Heating a private house with a solid fuel wood boiler. Long-burning wood-burning boilers Types of wood-burning boilers

With a limited choice of energy resources, there may be no alternative to heating with wood at all. It is important to purchase a suitable wood-burning boiler and understand the features of its operation. We will tell you about these heating units, from choosing the right type to installation issues.

Main types of wood boilers

The arsenal of heating equipment is constantly replenished with new, more advanced products, but nothing radically new has been invented among solid fuel boilers. In an attempt to increase efficiency, designers improved the design one way or another, which is why several varieties appeared with a number of characteristic features:

1. Complex Z-shaped firebox or its division into 2 combustion chambers. Such boilers are designed for long-term combustion and the most complete combustion of the released pyrolysis gases.

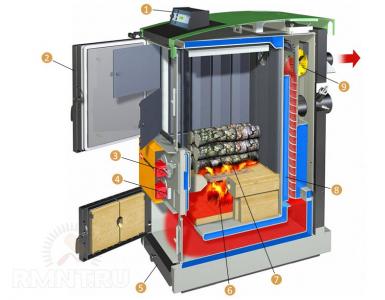

An example of the design of a long-burning solid fuel boiler: 1 - boiler automation; 2 - loading door; 3 — primary air supply; 4 — secondary air supply; 5 - ash pan; 6 - combustion of pyrolysis gases; 7 - pyrolysis of solid fuel; 8 - heat exchanger; 9 — fan-exhaust fan

An example of the design of a long-burning solid fuel boiler: 1 - boiler automation; 2 - loading door; 3 — primary air supply; 4 — secondary air supply; 5 - ash pan; 6 - combustion of pyrolysis gases; 7 - pyrolysis of solid fuel; 8 - heat exchanger; 9 — fan-exhaust fan

2. The presence of water-filled grates and/or jackets. It is believed that in this way the coolant absorbs up to 90% of the combustion heat, but in practice, good wood-burning boilers with an efficiency above 80% are already very rare.

3. Form of organization of blowing. By reducing the incoming oxygen, the combustion duration can be greatly extended, maintaining the water temperature within specified limits. Usually implemented through a manual or controlled damper; if the draft is not strong enough, a boost fan can be used. The damper is usually controlled by digital automation, which controls the temperature of the water in the supply pipe.

4. Type and design of heat exchanger. On the one hand, there is a race to maximize surface area for more efficient heat removal, and on the other, for durability and reliability. In the first case, we have cellular boiler-type heat exchangers, highly efficient, but problematic to clean and repair/replace. On the other hand, simple tubular coils made of cold-drawn seamless pipe are hard to argue with the classics.

5. Availability of insulation. The need for a mineral-filled casing is determined by the installation location. If it makes no sense to waste heat outside, then for a garage or workshop, a non-insulated boiler can be a good heating method.

There are also differences in the type of fuel, horizontal and vertical location of the shaft, as well as the firebox material. Chambers and coils made of cold-rolled low-carbon steel are simple and unpretentious, but are susceptible to scale formation. Coils and water-filled jackets made of cast iron are the most durable and are not subject to scale formation, but require special piping due to their high sensitivity to thermal shock.

Equipment power

Ultimately, what is important for a boiler is not so much the details of its internal structure, but the main performance indicators, which were achieved using a number of engineering innovations. The most important and determining parameter of the boiler is its rated instantaneous power. The heat capacity of different types of fuel is different, as is the case with different types of firewood; the manufacturer cannot accurately predict it and calculate the rated power in a particular operating mode.

Power is determined by two indicators. By the volume of the firebox one can judge the mass of the filling. On average, it is believed that for every kilowatt of power of a wood-burning boiler there is 2.5-3 liters of combustion chamber volume. Having received the instantaneous value of the power released during combustion, it is possible to predict what part of it can be absorbed by the heat exchanger at different operating temperature conditions. Typically, absorption is deliberately made higher than the calculated heat release under combustion conditions close to optimal, but this approach is fraught with troubles.

The fact is that all wood-burning boilers suffer from a common disease - the formation of tar due to the high humidity of the burned wood. Condensation only occurs when the temperature difference is high enough. Thus, the formation of build-up on the economizer or secondary heat exchanger can stop when the coolant is heated to 40-45 ºС. The point here is that if you load the boiler halfway, its power will not be enough to properly heat the walls and heat exchangers, which is why the equipment will simply “leak.”

Chimney device

The main impact of condensation of water vapor from firewood falls on the chimney system. The length of the pipe is large, the temperature difference (especially outside) is very high. There are two approaches to solving this problem.

The first is to install inspection outlets to drain condensed moisture. Such outlets should be located at the lowest point of each rotating segment, starting from the last vertical section and ending with the boiler connection point. The disadvantage is that the water drainage tubes periodically need to be cleaned and cannot be of significant length with a small diameter.

Such problems do not arise with brick chimneys or asbestos-cement pipes in the lining. The difficulties of constructing such chimneys are obvious, but they can also be circumvented by using more expensive materials. We are talking about insulated sandwich pipes made of stainless steel with a mineral filler. For a chimney installation today this is the best option. To summarize: condensation does not form only in insulated chimneys.

System inertia

Another disadvantage of a solid fuel boiler is hidden in the cyclical nature of its operation and the inability to independently replenish fuel reserves. Because of this, either a high heat capacity of the house structure itself is required, or solid insulation, close to a passive house, or a way to store a reserve of heat for the period of cooling of the system.

Since the volume of the heat exchanger itself in the boiler is small, the displacement of the system can be increased mainly by increasing the diameter of the pipes. Another alternative of this kind is the installation of a heat accumulator. With the right approach, it is possible to realize heat accumulation only after heating the main system, which will help speed up the heating of the house and solve the problem with condensation.

Underfloor heating systems have their own high inertia, which increases with the thickness of the accumulating screed. With a thermal cut-off under the floor, this can be a truly long-term heat source. With a sufficiently thick layer, even the use of water at a higher temperature will not cause discomfort and thermal zebra, but along with the inertia of the system, the time it takes to reach the operating mode increases. On the other hand, connecting a heated floor to a wood-burning boiler requires a rather complex piping that prevents overheating of both the boiler and the pipes in the floor.

Automation and piping of wood-burning boilers

As already mentioned, the boiler power can be adjusted only by changing the amount of oxygen supplied. This system works most efficiently and accurately in pyrolysis-type mine boilers using wood or briquettes.

The main automation complex includes an electronic control unit, a fan, an electrically driven draft regulator and a thermocouple tightly wound to the supply pipe. All these components are sold both individually and in sets for a specific boiler model. On average, all automation costs about 4-5 thousand rubles. We should separately mention the importance of having protection against falling dampers and sealing grooves on the loading and inspection hatches, chimney, and draft stabilization system.

For solid fuel boilers, a number of other types of protective devices are provided, installed in the hydraulic piping. Among the absolutely mandatory ones are a circulation pump and protection of the firebox from overheating - a safety group for relieving excess pressure. Please note that the outlet of the relief valve must be turned towards the wall or equipped with a hose so that when activated it does not injure anyone present. Safety requirements may require the installation of a chimney bleeder valve to stabilize draft and combustion; it is mounted immediately at the outlet of the boiler or immediately before the final vertical section.

Connection diagram for a solid fuel boiler with a heat accumulator: 1 - chimney; 2 — thermostat; 3 - security group; 4 — air separator; 5 - circulation pump; 6 - heat accumulator; 7 - three-way mixer; 8 — weather-dependent automatic; 9 — heating radiator; 10 - circulation pump; 11 - check valve; 12 — expansion tank; 13 — protection against dry running; 14 — make-up valve; 15 — overhead temperature sensor; 16 - solid fuel boiler

Connection diagram for a solid fuel boiler with a heat accumulator: 1 - chimney; 2 — thermostat; 3 - security group; 4 — air separator; 5 - circulation pump; 6 - heat accumulator; 7 - three-way mixer; 8 — weather-dependent automatic; 9 — heating radiator; 10 - circulation pump; 11 - check valve; 12 — expansion tank; 13 — protection against dry running; 14 — make-up valve; 15 — overhead temperature sensor; 16 - solid fuel boiler

For cast iron boilers, it is practiced to install a two-way valve that mixes water from the hot outlet to prevent cold water from entering the heated firebox. When installing a heat accumulator, a three-way electric valve is added, which starts the supply of heat to the tank only after the main composition has warmed up. Control is carried out based on the return temperature, the additional circuit is turned on 7-10 ºС before the cut-off temperature is reached. In this aspect, control units with a PID controller are most preferable.

Installation, connection

The boiler is installed on a concrete pedestal, the height of which is determined by the equilibrium of the hydraulic system. Ideally, the coolant in the boiler should be under the highest pressure compared to other sections of the pipeline. The position of the boiler is also determined by the direction and point of connection of the chimney. Its connection can be either vertical (from above) or horizontal (from behind or from the side).

It is recommended to use only steel or copper pipes in the boiler piping; for plastic there is too great a risk of overheating. The section of the supply pipeline 3-5 meters from the boiler is also traditionally made of metal. The connections can be welded, or if the necessary equipment is not available, they can be threaded using tow and anaerobic sealant.

The boiler must be configured taking into account the low heating rate and high inertia. The operating temperature of the coolant is usually maintained within 50-65 ºС. In this case, the reverse hysteresis temperature should be slightly higher than the maximum at which the boost completely stops. This is necessary so that ignition begins long before the water in the system cools down more than it should.

Owners of country cottages are increasingly giving preference to wood-burning boilers when installing autonomous heating systems. Indeed, this economical and efficient equipment makes it possible to heat a country house cheaply and efficiently without any additional investments.

How does a wood-burning boiler work for heating a private home?

The combustion chamber is located in the central part of the body. When burning, wood transfers heat to a heat exchanger, which supplies water to the batteries through pipes. It is worth noting that heat comes not only from the heat exchanger, but also from the heated body itself, pipe elements and the chimney. When installing modern smoke exhaust systems, special dampers are installed in the pipes, which significantly facilitate the process of cleaning the internal space from ash and soot. Combustion waste also accumulates in the lower tier of the device, which is called the ash pan. Through a cast-iron grate, combustion products are poured into this compartment. It is recommended to clean the ash pan regularly.

Advantages of using wood-burning units

In the PechiMax online store you can buy any heating devices for heating a country house and related products at low prices. All presented products have the appropriate certificates and have a number of advantages:

- Autonomy. By installing such a device, you get complete freedom from external factors associated with the supply of energy resources;

- Safe for the environment. Wood is an environmentally friendly material that does not contain all kinds of synthetic additives. Therefore, when it burns, no harmful chemicals are formed;

- Cheap fuel. In almost any region of the Russian Federation you can purchase firewood without problems and at an affordable price;

- Easy to use and maintain.

By contacting our managers, you will receive comprehensive advice on the selection and operation of heating units.

Reading time: 10 min

It's no secret that, based on cost-effectiveness and practicality of use, gas heat supply is considered more comfortable.

However, in situations where consumers are located at a considerable distance from the gas network, it is most reasonable to equip individual heating with a solid fuel boiler that runs on wood.

Recently, due to the significant cost of liquid fuel and electricity, as well as additional costs for connecting gas devices, many users prefer to choose a modern energy-efficient wood-burning boiler, even if it is technically possible to use blue fuel.

The design and principle of operation of a wood-burning boiler

Firewood belongs to the group of solid fuels and can be used on the same level as coal for heating residential buildings no higher than 2 floors, and is also well suited for organizing air heating in the house.

Installation of a wood-fired boiler. Photo source: rgagroup.ru

Wood-burning hot water boilers are conventionally divided into 2 types:

- non-volatile, operating with the natural draft of the chimney;

- supercharged, in which air is forced into the firebox.

The first ones use simple oven technology, with the only difference being that they have an internal water circuit. A large combustion chamber is located above the ash pit, separated from it by grates.

Air from the room is supplied to the combustion device through a damper in the ash pan, and then moves through the grate. The supply volume is adjusted by a thermostat that controls the temperature of the coolant in the water jacket of the boiler unit. The damper control is mechanical.

The exhaust gases formed in the combustion space at a high temperature move through the flame tubes of the internal heat exchanger and are cooled through the walls of the tubes by heating water.

Based on the structural elements of the boiler unit, flue gases are able to circulate several times through the flue pipes, effectively exchanging thermal energy with the water jacket.

Operating principle. Photo source: stroikabudet.ru

Giving up their heat, volatile substances formed from fuel combustion leave the heating boiler with flue gases using a flue exhaust system.

A non-volatile wood-burning boiler cannot boast of good efficiency, at most it is 70%.

The second version of the heat generator is the most productive; its efficiency can reach 75% due to forced air supply carried out by a supply fan.

Strapping scheme

A typical connection diagram for boilers for heating with wood contains two basic units that allow it to operate reliably in heating systems of an individual home. This is a safety group and a water group with a three-way valve with a thermal head and a temperature sensor.

Unfortunately, due to its design features, this heating source cannot use modern automation and control systems. The boiler's piping along the water circuit of the heating network and the exhaust of flue gases is carried out according to the counterflow principle, that is, the media move towards each other.

Connection diagram with boiler

This design of wood-burning boilers for heating allows you to reduce the temperature of the flue gases. But, as evidenced by the real efficiency of wood-burning boilers, this does not happen very well.

To increase the efficiency of the entire thermal circuit, it is recommended to include an indirect hot water boiler with a water tank. It allows you to reduce the temperature of exhaust gases and additionally heat hot water, at the same specific fuel consumption.

Advantages and disadvantages

This type of heating has a significant list of advantages, in the first place of which is the economy of the heating option, which is caused not only by the lowest prices for wood fuel, but also by the low costs of installing and operating heating equipment.

The main advantages of boilers for heating with wood:

- Environmental Safety. Due to low emissions of harmful substances into the atmosphere.

- The technological simplicity of the boiler using wood and coal guarantees a long period of operation.

- The variability of the stove device, the possibility of using all types of solid fuel, for any premises, for example, for a wood-burning bathhouse.

- Energy independence.

- Possibility of heating large areas of 1000-1500 m2.

- Wide selection of types of units with a water circuit.

- The ability to create a water heating circuit with your own hands.

Disadvantages of solid fuel boilers:

- Need for additional fuel storage space.

- Low comfort levels and the need for constant care.

- High download frequency.

- Low level of automation and regulation.

Types of wood boilers

A wood-burning boiler is a highly efficient heating equipment installed as a source of heat supply in autonomous systems in order to maintain sanitary and hygienic living conditions in houses of medium and small size.

These installations are equipped with special safety components to ensure safe operation. The units operate in the efficiency range from 70 to 80%.

There are quite a few modifications of boilers. Photo source: remoo.ru

Classification of solid fuel boilers:

- Classic direct combustion boilers. Despite the fact that they are significantly inferior to the latest devices in terms of operating time from 1 load, they are still popular due to their low price.

- Top combustion boilers are cylindrical in shape and equipped with a specialized telescopic air tube. Due to the fact that the combustion process also occurs at the top of the combustion chamber, a new portion of fuel can be added after the combustion of the previous layer.

- Bottom combustion boilers have a particularly well-thought-out and efficient design of mine boiler units with long-term combustion of the bottom layer. This makes it possible to fill the firebox with firewood at any time during operation.

- The pyrolysis device is a gas-generating wood-fired boiler with 2 combustion chambers. In the first, primary combustion takes place with a deficiency of oxygen, which triggers the process of pyrolysis and gas generation. The second is for complete combustion of synthesis gas. This design makes it possible to increase the operating time of the boiler with one filling of firewood.

- Pellet boilers are produced to operate on pressed or granulated wood waste and are equipped with a special hopper, from which fuel enters the combustion chamber using an auger.

Popular and reliable wood-burning boilers according to user ratings in 2019, with a load of up to 12 kW

- Evan WARMOS-TK-12.0, RF, 20,500 rub.

- Zota MASTER-12, RF, 24,200 rub.

- Kentatsu Furst ELEGANT-03, Japan, RUB 36,000.

- Zota Yenisei-12, RF, 17,540 rub.

- Lemax Forward-12.5, RF, 16,500 rub.

- Burzhuy-K TV-12, RF, 66,500 rub.

- Nibe PBMAX 12, Sweden, RUB 208,000

- Zota Forta 12, Russian Federation, 100,000 rub.

- Wirbel TOBY B compact 12, Austria, RUB 136,900.

Kentatsu Furst ELEGANT-03

Kentatsu Furst 03 is an improved brand of boiler unit that performs its function using hardwood.

The boiler is equipped with a water grate cooler, which acts as a protective system for the unit against overheating. The internal surfaces are made of corrosion-resistant material, cast iron sections guarantee a long service life.

Kentatsu boiler. Photo source: liongr.ru

Main characteristics:

- Brand country - Japan.

- Production - Türkiye.

- Heating capacity with wood – 14 kW.

- Boiler type - non-volatile

- The firebox is open.

- Automation - by air.

- The metal of the heat exchanger is cast iron.

- Firewood burning time is 4 hours.

- Chimney – 180 mm.

- Dimensions – 450x947x609 mm.

- Weight – 166 kg.

- Warranty – 2 years.

- Price – 36,000 rubles.

Zota Forta 12

The domestic Zota 12 kW boiler is the best choice for heating a house up to 120 m2. The model is absolutely unpretentious in maintenance and can operate independently for several days without stopping, automatically adjusting operating parameters to maintain the heating temperature.

Main characteristics:

- Brand country - Russia.

- Production - Russia.

- Boiler type - non-volatile

- Number of circuits - single-circuit, heating.

- The firebox is open.

- Automation - by air.

- Chimney – 120 mm.

- Dimensions – 1210x1090x917 mm.

- Weight – 250 kg.

- Warranty – 1 year.

- Price – 100,000 rubles.

Wirbel TOBY B compact 12

Austrian 12 kW model, manufactured in Russia, runs on wood fuel and pallets. Has an automated ignition, start and stop process. It can efficiently heat a house with an area of up to 150 m2.

Wirbel oven. Photo source: climargas.es

Main characteristics:

- Brand country - Austria.

- Production - Russia.

- Heating capacity with wood – 12 kW.

- Number of circuits - single-circuit, heating.

- The firebox is closed.

- Automation - by air.

- The metal of the heat exchanger is steel.

- Firewood burning time is 4 hours.

- Chimney – 80 mm.

- Dimensions – 1465x726x565 mm.

- Weight – 190 kg.

- Warranty – 1 year.

- Price – 136,900 rubles.

Wood and electric boiler

Manufacturers of wood-burning boilers, to protect the interests of consumers, decided to modify them and eliminated the main drawback - a significant decrease in the temperature of the coolant in the system between firing sessions.

Electric heating was integrated into the system of electric wood-burning boilers, thus creating boilers with combined heating.

Such heat sources combine all the advantages of electric and wood heating in one device, in which consumers are very interested.

Units powered by wood and electricity also work well in tandem with an indirect heating boiler and can heat water at night according to the tariff metering, thereby making such a heating system extremely economical.

The most reliable and economical wood boilers

Firewood burns out pretty quickly. To prolong this process as long as possible, they achieve the process of smoldering fuel. For this purpose, special combustion structures have been made that allow working on one load for 4 hours or more.

The results were very inexpensive, popular boiler designs: Evan WARMOS-TK-12.0 and Lemax Forward-12.5.

Main characteristics of Evan WARMOS-TK-12.0:

- Brand country - Russia.

- Production - Russia.

- Heating capacity using wood is 9 kW.

- Boiler type - non-volatile.

- Number of circuits - single-circuit, heating.

- The firebox is open.

- Automation - by air.

- The metal of the heat exchanger is steel.

- Firewood burning time is 5 hours.

- Chimney – 114 mm.

- Dimensions – 620x440x930 mm.

- Weight – 250 kg.

- Warranty – 1 year.

- Price – 20,500 rub.

Main characteristics of Lemax Forward-12.5:

- Brand country - Russia.

- Production - Russia.

- Heating capacity using wood is 12 kW.

- Boiler type - non-volatile.

- Number of circuits - single-circuit, heating.

- The firebox is open.

- Automation - adjusting the level of air supply to the burner.

- The metal of the heat exchanger is steel.

- Firewood burning time is 4 hours.

- Chimney – 140 mm.

- Dimensions – 121x109x917 mm.

- Weight – 70 kg.

- Warranty – 3 years.

- Price – 16,500 rub.

Wood boiler maintenance

Much to our chagrin, most owners of wood-burning boilers for heating a private home pay little attention to the operating features of the device.

Such boilers require high-quality maintenance. Photo source: hearth.com

However, a wood-burning boiler has its own differences in operation, which require certain operations:

- Preparing the chimney. Before putting such a unit into operation, it is necessary to inspect the gas duct and, if necessary, clean it of soot, and in the future it is recommended to perform this operation at least once every two months.

- The main points in boiler maintenance are loading firewood and cleaning the combustion chamber. In order to create oxygen access to the torch, when loading firewood, they are not stacked tightly.

- Cleaning is carried out using special devices included with the boiler.

- It is not recommended to completely clean the grate; a small amount of ash on the grate can serve as thermal insulation and, thereby, increase the service life of the boiler.

Is it possible to do it yourself?

The device that uses wood fuel is very simple and it is quite possible to make a wood-burning boiler with your own hands for those who know how to handle basic plumbing tools and a welding machine.

A cauldron made by myself. Photo source: biser.enjob.ru

Step-by-step instructions for a homemade wood-burning boiler:

Such homemade boiler units with a long-burning principle can operate for more than a day on one stack of firewood.

Just in case, I will give a little advice for those who are looking for firewood for heating. So, the law has article 7, paragraph 3, which says that for houses with stove heating, you can get 8 m3 of lumber once a year. (Not for all regions of Russia). Therefore, you can safely go to the administration and write a statement that you need wood. Documents you need are a passport and a property document.

Firewood is the most accessible and inexpensive type of fuel in our country. In addition, it is the most environmentally friendly fuel. To maintain thermal power, the manufacturer recommends heating the boiler with coarsely chopped dry logs of various types of wood.

Buy a wood-burning boiler in our store at the price of the manufacturer Ermak-Stoker. The dimensions of the firebox make our heating devices stand out among their analogues. The most inexpensive and budget model of the wood-burning boiler AOTV 8-E is designed for logs 50 cm long at a consumption of 5 kg/hour in long-term burning mode. The depth of the firebox of the most productive unit PRO 32-E is 62 cm. Thanks to the volumetric combustion space of the boilers, a large load of firewood is possible for autonomous operation in long-term burning mode.

In an economical mode of long-term burning with a minimum air supply, firewood logs smolder in the boiler firebox, and the emitted wood gases burn in the afterburner. The result of the device's operation is savings on heating with maximum operating time of the device. Economy mode makes full use of wood fuel reserves, reduces home heating costs and minimizes maintenance.

The heating system is heated through a water jacket; the coolant is distributed over a large heating area around the firebox. For ease of monitoring the temperature of the water jacket, all models are equipped with thermometers on the front wall of the case.

Useful options

To avoid temperature changes after firewood burns, the manufacturer recommends purchasing a heating element option with a thermostat for your boiler. This option will automate the heating process and maintain a constant comfortable temperature in the heating circuit. The threaded coupling for the heating element is located in the lower part of the housing.

By purchasing a draft regulator for a wood-burning boiler, you can automate the movement of the damper that supplies air to the firebox to regulate the set temperature of the coolant.

Since in many remote areas of the Russian Federation there is no gas supply, a wood-burning boiler for heating a private house with batteries is still a relevant solution to the heating issue. Modern models of wood-burning equipment have an increased operating time from one load, are characterized by high efficiency and safety.

Operating principles of wood-burning boilers for private homes

Modern wood-burning boilers for heating a private house with a water circuit have little in common with traditional classic stoves. By design, most models resemble an autonomous thermal station. But the basic principle of operation remains unchanged. The heat obtained by burning solid fuels is used to heat rooms.A significant difference and change made in the internal structure is the presence of a water circuit. After modifying the design, it became possible to connect a radiator heating system in a country house with a wood-burning boiler.

At the moment, according to the principle of operation, two main classes of equipment can be distinguished:

A solid fuel boiler is simply a modified wood stove, with better automation of the combustion process and high efficiency.

How to choose a wood-burning boiler for a private home

When choosing a heating boiler for a private home, several points regarding design features and performance are taken into account:- Heated area– approximate calculations of productivity are carried out using the formula 1 kW = 10 m². When connecting a second circuit for DHW, another 15-20% is added to the result obtained.

- Types of heating boilers– as already noted, there are classical units, as well as those that use the principle of pyrolysis combustion. The latter are considered the most economical wood-burning boilers for individual heating of private country households. The first ones cost 3-4 times cheaper.

- Heat exchanger type- There are two types. It differs in the type of materials used and design. Boilers made of steel are cheaper, but last on average 10-15 years less. The units are not afraid of shocks and mechanical damage, and are easy to repair and maintain.

Cast iron boilers, on average, last about 35 years and have the best thermal characteristics. They are afraid of mechanical damage. Repair will require replacing the entire section. Another disadvantage of cast iron is the large weight of the boiler. A pyrolysis unit, which has two combustion chambers, easily reaches a mass of 5 centners. - Design features of the combustion chamber– Manufacturers produce boilers with side loading of firewood. The design is used in most units, both classical and pyrolysis types.

Top-loading boilers deserve special attention. This design is used in gas generating units. The main advantage of the solution is the possibility of pre-drying the firewood, which increases the heating efficiency. - Availability of additional functions– automation, the presence of a backup power source, a built-in storage boiler, a remote control system - all this increases the comfort of operation and is provided as an additional package.

Which boiler to choose?

If funds allow, it is better to install a wood-burning boiler of German or Czech production. Polish and domestic units are somewhat worse in terms of production characteristics. Among foreign and domestic manufacturing companies, the leaders are:- German wood boilers– represented by companies:

- Lopper.

- Czech-made wood-burning boilers– the company’s products deserve attention: In terms of quality and automation, the models are in no way inferior to their German counterparts, but cost on average 10% less.

- Russian-made boilers– TT units are produced by almost every heating equipment manufacturer. The boilers are adapted to domestic conditions and are unpretentious in terms of fuel quality and coolant used.

The most popular products are from the following factories:- Teplodar.

- Polish wood boilers– several dozen modifications are offered on the domestic market. Models in demand:

- DREWMET

- ORLAN.

Most manufacturers, in addition to classic heating boilers operating exclusively on wood, offer universal or multi-fuel heat generators.

Cost of wood boilers for country houses

The cost of the unit is influenced by several factors:- Type of heat exchanger - a cast iron boiler will cost 1.5-2 times more than a steel counterpart.

- Manufacturer.

- The principle of operation is that the cost of a wood-burning gas generator boiler from a domestic manufacturer will cost 35-40 thousand rubles, and the price of a boiler of a classical design will drop to approximately 20 thousand rubles.

- Additional equipment.

Heating installation in a private house with a wood-burning boiler

Wood-burning boilers with a water circuit for heating a private house are connected to an existing heating system with forced or natural circulation of coolant. During installation work, the requirements of PPB and SNiP are met.Another important issue taken into account during connection is the need to accommodate large fuel storage. The boiler burns 10-15 cubic meters of wood per season. The storage must be dry, accessible, spacious and safe.

Where can a wood boiler be installed?

A wood-fired hot water boiler for heating a private home can be installed anywhere, provided that it meets the technical and fire safety requirements. General recommendations regarding the choice of premises for a boiler room are:

The main requirement for operating a wood-burning boiler is compliance with safety regulations. Modern models are equipped with a multi-level security system that prevents smoke in the room and boiling of the coolant.

Heating schemes for a private house with a wood-burning boiler

Heating in a private house using a wood boiler can be done in different ways. The choice of wiring diagram largely depends on the design of the boiler and the parameters of the room. All options can be divided into several classes, according to the following features:

A liquid heating system connected to a wood-burning boiler requires proper planning and execution of work in strict compliance with all existing building codes. The heating layout in a two-story house is especially carefully planned. Setting up a security group is required.

When installing, additionally connect voltage and uninterruptible power supply.

Modern wood-burning boilers are economical, safe and easy to control, and are successfully used as an alternative to gas equipment.