Indirect heating boiler: connection diagram to a gas boiler

The indirect heating boiler has been widely used in private houses or in summer cottages for its ability to provide a sufficient amount of hot water. Although the principle of operation of the boiler is very simple, the efficiency of this device largely depends on the correct choice of the scheme for connecting the boiler to the boiler.

The main nuances of connecting a boiler to a gas boiler

Water is supplied to the device for 2 circuits. One of which is a heating circuit connected to the heating system of the house. The second circuit is used to heat the water coming from the water supply and distributed to the water intake points.

To choose an indirect boiler installation scheme, you first need to remember some principles:

- Cold water must enter the lower space of the device, and the output of already heated water must be carried out through the upper part of the boiler.

- The coolant must be supplied to the tank from top to bottom, in other words, water or antifreeze enters the upper pipe of the device and then returns back to the system through the lower one.

- The recirculation point must be in the center of the water heater tank.

Compliance with all these principles will allow rational use of the device and increase its efficiency, since the water temperature in the upper part of the device will remain high, and the coolant will heat the cold water of the lower level of the tank.

Connection options for different situations

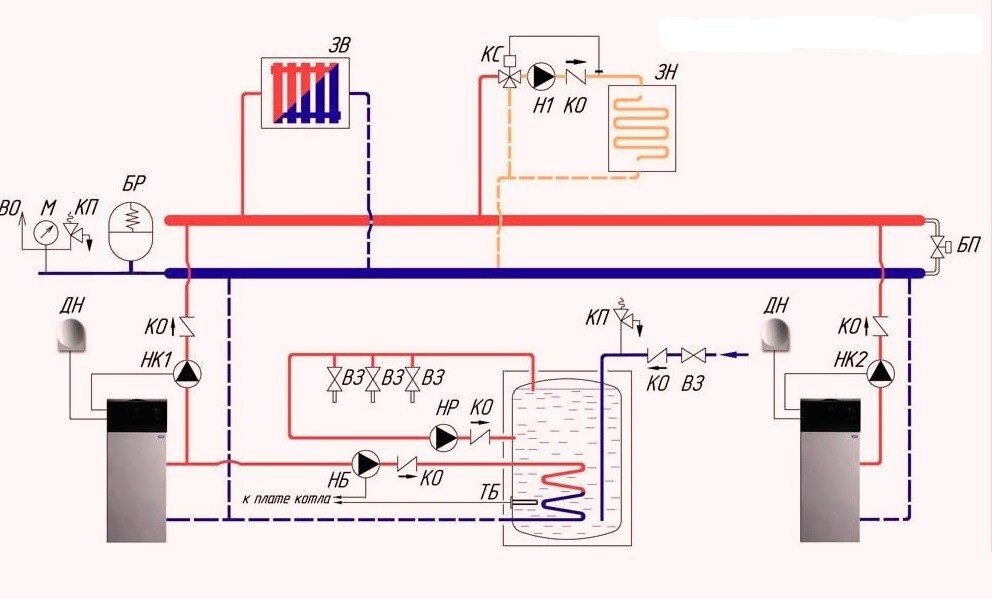

Often, when connecting an indirect boiler, three main schemes are used:

- installation method with a three-way valve;

- option of using two circulation pumps;

- option using a hydraulic arrow.

The use of a recirculation system also helps to significantly improve the quality of hot water.

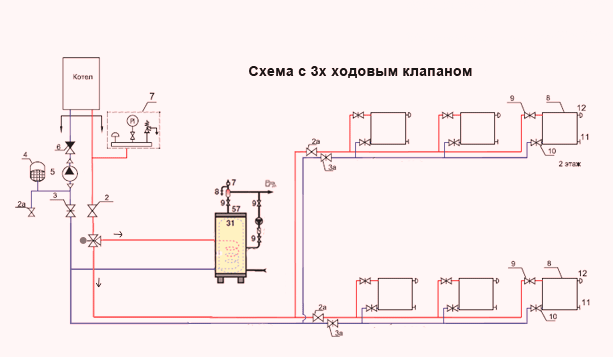

How is a three-way valve used?

If you plan to consume a large amount of hot water, then you should use the boiler connection diagram using a three-way valve. To do this, it is necessary to select 2 heating circuits: the main one, which heats the room, and the second one, which heats the water in the tank. To distribute the coolant flow between them, a three-way valve is used, which can be controlled using the boiler thermostat.

The principle of operation of such a system is as follows: when the temperature of the water in the tank drops below the set value, the valve supplies the coolant to the circuit that heats the water of the boiler. When the water heats up to the set temperature, the valve returns the direction of the coolant to the main heating circuit. In such a scheme, priority is given to heating the water in the boiler tank, and not to heating the room.

Note! If your area has hard water, then you should use this particular method of heating water (with a three-way valve), and not a double-circuit boiler, which in such conditions will fail very quickly.

It is also worth noting that for the correct operation of this type of system, it is necessary to correctly set the thermostat values. The maximum temperature for heating the water of the boiler must not exceed the heating value of the boiler heat carrier. Otherwise, the water in the tank will be heated constantly. And the inability to reach the maximum temperature in the tank will not allow switching to the heating circuit.

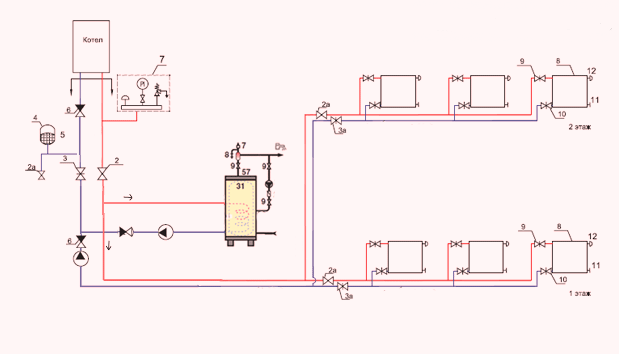

Dual pump system

In this scheme, instead of a three-way valve, two recirculation pumps are used, as well as a check valve. Thus, the installation of an indirect heating boiler also includes two parallel circuits: heating the room and heating the boiler. And the circuits are controlled by separate circulation pumps.

Since the hot water line has priority, the pump for controlling the boiler circuit is mounted before the pump for the heating system. The temperature sensor of the device is used to control the pumps. When the water temperature in the tank drops, the coolant flow is supplied to heat it, after which it returns to the heating system circuit. A non-return valve prevents mixing of the two coolant streams.

Do not worry that space heating will suffer when using a circuit heating boiler. Since the water in the tank heats up quickly enough (often less than an hour), the room simply does not have time to cool down.

How does a hydraulic arrow work?

Today, the heating system in ordinary apartments is so complex that, in addition to the radiator line, it can also include a boiler heating circuit, a floor heating system, and other elements.

And each such circuit is equipped with a separate circulation pump. And the flows in such circuits of the circuit should be balanced. The hydraulic distributor is used just to control such multi-circuit heating systems, including a hydraulic arrow, as well as a collector. It is also possible to mitigate pressure drops in such circuits with the help of various balancing valves.

And remember! The more circuits in the heating system, the more attention should be paid to its installation. The design of an indirect boiler installation using a hydraulic arrow should be entrusted to an experienced specialist, since it is quite difficult for an ignorant owner to adjust such a system.

recycling. A few words about the benefits

In order not to wait until the cold water in the tap changes to hot, a recirculation system is used. It creates a looped highway, through which the water is constantly moving and does not have time to cool down. Therefore, the consumer, opening a hot water tap, receives it almost instantly.

A constant cycle will help create another circulation pump. A good addition to such a system would be a heated towel rail.