in the wall with dowels and screws.

Tip: Before fixing the hatch, check its evenness several times to avoid damaging the appearance of the wall.

If the frame is made of steel, then elements in the form of wooden bars are inserted into it, which provide a strong connection and fixation of the hatch.

Next, the door is adjusted with special mechanisms that are provided for opening it. A special kind of plugs are installed on the side sections of the frames, which improve the attractiveness of its appearance.

4. Finishing the hatch with tiles.

In hinged areas, a tile protrusion is allowed, a maximum of 4.5 cm. In other areas, a tile protrusion outside the door by a maximum of 30% is allowed.

Tip: To ensure maximum adhesion between the tile and the door surface, it is recommended to prime the door before applying the adhesive. Please note that the tile adhesive must be of high quality, if desired, the option of using liquid nails is possible.

It is forbidden to stick tiles on the hatch door with cement-based tile adhesive, because due to the high weight of the structure, there is a risk of deformation of the door.

In order to ensure even joints between the tiles, crosses are installed in them. Only after the glue has dried, they are removed from the seams, and the door opens by pressing.

To ensure sound insulation and sealing of the door, stick masking tape around the perimeter of the door. The gap is treated with a sealant, after which the masking tape is removed after drying.

Tip: The sealant should be silicone based.

Please note that if the hatch has a pressure base, then not the entire space is filled with sealant, but only a 3-4 mm seam. In no case should the sealant get under the tile, otherwise, there will be problems with opening the door.

Using an elastic spatula, get rid of excess silicone. Remove the tape after the sealant has dried. After 48 hours, trim the seam at a forty-five degree angle.

Tip: To make it easier to open the hatch during its operation, you should cut the tile located on the wall, and not on the door.

Tile hatches video: