Types and features of the use of profile pipes. Variety of profile pipes and their application

Usually, after hearing the word "pipe" we imagine a long hollow tube with a circular cross-section. But in fact, there are a lot of varieties of this seemingly simple object, and they all look different. Recently, a wide application in the construction industry has received a pipe profile GOST 30245 2003. Constructions, which include a profile pipe GOST 30245, surround us literally everywhere. These products are used in the construction of sports complexes and shopping centers, bridges, public transport stops, furniture design, the creation of handrails and fences, the construction of greenhouses and private houses. As a rule, the profile pipe GOST is made of steel of different grades and has a section in the form of a square or rectangle. Thanks to the cross section with 4 ribs, these metal elements are extremely hardy, despite the low weight. A variety of shapes and suitability for welding make them indispensable in the creation of metal structures.

Profile pipes of GOST 30245 2003 are divided into steel seamless, electrically welded and profile electric welded, and both of them can have different shapes ?? square, rectangle, oval. Consider the properties of some of them.

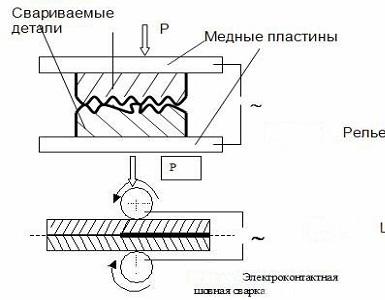

Electro-welded profile pipes

The electrically welded profile pipe of GOST outside has a size of 10 to 100 millimeters, and walls are from 1 to 5 millimeters thick. The profile pipe GOST 13663 86 can be of various lengths: an unlimited length from one and a half to nine meters, a dimensional length from five to nine meters, the length of a multiple dimensional - can have any multiplicity, but not above the lower limit, which is set for measuring pipes.Pipes square

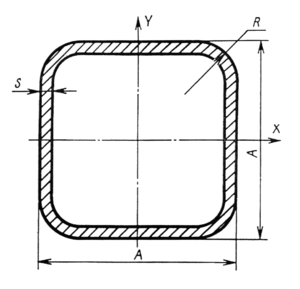

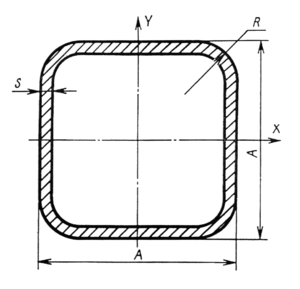

The profile pipe GOST 8639 82 has a section in the form of a square. The product range is regulated by GOST, which applies to cold-worked electrically welded and seamless steel hot-deformed pipes. According to this GOST, the sides of pipes can have dimensions from 10 to 180 millimeters.Among the advantages of a profile GOST 8639 82 pipe, it is worth noting that it can withstand loads directed to the pipe at right angles. The square cross section provides the pipe with a strength equal to the endurance of the cast rod. At the same time there is no over-consumption of metal, since the square tube has a void inside.

Profile pipes GOST 8639 are often used for the manufacture of fences and fences. Of these, it is also easy to construct a handrail.

Rectangular pipes

The profile pipe GOST 8645 has a section in the form of a rectangle. This type of pipe differs from the previous one only by its cross-sectional area and thickness. The assortment for this type of products is regulated in accordance with GOST 8645 68. The standard GOST is subject to seamless steel hot-rolled, and rectangular electric welded pipes. The dimensions of the sides can be represented by a range from 10 to 150 millimeters.Among the advantages of such profile pipes is the ease of installation, durability and increased strength, resistance to temperature drop and insensitivity to deformation, saving metal during construction. In addition, pipes are convenient form, they are easy to store, transport, use, and they are able to replace many elements of profile fittings and are much cheaper.

Pipes shaped GOST 8645 68 have been widely used. Understanding the direction of the maximum load vector makes the use of a rectangular tube the most justified.

Profile pipes: dimensions

Profile pipes have interrelated dimensions. In other words, the larger the tube, the thicker its metal walls, the products, with the pipe side up to 6 millimeters in length, are 6 meters long, if the metal structure has a wall thickness of more than 80 millimeters, its length is 12 meters.Theoretical weight: pipe profile GOST

The tables below show the weight of 1 kg, the theoretical weight, and the number of meters in 1 ton of the profile pipe, in accordance with GOST 8639 82 and GOST 8645 68. Pipes steel square GOST 8639-82 |

|||

| Outside diameter, mm | Wall thickness, mm | Weight of meter, kg | Meter per tonne |

| 15x15 | 1,5 | 0,605 | 1652,9 |

| 20x20 | 1,5 | 0,841 | 1189,1 |

| 2 | 1,075 | 930,2 | |

| 25x25 | 1,5 | 1,41 | 934,6 |

| 2 | 1,39 | 719,4 | |

| 30x30 | 1,5 | 1,401 | 713,8 |

| 2 | 1,7 | 588,2 | |

| 50х50 | 2 | 3,01 | 322,6 |

| 3 | 4,56 | 232 | |

| 4 | 5,56 | 179,9 | |

| 60x60 | 2 | 3,64 | 274,7 |

| 3 | 5,48 | 182,5 | |

| 4 | 6,82 | 146,6 | |

| 80x80 | 3 | 7,48 | 133,7 |

| 4 | 9,33 | 107,2 | |

| 5 | 11,44 | 87,4 | |

| 6 | 13,46 | 74,3 | |

| 100x100 | 3 | 9,1 | 109,9 |

| 4 | 11,38 | 87,9 | |

| 5 | 13,73 | 72,8 | |

| 6 | 17,22 | 58,1 | |

| 120x120 | 4 | 14,6 | 68,5 |

| 5 | 17,55 | 57 | |

| 6 | 20,99 | 47,6 | |

| 140x140 | 5 | 16,76 | 60 |

| 6 | 24,76 | 40,4 | |

| 160x160 | 4 | 19,27 | 51,9 |

| 5 | 23,83 | 42 | |

| 6 | 28,29 | 35,3 | |

Pipes steel rectangular GOST 8645-68 |

|||

| Outside diameter, mm | Wall thickness, mm | Weight of meter, kg | Meter per tonne |

| 40x20 | 1,5 | 1,32 | 713,8 |

| 2 | 1,86 | 429,2 | |

| 40x25 | 1,5 | 1,43 | 643,5 |

| 2 | 1,86 | 537,6 | |

| 40x40 | 1,5 | 1,849 | 540,8 |

| 2 | 2,48 | 429,2 | |

| 3 | 3,36 | 297,6 | |

| 50x25 | 1,5 | 1,67 | 562,4 |

| 2 | 2,17 | 460,8 | |

| 60x30 | 2 | 2,7 | 357,9 |

| 60x40 | 2 | 3,01 | 322,6 |

| 3 | 4,3 | 232,6 | |

| 4 | 5,56 | 179,9 | |

| 80x40 | 2 | 3,72 | 268,8 |

| 3 | 5,25 | 190,5 | |

| 4 | 6,82 | 146,6 | |

| 80x60 | 3 | 6,55 | 152,7 |

| 4 | 8,07 | 123,9 | |

| 100x50 | 3 | 6,95 | 143,9 |

| 4 | 8,7 | 114,9 | |

| 100x60 | 3 | 7,34 | 136,2 |

| 4 | 10,05 | 95,1 | |

| 120x60 | 3 | 8,44 | 118,5 |

| 4 | 11,06 | 90,4 | |

| 5 | 13,34 | 75 | |

| 120x80 | 4 | 12,18 | 82,1 |

| 5 | 14,91 | 67,1 | |

| 140x100 | 4 | 14,35 | 69,7 |

| 5 | 17,72 | 56,4 | |

| 160x120 | 4 | 16,87 | 59,3 |

| 5 | 20,86 | 48 | |

| 180x140 | 5 | 23,84 | 41,9 |

Profile pipes are the subject of use, both in professional and in amateur construction. With the help of profile pipes, it is easy to construct various structures that are capable of withstanding heavy loads. When there is a need for self-manufacturing of the profile pipe, use the recommendations on how to make a profile pipe using special equipment.

General concept of profile pipes

The profile pipe is an empty rod-like pipe with a section in the form of a square, rectangle or oval.

Profile pipes are made from:

- of stainless steel,

- carbon steel,

- low-alloy steel,

- plastic.

The industrial production of profile pipes includes the deformation of a conventional pipe, with the presence of a circular section in tubes of rectangular, oval or square shape. A strip is a metal blank from which a metal pipe is made, then with special equipment the pipe gets into the shape of a certain section and undergoes a thermal treatment.

The minimum cross-section of profile pipes is 1x1 cm, and the maximum is 50x40 cm. In relation to the wall thickness of the pipe, there are from 1 to 22 mm.

Profile pipes are capable of withstanding heavy loads due to the fact that the pipe walls withstand the main load and distribute it evenly. Since the pipes inside are empty - the weight of the profile pipe is small and facilitates the overall weight of the structure.

Field of use of the profile pipe

- the erection of the skeletons of buildings,

- the construction of stadiums,

- construction of bridges,

- device arches,

- construction of spans or trusses,

- machine-building industry,

- the sphere of advertising and the production of billboards,

- repair of attic rooms,

- in the construction of low spaces,

- the construction of warehouse or industrial premises,

- manufacturing of partitions.

Profile pipes with a rectangular or square cross-section are often used in the erection of load-bearing buildings or industrial structures. Such pipes are the basis for the construction of sports complexes or pavilions.

The profile pipes are used for closing industrial premises. When using profile pipes, as an overlap, a reliable design and economy in the consumption of materials is obtained.

Woods made from profile pipes make it easier to access the facade of the building, for repair or finishing.

Profile pipes are used for mounting metal frames. Due to the quick and easy connection of the profile, the tower crane construction passes without the use of heavy equipment.

Profile pipes, the cross section of which does not exceed 40x40 mm, is used in the manufacture of household appliances such as lamps, sports equipment, furniture.

Profile pipes made of aluminum are used in the device of tires, connectors and refrigerators, as well as conditioning equipment.

Profile pipes are very rarely used for installation of communications, pipes in the construction and construction of buildings, including trusses, are widely used.

Advantages of using structures from profile pipes:

1. Economical: a small consumption of metal in the construction of large structures.

2. The ease and speed of installation allows the construction of a large building in a short time.

3. Profile pipes are treated with special anti-corrosive compounds, which correspond to all sanitary and hygienic standards.

4. The use of profile pipes complies with all fire safety rules.

5. If it is necessary to replace the profile pipe, it is not necessary to disassemble the entire structure.

6. Due to the square and rectangular shape, it is much easier to transport pipes.

7. Profile pipes are resistant to bending and to high loads.

8. Installation of profile pipes, as a frame of the building will help to implement various architectural projects of any complexity.

Variety of profile pipes

Profile profile pipe:

Depending on the type of production, profile pipes are distinguished:

- hot-rolled type,

- cold-rolled type,

- seamless type,

- electric-welded type.

Depending on the method of production, rectangular and square tubes are divided into:

- profile pipes hot rolled seamless type - are characterized by high strength, anti-corrosion, resistance to aggressive environment;

- profile cold-rolled pipes, which are divided into heat-deformed and standard, such designs withstand large pressure drops and differ in elasticity;

- profiles of electrically welded cold-rolled type have high strength and durability characteristics.

Depending on the field of application, the profile pipes are divided into:

- standard profile pipes, the scope of which applies to the installation of pipelines, cable equipment, scaffolding, fencing or irrigation systems;

- trumpet type pipes are used in the arrangement of a gas, water or oil pipeline with high pressure drops;

- profiled pipes with heat resistance are used in food or chemical industry;

- pipes of structural type are used for the construction of buildings, transport elements, towers or cranes;

- profile pipes of engineering significance - used for the production of pistons, cylinders, shafts or bearings.

Depending on the type of section, the profile pipes are of the following forms:

- oval,

- rectangle,

- square,

- flat oval,

- pipes with flat ribs,

- specially profiled pipes.

Depending on the material from which the profile pipes are made:

- steel pipes,

- plastic profile pipes.

The profile steel pipe is more common. because of high strength. The plastic profile pipe is characterized by a lower cost and ease of construction.

According to the type of steel, the profile pipes are divided into:

- profiles, made of boiling steel - characterized by high strength, but low durability;

- profiles of calm steel - have a high plasticity index;

- profiles of polospokoynoy steel - characterized by both strength and plasticity.

Calculation of profile pipes

The pipe profile dimensions and weight are determined by the ratio of wall thickness and pipe size.

Example of calculation of a profile pipe:

1. When using a profile pipe 20x20 with a wall thickness of 1 mm, the total weight of one meter of pipe is 583 g.

2. Profile pipe 20x40 has a weight of 670 g.

3. The profile pipe 40x40 with a wall thickness of 2 mm weighs 2330 g.

4. The profile pipe 60x60 with a wall thickness of 8 mm, weighs 12200 g.

Deformation of profile pipes

To make a device for bending a profile pipe, the section of which does not exceed 20 mm, you need a concrete slab and a drill.

In a concrete pipe it is necessary to drill an aperture and to drive in steel pins, according to the drawing of a profile pipe. The maximum distance between the pins should not exceed 5 cm.

To bend the pipe in such a device, you should do the following:

1. Secure the end of the pipe at the location of the two end pins.

2. The other end of the pipe should be bent over the pins that are hammered into the plate.

3. At the end, the other end of the plate should be located between the extreme pins.

Tip: For reliable fixation of the profile pipe, weld a temporary rod in it, which will help to fix the bent position of the pipe.

In the absence of a concrete slab, drive the pins into the ground, and try to bend the profile pipe in this way.

Manufacturing technology of profile pipes

To produce a profile pipe, with a rectangular or square cross-section, special rollers are required, which by deformation of a large force deform the pipe.

When manufacturing profile pipes that do not carry a heavy load, for example, for furniture, canopies or greenhouses, it is enough to buy an ordinary machine that will help make profiles. But, if we make bearing structures from profile pipes, we need to buy pipes made under special conditions, since the power of the pipes from a conventional machine will not be enough.

In the process of production of profile pipes there are several cycles:

1. The factory, for the manufacture of pipes, bring metal strips - large round-shaped rolls of steel. Depending on the size of the profile pipe, the machines make cutting strips into strips.

2. The welding machine carries out joining of strips in one welding tape which is wound on a drum.

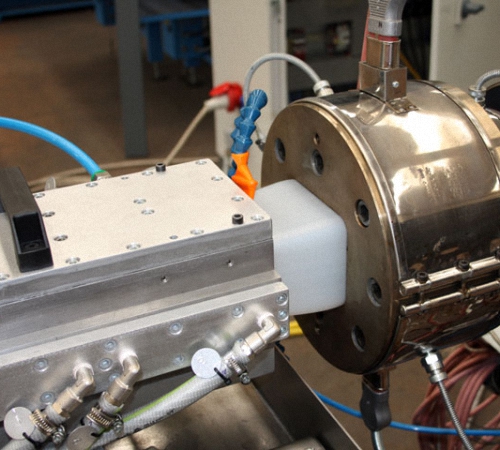

3. The next stage involves the formation of pipes with a circular cross-section. This process takes place in the forming mill.

4. Pipes with a circular cross section fall into the welding shop where they are welded.

5. After removing the melt from the pipe surface. The pipes are sent to cool.

6. A special machine adjusts the size of the pipe and makes the surface smooth and smooth.

7. The final stage is the formation of a profile pipe of square or rectangular cross-section with the help of rollers.

For the production of a rectangular shaped pipe, four rolls are required, as well as for a square shaped pipe. When manufacturing pipes with an oval cross-section, only two rollers should be used.

Methods for controlling the manufacture of a profile pipe

- the vortex defectoscopic method involves the interaction between the magnetic and electrical properties of steel,

- the visual method involves inspecting the pipe for defects and irregularities that have not been detected by the vortex device.

After the manufacture of pipes, heat treatment should be carried out, which includes:

- heating of the pipe,

- complete cooling.

Tip: When making a profile pipe by yourself using a special machine, use a blowtorch to heat the profile pipes.

The use of the machine for the production of profile pipes is characterized by a high level of noise and consists of a pull mechanism and four rolls that form a pipe.

Despite the changing crises, private construction continues to develop rapidly. Bricks, concrete and wood are considered to be classic materials for the construction of buildings, but construction has never been without metal, since profiled sheets and meshes, beams for floors, profiles for frameworks are necessary.

With the help of welding, it is possible to create any kind of metal from metal, and the joints in strength are not worse than the metal massif. In addition, metal elements can be to forge under heat, deform and bend under pressure. Any metal construction will always be more compact and lighter than those of the elements of reinforced concrete and stone. With competent care and proper assembly, they are much more durable, especially if from a range choose a certain grade of steel or metal that will ensure the procurement of suitable specific conditions of performance.

Profile metal pipes in our country began to be actively used relatively recently, but the popularity of rectangular and square pipes is constantly growing. They become cheaper and more qualitative, their assortment is expanded by types of cross-section and sizes.

As a rule, in the case of pipes, many represent a conventional cylindrical object. It is these surrounding waterways or gas communications that we are used to seeing. Round cross-section of the pipeline characterized by better conductivity with a minimum surface size.

As a rule, in the case of pipes, many represent a conventional cylindrical object. It is these surrounding waterways or gas communications that we are used to seeing. Round cross-section of the pipeline characterized by better conductivity with a minimum surface size.

But in absolutely not all conditions the tube of round cross section works in the best way. For example, it is easier to bend, which is good for constructing complete turns of the water pipe, but it is rather unfavorable for the rigidity of hinged structures. Profile pipes have completely different advantages and characteristics.

Profile pipe is a hollow tubular piece that has any cross section, except round. As a rule, in the section we see an oval, a square or a rectangle, although today rolling technology makes it possible to produce more complex geometry.

According to physical parameters, flat-oval pipes practically do not differ from round ones, but they are highly decorative, that's why they are often used for design of buildings, creation of fencing elements, furniture. Another point is the large surface of the outer area with a significant reduction in the internal space, which makes it possible to effectively use the oval pipe in cooling systems where the maximum heat removal from the carrier is needed. In addition, the oval profile is characterized by high, so it is also called "arched".

Rectangular and square tubes superbly hold transverse loads, because of this, they are used to create different elements of furniture and building bearing systems. Of the closed profiles, frames of architectural buildings are being built, columns, pillars, and joists are made. Profile pipes are required for the reinforcement of metal-plastic windows, for the assembly of openings and canals of steel doors.

Method of manufacturing profile pipes

The production of rectangular sections of pipes occurs similarly to round ones. On pipe welding machines, the preforms of the sheet are bent into the cylinder, and the seam is welded. After the round tube is passed through a roll system, in which it is compressed into hundreds of tons with compressed strength to the desired cross-section. Then the profile product is heated up to release the metal that is stressed after the pressure.

The production of rectangular sections of pipes occurs similarly to round ones. On pipe welding machines, the preforms of the sheet are bent into the cylinder, and the seam is welded. After the round tube is passed through a roll system, in which it is compressed into hundreds of tons with compressed strength to the desired cross-section. Then the profile product is heated up to release the metal that is stressed after the pressure.

Taking into account whether the workpiece is heated during rolling, the pipes are divided into hot-rolled and cold-rolled pipes. Then the geometry of the profile and the quality of the seam are checked, the products are cut to the correct size and stored. The pipe is shipped in packs of up to 5 tons. To protect the product can be treated with grease and packed in steel boxes.

Not always a closed profile made of electrically welded pipe. There are also shaped seamless products, they are rolled by rolling on calibrated rolls made of a seamless tube of circular cross-section. A seamless pipe does not have a seam, it is made from a single cylindrical billet. Seamless profile section is characterized by increased tightness and stability, but it is much more expensive.

Design characteristics and the process of manufacturing oval pipes are specified in GOST-8642 68. Square pipes are manufactured using GOST-8639 82, GOST-30245 2003, for rectangular products use GOST-30245 2003 and GOST-8645 68. These rules contain:

That is, if you need to buy a batch of rolled products for high-quality products, the assortment and conformity of the GOST pipe can be checked without problems with a measuring device.

The main advantages of profile pipes

Naturally, the main advantage of a square or rectangular profiled pipe is its considerable spatial stiffness, in contrast to products of circular cross-section. Since this is a closed profile with four stiffeners. If the proftrub is used in the role of a bearing beam, and the load is at an angle of 90 degrees to some plane, the resistance of the profile to the bend will be approximately 35% greater than that of the analog of the circular section.

This indicator is close to the parameters solid steel rod. If the vector of the action force is predetermined, then instead of a square one, you can choose a rectangular cross-section by setting the long part of the profile along the impact vector. At the same time, the use of a rectangular pipe reduces the material consumption of the pipe by approximately 25%.

Due to flat surfaces, pipes of rectangular and square cross-section are much easier to process. They are easier to ground and dye, protective coatings are better retained on surfaces. This metal product, for example, unlike a channel or an I-beam, has no hard-to-reach places for processing, which has a favorable effect on corrosion resistance.

Flat faces provide good ergonomics. These profiles are stably connected to any structural elements, they are rather convenient to stack on the bearing surfaces. The profile pipes occupy the minimum volume of space near the base, without creating dead zones. They are easier to screw screws, they are easier to revet sheet materials.

The presence of planes provides the products with good resistance to transport and storage, they can be packed in rectangular packs. In this case, the round pipes, especially the large diameter, because of the possibility of rolling, are considered to be a source of high danger - they are loaded and delivered by special transport and are packed only with a "pyramid".

How to choose the right pipe

In order for the rolled metal to have sufficient durability and design performance, you need to carefully select the type of profile pipe. There are many criteria, and each displays certain properties of the product.

Preparation method

Taking into account the features of the manufacturing process, the profile products are divided into:

Taking into account the features of the manufacturing process, the profile products are divided into:

- Seamless;

- Welded;

- Cold-rolled;

- Hot-rolled.

Hot-rolled pipes - are general and construction products, they are used to create external metal structures, for the construction of load-bearing frames and building supports. They, due to the processing of blanks under high temperature, are characterized by a slight surface roughness, but they do not have internal stresses. This technology makes it possible to make large diameter tubing with a high wall thickness. Since high-carbon and alloyed steel at elevated temperatures is easier to deform - the HA pipes often have anticorrosive properties.

Cold rolling makes it possible to make high-quality profiles. This concerns the accuracy of geometric dimensions and surface cleanliness. This type of product is chosen for the creation of structures to which high operational requirements are required. Deformation of the workpiece without the use of elevated temperatures makes this profile more resistant to internal or external pressure, and it is better than flexing the bend.

Seamless Tubes have much greater strength than electrically welded, because a seam of poor quality can be a weak point. In addition, hot-deformed seamless pipes are usually made with an increased wall thickness - more than one centimeter. Seamless products are characterized by good surface quality, elasticity, resistance to increased pressure.

Proftruby can be made of any carbon steel. Increased anti-corrosion properties have products with a thin coating of the zinc layer, they rust 7-8 times slower, rather than ordinary black. Galvanization occurs by spraying or immersing the profile in a zinc alloy.

Proftruby can be made of any carbon steel. Increased anti-corrosion properties have products with a thin coating of the zinc layer, they rust 7-8 times slower, rather than ordinary black. Galvanization occurs by spraying or immersing the profile in a zinc alloy.

Practically corrosion resistant pipes have stainless steel pipes, they are made, as a rule, from the steel grade AISI304 and AISI316, slightly less often - from AISI439. Most often they are used for building architectural elements of a building and less often for the construction of load-bearing skeletons. The profile of stainless steel is characterized by a variety of options for finish finishing, heat resistance, resistance to abrasion.

Rounding corners

This parameter is indicated by the current GOST of pipe manufacturing. The optimal the radius of the angle in 2S (double wall thickness). Taking into account the characteristics of equipment and manufacturing, in practice the radius of rounding of corners is often higher than the design radius, this allows the manufacturer to make the products cheaper and easier. Products with ultra-small roundings look more beautiful, but they are more expensive and heavier than standard ones. It should be noted that the autumn round and too straight angles reduce the bearing characteristics in the design.

Wall Thickness

The division of pipes in the thickness of the walls is a rather conditional criterion. Here we need to take into account the ratio of the outer diameter to the thickness of the outer wall. Pipe rolling is thin-walled, when this ratio does not cross the line at 0,025, at a ratio of 0.05 - the profile is called standard, thick-walled pipe has proportions more than 0,1 and. In any case, the technology is such that the larger the diameter of the product - the thicker the wall.

GOST clearly defines what opportunities this ratio is possible with a certain manufacturing method. For example, a square profile with a side of 190 millimeters and a wall of 5-15 millimeters can be made only by hot deformation. The thickness of the walls of closed products can vary in thickness in the range of 2-14 millimeters, of course, for heavier buildings it is necessary to use a profile with thicker walls.

Mechanical characteristics

Classification of proftrub, taking into account the chemical and mechanical characteristics of the billet, can talk about the purpose of the profile. For this type of rectangular metal products the following designation is used:

Classification of proftrub, taking into account the chemical and mechanical characteristics of the billet, can talk about the purpose of the profile. For this type of rectangular metal products the following designation is used:

- A - only mechanical indicators are normalized;

- B - the chemical composition and mechanical parameters are normalized.

As a rule, rationing according to the "B" marking is assumed for large items, because they are most often chosen for the construction of load-bearing structures. Products are tested for impact strength at a temperature of -25 to +25. The same test is done after the artificial aging of steel. Metal rolling is not subjected to hydraulic tests, but some manufacturers do it on their own initiative, and, of course, can guarantee the normal operation of the products at a certain pressure. These profiles are assigned the "D" mark.

Obviously, the profile rectangular tube is quite convenient for work, and really a universal and indispensable material for construction. It is difficult to underestimate the financial and technological advantages that are obtained by using a closed profile of a rectangular or square section.

Applications profile pipes are very wide. Profile, called any tube of carbon steel or non-ferrous metal, having a non-standard section, in the form of a rectangle or square. Such a constructive feature is not caused by the whims of the producers and not by the decorative purpose, but by the market demand. Due to a number of special physical and mechanical properties, they can not be replaced by plastic analogs and are widely used in many business sectors.

Profile pipe has several advantages before round:

- convenience of warehousing, loading and transportation of rolled metal;

- tightly adjacent to flat surfaces;

- improvement of the quality of steel in production.

Profile pipes have a low weight and are inexpensive. Simultaneously, the products feature high bending strength, are not afraid of changes in the temperature regime. Four stiffeners are responsible for the strength of the structure. Each product is tested for the integrity of the weld. The scope of use is practically unlimited.

Metal profile pipes in construction

Resistance to humidity allows you to use rolled metal products both inside and outside the building. If necessary, powder coating is applied, which protects the steel against corrosion. Such products can be purchased from the company "Building Structures" http: //ск37.рф/izdeliya-iz-metalla/ofakturovannye-profilnye-truby-21, every detail in the manufacturer's warehouse meets GOST.

Based on the production method, the profile pipes can have a length of 4 to 12.5 m, they are successfully replaced by metal beams and channel bars when creating a prefabricated object. Of the pipes, roofing systems, staircases, interfloor ceilings are made. Of these, make-up structures, canopies and awnings are made, and they are often used in the construction of columns, various towers and towers. Usually, parts with a thickness of 4-12 mm are selected. When installing the frame, profile pipes 200x200 mm and 150x150 mm, thickness from 6 mm are used. Products with the size of 80x80 act as a bar. Of thin-walled - lightweight partitions are erected.

Use of metal parts in furniture production

Most common use of profile pipes in the manufacture of school furniture. The frame with plastic plugs is the base of the desks and school chairs. Similar products from metal can also be found in the mechanisms of sliding sofas, book shelves and decorative shelves. In the storehouse of many stores there are structures for storing goods created with the help of a rectangular pipe.

Application of profile pipes in engineering and agriculture

Pipes, with a wall thickness of 3-8 mm., are used in engineering, as well as in the machine tool industry. From a rectangular part, caravans, scooter frames and motor scooters are manufactured. It can also be seen on the bicycle frame.

Creation of demountable and stationary greenhouses is impossible without a profile pipe. Without metal rolling can not do with the creation of attachments for tractors, temporary vegetable stores, livestock facilities.

It is made of frameworks for billboards, exhibition pavilions, used for decoration of premises. It is difficult to list all the spheres of application of rolled metal. A profile pipe you can meet absolutely anywhere: in the park or on the playground, as a support in the garage and even in shipbuilding.

The price of a trade pipe consists of several components:

- Section.

- Methods of manufacture.

- Stamps of used steel.

- Wall thickness.

In our catalog you will find this rolled metal of different thickness and diameter. All products are manufactured in strict accordance with national, as well as international standards.

Price per meter of profile pipe is presented in the price list, which you can read on our website.

Characteristics

These products are rolled products with a square, cross-section, or a rectangular or oval shape. The products are made from different grades of steel, the composition of which subsequently determines the final properties and purpose of the product.

By the method of production, the proftrub pipes are divided into 2 types:

- Cold-drawn. As the initial billet in production round tubes are used, which are obtained by the method of cold or hot deformation. The workpiece is compressed with the same force from all sides and the result is the product of the desired profile. The dimensions and characteristics of such a pipe are directly dependent on the parameters of the initial workpiece.

- Welded . This method does not involve the use of round "donors". A metal sheet is cut into blanks of a certain size, then it goes to the forming mill, where it is given the necessary shape. The final stage is fixation of the seam by welding.

A very popular is both a welded and seamless profile pipe. The price of such products varies slightly. Both options have a low weight and withstand considerable loads.

The requirements for the production of these rolled metal products are set out in GOST 13663-86. There is also a separate state standard for each type of pipe:

- For rectangular products - GOST 8645-68.

- For square - GOST 8639-82.

- For products with an oval section - GOST 8642-68.

Scope of profile pipes

Properties inherent in the product of rolled metal products allow it to be used in a variety of industries, manufacturing, construction, etc. Galvanized pipe is used in the chemical and food industries, as well as in the construction of engineering communications. Lightweight and durable metal structures are used as frames of massive objects: buildings of various types, industrial shops, trade pavilions, warehouses and exhibition pavilions.

Widely used profile pipe for arches, columns, stairs, bridges. Not less popularity it has received in furniture production, with its help create a metal decor, frames of tables, legs of sofas, handrails, etc. Great for this fence pipe around parks, gardens and other public places. This fence looks more attractive than brick walls, provides a good overview and does not obscure the plants. In addition, such fences are relatively easy to build.

Buy a profile pipe in Moscow

The company "Metal XL" offers a full range of profile rolled metal products, which you can familiarize with on our website. We can meet the needs of consumers in any volume of this product.

Wholesale and regular customers buy a pipe can on the most favorable terms. The company provides attractive discounts, the sizes of which depend on the volume of the ordered batch.

We guarantee the fulfillment of the assumed obligations for the delivery of any volumes and assortment of these products. Be sure, having decided to buy a profile pipe with us, you will not encounter any difficulties. The order will be executed on time so as not to disrupt the client's plans.

Additional questions related to the delivery and payment of the goods you can check with our managers.