Sealant for sewer pipes: types, overview of manufacturers, which are better and why

The sewerage system must be sealed. If wastewater enters the environment, it can cause serious harm. Seeping into the ground, runoff pollutes fertile soils, enters aquifers and spoils drinking water. If impurities seep into the room, they poison the air and damage people's health. The solution to the problem is a good sealant for sewer pipes. Let's figure out how to choose it.

Sewerage is reliably sealed even at the installation stage. During operation, the internal system is regularly inspected in order to detect and eliminate leaks in time. Waste water should not flow out, and nothing should get into the sewer from the outside, because. this can disrupt its operation and lead to serious damage.

Particular attention should be paid to sealing pipes located underground, as they are much more difficult to repair if leaks occur. If the operation of the system is disrupted due to groundwater entering it, a lot of effort will have to be made to determine this.

Repairing the underground part of the sewerage system is almost as laborious and expensive as installing a new section of the pipeline. It involves a large amount of excavation, replacement of damaged elements of the system

Careful sealing during the construction phase of the sewer system prevents problems such as:

- Leaks out. Once in the soil, sewage can contaminate the water in drinking wells and cause serious diseases. The smell of sewage in the premises is also dangerous, because. decaying organic matter emit gases harmful to humans: hydrogen sulfide, ammonia, methane.

- Flooding of buildings and structures. With strong leaks, erosion of the soil is possible. Wastewater floods foundations, cellars, basements, basements. Due to the high content of chemically active substances, they accelerate the destruction of building materials, provoke corrosion.

- Leaks inside the system. If atmospheric or groundwater enters the system, the pressure in the pipeline increases. Due to the strong pressure of sewage, the operation of pipes is disrupted, and treatment or storage facilities may not be able to cope with the additional load and fail.

- Leaks at the joints due to temperature changes. If the system is initially mounted with high quality, the joints are reliable and do not leak even without additional sealing. However, processing is still necessary, because. temperature fluctuations over time lead to a decrease in tightness.

For the installation of sewage systems, pipes from different materials are used, and a suitable sealant should be selected for each type of pipe. Also, the choice depends on the installation technology and the intended purpose of each individual element of the system.

Main types of sealing materials

To seal the joints of sewer pipes, many different materials are used:

- sealing tapes;

- polymer sealants;

- technical sulfur;

- jute and hemp ropes;

- epoxy resin;

- Portland cement;

- mastics based on petroleum products.

Each sealing material has its own varieties, features, purpose and scope.

Option #1: Sealing Tapes

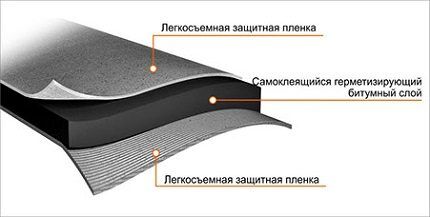

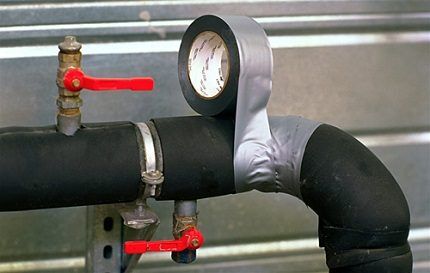

There are ordinary and foil self-adhesive tapes. They are designed to seal joints of water and sewer pipes and have unique properties. The composition of the tapes includes bitumen-polymer materials, so that they are absolutely waterproof.

Sealing tapes are multi-layered. Their basis is polymeric materials. Layers of bituminous compounds are applied to them, protecting sewerage elements from the effects of negative environmental factors.

Depending on the operating temperature range, there are three main types of tapes:

- Summer (in the marking it is indicated by the letter L). The tape can be used at temperatures up to +300˚С. It is suitable for insulating pipelines carrying hot liquids.

- Winter (in the marking - the letter Z). The temperature range at which the material does not lose its sealing properties is from -200˚ to +100˚С.

- Heat-resistant (properties are indicated by the letter T in the marking). This tape is used to insulate pipelines through which liquids with temperatures up to +1500˚С are pumped. In this case, the ambient temperature can vary from -100 to +300˚С.

For insulation of sewer pipes indoors, a summer or winter sealing tape is suitable, and for outdoor work it is better to choose a winter one.

The sealing tape is applied with a mastic layer inside. It is wound with an overlap in a spiral, evenly, achieving perfect smoothness and density of joints - without wrinkles and distortions

The advantages of the material include the following properties:

- No deformation. If the tape is applied correctly, bubbles will not appear under it during operation.

- dielectric properties. The tape protects against electrical stress, which often becomes one of the causes of corrosion of metal pipelines.

- Resistant to all types of influences. The material does not delaminate, differs in mechanical strength, resistance to chemicals, soil corrosion. It is so reliable that it can be used even when laying oil pipelines, so you can definitely be calm about sewerage.

The unique characteristics and strength of sealing tapes allow them to be used at any temperature and in almost any conditions. The service life of the adhesive coating is at least 30 years. During this time, the tape does not lose its properties and maintains 100% tightness.

Self-adhesive sealing tape is not only suitable for sealing pipeline joints. It is used for sealing tie-ins, bends, plugs, etc.

In order for the material not to lose its properties for a long time, it must be applied correctly. The stage of surface preparation is very important. They are thoroughly cleaned of old coatings, degreased and dried.

It is necessary to monitor the uniformity and tension of the tape during wrapping of the pipe and make wide overlaps equal to half the width of the material. If the tape is applied correctly, the surface will be covered with two protective layers.

Option #2: Polymer Sealants

For the treatment of joints of sewer systems, silicone sealants are most often used. Another option is polyurethane compounds. They are universal, suitable for sealing and gluing a wide variety of structures and elements. The best solution is to buy a special silicone-based plumbing composition, choosing it taking into account the material and operating conditions of the system.

The composition of silicone includes rubber, thanks to which the finished material is highly elastic and adheres to any substrate. When using silicone sealants, it is not necessary to treat the surfaces with primers to improve adhesion.

Silicone sealants are considered the most reliable for processing plumbing systems, but there are other options. When buying, carefully read the descriptions and instructions of manufacturers

Depending on the composition of the hardener, there are two main types of silicone sealants:

- Acidic. The main advantage of acid compositions is an acceptable price with good quality. The disadvantages include a limited scope: sealants are not suitable for all surfaces and can enter into chemical reactions.

- Neutral. These sealants do not contain acids, so they do not destroy the pipes. This significantly expands the scope of application and makes the materials universal. Minus - a higher cost than that of acidic formulations.

Silicone sealants are usually used to process the joints of plastic and metal sewer pipes. After polymerization, they form dense elastic coatings resembling rubber. Due to their high elasticity, they tolerate loads well and do not crack.

Sealants are packed in solid tubes. It takes effort to push them out. If there is no special gun, a hammer handle can be used instead of a piston

Sealants are applied using mounting guns that squeeze out the contents of the package. Joints are processed around the entire circumference. The line must be continuous so that there are no gaps. After applying the composition, the seam is carefully leveled with a special soft spatula or with a wet gloved finger.

Option #3: technical sulfur

Technical sulfur is produced by processing petroleum products. It can be powdered or lumpy and is sold in hardware stores. This is a good option for sealing joints in cast iron pipes. An additional plus is the low price.

Sulfur is a hard and brittle sealant. To make it more elastic, do not overheat the material. Also, ground kaolin can be added to the sealing composition (in a ratio of 1:10)

Sulfur is crushed (if purchased lumpy), heated to a melting point (about 130-150˚С), after which it is poured into the space of the socket. When the material hardens, it will turn into a dense waterproof mass. Its only drawback is low elasticity.

Option #4: Portland cement

Portland cement is indispensable for many types of work. The composition of the material includes clinker, gypsum, calcium silicates. The dry mixture is diluted with water until a thick solution is obtained. It quickly hardens, forming a high-strength frost-resistant and water-repellent monolith.

Portland cement begins to harden within 5-10 minutes, so the mortar should be prepared immediately before use, and the work should be carried out as soon as possible

Special additives are added to the cement mixture to increase its elasticity. This allows you to reliably seal the joints of cast-iron pipes. The material is resistant to temperatures, tolerates freezing-freezing well, so it is successfully used in the arrangement of external sewage.

Option #5: Epoxy

Epoxy resin is a universal adhesive that can also help out when installing sewers. To prepare a sealant, epoxy resin is mixed with a hardener. The proportions depend on the brand of material and are indicated in the instructions for use.

Be careful when preparing the sealant. If there is too much hardener, the finished mixture may become hot or even boil.

When mixing resin and hardener, it is important to strictly follow the manufacturer's recommendations, otherwise the setting time of the composition and the operational properties of the finished coating may change.

Option #6: bituminous mastics

The sockets of ceramic pipes are often filled with bituminous materials. Bitumen-rubber, bitumen-polymer mastics have proven themselves well. By type of application, they are divided into cold and hot.

Cold and hot mastics are an inexpensive sealing material that is freely sold in building supermarkets. They are flexible, durable and resistant to chemicals.

For sealing pipes, it is better to use cold-applied compounds, because. they are much easier to use, and the work itself is safer. The only disadvantage of such sealants for sewer pipes is that they are somewhat more expensive.

Option #7: Jute and Hemp Ropes

To seal the joints of cast-iron and ceramic sewer pipes, hemp and jute ropes, and a resin strand are traditionally used. These are cheap and easy-to-use materials, however, in terms of their technical and operational properties, they are significantly inferior to modern sealants.

Jute ropes look more attractive than hemp ropes, however, the materials differ little in their performance properties. It is better to give preference to hemp, because. it's cheaper

For sewer pipes, it is better to use sanitary silicone or polyurethane sealants. Their quality and durability can vary greatly depending on the manufacturer, so pay attention to brands and choose the most reliable ones.

Top 8 Sealant Manufacturers

branded sealants Ceresit And Moment out of competition. They are reliable, durable, highly elastic and adhere to any surface. If it is possible to purchase the compositions of these brands, do not hesitate, because. you will pay not just "for the name", but for the real quality.

There are 6 more brands that produce decent products:

- Ciki Fix. Under this brand, high-quality transparent sealants are produced, which are perfect for metal and ceramic pipes. The finished coating is resistant to detergents and solvents.

- Belinka. These are popular one-component compounds for sealing seams and joints. They are resistant to negative influences, durable and elastic.

- Tytan. The Tytan brand produces high-quality silicone-based sanitary sealants. If you need a high-strength seam, you should give preference to the Tytan Professional polyurethane composition.

- Krass. Under the Krass brand, quick-hardening, one-component sealants are produced, which, after hardening, form tight seams that do not shrink.

- S 400. A distinctive feature of the sealants of this brand is increased biological stability. The composition includes a large number of fungicides that prevent the appearance of fungus and mold on the seams.

- Dow Corning. Sealants of this brand hold surfaces together so firmly that they are used as glue. They are thicker than the compositions of other brands, penetrate deeply into the seams and joints.

Sometimes sealants are subject to increased requirements for any individual performance characteristics. In such cases, it makes sense to carefully study the descriptions of manufacturers and consult with sellers.

When buying, pay attention to the presence of antifungal additives in the composition of the sealant. Microorganisms thrive especially at sewer joints, and a high concentration of fungicides is needed to prevent this.

For example, the best sealant for rooms with increased fire hazard is the Krass universal compound; for complex connections - "Moment Germent"; for ceramic pipes - Belinka Belsil Sanitary Acetate; and for rooms with constant high humidity - Ceresit CS 25 or S 400.

Videos on the use of sealants

In the process of sealing the sewer system, many questions arise. We offer videos that will help you cope with difficulties and do all the work yourself.

Instructions for sealing sewer pipes with silicone sealant:

We offer a video instruction on the correct mixing of epoxy and hardener:

Do-it-yourself video tutorial on sealing the socket of a cast-iron external sewage system:

Detailed instructions for sealing the socket of sewer pipes when switching from cast iron to plastic:

Whatever type of sealant for sewer pipes you choose, you need to carefully prepare the surfaces and perform the work efficiently. The pipes must be free of cracks and fistulas. Before sealing, they are cleaned, repaired, degreased. When working, you should strictly adhere to the technology, and after its completion, wait the allotted time until the composition solidifies. Only then can the system be operated normally.