Horizontal distance from the gas pipeline. SNPs and standards: distance, length and height of buildings, regulations for laying utility networks. Gas pipeline crossings across railways, tramways and roads

Table B.1

|

Buildings, structures and communications |

Vertical distances (clear), m, when crossing |

Horizontal distances (clear), m, at gas pipeline pressure, MPa |

|||

|

up to 0.005 |

St. 0.005 to 0.3 |

St. 0.3 to 0.6 |

St. 0.6 to 1.2 |

||

|

1. Water supply |

|||||

|

2. Domestic sewerage |

|||||

|

3. Gutter, drainage, rainwater drainage |

|||||

|

4. Heating networks: |

|||||

|

from the outer wall of the channel, tunnel |

|||||

|

from the shell of the channelless laying |

|||||

|

5. Gas pipelines with pressure up to 1.2 MPa |

|||||

|

6. Power cables voltage: |

|||||

|

up to 35 kV |

|||||

|

110 - 220 kV |

|||||

|

Communication cables |

|||||

|

7. Channels, tunnels |

|||||

|

8. Oil product pipelines on the territory of settlements: |

|||||

|

for steel gas pipelines |

0,35 |

||||

|

for polyethylene gas pipelines |

0,35* |

20,0 |

20,0 |

20,0 |

20,0 |

|

Main pipelines |

0,35* |

By |

|||

|

9. Foundations of buildings and structures up to gas pipelines with nominal diameter: |

|||||

|

up to 300 mm |

10,0 |

||||

|

St. 300 mm |

20,0 |

||||

|

10. Buildings and structures without a foundation |

From the conditions of possibility and safety of work during the construction and operation of a gas pipeline |

||||

|

11. Foundations of fences, enterprises, overpasses, contact and communication supports, railways |

|||||

|

12. 1520 mm gauge public railways: |

|||||

|

inter-settlement gas pipelines: the bottom of the embankment or the edge of the excavation slope (the outermost rail at zero marks) of railways of the general 1520 mm gauge network |

|||||

|

gas pipelines on the territory of settlements and inter-settlement gas pipelines in cramped conditions: |

|||||

|

axis of the outer rail, but not less than the depth of the trench to the base of the embankment and the edge of the excavation |

10,8 |

||||

|

13. Axle of the extreme track of 750 mm gauge railways and trams |

Depending on the method of work production |

||||

|

14. Side stone of a street, road (edge of the roadway, reinforced strip, curb) |

Same |

||||

|

15. The outer edge of the ditch or the bottom of the road embankment |

|||||

|

16. Foundations of overhead power transmission line supports: |

|||||

|

up to 1.0 kV |

|||||

|

St. 1 kV to 35 kV |

|||||

|

» 35 kV |

10,0 |

10,0 |

10,0 |

10,0 |

|

|

17. Tree trunk axis with crown diameter up to 5 m |

|||||

|

18. Gas stations |

|||||

|

19. Cemeteries |

|||||

|

20. Buildings of closed warehouses of categories A, B (outside the territory of industrial enterprises) to the gas pipeline with a nominal diameter: |

|||||

|

up to 300 mm |

10,0 |

||||

|

St. 300 mm |

20,0 |

||||

|

up to 300 mm |

10,0 |

||||

|

St. 300 mm |

20,0 |

||||

|

21. Edge of the irrigation canal (for non-subsidence soils) |

According to |

||||

|

Notes: 1. The above distances should be taken from the boundaries of the territories allocated to enterprises, taking into account their development, for detached buildings and structures - from their nearest protruding parts, for all bridges - from the base of the cones. 2. It is allowed to reduce the vertical distance between the gas pipeline and an electrical cable of all voltages or a communication cable to 0.25 m, provided that the cable is laid in a case. The ends of the case should extend 2 m on both sides from the walls of the gas pipeline being crossed. 3. The “-” sign indicates that the laying of gas pipelines in these cases is prohibited. 4. When laying polyethylene gas pipelines along pipelines, warehouses, tanks, etc., containing substances (environments) aggressive to polyethylene, the distance from them is taken to be at least 20 m. 5. The sign “*” indicates that polyethylene gas pipelines should be enclosed in a case extending 10 m on both sides of the intersection. |

|||||

The distance from the gas pipeline to the supports of the overhead communication line, the contact network of trams, trolleybuses and electrified railways should be taken as to the supports of the overhead power line of the corresponding voltage.

The minimum distances from gas pipelines to the heating network of channelless installation with longitudinal drainage should be taken similarly to the channel installation of heating networks.

The minimum clear distances from the gas pipeline to the nearest pipe of a ductless heating network without drainage should be taken as to the water supply.

The distance from anchor supports that extend beyond the dimensions of the heating network pipes should be taken taking into account their safety.

The minimum horizontal distance from the gas pipeline to the pressure sewer can be taken as to the water supply.

The minimum distance from railway and highway bridges of no more than 20 m in length should be taken as from the corresponding roads.

APPENDIX D

SMOKE AND VENTILATION CHANNELS

D.1 This appendix provides recommended provisions for the design of smoke and ventilation ducts for gas-using equipment, household heating and heating and cooking stoves.

When designing smoke ducts from gas-using installations in industrial buildings and boiler houses, one should be guided by the requirements.

When converting existing boilers, industrial furnaces and other installations from solid and liquid fuel to gas fuel, a verification calculation of the gas-air path must be performed.

D.2 The installation of smoke and ventilation ducts must comply with the requirements of SNiP 2.04.05.

D.3 Smoke ducts from gas-using equipment installed in the premises of public catering establishments, trade, consumer services, offices built into a residential building are prohibited from being combined with smoke ducts of a residential building.

Ventilation of the above premises must also be autonomous.

D.4 The removal of combustion products from gas-using equipment installed in office premises located within the dimensions of one apartment, as well as the ventilation of these premises should be provided for as for residential buildings.

D.5 The removal of combustion products from household stoves and gas-using equipment, the design of which provides for the removal of combustion products into a smoke channel (chimney) (hereinafter referred to as the channel), is provided from each stove or equipment through a separate channel into the atmosphere.

In existing buildings, it is allowed to provide for the connection to one duct of no more than two furnaces, appliances, boilers, apparatus, etc., located on the same or different floors of the building, provided that combustion products are introduced into the duct at different levels (no closer than 0.75 m one from the other) or at the same level with the device in the cutting channel to a height of at least 0.75 m.

In residential buildings, it is allowed to provide for the connection to one vertical smoke duct of more than one gas-using heating equipment with a sealed combustion chamber and a built-in device for forced removal of flue gases. This equipment is located on different floors of the building. The amount of equipment connected to one channel is determined by calculation.

D.6 Channels from gas equipment should be placed in the internal walls of the building or attached channels should be provided to these walls.

In existing buildings, it is allowed to use existing smoke ducts made of non-combustible materials in the external walls or provide extension ducts to them.

D.7 It is allowed to connect gas-using equipment of periodic operation (instantaneous water heater, etc.) to the channel of a heating furnace with periodic combustion, provided that they operate at different times and the channel cross-section is sufficient to remove combustion products from the connected equipment.

Connecting the connecting pipe of gas-using equipment to the chimney revolutions of a heating stove is not allowed.

D.8 The cross-sectional area of the channel should not be less than the cross-sectional area of the pipe of the connected gas-using equipment or furnace. When connecting two devices, apparatus, boilers, furnaces, etc. to the channel. its cross section should be determined taking into account their simultaneous operation. The structural dimensions of the channels are determined by calculation.

D.9 Removal of combustion products from restaurant stoves, food boilers, etc. It is allowed to be provided both in a separate channel from each equipment, and in a common channel. The removal of combustion products from gas-using equipment installed in close proximity to each other can be carried out under one umbrella and then into a collection channel.

It is allowed to provide connecting pipes common to several devices (equipment).

The cross-sections of channels and connecting pipes must be determined by calculation based on the condition of simultaneous operation of all equipment connected to the channel and connecting pipes.

D.10 Smoke ducts should be made of ordinary ceramic bricks, clay bricks, heat-resistant concrete, as well as steel and asbestos-cement pipes for one-story buildings. The outer part of brick channels should be made of brick, the degree of frost resistance of which meets the requirements.

Smoke ducts can also be factory-made and supplied complete with gas equipment.

When asbestos-cement and steel pipes are installed outside a building or when passing through the attic of a building, they must be insulated to prevent condensation. The design of smoke channels in external walls and channels attached to these walls must also ensure that the temperature of the gases leaving them is above the dew point.

It is not allowed to make channels from slag concrete and other loose or porous materials.

D.11 Channels must be vertical, without ledges. A slope of channels from the vertical is allowed up to 30° with a side deviation of up to 1 m, provided that the cross-sectional area of the inclined sections of the channel is not less than the cross-section of the vertical sections.

To remove combustion products from restaurant stoves, cooking boilers and similar gas appliances, it is allowed to provide horizontal sections of channels placed in the floor with a total length of no more than 10 m, provided that fire-proof cutting is installed for combustible and non-combustible floor and ceiling structures. The channels must be accessible for cleaning.

D.12 The connection of gas-using equipment to the ducts should be provided by connecting pipes made of roofing or galvanized steel with a thickness of at least 1.0 mm, flexible metal corrugated pipes or standardized elements supplied with the equipment.

The total length of horizontal sections of the connecting pipe in new buildings should be no more than 3 m, in existing buildings - no more than 6 m.

The slope of the connecting pipe should be at least 0.01 towards the gas equipment.

On connecting pipes it is allowed to provide no more than three turns with a radius of curvature not less than the diameter of the pipe.

Below the point where the connecting pipe is connected to the channels, a “pocket” device with a cleaning hatch must be provided, to which free access must be provided.

Connecting pipes laid through unheated rooms must, if necessary, be thermally insulated.

D.13 It is not allowed to lay connecting pipes from gas-using equipment through living rooms.

D.14 The distance from the connecting pipe to the ceiling or wall made of non-combustible materials should be at least 5 cm, and from combustible and non-combustible materials - at least 25 cm. The distance can be reduced from 25 to 10 cm, provided that combustible and non-combustible structures are protected with roofing steel on an asbestos sheet with a thickness of at least 3 mm. Thermal insulation should extend beyond the dimensions of the connecting pipe by 15 cm on each side.

D.15 When connecting one gas-using device (equipment) to the channel, as well as equipment with draft stabilizers, gates are not provided on the connecting pipes.

When connecting gas-using equipment that does not have draft stabilizers to the prefabricated chimney, dampers with a hole with a diameter of at least 15 mm must be provided on the connecting pipes from the equipment.

D.16 When installing a periodic gas burner device in a heating furnace, a gate must be provided in the furnace design. The installation of dampers in a furnace with continuous combustion is prohibited. When switching to gas fuel, a heating and cooking stove must have three dampers (one for summer operation, another for winter operation, and a third for ventilation).

D.17 Smoke ducts from gas-using equipment in buildings must be removed (Figure):

At least 0.5 m above the ridge or parapet of the roof when they are located (counting horizontally) no further than 1.5 m from the ridge or parapet of the roof;

Level with the roof ridge or parapet, if they are located at a distance of up to 3 m from the roof ridge or parapet;

Not lower than a straight line drawn from the ridge or parapet downwards at an angle of 10° to the horizontal, when the pipes are located at a distance of more than 3 m from the ridge or parapet of the roof;

At least 0.5 m above the boundary of the wind support zone if there are higher parts of the building, structures or trees near the canal.

In all cases, the height of the pipe above the adjacent part of the roof must be at least 0.5 m, and for houses with a combined roof (flat) - at least 2.0 m.

The mouths of brick channels to a height of 0.2 m should be protected from precipitation with a layer of cement mortar or a cap made of roofing or galvanized steel.

Drawing G. 1 - Scheme of smoke ducts exiting to the roof of the building

It is allowed to provide windproof devices on the channels.

D.18 Smoke ducts in walls may be installed together with ventilation ducts. At the same time, they must be separated along the entire height by sealed partitions made of wall material with a thickness of at least 120 mm. The height of the exhaust ventilation ducts located next to the smoke ducts should be taken equal to the height of the smoke ducts.

D.19 Discharge of combustion products into ventilation ducts and installation of ventilation grilles on smoke ducts are not allowed.

D.20 It is permitted to discharge combustion products into the atmosphere through the outer wall of the gasified room without installing a vertical channel from gas-fired heating equipment with a sealed combustion chamber and a device for forced removal of combustion products.

D.21 Openings of smoke ducts on the facade of a residential building when venting combustion products from heating gas-using equipment through an external wall without installing a vertical duct should be placed in accordance with the installation instructions for gas-using equipment of the manufacturer, but at a distance of no less than:

2.0 m from ground level;

0.5 m horizontally to windows, doors and open ventilation openings (grills);

0.5 m above the top edge of windows, doors and ventilation grilles;

1.0 m vertically to windows when placing holes underneath them.

The specified distances do not apply to window openings filled with glass blocks.

It is not allowed to place duct openings on the façade of buildings under the ventilation grille.

The smallest distance between two channel openings on the facade of the building should be at least 1.0 m horizontally and 2.0 m vertically.

When placing a smoke channel under a canopy, balconies and roof eaves of buildings, the channel must extend beyond the circle described by the radiusR(drawing ).

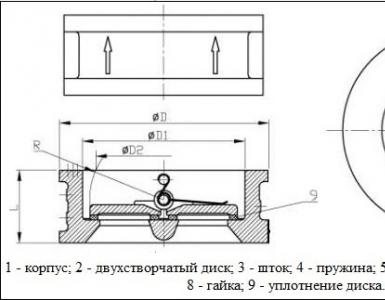

Drawing G.2 - Layout of a smoke channel under a canopy or balcony

D.22 The length of the horizontal section of the smoke duct from heating gas-using equipment with a sealed combustion chamber when exiting through the outer wall should be no more than 3 m.

D.23 Gas-using equipment with a thermal power of up to 10 kW with exhaust of combustion products into the gasified room is placed in such a way as to ensure free exit of combustion products through exhaust ventilation devices (duct, axial fan) of this room.

D.24 In residential buildings, ventilation ducts from rooms in which gas-based heating equipment for apartment heating is installed are not allowed to be combined with ventilation ducts from other rooms (bathrooms, storerooms, garages, etc.).

D.25 Existing smoke ducts that are not connected to other existing smoke ducts can be used as ventilation ducts.

Grilles with devices for regulating air flow, excluding the possibility of their complete closure, are provided on the exhaust ventilation ducts of gasified premises.

Currently, it is difficult to imagine the life of large and small cities, as well as industrial enterprises, without an established pipeline system. They supply liquids and gases, allow people to heat their homes, and allow businesses to operate successfully. However, while benefiting from the existence of gas pipelines, one must remember that gas communications are quite dangerous, and damage to them can lead to a serious accident.

From the history of gas pipelines

The first gas pipelines were used in Ancient China. Bamboo was used as pipes, but there were no pipes and gas was supplied by gravity. The connections of bamboo pipes were packed with tow; such structures allowed the Chinese to heat and light their homes and evaporate salt.

The first European gas pipelines appeared in the second half of the 19th century. At that time, gas was used to create street lighting. The first street lamps were oil lamps, and in 1799 the Frenchman Lebon proposed thermal lamps that could illuminate and heat rooms. The idea was not supported by the government, and he equipped his house with thousands, which remained a Parisian landmark until the engineer’s death. It was only in 1813 that Le Bon's students managed to begin illuminating cities in this way, but this was already in England. It arrived in Paris six years later, in 1819. Artificial coal gas was used as fuel.

St. Petersburg began heating its premises by transmitting gas through a gas pipeline in 1835, and Moscow began in 1865.

Types of gas pipelines depending on the gas pressure inside them and the method of installation

A gas pipeline is a structure made of pipes, supports and auxiliary equipment designed to deliver gas to the required location. Gas movement is always carried out under pressure, on which the characteristics of each section depend.

Gas pipelines can be main or distribution. The former transport gas over long distances from one gas distribution station to another. The latter are designed to deliver gas from the distribution station to the place of consumption or storage. The pipeline may include one or several lines connected to each other by a single technological chain.

Main gas pipelines come in two categories depending on the gas pressure in them.

- The first category of main gas pipelines operates under pressure up to 10 MPa.

- The second category of main gas pipelines is designed to work with gas whose pressure is up to 2.5 MPa.

Gas distribution pipelines are divided into three groups depending on the gas pressure in them.

- Low pressure. Gas is transferred into them at 0.005 MPa.

- Medium pressure. Gas is transferred in such pipelines under pressure from 0.005 to 0.3 MPa.

- High pressure. They operate under pressure from 0.3 to 0.6 MPa.

Another classification makes it possible to divide all gas pipelines depending on the method of their installation into underground, underwater and above-ground.

What is a gas pipeline security zone and why is it needed?

This is a piece of land that is symmetrical relative to the axis of the gas pipeline, the width of which depends on the type of gas pipeline and is established by special documents. The establishment of security zones for gas pipelines makes it possible to prohibit or limit construction in the area where the gas pipeline passes. The purpose of its creation is to create normal conditions for the operation of the gas pipeline, its regular maintenance, maintaining integrity, as well as minimizing the consequences of possible accidents.

There are “Rules for the Protection of Trunk Pipelines” that regulate the establishment of security zones for various pipelines, which include gas pipelines transporting natural or other gases.

Agricultural work is permitted within the protected zone, but construction is prohibited. Work on the reconstruction of existing networks must be coordinated with the organization that maintains and operates the gas pipeline. The work that is prohibited to be carried out in the security zone also includes the arrangement of basements, welding work, installation of fences that prevent free access to pipes, the creation of landfills and storage facilities, the installation of stairs resting on the gas pipeline, as well as the installation of unauthorized connections.

Features of the security zone of high pressure gas pipelines

The security zone of a gas pipeline of the 1st and 2nd categories is arranged in the same way. Their function is to supply gas to low and medium pressure distribution networks.

- High-pressure gas pipelines of the 1st category operate with gas under pressure from 0.6 MPa to 1.2 MPa if they transport natural gas or gas-air mixtures. For hydrocarbon gases transported in liquefied form, this pressure should not exceed 1.6 MPa. Their security zone is 10 m on both sides of the gas pipeline axis in the case of gas distribution pipelines and 50 meters for high-pressure gas pipelines through which natural gas is transported. If liquefied gas is being transported, the security zone is 100 m.

- High-pressure gas pipelines of the 2nd category transport natural gas, gas-air mixtures and liquefied gas under pressure from 0.3 to 0.6 MPa. Their security zone is 7 m, and in the case of a main gas pipeline - 50 m for natural gas and 100 m for liquefied gas.

Organization of a security zone for a high-pressure gas pipeline

The security zone of a high-pressure gas pipeline is organized by the organization operating it on the basis of the project, clarifying surveys carried out after completion of construction and issued permits. To maintain it, the following activities are carried out.

- Every six months, the organization operating high-pressure gas pipelines is obliged to remind individuals and organizations that operate land in protected zones about the peculiarities of land use of these areas.

- Every year the route must be clarified and, if necessary, all documentation issued on it must be adjusted. The security zone of the high-pressure gas pipeline is specified accordingly.

- The security zone of a high-pressure gas pipeline is marked on its linear sections using posts located at a distance of no more than 1000 m (Ukraine) and no more than 500 m (Russia), all angles of rotation of the pipe must also be marked with a post.

- The intersections of the gas pipeline with transport highways and other communications must be marked with special signs notifying that there is an exclusion zone for the high-pressure gas pipeline. Stopping vehicles within the designated security zone is prohibited.

- Each column is equipped with two posters with information about the depth of the route, as well as its direction. The first plate is installed vertically, and the other with mileage marks is installed at an angle of 30 degrees to allow visual inspection from the air.

Features of the security zone of medium pressure gas pipelines

The security zone of a medium-pressure gas pipeline, according to regulatory documents, is 4 meters. As with high-pressure routes, it is established on the basis of technical documentation provided by design organizations. The basis for creating a security zone and putting it on the master plan is an act issued by local government or executive authorities.

The security zone of a medium-pressure gas pipeline assumes the presence of restrictions similar to those indicated for high-pressure routes. To carry out any excavation work in the security zone, it is necessary to obtain permission from the organization servicing this section of the gas pipeline.

Marking of security zones for medium pressure is carried out similarly. The posts should contain signs with information about the name of the gas pipeline, the location of the route, the distance from the sign to the axis of the pipeline, the dimensions of the security zone, and telephone numbers for contacting the organization servicing this section of the gas pipeline. Shields are allowed to be placed on communication networks and control and measuring columns.

Features of the security zone of low pressure gas pipelines

The main function of low-pressure gas pipelines is to provide gas supply to residential buildings and structures, which can be either built-in or free-standing. Transporting large amounts of gas using them is unprofitable, so large utility consumers do not use such networks.

The security zone of a low-pressure gas pipeline is 2 m on both sides of the pipe laying axis. Such gas pipelines are the least dangerous, so the security zone around them is minimal. Restrictions on its operation are similar to those introduced for security zones of other types of gas pipelines.

The security zone of the low-pressure gas pipeline is marked similarly to the previous two. If the signs located on the bindings are yellow, then the laid pipeline is made of polyethylene. If it is green, then the pipe material is steel. The plate does not have the red border on top that is typical for high-pressure pipelines.

Security zone of external gas pipeline

An external gas pipeline is a gas pipeline located outside buildings to a diaphragm or other shut-off device, or to a casing that is used to enter the building in the underground version. It can be located underground, above ground or above ground.

For external gas pipelines, the following rules exist for determining security zones:

- The security zone of the external gas pipeline along the routes is 2 m on each side of the axis.

- If the gas pipeline is underground and made of polyethylene pipes, and a copper wire is used to mark the route, then the security zone of the underground gas pipeline in this case is 3 m on the side where the wire is located, and 2 m on the other side.

- If a gas pipeline is constructed for this purpose, regardless of the pipe material, its security zone is 10 m on both sides of the pipe axis.

- If the gas pipeline is inter-settlement and crosses a wooded area or areas overgrown with bushes, its security zone is 3 meters on both sides of the axis. They are arranged in the form of clearings, the width of which is 6 meters.

- The security zone of gas pipelines located among tall trees is equal to their maximum height, so that the fall of a tree cannot damage the integrity of the gas pipeline.

- The security zone of an external gas pipeline passing under water through rivers, reservoirs or lakes is 100 m. It can be represented visually as the distance between two parallel planes passing through conventional boundary lines.

How to establish a security zone for a specific gas pipeline

The gas pipeline security zone is one of the territories with a special land use regime. At the same time, there is a sanitary protection zone for these objects, the rules for the arrangement of which are established by SanPiN 2.2.1/2.1.1.1200-03.

According to Appendix 1 to these rules, the sanitary zone of a high-pressure gas pipeline depends on the pressure in the pipe, its diameter, as well as the type of buildings and structures in relation to which the distance is calculated.

The minimum distance from rivers and other reservoirs, as well as water intakes and irrigation structures is 25 m for main gas pipelines of any diameter and type.

The largest protective zone of a high-pressure gas pipeline is necessary if we are talking about a class 1 gas pipeline with a diameter of 1200 mm in cities, holiday villages and other crowded places. In this case, the length of the sanitary zone reaches 250 m.

More detailed data on sanitary protection zones of natural and liquefied gas main gas pipelines can be found in the corresponding tables of this document. For highways transporting liquefied gas, sanitary zones have been significantly increased.

Violation of the gas pipeline security zone. Legal and environmental implications

Violation of the gas pipeline security zone can cause a serious man-made accident, fire or explosion. They may be caused by unauthorized excavation work in security zones without agreement with the organization servicing the gas pipeline, falling trees, or damage by cars.

In the best case, the insulation will fail, in the worst case, cracks and other defects will appear on the pipe, which over time will cause a gas leak. Such defects may not appear immediately and only cause an emergency over time.

Damage to gas pipelines due to violation of security zones is punishable by a large administrative fine, which depends on the extent of the damage caused. The demolition of buildings and structures built on the territory of protected zones is carried out by decision of the administrative court.

Carrying out unauthorized excavation work, unauthorized planting of trees and shrubs, organizing sports competitions, placing fire sources, constructing buildings, developing sand quarries, as well as fishing, carrying out work to deepen or clean the bottom and setting up a watering hole in places where the underwater section of the gas pipeline passes is punishable by fines from 5 thousand rubles.

Security zones when designing gas pipelines: land acquisition and arrangement

The Rules for the Protection of Gas Distribution Networks will help determine which gas pipeline security zone should be applied in each specific case. Typically this documentation, along with other permissions, is provided by the designers. The question of who will coordinate the project with the services that operate the networks, as well as with local authorities, is determined by the contract for the work. The organization carrying out the project must have a license for these types of work.

The first stage of creating a security zone is to carry out a control survey. Its main purpose is to check the correctness of the bindings and their compliance with the project documentation.

The result of this survey is the updated coordinates of the characteristic points of the finished route, the location, quantity and geometry of elements and parts of the gas pipeline, as well as installed regulatory points, measuring instruments, hydraulic fracturing and gas distribution points, supports and other structures.

Security zones for gas distribution networks are determined by the Rules approved on November 20, 2000 by Government Resolution No. 878.

Security zones of gas mains are regulated by the Rules approved by the Ministry of Fuel and Energy on April 29, 1992 and Gostekhnadzor (No. 9) on April 22, 1992.

The result of these works is a map or plan for a given land management facility, which is subject to agreement with the owners or users of the land plots through which the gas pipeline passes. One copy of the land management file for this site is transferred to the state land registry authorities.

Page 11 of 41

UNDERGROUND GAS PIPELINES

4.9 Minimum horizontal distances from underground gas pipelines to buildings and

SP 42-101-2003

structures are accepted in accordance with the requirements of SNiP 2.07.01, SNiP P-89, given in Appendix B.

The distance from the gas pipeline to the outer walls of wells and chambers of other underground utility networks should be taken at least 0.3 m (clear distance), subject to compliance with the requirements for laying gas pipelines in cramped conditions in areas where the clear distance from the gas pipeline to wells and chambers of other underground utility networks is less than the standard distance for this communication.

4.10 It is allowed to lay two or more gas pipelines, including steel and polyethylene, in one trench at the same or different levels (steps). In these cases, and also when laying the projected gas pipeline along an existing high-pressure gas pipeline (over 0.6 MPa to 1.2 MPa), the distance between gas pipelines should be taken based on the conditions for the possibility of carrying out construction, installation and repair work works for steel gas pipelines with a diameter of up to 300 mm - no less than 0.4 m, with a diameter of more than 300 mm - no less than 0.5 m and no less than 0.1 m for polyethylene gas pipelines. When laying gas pipelines in parallel, the distance between them should be taken as for a gas pipeline with a larger diameter.

If the difference in the depth of the laying of adjacent gas pipelines is more than 0.4 m, the indicated distances should be increased taking into account the steepness of the slopes of the trenches, but no less than the difference in the laying of the gas pipelines should be accepted.

4.11 When laying a gas pipeline for undrained gas, provision should be made for the installation of condensate collectors.

The laying of gas pipelines transporting undrained gas must be provided below the zone of seasonal soil freezing with a slope towards condensate collectors of at least 2%.

Inputs of undrained gas pipelines into buildings and structures must be provided with a slope towards the distribution gas pipeline. If, due to the conditions of the terrain, the required slope to the distribution gas pipeline cannot be created, it is permissible to provide for the laying of a gas pipeline with a bend in the profile with the installation of a condensate collector at the lowest point.

4.12 When laying LPG vapor phase gas pipelines, as a rule, the provisions of Section 8 should be additionally taken into account.

4.13 Gas pipelines laid in cases must have a minimum number of butt joints.

4.14 At the intersection of gas pipelines with drainage pipes, the latter are provided with

seal holes and joints at a distance of 2 m in both directions (in the clear).

4.15 The depth of laying the underground gas pipeline should be taken in accordance with the requirements of SNiP 42-01.

When laying gas pipelines on arable and irrigated lands, the laying depth is recommended to be at least 1.0 m to the top of the gas pipeline.

In landslide and erosion-prone areas, gas pipelines are laid to a depth of at least 0.5 m below:

For landslide areas - sliding mirrors;

For areas susceptible to erosion, the boundaries of the predicted erosion.

4.16. When laying gas pipelines in rocky, gravel-pebble, crushed stone and other soils with inclusions of the above soils (over 15%) along the entire width of the trench, provide for the construction of a base for the gas pipeline with a thickness of at least 10 cm from non-heaving, non-subsidence, non-swelling clayey soils or sands (except for dusty ones) and backfilling with the same soil to a height of at least 20 cm above the upper generatrix of the pipe.

4.17 In soils with a bearing capacity of less than 0.025 MPa (non-compacted bulk or silty soils, etc.), as well as in soils containing construction waste and humus (content more than 10-15%), it is recommended to strengthen the bottom of the trench by laying a ton, antiseptic wooden beams, installation of a pile foundation, compaction of crushed stone or gravel or other methods.

4.18 When laying gas pipelines in terrain with a slope of more than 200%, the project provides for measures to prevent erosion of the trench backfill: installation of anti-erosion screens and lintels both from natural soil (for example, clayey) and from artificial materials (concreting, sheet piling, etc.), upland ditches, embankments or other measures to drain surface water from the gas pipeline route.

The choice of protection method is determined in each specific case based on the engineering-geological, topographic and hydrogeological conditions of the area.

4.19 If there are growing ravines and failures, karsts, etc. near the security zone of the gas pipeline route, which may affect the safe operation of gas pipelines, it is recommended to take measures to prevent their development.

SP 42-101-2003

4.20 To determine the location of the gas pipeline, identification marks are installed at the corners of the route, places where the diameter changes, installation of fittings and structures belonging to the gas pipeline, as well as on straight sections of the route (every 200-500 m).

The identification mark contains data on the diameter, pressure, depth of the gas pipeline, pipe material, distance to the gas pipeline, structure or characteristic point, and other information.

Identification signs are installed on reinforced concrete posts or metal benchmarks with a height of at least 1.5 m or other permanent landmarks.

In places where gas pipelines cross navigable and timber-rafting water barriers, it is planned to install signal signs on both banks in accordance with the requirements of the Inland Water Transport Charter. At the border of the underwater crossing, it is planned to install permanent benchmarks: if the width of the barrier at low-water horizon is up to 75 m - on one bank, with a larger width - on both banks.

| Content |

|---|

Many owners of dachas and private houses often provoke legal proceedings themselves by building houses or any other buildings so that, for example, the neighbor’s “plot” is buried in the shadows. But there is a whole list of rules and regulations that provide for distances, lengths, heights and other parameters during the construction and laying of engineering lines (water pipelines, gas pipelines, etc.)

We will present the most common of them during individual construction - knowing them will help you not make mistakes, so that later you do not have to demolish what you built with your own hands and start construction again.

There are regulations for laying utility networks

Furnace

If the standards are not met, gas services may prohibit connection to the gas pipeline. This is what furnaces and kitchens with gas stoves should be like.

- Ceiling height - at least 2.4 m (2.2 m with a boiler power of less than 60 kW).

- The window (necessarily with a window) must have a glazing area of 0.03 square meters. m per 1 cubic. m of room volume, but not less than 0.8 sq. m.

- The volume of the room for 1 boiler is convenient for maintenance, but not less than 7.5 cubic meters. m. For 2 boilers - at least 15 cubic meters. meters

- For installations with a power of more than 60 kW - a gas alarm.

- When installing boilers in the basement, in free-standing furnace floors - a gas alarm.

- Size - according to the boiler passport.

The kitchen has its own rules. If the stove is gas, the following requirements are met:

- the distance from the gas meter to the electric meter is at least 0.5 m;

- the distance from the gas meter to gas appliances is at least 1 m;

- when installing 4-burner stoves, the volume of the room is at least 15 cubic meters. m;

- when installing 2-burner stoves, the volume of the room is at least 8 cubic meters. m;

- ventilation in the kitchen - duct D 200 mm;

- ceiling height – at least 2.2 m.

Standards for underground gas pipeline:

- the distance of the underground gas pipeline to other communications with parallel installation is 1 meter;

- underground distance d. (low pressure) gas pipeline to buildings (sheds, gazebos) - at least 2 meters;

- underground distance d. gas pipeline to wells - at least 1 meter;

- underground distance d. gas pipeline to power lines - at least 1 m;

- underground distance gas pipeline to trees - at least 1.5 meters;

- the distance from the burner to the opposite wall is at least 1 m;

- safe distances from the gas tank to objects on the site.

The system should be located at a distance (in particularly cramped conditions, distances can be halved):

- from a residential building -10 meters;

- from the fence on the foundation and the garage -2 meters;

- from the septic tank - 5 meters;

- from the well -15 meters;

- from a tree with a developed crown -5 meters;

- from the power line - one and a half heights of the support.

Distances between houses and buildings - standards and regulations

The distances between houses are determined by the rules, but can be reduced if lighting standards are observed and if the rooms are not visible from window to window:

- between the long sides of residential buildings with a height of 2-3 floors - at least 15 meters, and a height of 4 floors - at least 20 meters;

- between the long sides and ends of the same buildings with windows from living rooms - at least 10 meters;

- in estate development areas, the distance from the windows of residential premises (rooms, kitchens and verandas) to the walls of the house and outbuildings (barn, garage, bathhouse) located on neighboring plots of land must be at least 6 meters;

- outbuildings are located from the boundaries of the site at a distance of 1 meter.

It is allowed to block outbuildings in adjacent areas by mutual consent of the homeowners.

At what distance from each other should utility networks be located? This table reflects internecine relations.

Network engineering | Distance, m, horizontally to: |

||||

water supply | domestic sewerage | drainage and rainwater drainage | pressure gas pipelines. MPa (kgf/cm 2) |

||

low to 0.005 (0.05) | middle St. 0.005 (0.05) to 0.3(3) |

||||

Water pipes | 1.5 | ||||

Domestic sewerage | 0.4 | 0,4 | 1.5 |

||

Storm drain | 1.5 | 0,4 | 0.4 | 1.5 |

|

Gas pipelines pressure, MPa (kgf/cm2): | |||||

low | 0,5 | 0,5 |

|||

average | 1.5 | 1.5 | 0,5 | 0,5 |

|

high: |

|||||

St. 0.3 (3) TO 0.6 (6) | 1,5 | 0,5 | 0,5 |

||

St. 0.6 (6) TO 1.2 (12) | 0,5 | 0,5 |

|||

Power cables | 0,5 | 0.5 | 0,5 | ||

Communication cables | 0.5 | 0,5 | 0,5 | ||

Heating network: |

|||||

from the shell ductless gaskets | 1.5 | ||||

Lawyer's opinion (K. Andreev)

The most common subject of controversy is unauthorized buildings(if there is a construction permit, then it must take into account the standards - SNiP).

The second type of violation is construction on a site that does not belong to the “builder” (this is called squatting). An example would be a fence being moved. According to paragraph 17 of Article 51 of the Town Planning Code of the Russian Federation, some objects do not require a building permit: gazebos, sheds.

A permit is required, so it is important what you are actually building: if according to the technical passport you have a garage, but in fact a residential building, the construction can be challenged in court.

The third subject of controversy is building that does not meet standards. For example, if a site is intended for gardening, construction standards SNiPZO-02-97 (“Planning and development of territories of gardening associations of citizens. Buildings and structures”) are applied to it. According to paragraph 1.1 of this SNiP, norms and rules apply to the design and construction of houses. You cannot build an 8-story house in a gardening partnership (and such cases do happen) - neighbors have the right to sue, and such a building will be demolished.

If the site is intended for individual housing construction, other standards apply - a set of rules for urban planning, planning and development of urban and rural settlements (version SNiP 2.07.01-89, approved on December 28, 2010). In disputes about non-standard buildings, it is necessary to establish what kind of building is in front of us. An expert arrives, inspects the property and makes a verdict: “This is a garage” or “This is a low-rise building.” It is then decided what regulations the disputed structure falls under, and then the defendants are forced to prove that it complies with the regulations. For fences there is a separate SNiP 30-02-97, clause 6.2. It states that areas should be fenced, taking into account minimal shading of neighboring ones - fences should be lattice, up to one and a half meters high. By decision of the general meeting of gardeners, the installation of blind fences on the side of the street and driveway is allowed.

Claims that are filed for violation of rights are called negatory. The reason for filing them is an obstacle to the use of your land, which is caused by a neighbor (he has illegally invaded your territory and is obscuring it). The owner may demand that all violations be corrected. The statute of limitations in this matter is 3 years from the moment the victim learned of the violation of his rights. This means that it doesn't matter at all when a neighbor moves a fence or builds a house right under your nose. It's important when you found out about it.

5.1.1 The placement of external gas pipelines in relation to buildings, structures and parallel adjacent utility networks should be carried out in accordance with the requirements of SNiP 2.07.01, and on the territory of industrial enterprises - SNiP II-89.

When laying underground gas pipelines with a pressure of up to 0.6 MPa in cramped conditions (when the distances regulated by regulatory documents are not possible), in certain sections of the route, between buildings and buildings, as well as gas pipelines with a pressure of over 0.6 MPa when they are brought closer together with detached ancillary buildings (buildings without permanent presence of people), it is allowed to reduce the distances specified in SNiP 2.07.01 and SNiP II-89 by up to 50%. In this case, in areas of approach and at a distance of at least 5 m in each direction from these areas, the following should be used:

seamless or electric-welded steel pipes laid in a protective case, with 100% physical control of factory welded joints;

polyethylene pipes laid in a protective case, without welded joints or connected by parts with embedded heaters (ZH), or connected by butt welding with 100% control of the joints by physical methods.

When laying gas pipelines at distances corresponding to SNiP 2.07.01, but less than 50 m from public railways in the convergence area and 5 m in each direction, the laying depth must be at least 2.0 m. Butt welded joints must pass 100% - nal control by physical methods.

In this case, the wall thickness of steel pipes must be 2–3 mm greater than the calculated one, and polyethylene pipes must have a safety factor of at least 2.8.

5.1.2 The laying of gas pipelines should be provided underground and above ground.

In justified cases, it is allowed to lay gas pipelines above ground along the walls of buildings inside residential courtyards and neighborhoods, as well as in certain sections of the route, including sections of transitions through artificial and natural barriers when crossing underground communications.

Above-ground and above-ground gas pipelines with embankment can be laid in rocky, permafrost soils, wetlands and other difficult soil conditions. The material and dimensions of the embankment should be taken based on thermal engineering calculations, as well as ensuring the stability of the gas pipeline and embankment.

5.1.3 Laying gas pipelines in tunnels, collectors and canals is not permitted. An exception is the laying of steel gas pipelines with a pressure of up to 0.6 MPa in accordance with the requirements of SNiP II-89 on the territory of industrial enterprises, as well as in channels in permafrost soils under roads and railways.

5.1.4 Pipe connections should be permanent. Connections of steel pipes with polyethylene and

in places where fittings, equipment and control and measuring instruments (instruments) are installed. Detachable connections of polyethylene pipes with steel pipes in the ground can only be provided if a case with a control tube is installed.

5.1.5 Gas pipelines at the points of entry and exit from the ground, as well as gas pipeline entries into buildings should be enclosed in a case. The space between the wall and the case should be sealed to the full thickness of the structure being crossed. The ends of the case should be sealed with elastic material.

5.1.6 Gas pipeline entries into buildings should be provided directly into the room where gas-using equipment is installed, or into an adjacent room connected by an open opening.

It is not allowed to enter gas pipelines into the premises of the basement and ground floors of buildings, except for the introduction of natural gas pipelines into single-family and semi-detached houses.

5.1.7 Shut-off devices on gas pipelines should be provided:

in front of detached or blocked buildings;

to disconnect risers of residential buildings above five floors;

in front of outdoor gas-using equipment;

in front of gas control points, with the exception of gas distribution points of enterprises, on the gas pipeline branch to which there is a shut-off device at a distance of less than 100 m from the gas distribution point;

at the exit from gas control points connected by gas pipelines;

on branches from gas pipelines to settlements, individual microdistricts, blocks, groups of residential buildings, and when the number of apartments is more than 400, to a separate house, as well as on branches to industrial consumers and boiler houses;

when crossing water barriers with two lines or more, as well as with one line when the width of the water barrier at a low-water horizon is 75 m or more;

at the intersection of railways of the general network and highways of categories I–II, if the shut-off device that ensures the cessation of gas supply at the crossing section is located at a distance from the roads of more than 1000 m.

5.1.8 Shutting off devices on above-ground gas pipelines laid along the walls of buildings and on supports should be placed at a distance (within a radius) from door and opening window openings of at least:

for low pressure gas pipelines – 0.5 m;

for medium pressure gas pipelines – 1 m;

for high-pressure gas pipelines of category II – 3 m;

for high-pressure gas pipelines of category I – 5 m.

In areas of transit laying of gas pipelines along the walls of buildings, the installation of disconnecting devices is not allowed.

5.2.1 Gas pipelines should be laid at a depth of at least 0.8 m to the top of the gas pipeline or casing. In places where traffic and agricultural machinery are not expected, the depth of laying steel gas pipelines can be at least 0.6 m.

5.2.2 The vertical (clear) distance between the gas pipeline (case) and underground utilities and structures at their intersections should be taken taking into account the requirements of the relevant regulatory documents, but not less than 0.2 m.

5.2.3 At places where gas pipelines intersect with underground communication manifolds and channels for various purposes, as well as at places where gas pipelines pass through the walls of gas wells, the gas pipeline should be laid in a case.

The ends of the casing must be brought out at a distance of at least 2 m on both sides from the outer walls of the crossed structures and communications, when crossing the walls of gas wells - at a distance of at least 2 cm. The ends of the casing must be sealed with waterproofing material.

At one end of the case at the top point of the slope (with the exception of places where the walls of the wells intersect), a control tube should be provided that extends under the protective device.

In the interpipe space of the casing and the gas pipeline, it is permitted to lay an operational cable (communications, telemechanics and electrical protection) with a voltage of up to 60 V, intended for servicing gas distribution systems.

5.2.4 Polyethylene pipes used for the construction of gas pipelines must have a safety factor in accordance with GOST R 50838 of at least 2.5.

It is not allowed to lay gas pipelines from polyethylene pipes:

on the territory of settlements at pressure above 0.3 MPa;

outside the territory of settlements at pressure above 0.6 MPa;

for transporting gases containing aromatic and chlorinated hydrocarbons, as well as the liquid phase of LPG;

when the temperature of the gas pipeline wall under operating conditions is below minus 15 °C.

When using pipes with a safety factor of at least 2.8, it is permitted to lay polyethylene gas pipelines with pressures exceeding 0.3 to 0.6 MPa in settlements with predominantly one- or two-story and cottage residential buildings. In the territory of small rural settlements, it is permitted to lay polyethylene gas pipelines with a pressure of up to 0.6 MPa with a safety factor of at least 2.5. In this case, the laying depth must be at least 0.8 m to the top of the pipe.

5.3.1 Depending on the pressure, overhead gas pipelines should be laid on supports made of non-combustible materials or along the structures of buildings and structures in accordance with Table 3

Table 3

Placement of above-ground gas pipelines | Gas pressure in the gas pipeline, MPa, no more |

1. On free-standing supports, columns, overpasses and shelving | 1.2 (for natural gas); 1.6 (for LPG) |

2. Boiler houses, industrial buildings with premises of categories B, G and D and GNS (GNP) buildings, public and domestic buildings for industrial purposes, as well as built-in and attached roof boiler houses to them: |

|

a) on the walls and roofs of buildings of I and II degrees of fire resistance, fire hazard class SO (according to SNiP 21-01) | |

II degree of fire resistance class C1 and III degree of fire resistance class CO | |

b) on the walls of buildings of Ill degree of fire resistance class C1, IV degree of fire resistance class CO | |

IV degree of fire resistance classes C1 and C2 | |

3. Residential, administrative, public and service buildings, as well as built-in, attached and roof boiler rooms |

|

on the walls of buildings of all degrees of fire resistance | |

in cases of placement of SHRP on the external walls of buildings (only for SHRP) | |

* The gas pressure in the gas pipeline laid on building structures should not exceed the values indicated in table 2 for the corresponding consumers. |

5.3.2 Transit laying of gas pipelines of all pressures along the walls and above the roofs of buildings of children's institutions, hospitals, schools, sanatoriums, public, administrative and domestic buildings with large numbers of people is not allowed.

It is prohibited to lay gas pipelines of all pressures along the walls, above and below rooms of categories A and B, determined by fire safety standards, with the exception of GRP buildings.

In justified cases, transit laying of gas pipelines not exceeding average pressure with a diameter of up to 100 mm is permitted along the walls of one residential building not lower than the III degree of fire resistance class CO and at a distance to the roof of at least 0.2 m.

5.3.3 High-pressure gas pipelines should be laid along blank walls and sections of walls or at least 0.5 m above the window and door openings of the upper floors of industrial buildings and adjacent administrative and domestic buildings. The distance from the gas pipeline to the roof of the building must be at least 0.2 m.

Low and medium pressure gas pipelines can also be laid along the frames or mullions of non-opening windows and cross window openings of industrial buildings and boiler rooms filled with glass blocks.

5.3.4 The height of laying overhead gas pipelines should be taken in accordance with the requirements of SNiP 11-89.

5.3.5 On pedestrian and automobile bridges built from non-combustible materials, it is permitted to lay gas pipelines with a pressure of up to 0.6 MPa from seamless or electric-welded pipes that have undergone 100% control of factory welded joints by physical methods. Laying gas pipelines over pedestrian and automobile bridges built from flammable materials is not permitted.

5.4.1 Underwater and overwater gas pipelines where they cross water barriers should be placed at a horizontal distance from bridges in accordance with Table 4.

5.4.2 Gas pipelines at underwater crossings should be laid deep into the bottom of the water barriers being crossed. If necessary, based on the results of floating calculations, it is necessary to ballast the pipeline. The elevation of the top of the gas pipeline (ballast, lining) must be at least 0.5 m, and at crossings through navigable and floating rivers - 1.0 m below the predicted bottom profile for a period of 25 years. When carrying out work using directional drilling - at least 2.0 m below the predicted bottom profile.

5.4.3 At underwater crossings the following should be used:

steel pipes with a wall thickness 2 mm greater than the calculated one, but not less than 5 mm;

polyethylene pipes having a standard dimensional ratio of the outer diameter of the pipe to the wall thickness (SDR) of no more than 11 (according to GOST R 50838) with a safety factor of at least 2.5 for transitions up to 25 m wide (at the level of maximum water rise) and not less 2.8 in other cases.

When laying a gas pipeline with a pressure of up to 0.6 MPa using directional drilling, polyethylene pipes with a safety factor of at least 2.5 can be used in all cases.

5.4.4 The height of laying the surface passage of the gas pipeline from the calculated level of water rise or ice drift according to SNiP 2.01.14 (high water horizon - GVV or ice drift - GVL) to the bottom of the pipe or span should be taken:

when crossing ravines and gullies - not lower

Table 4

Water obstacles | Bridge type | The horizontal distance between the gas pipeline and the bridge, not less than m, when laying the gas pipeline |

|||||

above the bridge | below the bridge |

||||||

from an overwater gas pipeline with a diameter, mm | from an underwater gas pipeline with a diameter, mm | from the overwater gas pipeline | from an underwater gas pipeline |

||||

300 or less | 300 or less | all diameters |

|||||

Shipping freezing | All types | ||||||

Shipping anti-freeze | |||||||

Non-navigable freezing | Multi-span | ||||||

Non-navigable anti-freeze | |||||||

Non-navigable for gas pipelines pressure: low medium and high | Single and double span | ||||||

Note – Distances are from overhanging bridge structures. |

0.5 m above GVV 5% probability;

when crossing non-navigable and non-floating rivers - at least 0.2 m above the water supply line and water line of 2% probability, and if there is a crutch boat on the rivers - taking it into account, but not less than 1 m above the water supply line of 1% probability;

when crossing navigable and raftable rivers - no less than the values established by design standards for bridge crossings on navigable rivers.

Shut-off valves should be placed at a distance of at least 10 m from the transition boundaries. The transition boundary is considered to be the place where the gas pipeline crosses the high water horizon with a 10% probability.

5.5.1 The horizontal distances from the places where underground gas pipelines intersect tramways, railways and highways must be no less than:

to bridges and tunnels on public railways, tram tracks, roads of categories I–III, as well as to pedestrian bridges and tunnels through them – 30 m, and for non-public railways, motor roads of categories IV–V and pipes – 15 m ;

to the turnout zone (the beginning of the switches, the tail of the crosses, the points where suction cables are connected to the rails and other track intersections) - 4 m for tram tracks and 20 m for railways;

to the contact network supports – 3m.

It is permitted to reduce these distances in agreement with the organizations in charge of the crossed structures.

5.5.2 Underground gas pipelines of all pressures at intersections with railway and tram tracks, highways of categories I–IV, as well as main city streets should be laid in cases. In other cases, the issue of the need to install cases is decided by the design organization.

Cases must meet the conditions of strength and durability. At one end of the case there should be a control tube extending under the protective device.

5.5.3 The ends of the casings when crossing gas pipelines of public railways should be placed at a distance from them not less than those established by SNiP 32-01. When laying inter-settlement gas pipelines in cramped conditions and gas pipelines on the territory of settlements, it is allowed to reduce this distance to 10 m, provided that an exhaust candle with a sampling device is installed at one end of the case, placed at a distance of at least 50 m from the edge of the roadbed (the axis of the outermost rail at zero marks).

In other cases, the ends of the cases should be located at a distance:

at least 2 m from the outermost rail of tram tracks and 750 mm gauge railways, as well as from the edge of the roadway of streets;

at least 3 m from the edge of the road drainage structure (ditch, ditch, reserve) and from the outermost rail of non-public railways, but not less than 2 m from the base of the embankments.

5.5.4 When gas pipelines cross 1520 mm gauge public railway lines, the gas pipeline laying depth must comply with SNiP 32-01.

In other cases, the depth of laying the gas pipeline from the base of the rail or the top of the road surface, and in the presence of an embankment, from its base to the top of the casing, must meet safety requirements, but be no less than:

when performing open-pit work – 1.0 m;

when carrying out work using the method of punching or directional drilling and shield penetration – 1.5 m;

when performing work using the puncture method - 2.5 m.

5.5.5 The thickness of the walls of steel gas pipeline pipes when crossing public railways should be 2–3 mm greater than the calculated one, but not less than 5 mm at distances of 50 m in each direction from the edge of the roadbed (the axis of the outer rail at zero marks) .

For polyethylene gas pipelines in these sections and at the intersections of highways of categories I–Ill, polyethylene pipes of no more than SDR 11 with a safety factor of at least 2.8 should be used.

5.6.1 Gas supply to cities with a population of more than 1 million people. when the seismicity of the area is more than 6 points, as well as cities with a population of more than 100 thousand people. if the seismicity of the area is more than 7 points, it should be provided from two sources or more - main gas distribution stations with their placement on opposite sides of the city. In this case, high and medium pressure gas pipelines should be designed in a loop with their division into sections by shut-off devices.

5.6.2 Transitions of gas pipelines through rivers, ravines and railway tracks in excavations, laid in areas with seismicity of more than 7 points, must be provided above ground. The structures of the supports must ensure the possibility of movements of gas pipelines that occur during an earthquake.

5.6.3 During the construction of underground gas pipelines in seismic areas, in mined and karst areas, at intersections with other underground utilities, at the corners of turns of gas pipelines with a bend radius of less than 5 diameters, in places where the network branches, transition of underground to above-ground, location of permanent connections “polyethylene-steel”, as well as within settlements, control tubes should be installed every 50 m in linear sections.

5.6.4 The depth of laying gas pipelines in soils of varying degrees of heaving, as well as in bulk soils, should be taken to the top of the pipe - at least 0.9 of the standard freezing depth, but not less than 1.0 m.

With uniform heaving in pounds, the depth of laying the gas pipeline to the top of the pipe should be:

not less than 0.7 standard freezing depth, but not less than 0.9 m for medium heaving soils;

not less than 0.8 standard freezing depth, but not less than 1.0 m for strongly and excessively heaving soils.

5.6.5 For LPG tank installations with underground tanks in heaving (except slightly heaving), medium and highly swelling soils, provision must be made for above-ground laying of liquid and vapor phase gas pipelines connecting the tanks.

5.6.6 If the seismicity of the area is more than 7 points, in undermined and karst areas, in areas of permafrost, pipes with a safety factor of at least 2.8 should be used for polyethylene gas pipelines. Welded butt joints must undergo 100% control by physical methods.

5.7.1 To restore (reconstruct) worn-out underground steel gas pipelines outside and on the territory of urban and rural settlements, the following should be used:

at a pressure of up to 0.3 MPa inclusive, drawing polyethylene pipes in a gas pipeline with a safety factor of at least 2.5 without welded joints or connected using parts with a seal, or connected by butt welding using welding equipment of a high degree of automation;

at a pressure from 0.3 to 0.6 MPa inclusive, stretching polyethylene pipes in a gas pipeline without welded joints or connected using parts with welded joints or butt welding using highly automated welding equipment with a safety factor for gas pipelines in settlements of at least 2, 8, and outside settlements – at least 2.5. The space between the polyethylene pipe and the worn-out steel gas pipeline (frame) along its entire length must be filled with sealing (sealing) material (cement-sand mortar, foam material);

at a pressure of up to 1.2 MPa, lining (using Phoenix technology) the cleaned inner surface of gas pipelines with a synthetic fabric hose using a special two-component glue, subject to confirmation in the prescribed manner of their suitability for these purposes at the specified pressure or in accordance with standards (technical conditions) ; the scope of which extends to this pressure.

5.7.2 Restoration of worn-out steel gas pipelines is carried out without changing the pressure, with an increase or decrease in pressure compared to the existing gas pipeline.

In this case, it is allowed to save:

intersections of restored areas with underground utilities without installing additional casings;

depth of installation of restored gas pipelines;

distances from the restored gas pipeline to buildings, structures and utilities according to its actual location, if the pressure of the restored gas pipeline does not change or when the pressure of the restored gas pipeline increases to 0.3 MPa.

Restoring worn-out steel gas pipelines with increasing pressure to high is permitted if the distances to buildings, structures and utilities meet the requirements for a high-pressure gas pipeline.

5.7.3 The ratio of the sizes of polyethylene and steel pipes during reconstruction by the pulling method should be selected based on the possibility of free passage of polyethylene pipes and parts inside steel ones and ensuring the integrity of polyethylene pipes. The ends of the reconstructed sections between the polyethylene and steel pipes must be sealed.