Automation for gas heating boilers: what you need to know when purchasing it

Gas heating boilers are devices of increased danger. If misused or malfunctioning, they can cause natural gas poisoning, combustion products, fire or even explosion. That is why all processes taking place in boiler units must be carried out under constant control, for which gas automatics for boilers is responsible.

Design and principle of operation

All components of automation used in heating systems can be divided into two large groups:

- Devices that ensure the correct and safe operation of boiler equipment.

- Devices that increase comfort when using the boiler.

The automatic safety of gas boilers includes:

- Flame control module. This module includes a thermocouple and an electromagnetic gas valve that shuts off the gas supply.

- The device for protection against overheating and maintaining the set temperature, in the role of which the thermostat acts. This device is responsible for turning off and on the boiler when the temperature of the coolant in the circuit reaches the peak levels set by the user.

- Traction control sensor. The operation of this device is based on changing the position of a bimetallic plate, which is connected by a lever to a gas valve that shuts off the fuel supply to the burner.

- The disruptive (safety) valve is responsible for the excess coolant in the heating circuit.

- Gas pressure. If it falls below the permissible value, the fuel supply to the burner stops. This happens automatically thanks to a valve mechanism set to a specific fuel pressure. In volatile safety modules, the maximum and minimum pressure switches are responsible for monitoring the gas pressure. These devices consist of a diaphragm with a stem. With an increase in fuel pressure, the membrane bends and opens the power contacts of the boiler plant. When the pressure normalizes, the power contacts are set to the closed position.

- The presence of a flame in the burner. In the absence of a flame, the thermocouple cools down and stops producing the current necessary to operate the gas valve solenoid valve, which shuts off the fuel supply to the burner.

- The presence of draft in the smoke duct. When the thrust is reduced, the bimetallic plate of the sensor heats up and changes its shape. The rod connecting the sensor plate to the valve puts it out of operation and the gas supply to the burner stops.

- The temperature of the coolant in the circuit. The thermostat is responsible for preventing overheating and maintaining the temperature of the coolant in the circuit.

In some models of boiler equipment, the manufacturer provides for the presence of an air exhaust device. All devices included in the automatic security system are non-volatile or mechanical. In the presence of actuators and a control controller, they can operate under electronic control.

Automation for comfort provides the owner of the unit with additional functionality: auto-ignition of the burner; self-diagnosis functions and selection of the optimal operating mode, flame modulation, etc. This type of automation is optional and is not used in some models.

The principle of operation of the electronic security system is based on the receipt of data from sensors that are processed by a microprocessor-controlled controller. Based on the data received from the sensors and sensors, the controller sends commands to the actuators of the safety executive devices.

The principle of operation of the mechanical automation of a gas boiler will be considered in more detail. The heating system does not work - the gas valve is closed. To start the boiler, the washer on the valve is squeezed out. This operation forcibly opens the valve, gas flows to the igniter. After ignition of the igniter, the thermocouple heats up. It generates enough voltage to operate an electromagnet that holds the gas valve open.

By turning the washer, the required boiler power is set: gas with the required pressure enters the burner - ignition occurs from the igniter. After starting the boiler plant, the thermostat takes over the control of the temperature of the coolant.

https://www.youtube.com/watch?v=VeK4dSo3B9Y Almost all boiler equipment security systems work on this principle, regardless of the brand. When choosing this system for the boiler, it is recommended to pay attention to the equipment of the same brand as the boiler. For example, it is best to look for automation for BOSH gas boilers of this particular brand.

Functionality of the heating system security system

Under the control of automation are all the important processes that occur in the boiler. Automation for gas heating boilers provides control over:

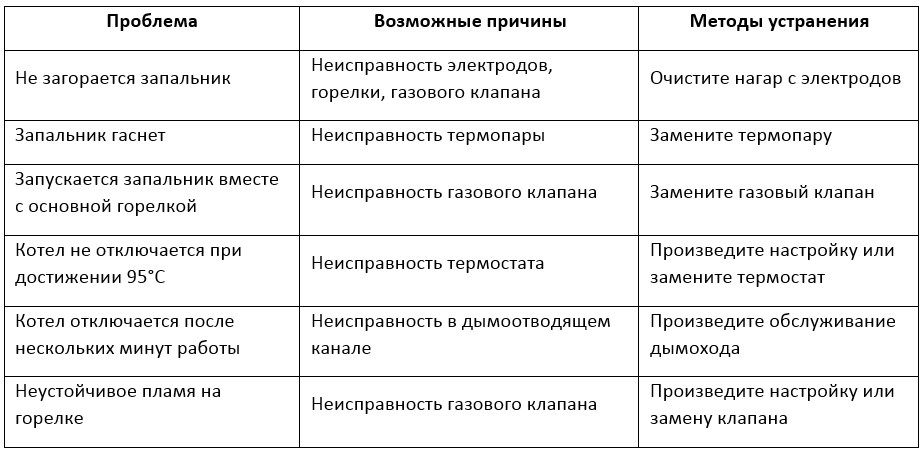

Almost all modern security systems are equipped with control sensors and relays for the presence and pressure of the coolant in the system. This type of automation is most often implemented in volatile systems. Any automation can fail due to poor quality, improper operation and maintenance. Next, you can get acquainted with the characteristic malfunctions of the boiler automation and methods for their self-elimination.

You should be aware that independent intervention in the design of gas installations is prohibited by law. That is why we strongly recommend that in case of malfunctions in the heating installation, contact specialists who have a state certificate for the right to carry out these works.

Departing from the topic, we want to inform you that we have prepared comparative reviews on gas boilers. You can get acquainted with them in the following materials:

The most popular models of security systems for boiler equipment

Today, more than a dozen models of automation from different brands are represented on the Russian market of climate technology. The popularity of a particular brand depends entirely on the demand for heating installations of the same brand. Many owners of domestic boiler equipment ask how the automation works in the Lemax gas boiler? These units use EvroSit automation from an Italian manufacturer. It is this automation system that is in first place in popularity among domestic manufacturers of heating devices.

Models of this line have good functionality and are easily integrated into almost any design of the boiler unit. Standard features: gas pressure control; control over the presence of a flame in the burner and on the igniter; control over the temperature of the coolant and draft in the chimney. Using the automation of this brand does not cause any particular difficulties for the owners, but requires some skills.

Models of this line have good functionality and are easily integrated into almost any design of the boiler unit. Standard features: gas pressure control; control over the presence of a flame in the burner and on the igniter; control over the temperature of the coolant and draft in the chimney. Using the automation of this brand does not cause any particular difficulties for the owners, but requires some skills.

- Before starting the device, it is necessary to press the adjustment and ignition knob and at the same time the button of the piezoelectric element.

- After ignition of the igniter, it is necessary to keep the knob pressed for 5 to 10 seconds to heat the thermocouple.

- If, after depressing the handle, the igniter does not go out, then you can proceed to turn the washer to adjust the gas pressure. After that, the main burner is ignited.

Automation of this brand is quite widespread in the Russian market of climate technology due to its relatively low cost, good functionality and a wide range of models. Standard functionality: maintaining the temperature of the coolant in the range from 40 to 90°C; control over pressure and fuel supply; automatic stop of the device in the absence or occurrence; control over the presence of a flame in the burner.

Automation of this brand is quite widespread in the Russian market of climate technology due to its relatively low cost, good functionality and a wide range of models. Standard functionality: maintaining the temperature of the coolant in the range from 40 to 90°C; control over pressure and fuel supply; automatic stop of the device in the absence or occurrence; control over the presence of a flame in the burner.

Today, Rostov products are in demand by domestic users on a par with European models of automation because of their reliability and low cost. The functionality of automatic AOGV systems is also quite rich. The standard features of this technique allow you to stop the operation of the boiler in the event of the following situations: the temperature of the coolant exceeds the set level; flame failure in the igniter and burner; low pressure and lack of coolant in the system; any failure in the gas supply system; decrease in fuel pressure below the established norm; in the absence or insufficient traction. How does automatic gas boiler aogv work? The operation of the gas valve is controlled by the voltage generated by the thermocouple. It is this voltage that acts on the valve coil and keeps it open while the burner burns. The temperature is controlled by a thermostat and valves that, when the temperature rises or falls, open or shut off the fuel supplied to the burner. Exhaust gases are controlled by a draft sensor. Making the right choice of automation for gas boilers is quite difficult. We strongly recommend that you seek professional help.

Today, Rostov products are in demand by domestic users on a par with European models of automation because of their reliability and low cost. The functionality of automatic AOGV systems is also quite rich. The standard features of this technique allow you to stop the operation of the boiler in the event of the following situations: the temperature of the coolant exceeds the set level; flame failure in the igniter and burner; low pressure and lack of coolant in the system; any failure in the gas supply system; decrease in fuel pressure below the established norm; in the absence or insufficient traction. How does automatic gas boiler aogv work? The operation of the gas valve is controlled by the voltage generated by the thermocouple. It is this voltage that acts on the valve coil and keeps it open while the burner burns. The temperature is controlled by a thermostat and valves that, when the temperature rises or falls, open or shut off the fuel supplied to the burner. Exhaust gases are controlled by a draft sensor. Making the right choice of automation for gas boilers is quite difficult. We strongly recommend that you seek professional help.